Stiffness curve test method for axial displacement of micro bearing under continuously progressively increased axial force

A miniature bearing and axial displacement technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problem of little improvement in the design of miniature bearings, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

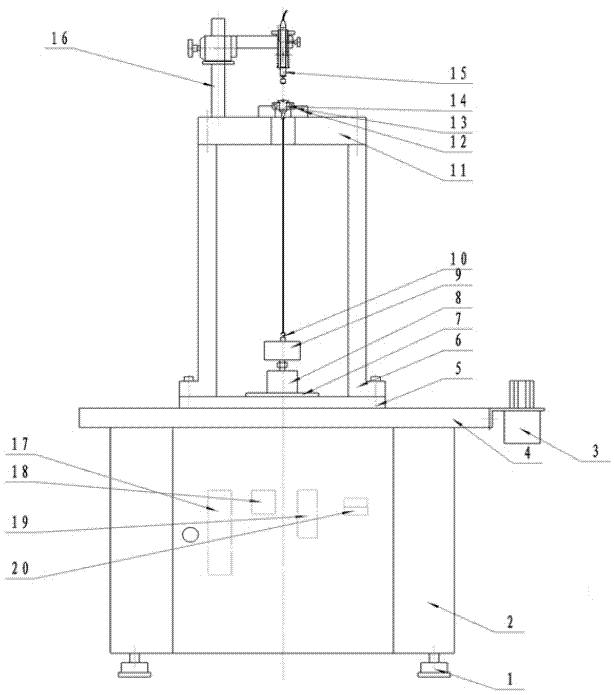

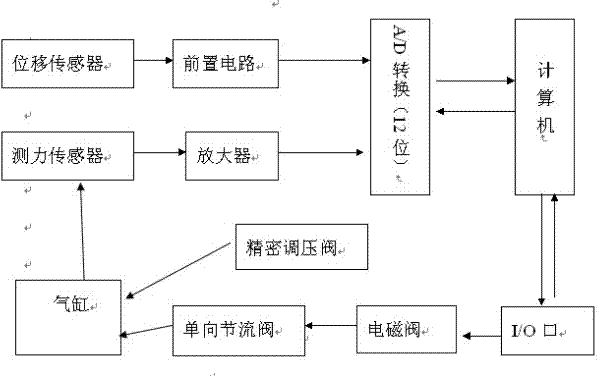

[0025] The present invention is a stiffness curve testing method for the axial displacement of miniature bearings under continuous increasing axial force. Through the precise control of the cylinder, continuous increasing axial force can be applied to the miniature bearings. The axial force is measured by the force sensor and measured. Recorded, the displacement sensor records the axial displacement of the miniature bearing under the corresponding axial force in real time, and finally the stiffness curve is automatically generated after storage and processing by the computer. The stiffness curve is to optimize the design of the miniature bearing and reduce the The noise and improve the service life of miniature bearings provide an important reference.

[0026] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com