Automatic feeding device for upper cover shell of charger

A technology of automatic feeding and charging, applied in vibration conveyors, transportation and packaging, conveyors, etc., can solve the problems of low production efficiency, unstable product quality, and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

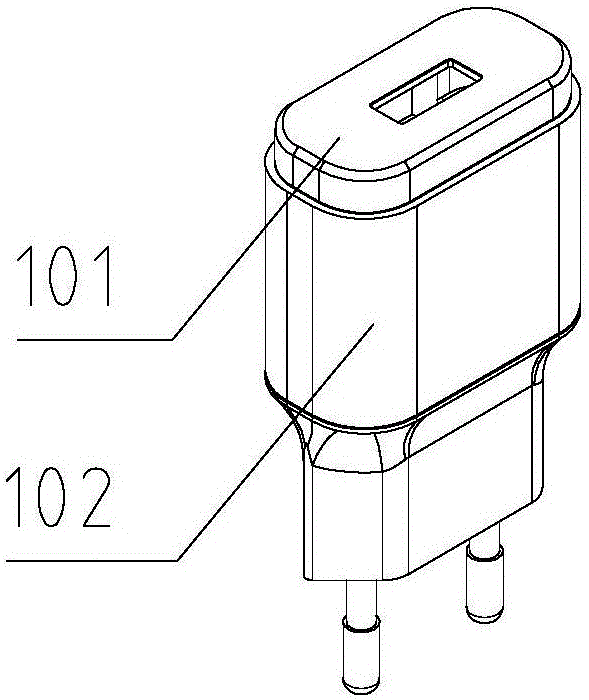

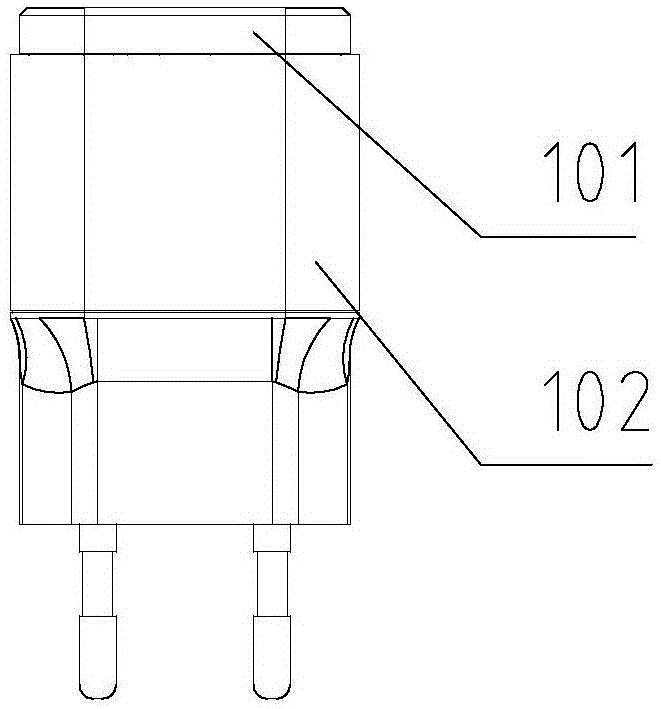

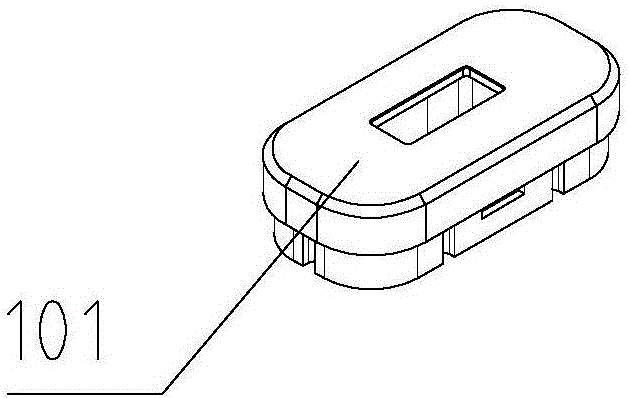

[0043] Such as Figure 1-Figure 17 Shown, be embodiment 1 of the present invention, be provided with vibrating feeding machine 9, be provided with front and rear feeding cylinder 8 on the vibrating feeding machine 9, be provided with vibrating conveying linear guide 7 on the front and rear feeding cylinder 8, vibrating conveying linear guide 7 The front end is respectively provided with a left positioning shrapnel 17 and a right positioning shrapnel 18. The upper part of the front end of the vibration conveying linear guide 7 is provided with a lifting and retrieving cylinder 2, and the front end of the lifting and retrieving cylinder 2 is provided with a clamping and retrieving cylinder 3. A clamping block 4 is provided at the front end.

[0044] During work, the charger upper cover shell 101 is placed on the vibrating conveying linear guide rail 7, the vibrating feeder 9 is opened, the vibrating feeder 9 starts to vibrate, and the charger upper cover 101 is vibrated forward ...

Embodiment 2

[0050] Figure 18-23 It is embodiment 2 of the present invention, Figure 18 It can be seen from the figure that a vibrating feeding machine 9 is provided on one side of the vibrating feeding machine 9, and the front and rear feeding cylinders 8 are arranged on the vibrating feeding machine 9, and the front and rear feeding cylinders 8 are provided with a vibrating conveying linear guide rail 7, and the vibrating conveying straight line The front end of the guide rail 7 is respectively provided with a left positioning shrapnel 17 and a right positioning shrapnel 18. The upper part of the front end of the vibration conveying linear guide rail 7 is provided with a lifting and retrieving cylinder 2, and the front 2 ends of the lifting and retrieving cylinder are provided with a clamping and retrieving cylinder 3. The front end of the material cylinder 3 is provided with a clamping block 4 .

[0051] This embodiment mainly solves that when a set of vibrating feeder 9 cannot meet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com