Intelligent environment-friendly constant-pressure medium-temperature fast rubber plasticizing unit

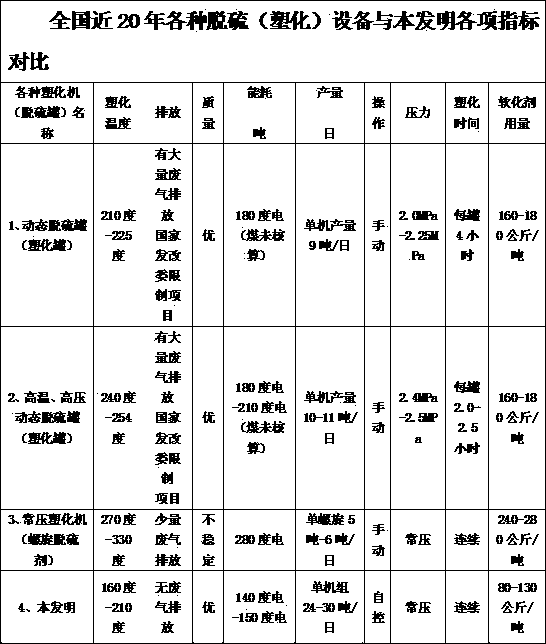

An environmentally friendly, atmospheric technology, applied in the chemical industry, plastic recycling, climate sustainability, etc., can solve the problems of unstable product quality, low production efficiency, high plasticizing temperature, improve the level of intelligence, reduce labor cost, the effect of accelerating the plasticization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

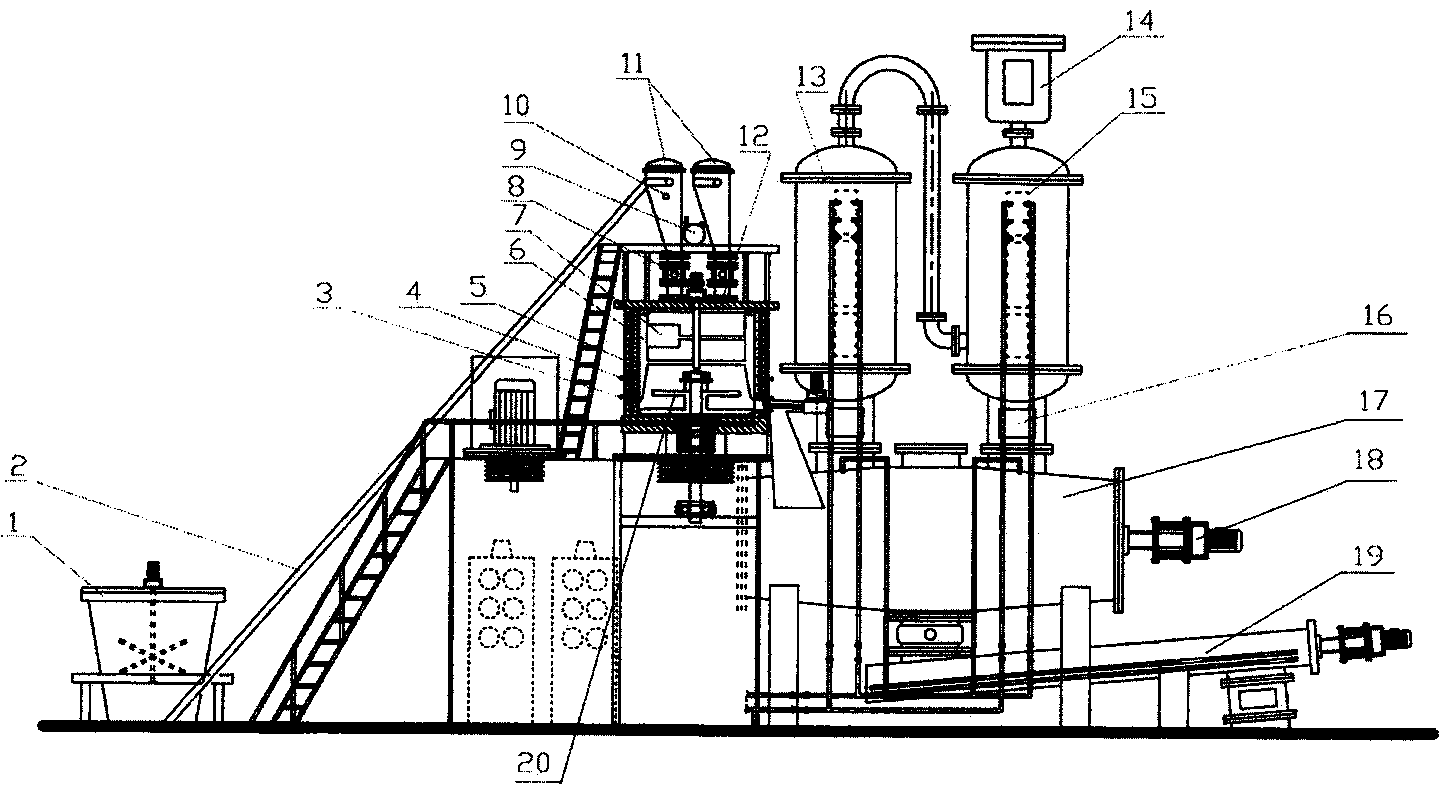

[0032] An intelligent environment-friendly normal pressure medium temperature rapid rubber plasticizing unit, such as figure 1 As shown, the outlet of the lower part of the rubber pretreatment tank 1 is connected to the sealed storage tank 11 installed on the frame through the feeding suction pipe 2, and the sealed storage tank 11 connected to the vacuum feeding device 9 driven by the motor, its outlet is through the sealed The feeding valve 8 is connected to the feed port of the waste rubber friction plasticizing reaction kettle 5, and a stirrer with horizontal blades 12 and vertical blades 6 is arranged in the reaction kettle 5, and a heating pad is arranged in the tank interlayer of the reaction kettle 5. oil, the discharge port of the reaction kettle 5 is connected to the inlet of the cooling tank 17 through a sealed feed valve, and the gas outlet of the tank body on the top of the cooling tank 17 is respectively connected with the first-level and second-level waste gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com