A kind of colloidal battery and production method thereof

A colloidal battery and battery technology, applied in the direction of lead-acid batteries, battery components, lead-acid battery construction, etc., can solve the problems of high process requirements, difficult to achieve penetration and sealing, etc., to achieve efficient glue filling process and consistent products Good, easy-to-produc effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

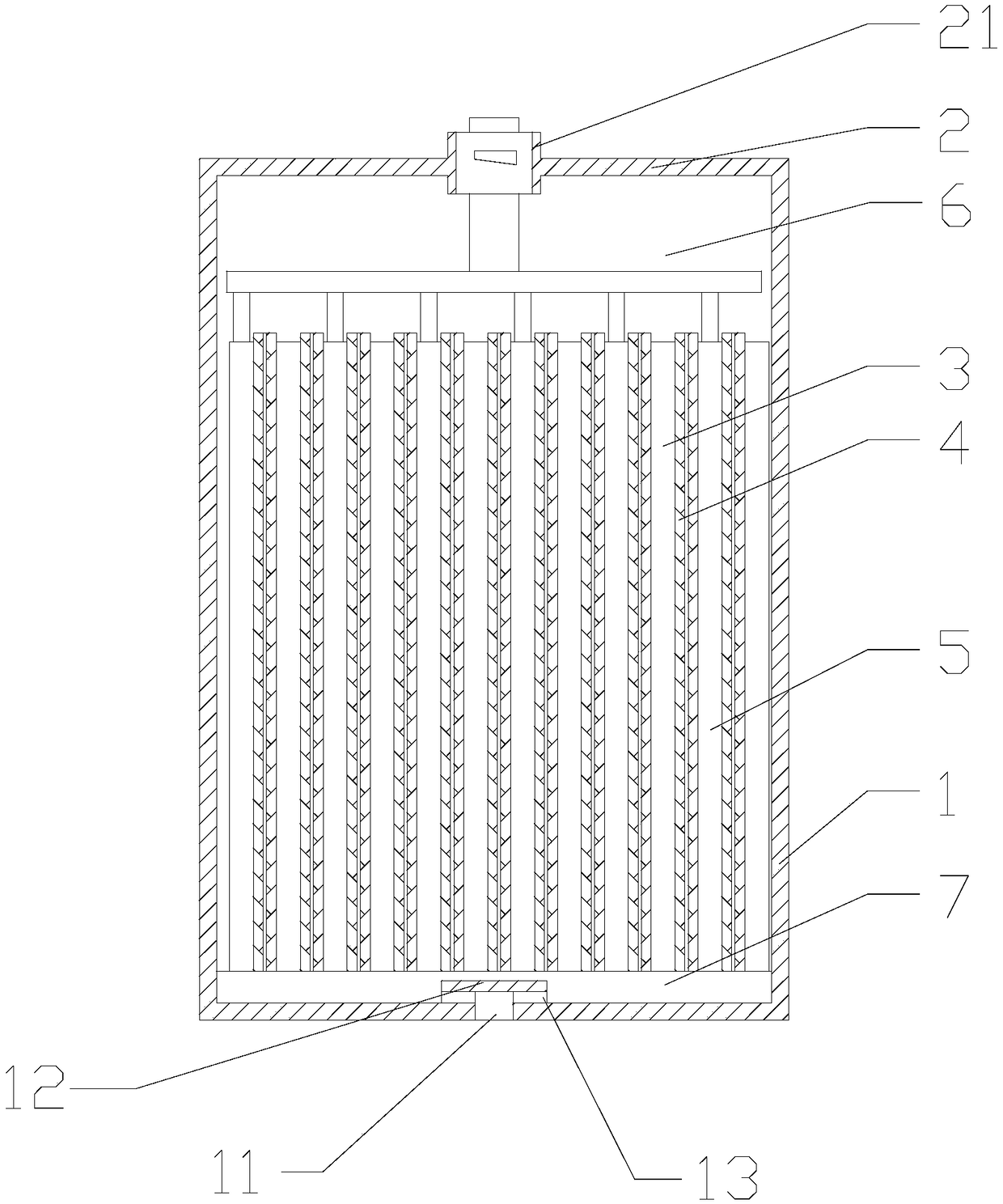

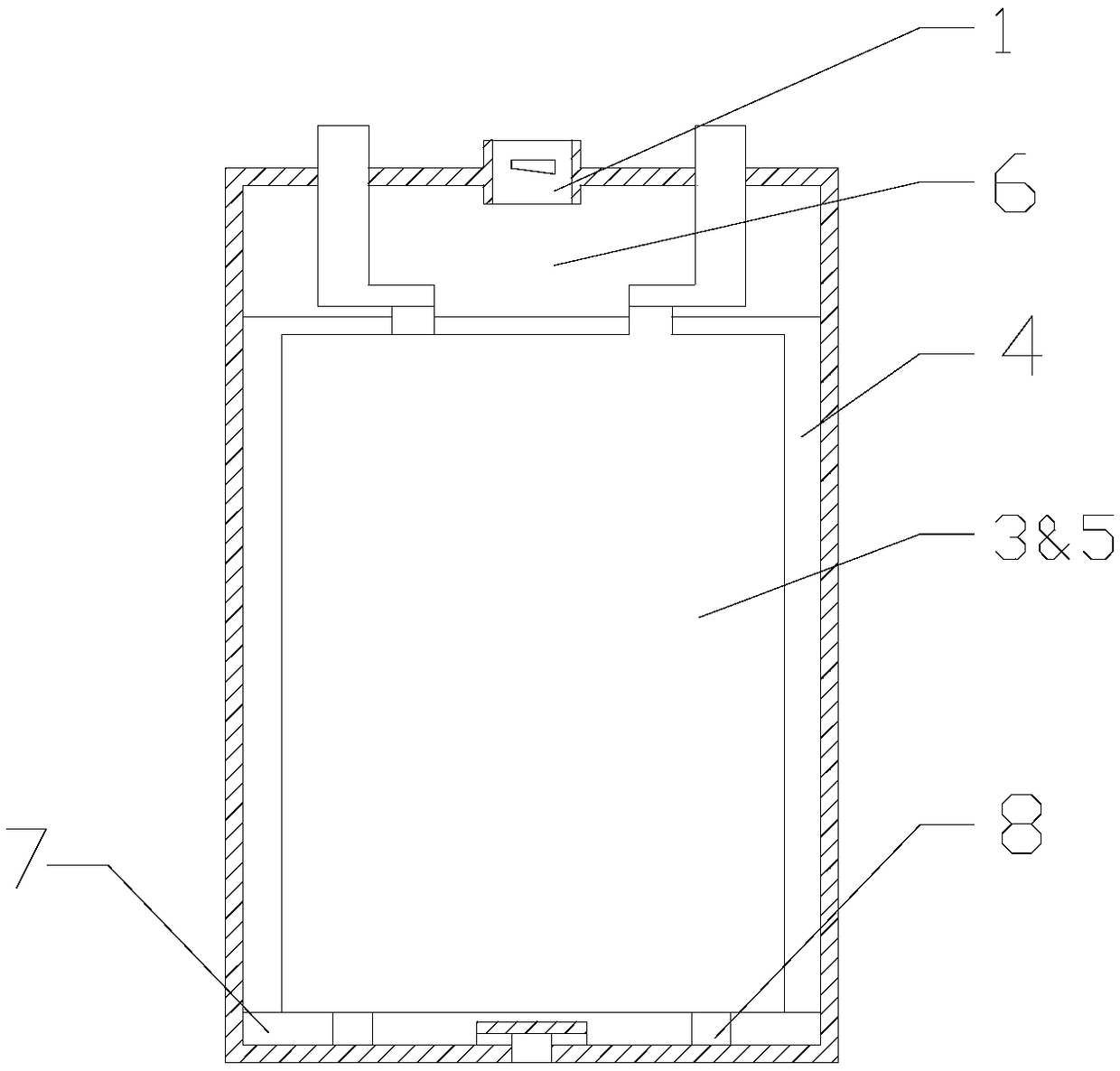

[0057] like figure 1 , figure 2 As shown, a gel battery includes a battery compartment 1, a battery cover 2 and a pole group disposed in the battery compartment.

[0058] The pole group includes stacked positive plates 3 , composite separators 4 and negative plates 5 . The composite separator is formed by stacking a glass fiber separator 41 and a microporous PE separator 42 . like Figure 5 As shown, in this embodiment, the composite separator has a three-layer structure: a microporous PE separator-glass filament separator-microporous PE separator.

[0059] The battery cover is provided with a safety valve hole 21, and an upper reserved space 6 is provided between the safety valve hole and the pole group.

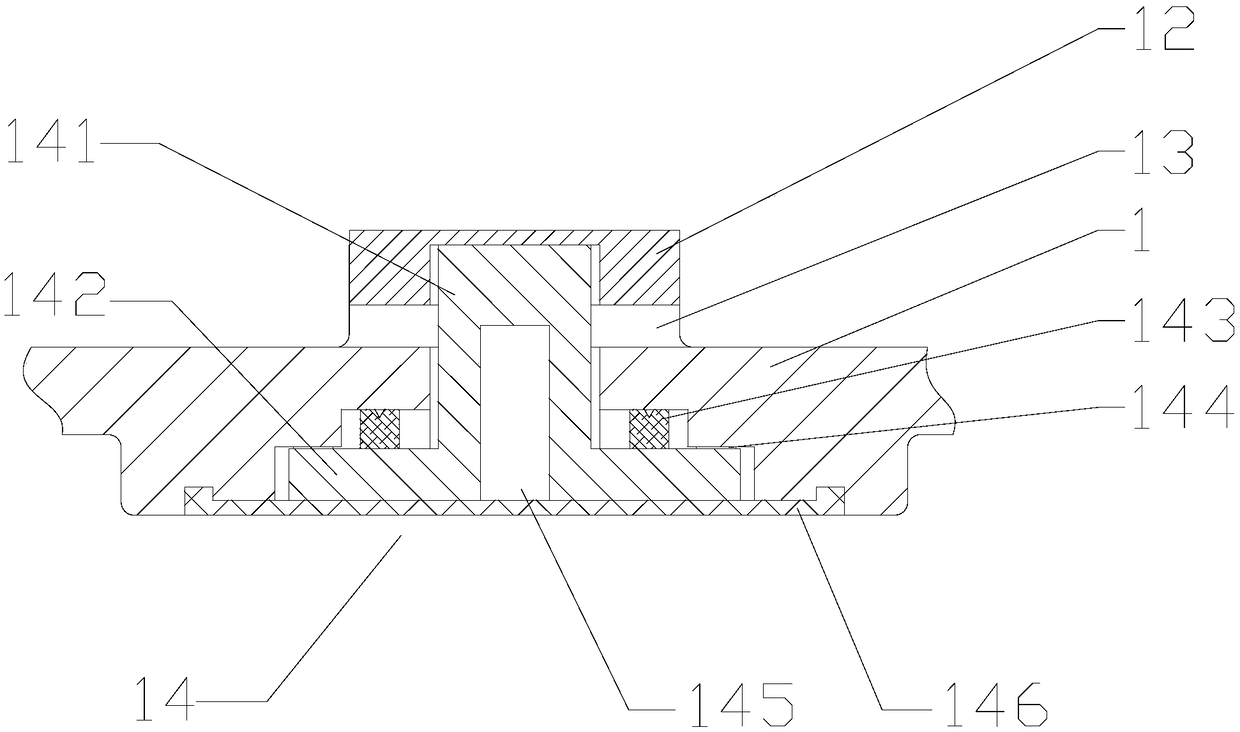

[0060] like image 3 , 4 As shown, the bottom of the battery tank is provided with a liquid injection hole 11; a lower reserved space 7 is provided between the bottom of the battery tank and the electrode group; the inner wall of the battery tank bottom is located ab...

Embodiment 2

[0064] like figure 1 As shown, a gel battery includes a battery compartment 1, a battery cover 2 and a pole group disposed in the battery compartment.

[0065] The pole group includes stacked positive plates 3 , composite separators 4 and negative plates 5 . The composite separator is formed by stacking a glass fiber separator 41 and a microporous PE separator 42 . like Image 6 As shown, in this embodiment, the composite separator has a three-layer structure: a glass filament separator-microporous PE separator-glass filament separator.

[0066] The battery cover is provided with a safety valve hole 21, and an upper reserved space 6 is provided between the safety valve hole and the pole group.

[0067] like image 3 , 4 As shown, the bottom of the battery tank is provided with a liquid injection hole 11; a lower reserved space 7 is provided between the bottom of the battery tank and the electrode group; the inner wall of the battery tank bottom is located above the liquid...

Embodiment 3

[0071] The difference between this embodiment and Embodiment 1 is that: Figure 7 As shown, in this embodiment, the composite separator is a two-layer structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com