Full-automatic wrapper pressing and stuffing integrated forming machine

A fully automatic, forming machine technology, applied in the direction of food forming, food science, application, etc., can solve the problems of poor bonding performance, increased labor cost, low degree of automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

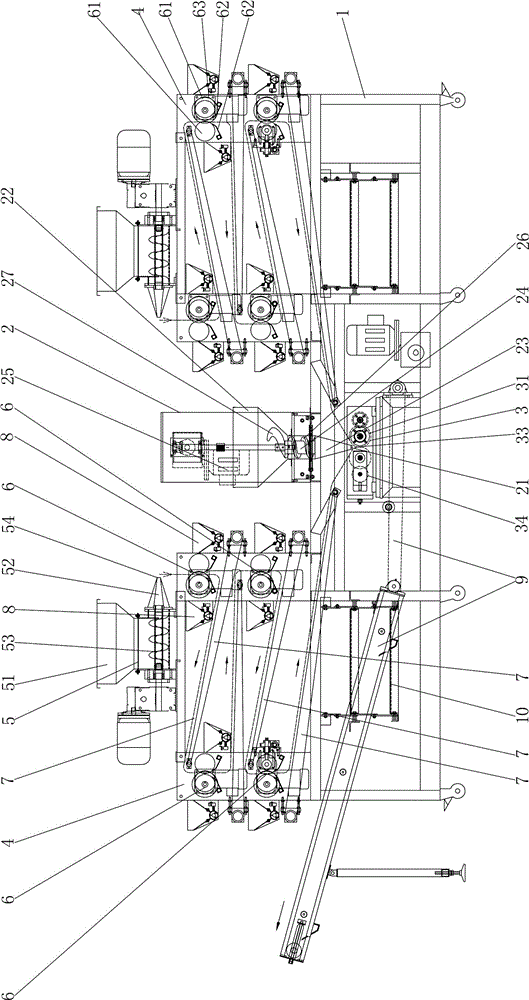

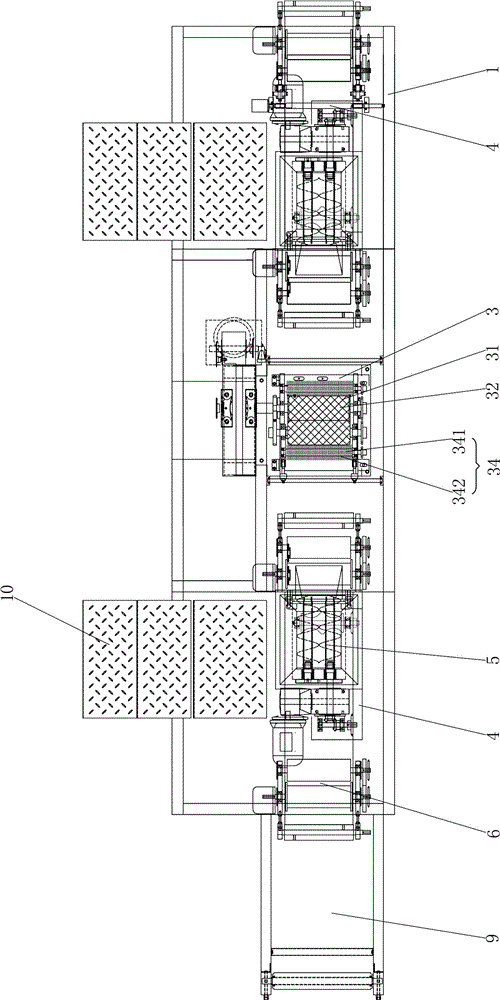

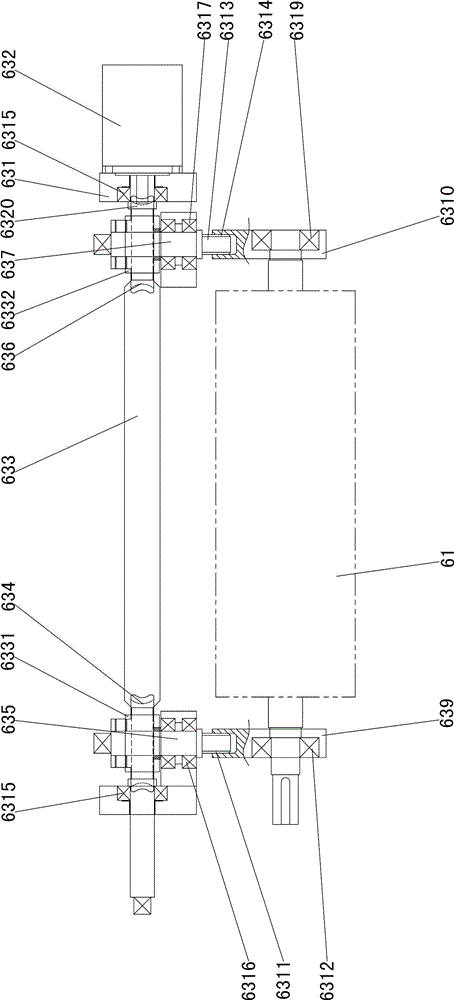

[0057] Such as figure 1 and figure 2 As shown, this fully automatic leather pressing and stuffing integrated forming machine includes a frame 1, a filling material supply mechanism 2, a forming pressing and cutting mechanism 3, and two leather material pressing and conveying mechanisms 4 capable of pressing and conveying leather materials; Mechanism 2, forming press-cutting mechanism 3 and two leather pressing and conveying mechanisms 4 are all installed on the frame 1; Forming die unit 32; two leather material pressing and conveying mechanisms 4 are respectively located on both sides of the forming pressing and cutting mechanism 3, and the leather material pressed by the leather material pressing and conveying mechanism 4 is transported between the two forming pressing and cutting rollers 31; The discharge port 21 of the supply mechanism 2 corresponds to the position of the forming and pressing mechanism 3 .

[0058] In this embodiment, a leather pressing and conveying mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com