Method for preparing multi-functional rubber additives by recycling alkali reduction processing drainage liquid

A rubber additive and multi-functional technology, which is applied in the field of preparation of multi-functional rubber additives, can solve the problems of low product purity and restrictions on industrial application, so as to increase the plasticizing speed, improve the anti-vulcanization reversion performance, and realize resource recovery. The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Alkali decrement drainage passes through the advection type sedimentation tank and activated carbon filter in turn, and then enters the acid analysis tank. Under stirring at 80 rpm, sulfuric acid is added. When the pH of the water quality drops to 4, continue to stir and age for 2 hours, and finally Filtration yielded crude terephthalic acid. In the reaction kettle, add 60 parts of terephthalic acid, 40 parts of stearic acid, 160 parts of water, and 60 parts of sodium hydroxide, stir, and after the terephthalic acid and stearic acid are completely dissolved, add zinc chloride solution 60 parts, stir while adding zinc chloride, the stirring speed is 60 rev / min, add in 20 minutes, continue to stir for 40 minutes after adding zinc chloride, centrifuge, filter cake is washed and dried, that is multi-functional Finished rubber additives.

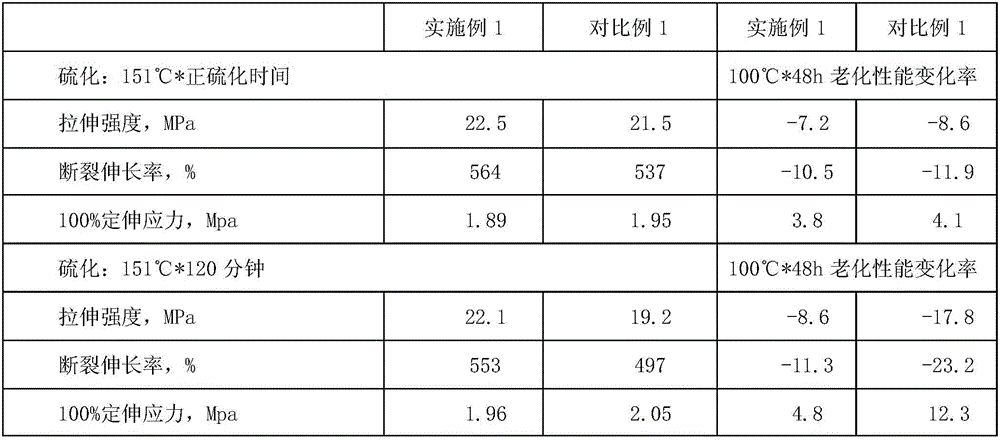

[0016] The rubber formula used is: NR 100, stearic acid 2, N220 45, silica 8, Si69 0.8, aromatic oil 5, protective wax 2, 4010NA 1.5, su...

Embodiment 2

[0018] Alkali decrement drains pass through the advection sedimentation tank and activated carbon filter in sequence, and then enter the acid analysis tank. Under stirring at 80 rpm, add sulfuric acid. When the pH of the water drops to 4, continue to stir and age for 3 hours, and finally Filtration yielded crude terephthalic acid. In the reaction kettle, add 60 parts of terephthalic acid, 40 parts of stearic acid, 120 parts of water, and 10 parts of sodium hydroxide, stir, and after the terephthalic acid and stearic acid are completely dissolved, add zinc chloride solution 60 parts, stir while adding zinc chloride, the stirring speed is 100 rpm, and finish adding in 30 minutes. After adding zinc chloride, continue stirring for 30 minutes, centrifuge, filter cake is washed and dried, that is, multi-functional Finished rubber additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com