Gel battery and production method thereof

A colloidal battery and battery technology, applied in the direction of lead-acid batteries, battery components, lead-acid battery construction, etc., can solve the problems of high process requirements, difficult to achieve penetration and sealing, etc., to achieve efficient glue filling process and consistent products Good performance and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

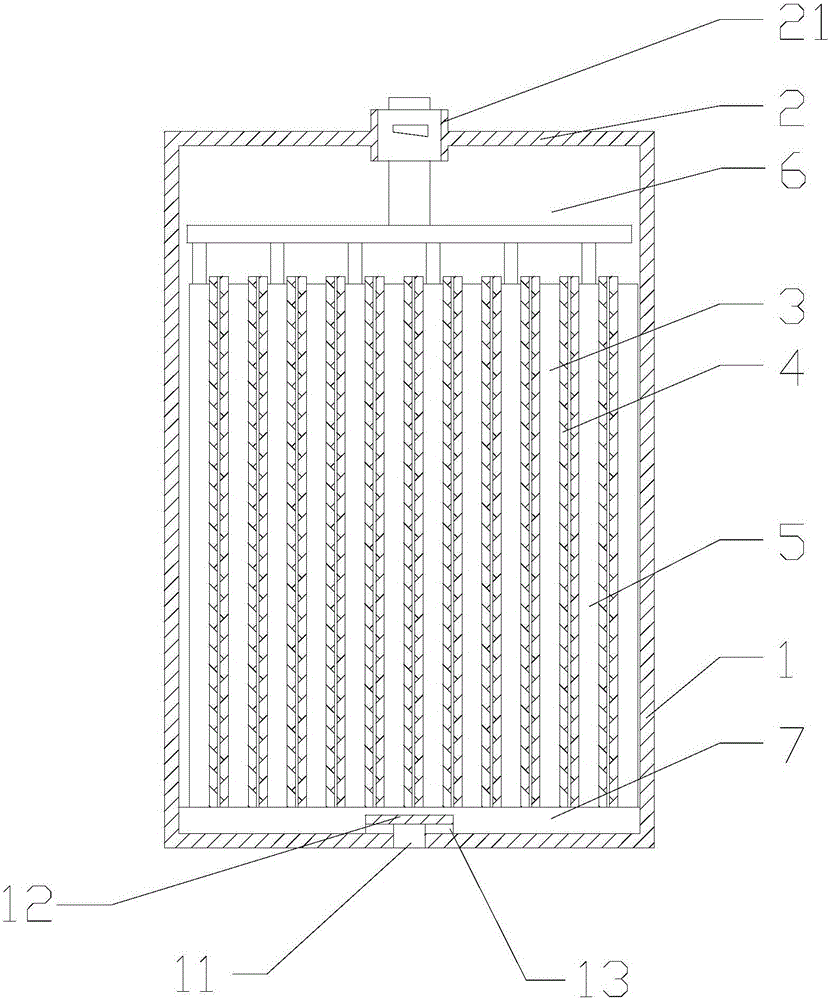

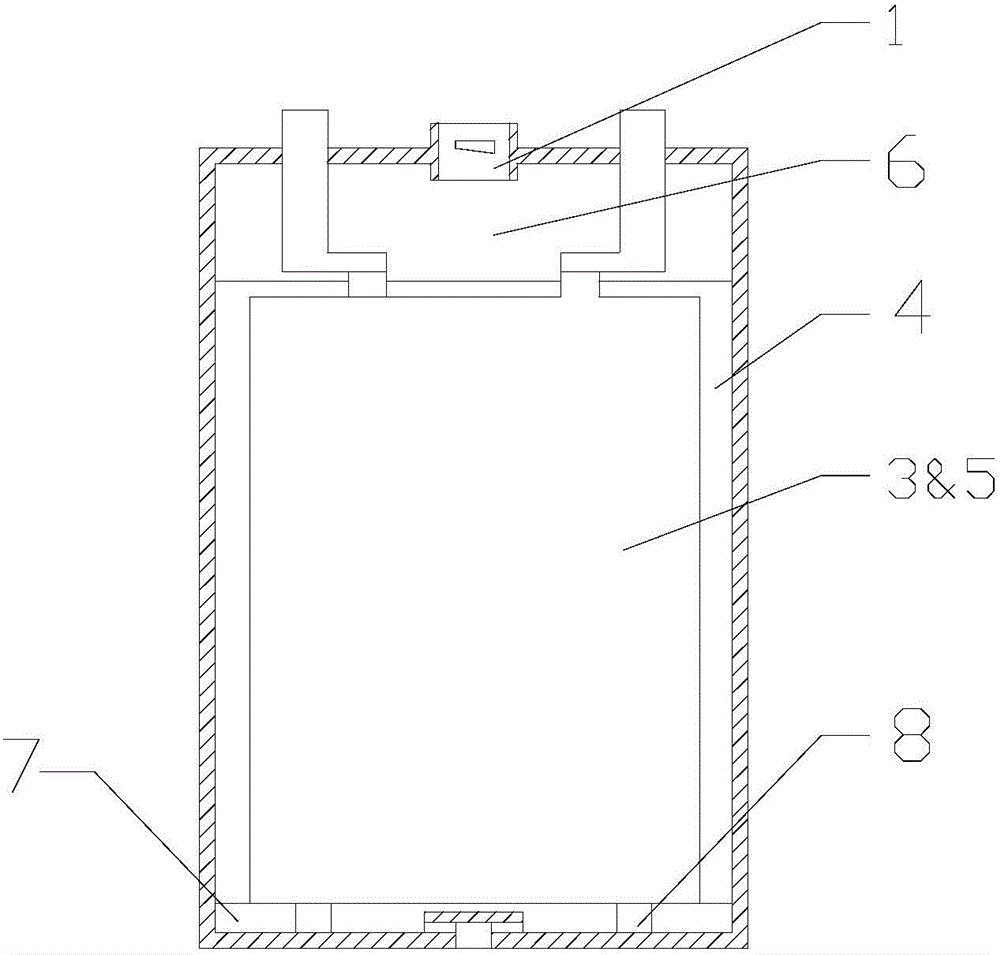

[0057] Such as figure 1 , figure 2 As shown, a colloidal battery includes a battery container 1 , a battery cover 2 and an electrode group disposed in the battery container.

[0058] The electrode group includes stacked positive plates 3 , composite separators 4 and negative plates 5 . The composite separator is composed of a glass wool separator 41 and a microporous PE separator 42 . Such as Figure 5 As shown, in this embodiment, the composite separator has a three-layer structure: microporous PE separator-glass wool separator-microporous PE separator.

[0059] A safety valve hole 21 is provided on the battery cover, and an upper reserved space 6 is provided between the safety valve hole and the electrode group.

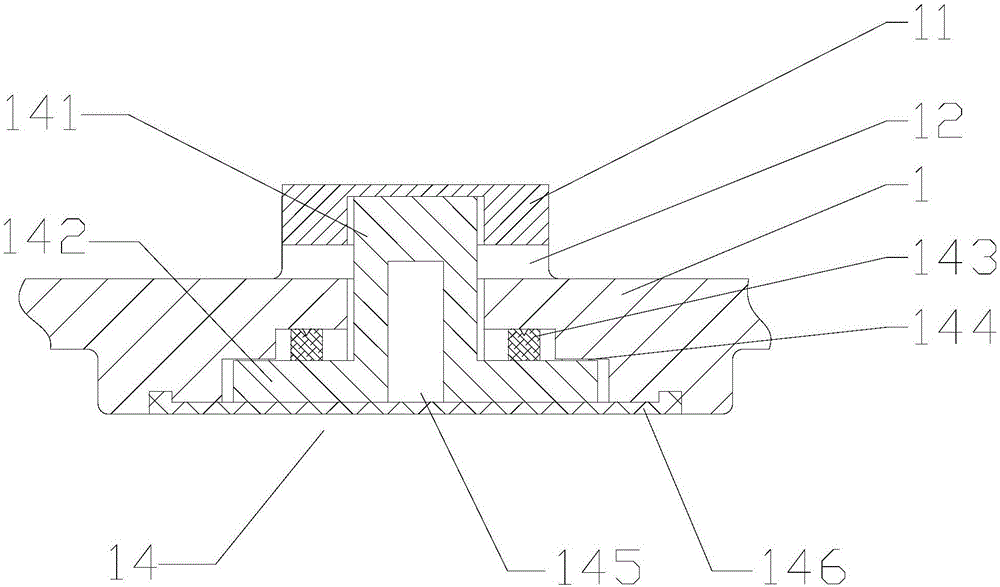

[0060] Such as image 3 , 4 As shown, the bottom of the battery tank is provided with a liquid injection hole 11; a lower reserved space 7 is provided between the bottom of the battery tank and the electrode group; a liquid injection hole is provided on the ...

Embodiment 2

[0064] Such as figure 1 As shown, a colloidal battery includes a battery container 1 , a battery cover 2 and an electrode group disposed in the battery container.

[0065] The electrode group includes stacked positive plates 3 , composite separators 4 and negative plates 5 . The composite separator is composed of a glass wool separator 41 and a microporous PE separator 42 . Such as Image 6 As shown, in this embodiment, the composite separator has a three-layer structure: glass wool separator-microporous PE separator-glass wool separator.

[0066] A safety valve hole 21 is provided on the battery cover, and an upper reserved space 6 is provided between the safety valve hole and the electrode group.

[0067] Such as image 3 , 4 As shown, the bottom of the battery tank is provided with a liquid injection hole 11; a lower reserved space 7 is provided between the bottom of the battery tank and the electrode group; a liquid injection hole is provided on the inner wall of the ...

Embodiment 3

[0071] The difference between this embodiment and embodiment 1 is: as Figure 7 As shown, in this embodiment, the composite separator has a two-layer structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com