Multifunctional flow guider

A deflector and multi-functional technology, applied in the field of multi-functional deflectors, can solve the problems of high energy consumption and long production plasticization time, and achieve the effects of low energy consumption, improved plasticization quality, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

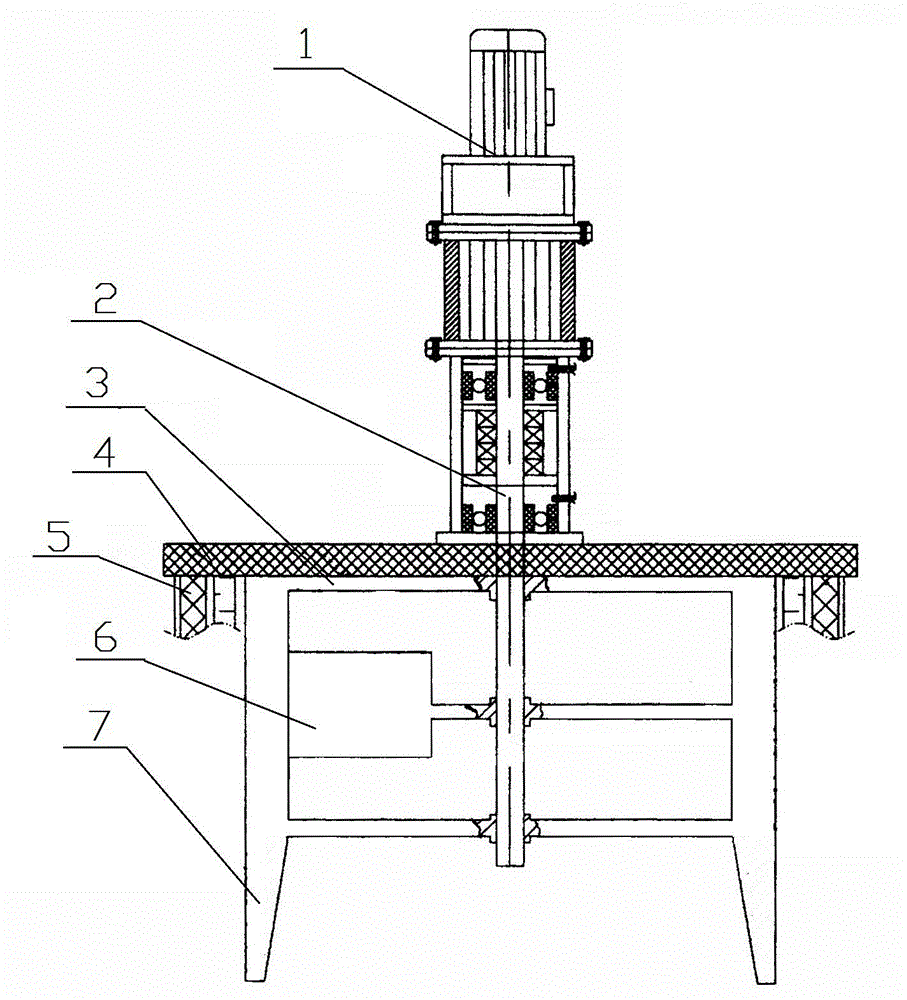

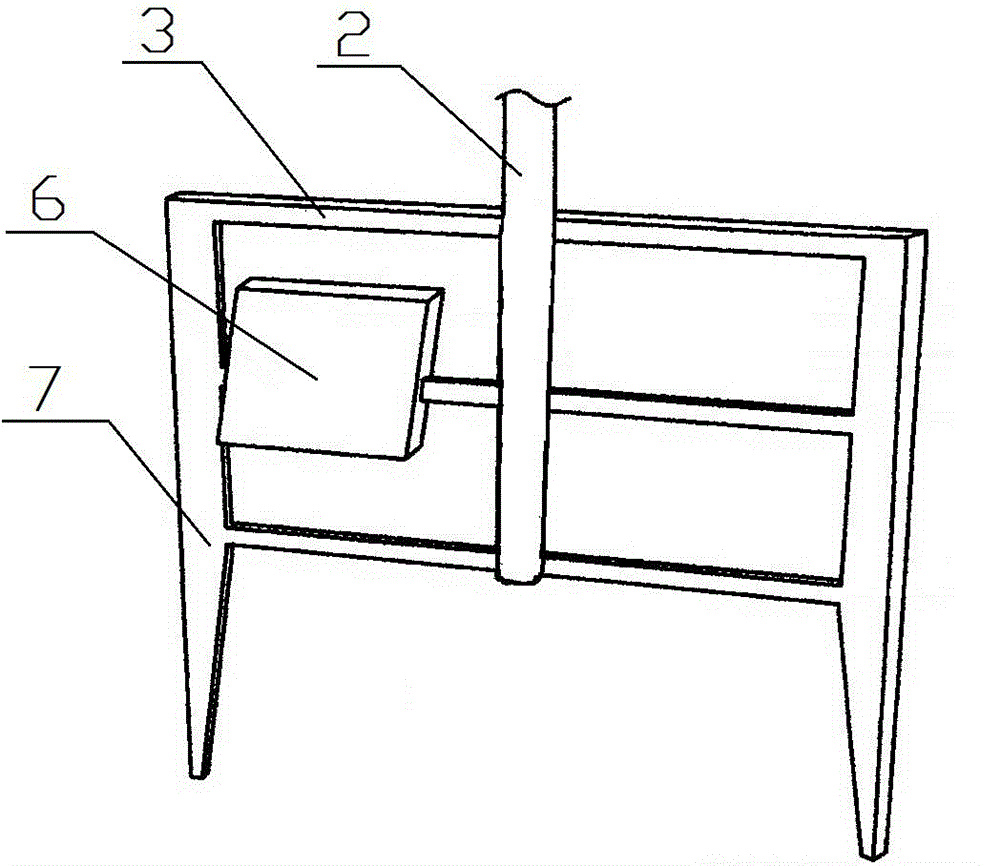

[0008] A multifunctional deflector, such as figure 1 , figure 2 As shown, the desulfurization tank 5 is included, and the transmission shaft 2 driven by the reduction motor 1 is arranged on the top cover 4 of the desulfurization tank 5, and the deflector is installed on the transmission shaft 2 extending into the desulfurization tank 5. The structure is that a symmetrical horizontal scraper 3 is arranged on the upper part of the transmission shaft 2, the top surface of the horizontal scraper 3 matches the inner wall of the top cover 4 of the desulfurization tank, and the outer ends of the symmetrical horizontal scraper 3 are respectively fixed with vertical scrapers 7. The outer surface of the upright scraper 7 is matched with the inner wall of the desulfurization tank 5, and the inner side of one of the upright scraper 7 is connected with a turbulence plate 6 at an angle with the vertical plane, and is set in the middle of the transmission shaft 2 There are symmetrical hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com