Solid acid battery with absorbed partition plate and high-efficiency internal formation process thereof

An adsorption type battery technology, applied in the direction of lead-acid batteries, lead-acid battery construction, secondary battery repair/maintenance, etc., can solve the problems of high process requirements, difficult to achieve penetration and sealing, etc., to achieve efficient glue filling process, The effect of good product consistency and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

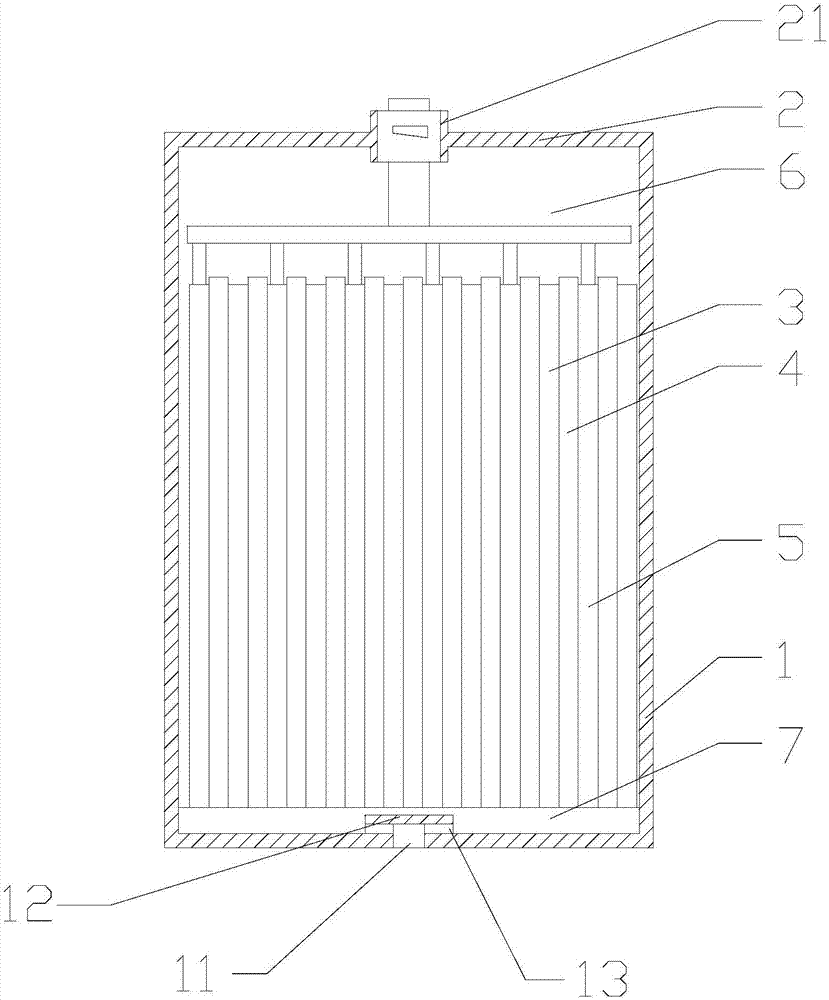

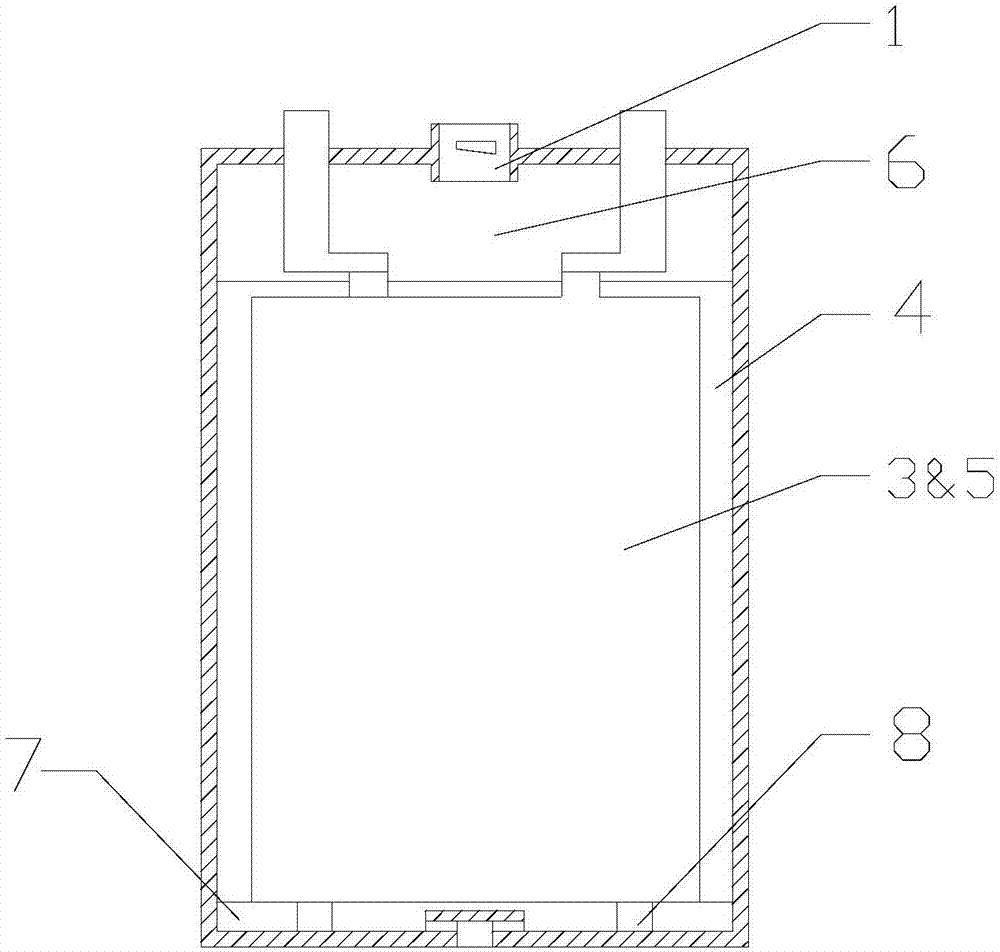

[0053] Such as figure 1 , figure 2 As shown, an adsorption-type separator solid-acid battery includes a battery container 1, a battery cover 2, and an electrode group disposed in the battery container.

[0054] The electrode group includes stacked positive plates 3 , adsorption separators 4 and negative plates 5 .

[0055] A safety valve hole 21 is provided on the battery cover, and an upper reserved space 6 is provided between the safety valve hole and the electrode group.

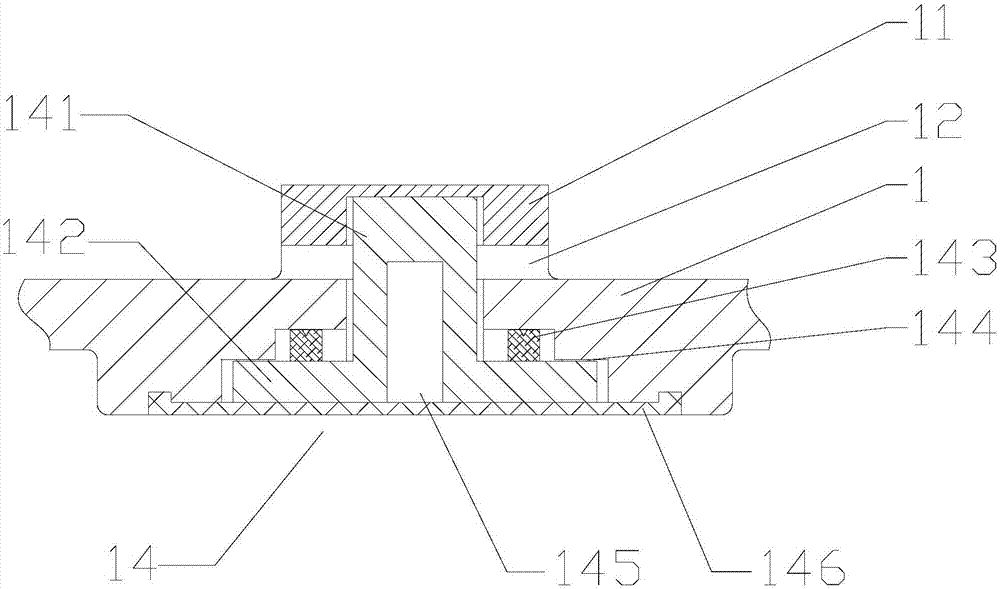

[0056] Such as image 3 , 4 As shown, the bottom of the battery tank is provided with a liquid injection hole 11; a lower reserved space 7 is provided between the bottom of the battery tank and the electrode group; a liquid injection hole is provided on the inner wall of the bottom of the battery tank above the liquid injection hole Cover 12, at least two acid holes 13 are formed between the liquid injection hole cover and the inner wall of the bottom of the battery tank; the acid holes are tangent t...

Embodiment 2

[0060] Such as figure 1 As shown, an adsorption-type separator solid-acid battery includes a battery container 1, a battery cover 2, and an electrode group disposed in the battery container.

[0061] The electrode group includes stacked positive plates 3 , adsorption separators 4 and negative plates 5 .

[0062] A safety valve hole 21 is provided on the battery cover, and an upper reserved space 6 is provided between the safety valve hole and the electrode group.

[0063] Such as image 3 , 4 As shown, the bottom of the battery tank is provided with a liquid injection hole 11; a lower reserved space 7 is provided between the bottom of the battery tank and the electrode group; a liquid injection hole is provided on the inner wall of the bottom of the battery tank above the liquid injection hole Cover 12, at least two acid holes 13 are formed between the liquid injection hole cover and the inner wall of the bottom of the battery tank; the acid holes are tangent to the inner w...

Embodiment 3

[0067] A high-efficiency internalization process for an adsorption-type separator solid-acid battery, comprising the following steps:

[0068] Step 1: Fasten the liquid injection hole cover above the liquid injection hole at the bottom of the battery slot;

[0069] Step 2: Insert the welded electrode group into the battery slot, cover the battery cover, and then seal the battery lead-out terminal to obtain a semi-finished battery;

[0070] Step 3: If Figure 7 As shown, the semi-finished battery is positioned on the acid cycle production line, the acid inlet pipe with a sealing ring is connected to the bottom liquid injection hole of the semi-finished battery, and the acid outlet pipe is screwed into the safety valve hole; using the weight of the battery itself, if necessary The tightening device can be supported so that the acid inlet and outlet pipes of the battery can be reliably connected to the battery.

[0071] Step 4: For the first production, concentrated sulfuric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com