Method for manufacturing electrochemical active material

An active material and electrochemical technology, which is applied in the field of designing a cyclic continuous carbon-free reduction-low temperature synthesis to prepare electrochemical active materials, can solve the problems of incomplete sintering reaction, low production efficiency, large power consumption, etc. Short time, good consistency of finished products, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation of embodiment 1 lithium iron phosphate

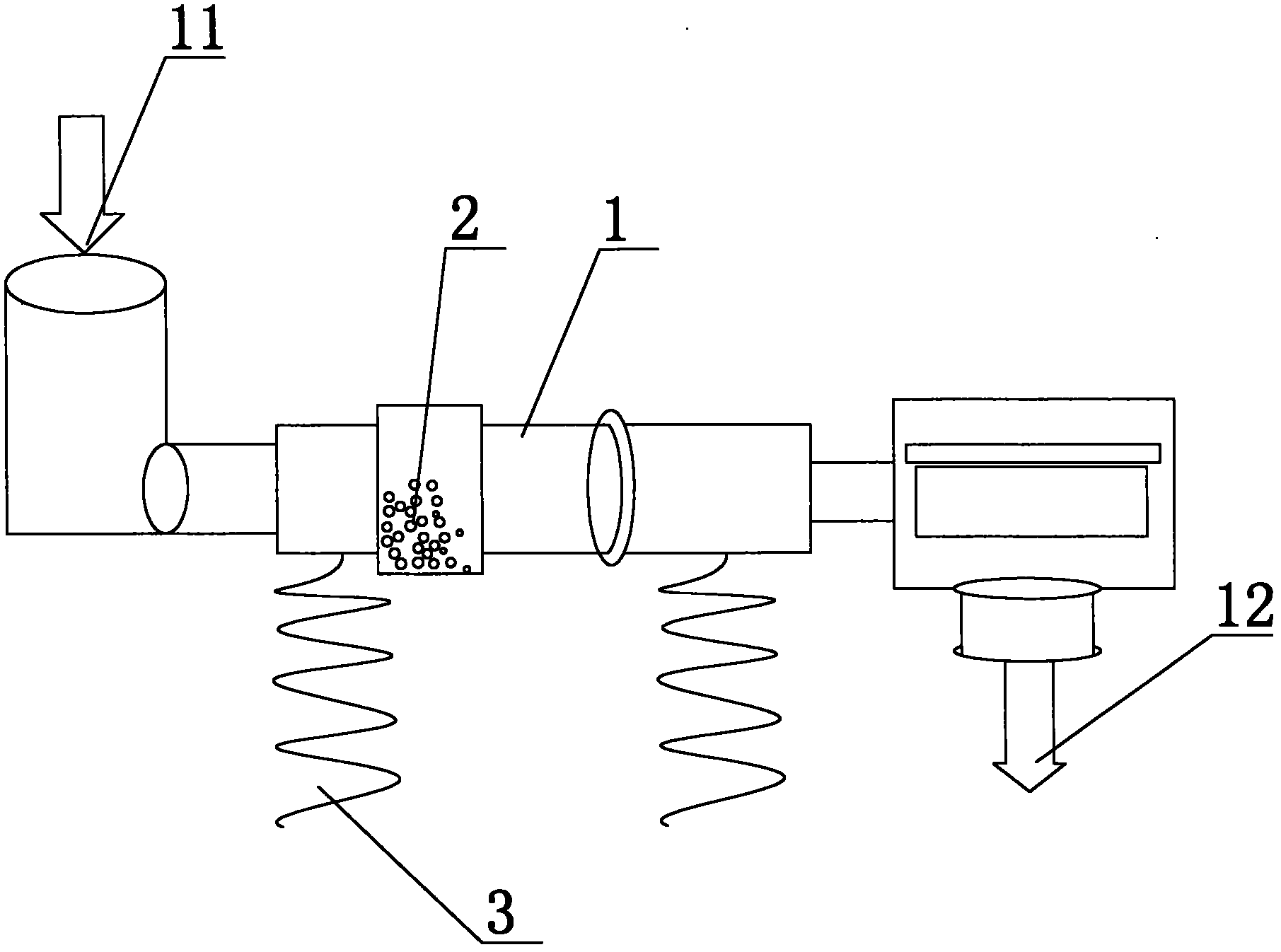

[0036] In this embodiment, a vibrating ball mill is used to pulverize, mix, and circulate materials. The vibrating ball mill includes a grinding cylinder 1, which is provided with a ball milling medium 2, and two ends of the grinding cylinder are provided with a feed port 11 and a discharge port. 12, the outlet port 12 of the grinding cylinder is connected to the feeding port 11 of the grinding cylinder through a circulating feeding pipe, the lower end of the grinding cylinder is provided with a base supporting the grinding cylinder 1, and a damping spring is arranged between the base and the grinding cylinder 1 3.

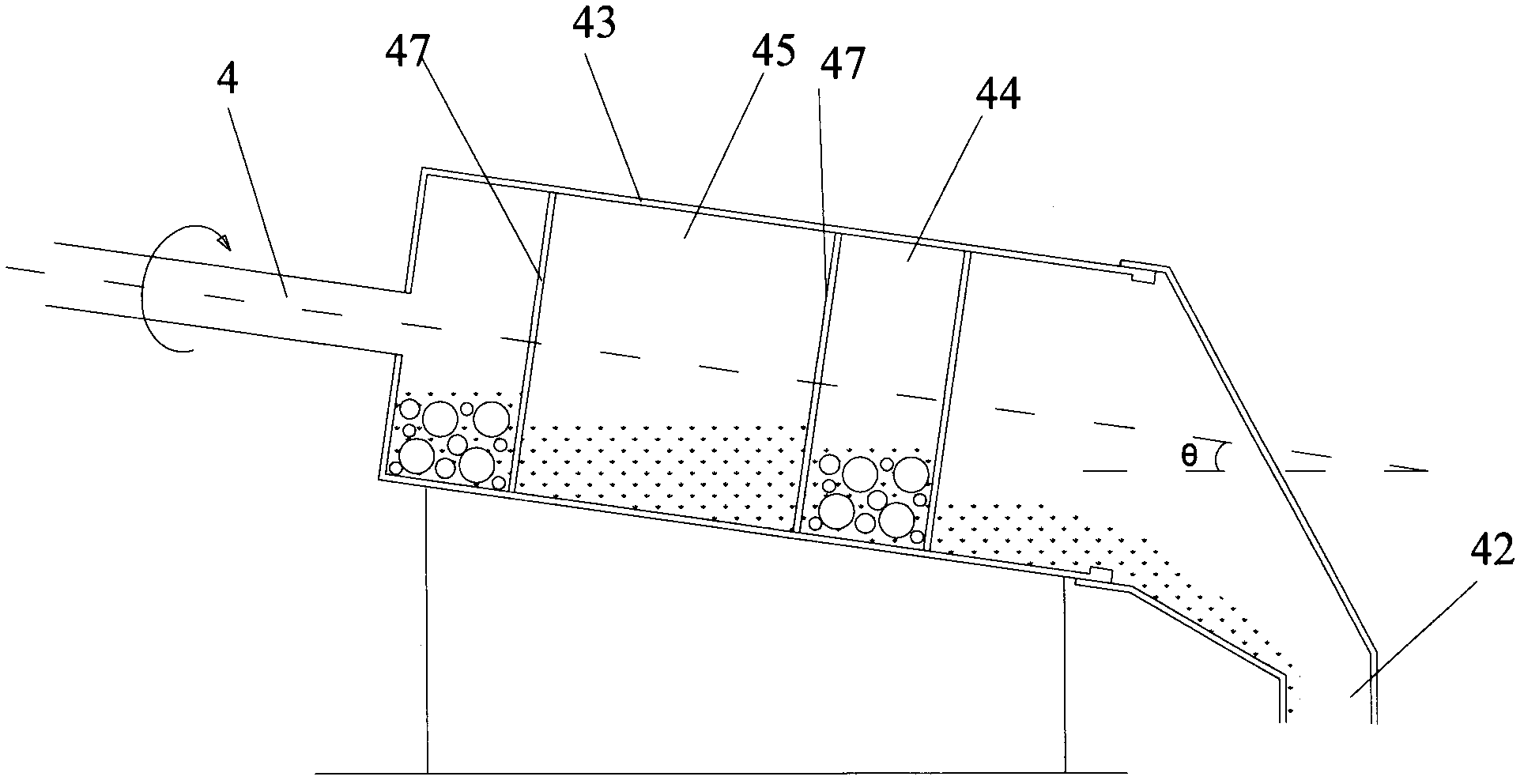

[0037] Then adopt ball milling rotary furnace to synthesize, the structure of ball milling rotary furnace 4 is as follows figure 2As shown, it includes a feeding system, a discharging system and a furnace tube 42 . The furnace tube 42 of the ball milling rotary furnace 4 is provided with at least on...

Embodiment 2

[0039] The preparation of embodiment 2 lithium ferrous phosphate

[0040] Vibrating ball mill and ball milling rotary kiln are as described in Example 1.

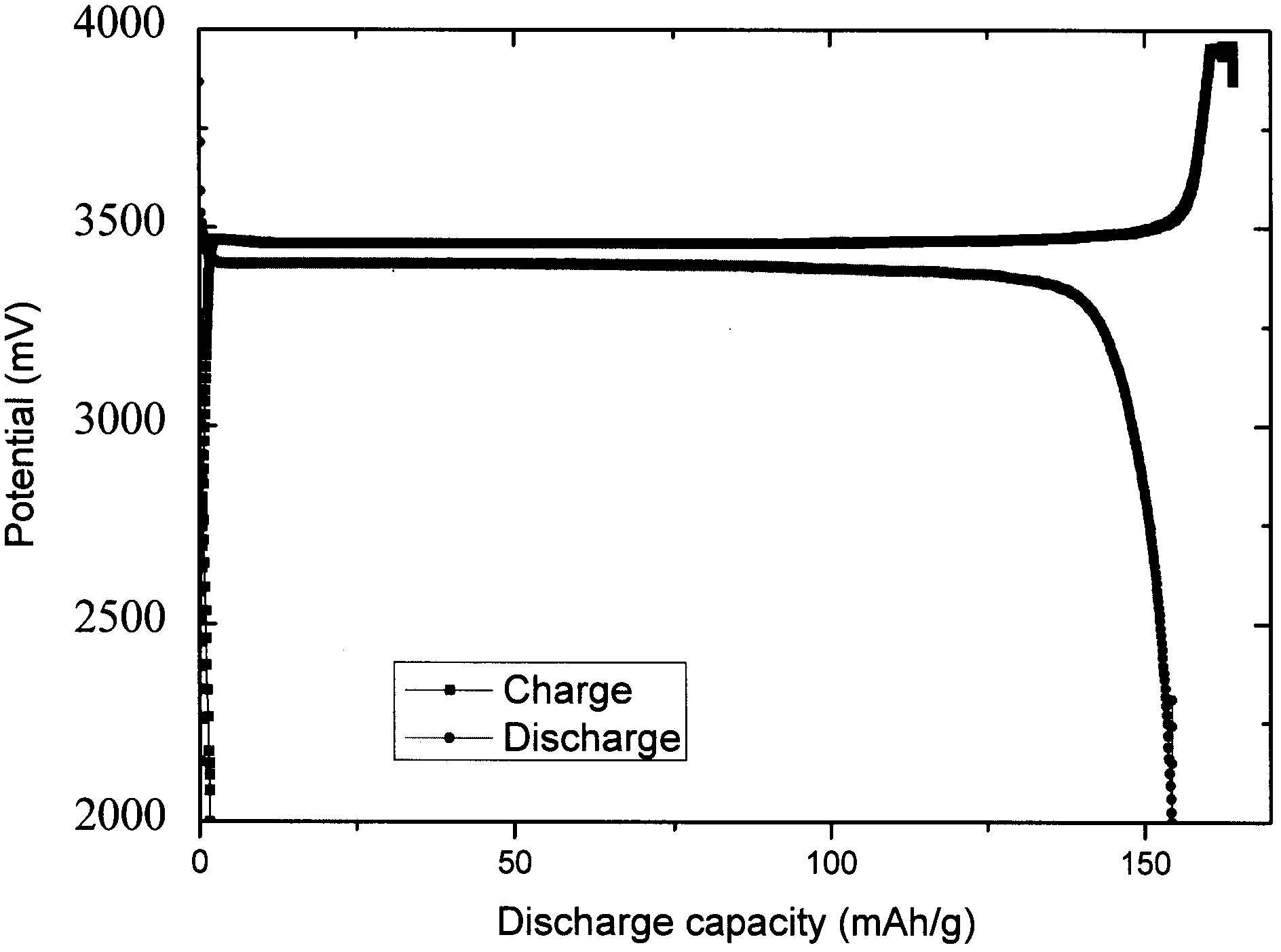

[0041] Fully mix iron oxide, ammonium dihydrogen phosphate and lithium carbonate or lithium hydroxide in a vibrating ball mill at a molar ratio of 1:1:1, then add conductive carbon black and mix, and then continuously enter the ball milling rotary furnace under nitrogen protection conditions. During the low-temperature synthesis process, the temperature is controlled at 200-400 degrees, and the temperature is kept at 1-4 hours. When the temperature in the high-temperature zone is controlled at 400-800 degrees, the temperature is kept at 1-4 hours, and the rotation speed is 1 revolution / minute, and then cooled at room temperature. The product lithium ferrous phosphate is obtained through milling, testing and packaging. In the process of electrochemical test, conductive agent and binder are added to make pole piece, and meta...

Embodiment 3

[0042] The preparation of embodiment 3 lithium ferrous phosphate

[0043] Vibrating ball mill and ball milling rotary kiln are as described in Example 1.

[0044] Fully mix iron oxide and lithium phosphate in a vibrating ball mill at a molar ratio of 1:1, then add conductive carbon black and mix, and then continuously enter the ball milling rotary furnace under nitrogen protection. During the low-temperature synthesis process, the temperature is controlled at 200~ 400 degrees, heat preservation for 1 to 4 hours, when the temperature in the high temperature zone is controlled at 400 to 800 degrees, heat preservation for 1 to 4 hours, the rotation speed is 1 revolution / minute, and then cooled at room temperature. The product lithium ferrous phosphate is obtained through milling, testing and packaging. In the process of electrochemical test, conductive agent and binder are added to make pole piece, and metal lithium piece is used as the test counter electrode. The tap density o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Discharge gram capacity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com