Patents

Literature

30results about How to "Effect on physical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

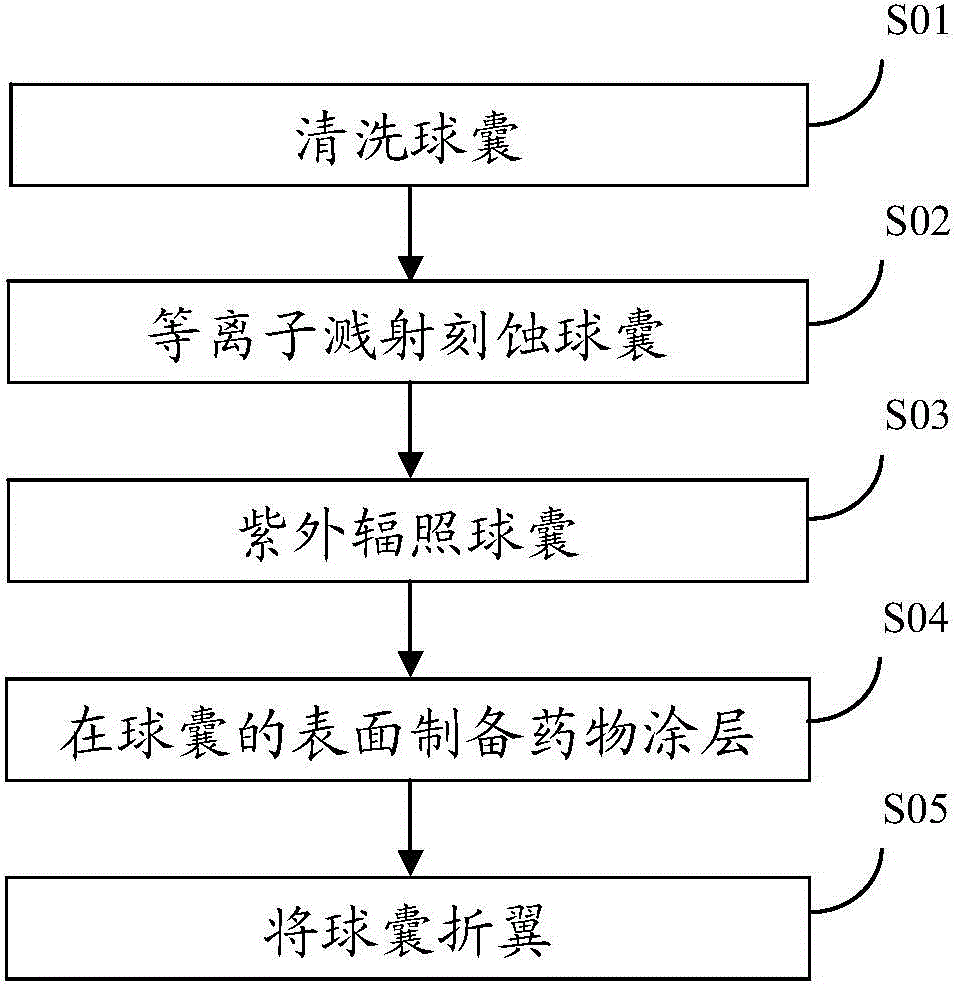

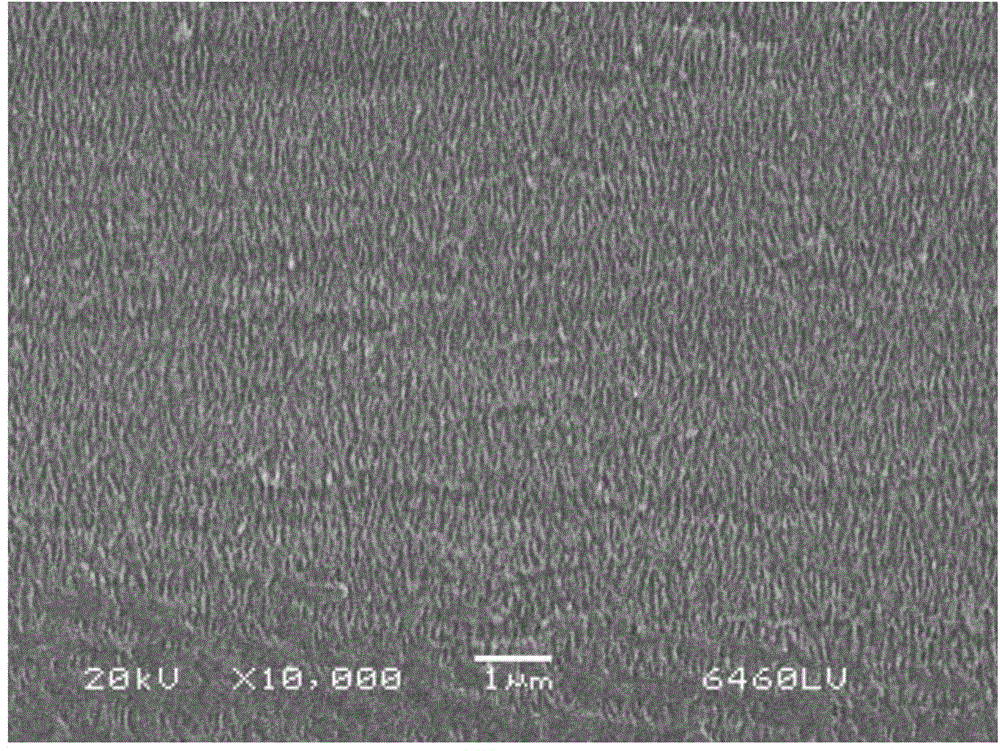

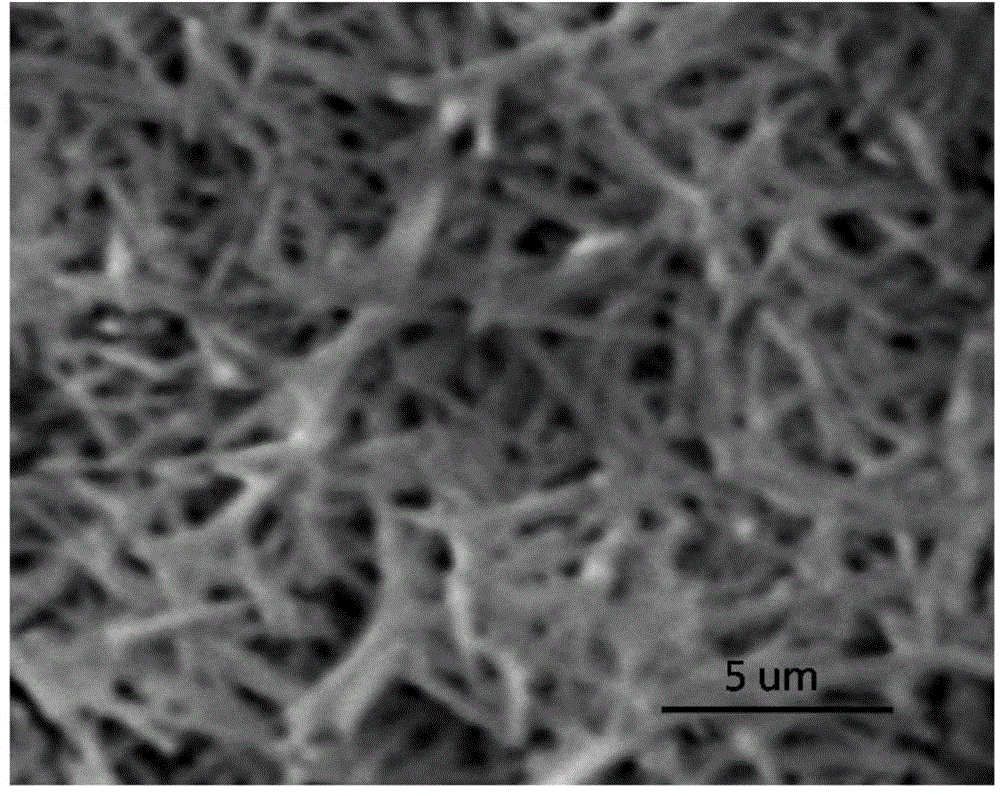

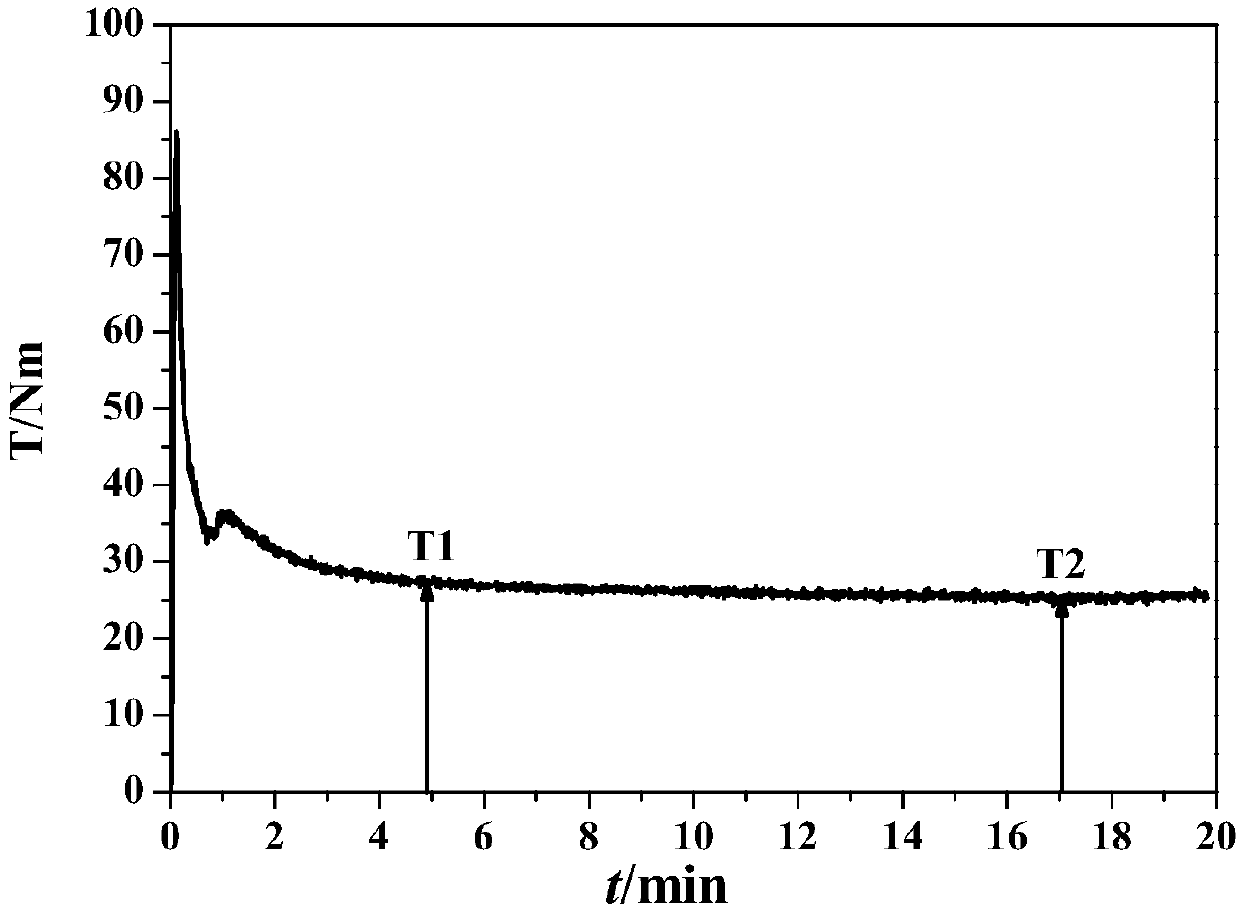

Medicament balloon and preparation method thereof

ActiveCN104056341AEffect on physical propertiesLarge specific surface areaBalloon catheterMedical devicesMedicineBond Force

The invention provides a medicament balloon, which comprises a balloon and a medicament coating, wherein the surface of the balloon has a nanometer scale micro-hole structure. The invention further provides a method for preparing the medicament balloon. The method comprises the following steps: performing plasma sputter etching on the surface of the balloon to form the nanometer scale micro-hole structure on the surface of the balloon; preparing the medicament coating on the surface of the balloon. The surface of the balloon has the uniform nanometer scale micro-hole structure, so that the surface of the balloon has a greater specific surface area, and the medicament carrying amount on the surface of the balloon is increased; the physical performance of the balloon is not influenced. According to the preparation method of the medicament balloon provided by the invention, the plasma sputter etching method is adopted, so that the nanometer scale micro-hole structure can be formed on the surface of the balloon, the bonding force between the surface of the balloon and the medicament coating can be improved, and the loss of medicaments in the conveying process of the balloon is reduced.

Owner:深圳市金瑞凯利生物科技有限公司

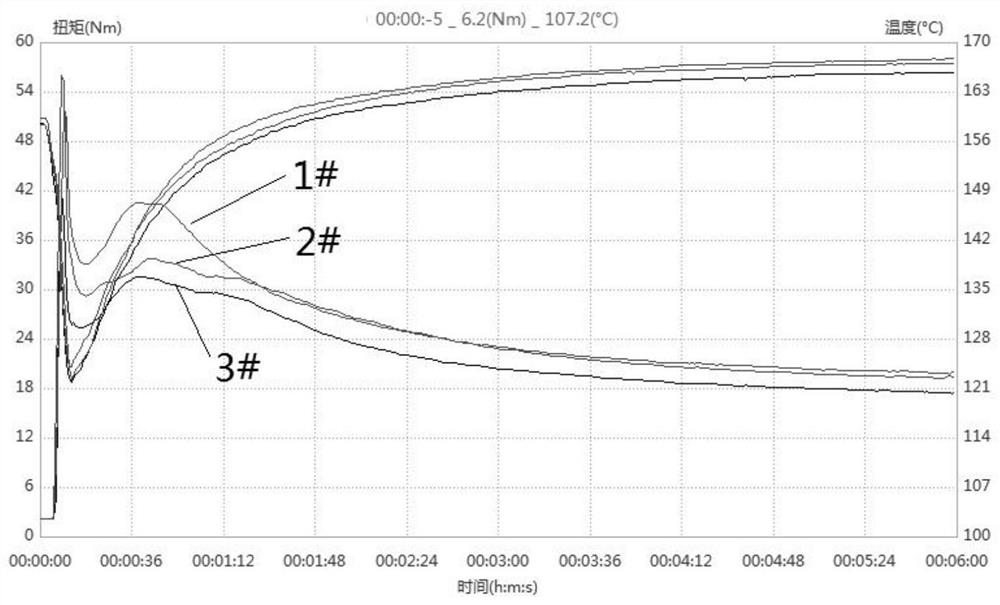

Preparation method for highly thermal stable CPVC blend composition

The invention provides a preparation method for a highly thermal stable CPVC blend composition. The preparation method comprises steps of heating and mixing materials and cooling, wherein in the heating and mixing step, hydrotalcite, a tin ethyl thermal stabilizer compound, CPVC and additives are heated and blended in a mixing machine. The thermal stability of CPVC is improved, less tin ethyl thermal stabilizer is used at the same time, and the problems that CPVC is difficult to process and the thermal stabilizer is high in cost are solved.

Owner:杭州电化新材料有限公司

Intumescent flame retardant and application thereof in polyurethane foam

InactiveCN106146891AImprove packaging efficiencyGood water resistance and solubilityPolymer scienceFoaming agent

The invention discloses an intumescent flame retardant and application thereof in polyurethane foam, the intumescent flame retardant is a microcapsule which takes a phosphate as a capsule core and is coated with a polymer as a wall shell, and the intumescent flame retardant is prepared by the following process: a solvent is divided into two equal parts, an emulsifying agent, the phosphate and a water solution of a water soluble polymer reaction monomer are added into one part of the solvent for mixing to obtain an emulsion A; isocyanate and a catalyst are added into the other part of the solvent to obtain an emulsion B; and the emulsion A and the emulsion B are stirred for mixing reaction to obtain the intumescent flame retardant. The intumescent flame retardant is the microcapsule which takes the phosphate as the capsule core, is coated with the polymer as the wall shell and is prepared by interfacial polymerization method, when the microcapsule is heated, the phosphate is used as an acid source and a foaming agent, the coating polyurea or polyurethane is used as a charring agent, and the new intumescent flame retardant comprising the microcapsule has prominent flame retardant effect and can be widely used.

Owner:HEFEI GENIUS NEW MATERIALS

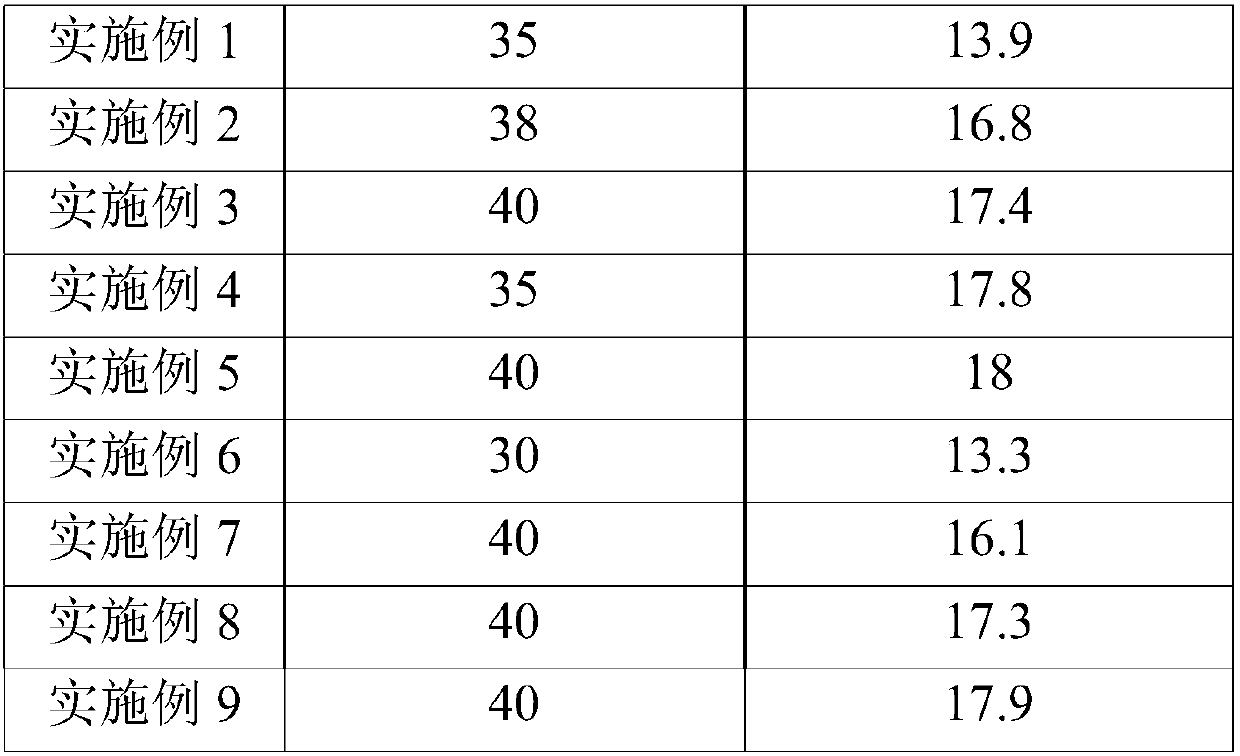

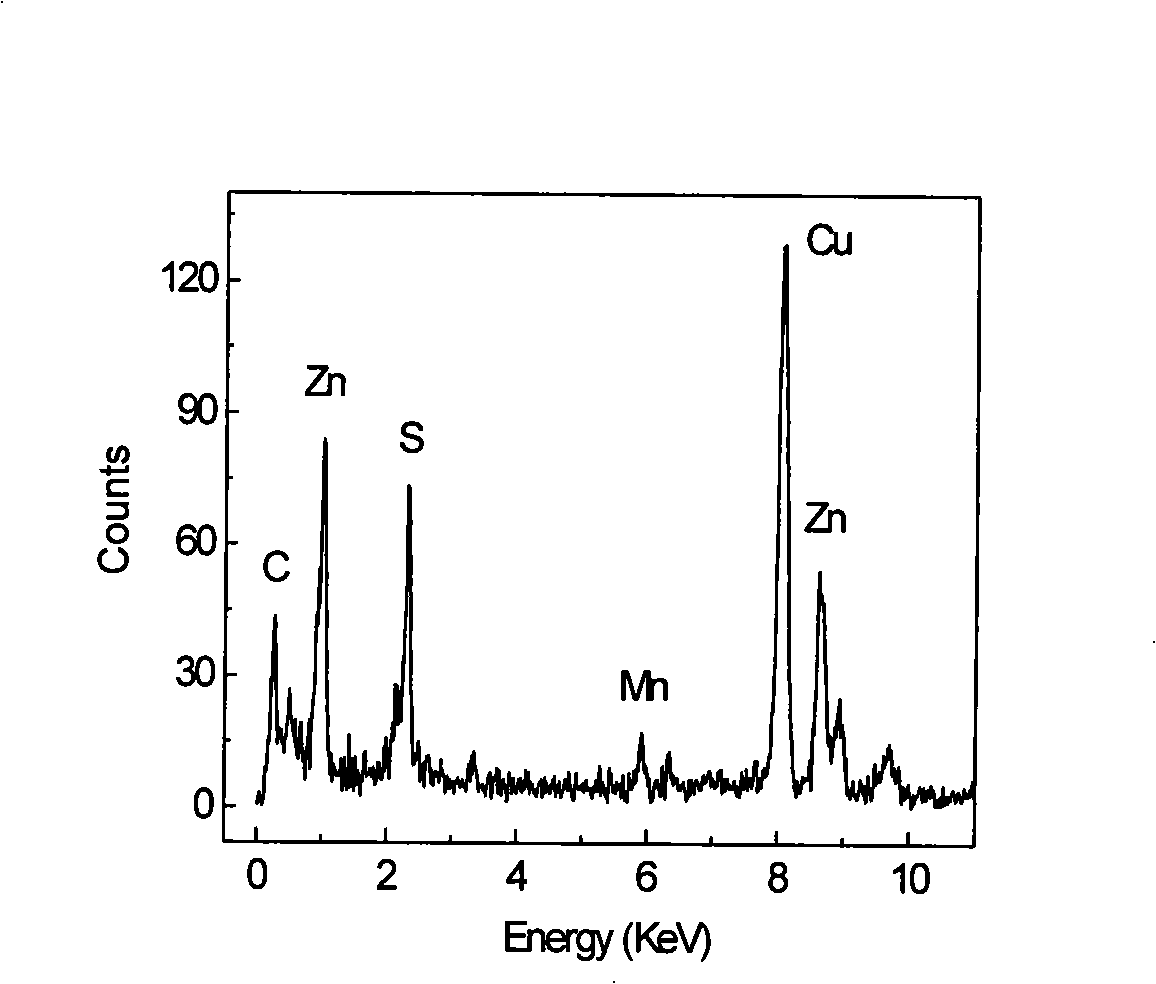

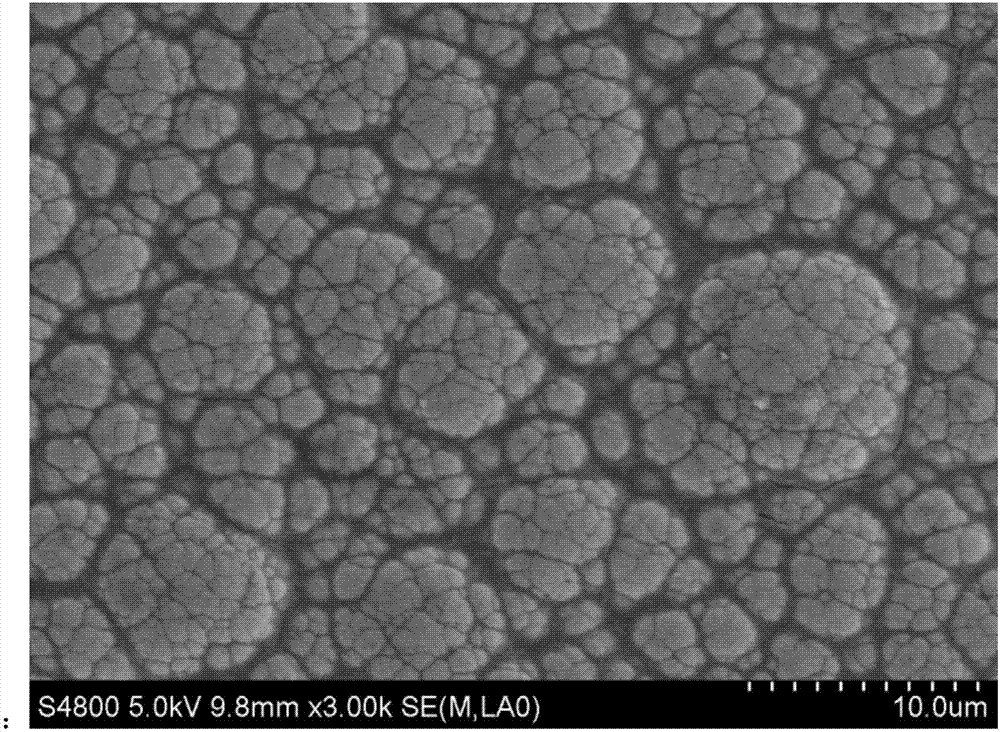

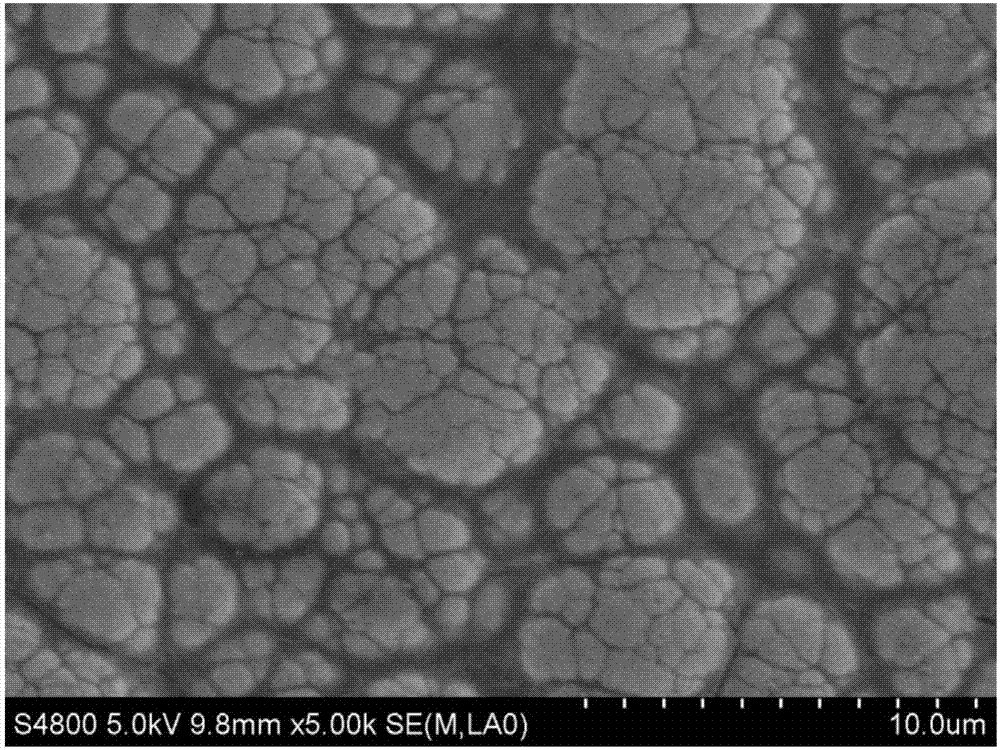

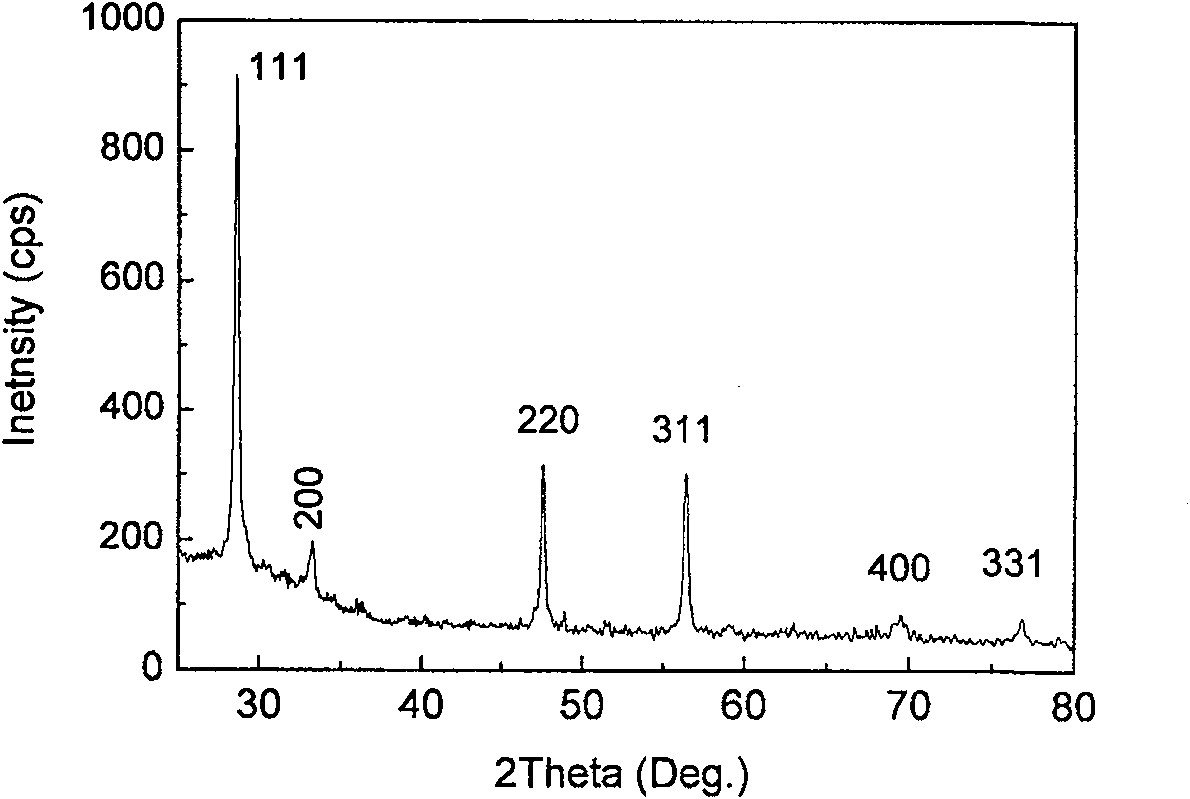

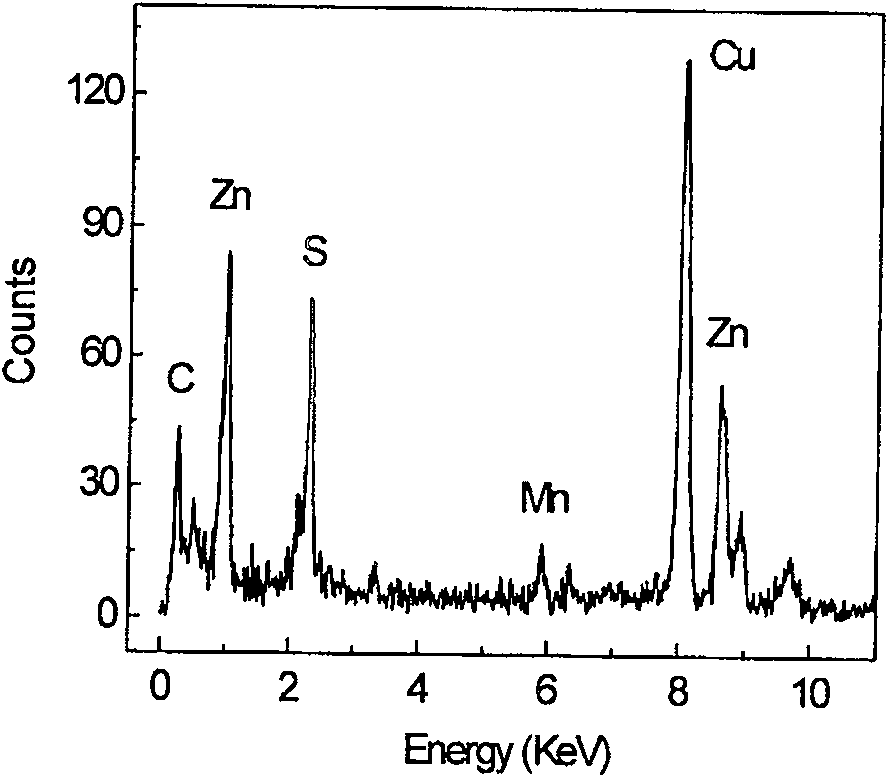

Method for preparing Mn-doped ZnS nanostructure

The invention provides a preparation method of Mn-doped ZnS nano-structure, which belongs to the technology field of semiconductor nano-material preparation. The method is characterized in including adopting a manner of chemical gas deposition, charging mixed gas of the argon gas and the hydrogen gas at a flow rate of 108-113 ml / min into a pipe heater, and evaporating the ZnS powder and the MnCl2 powder in the mixed atmosphere of the argon gas and the hydrogen gas; and heating the pipe heater to 900-920 DEG C, maintaining the temperature for 60-200min and furnace-in pressure of 0.015-0.03MPa, and depositing Mn-doped ZnS nano-structure on a blank silicon wafer. An evaporation source is arranged in an inlet direction of mixed gas stream of the argon gas and the hydrogen gas, the silicon wafer is arranged in an outlet direction of the mixed gas stream of the argon gas and the hydrogen gas, and horizontal distance between the silicon wafer and the evaporation source is 3-6mm. The method is capable of obtaining high purity and high crystalline quality Mn-doped ZnS nano-material without catalyst, and has simple preparation, low cost and easy operation.

Owner:UNIV OF SCI & TECH BEIJING

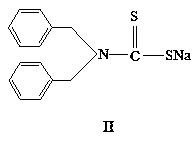

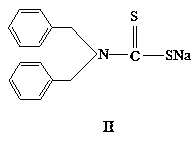

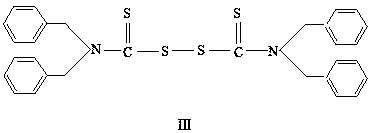

A kind of tetrabenzylthiuram monosulfide and its preparation method and application

The invention discloses sulfide tetrabenzyl thiuram and a preparation method and application thereof. The preparation method comprises the following steps: enabling dibenzylamine, sodium hydroxide and carbon disulfide to react in a solvent to generate an intermediate sodium dibenzyldithiocarbamape, then oxidizing the sodium dibenzyldithiocarbamape into the disulfide tetrabenzyl thiuram by use of hydrogen peroxide, and then desulfurizing the disulfide tetrabenzyl thiuram by use of hydrogen to obtain the sulfide tetrabenzyl thiuram. The sulfide tetrabenzyl thiuram disclosed by the invention is high in purity, high in melting point, and white in appearance, the vulcanization rate can be obviously accelerated, the sulfide tetrabenzyl thiuram can express good scorching security and fast vulcanization performance whether to increase the vulcanization temperature and change the sulfur dosage or to add the white carbon black, and the use of the sulfide tetrabenzyl thiuram has no bad influence to the physical performance of the sulfide rubber.

Owner:SHANDONG YANGGU HUATAI CHEM

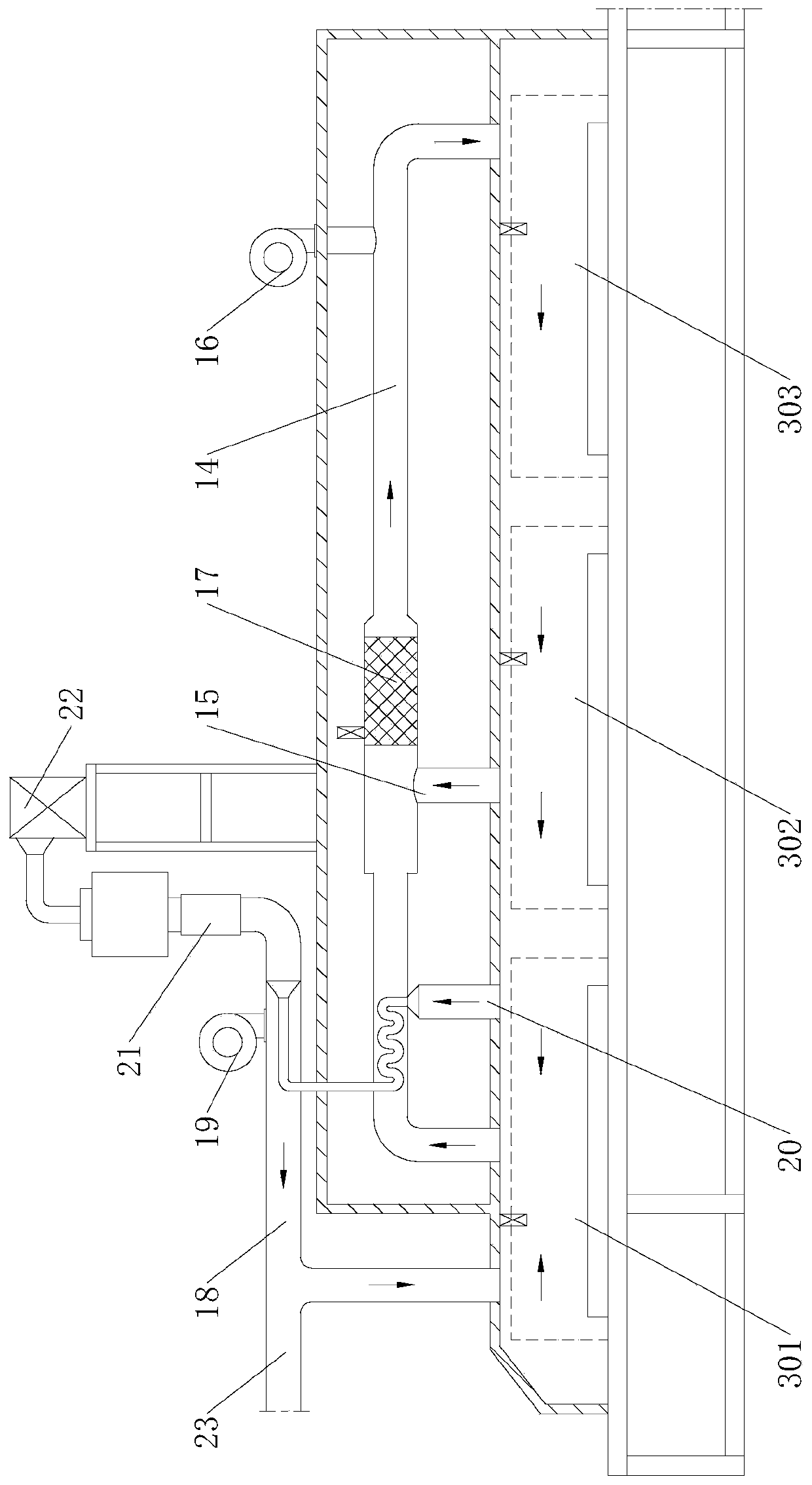

Processing technology of special self-adhesive enameled wire for household motor and device

ActiveCN110310782AImprove processing stabilityGood coating effectInsulating conductors/cablesCopper wireSelf adhesive

The invention discloses a processing technology of a special self-adhesive enameled wire for a household motor and a device. The processing technology comprises the steps of softening a copper bare wire through an annealing oven to obtain a copper wire A; sensing the copper wire A into a drying furnace for drying to obtain a copper wire B; coating the surface of the copper wire B with primer, sending the copper wire B into a first enamelling furnace, and drying the copper wire B for the first time in different temperature environments through the first enamelling furnace to obtain an enameledwire C; coating the surface of the enameled wire C with finish paint, then sending the enameled wire C into a second enamelling furnace, and drying the enameled wire C for the second time in differenttemperature environments through the second enamelling furnace to obtain an enameled wire D; and winding the enameled wire D to obtain a finished enameled wire. The working stability and the bondingeffect of the self-adhesive paint after being coated can be effectively improved according to the invention.

Owner:浙江郎立电工器材有限公司

Plating solution for electroless Ni-Mo-B/GO multifunctional nano-composite deposition layer and preparation method and application of plating solution

InactiveCN106894006AGood organizational performanceImprove coating crystal orientationLiquid/solution decomposition chemical coatingCarbon steelLead acetate

The invention discloses a plating solution for an electroless Ni-Mo-B / GO multifunctional nano-composite deposition layer and a preparation method and application of the plating solution. The plating solution comprises, by liter, 20-55g of nickel chloride hexahydrate, 0.5-4g of sodium borohydride, 10-25g of sodium molybdate, 20-65g of sodium hydroxide, 15-65g of ethanediamine, 0.1-0.2g of lauryl sodium sulfate, 0.1-10g of graphene oxide, 0.01-1g of lead acetate, and the balance distilled water. The preparation method includes the steps that the nickel chloride hexahydrate, the sodium borohydride, the sodium molybdate, the sodium hydroxide, the ethanediamine, the lauryl sodium sulfate, the graphene oxide and the lead acetate are sequentially added into the distilled water to be dissolved; and then standing is performed, and accordingly the plating solution can be obtained. The plating solution is plated on the surface of a low-carbon steel workpiece, so that a composite coating with good abrasion resistance and high corrosion resistance is formed.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

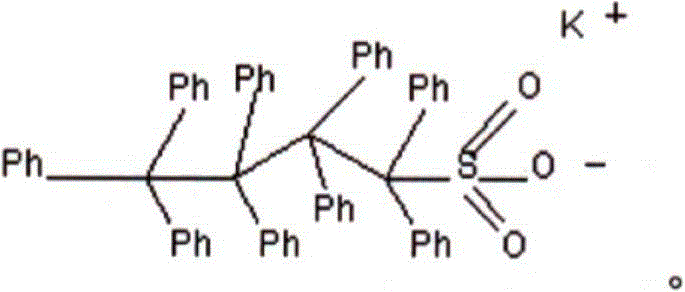

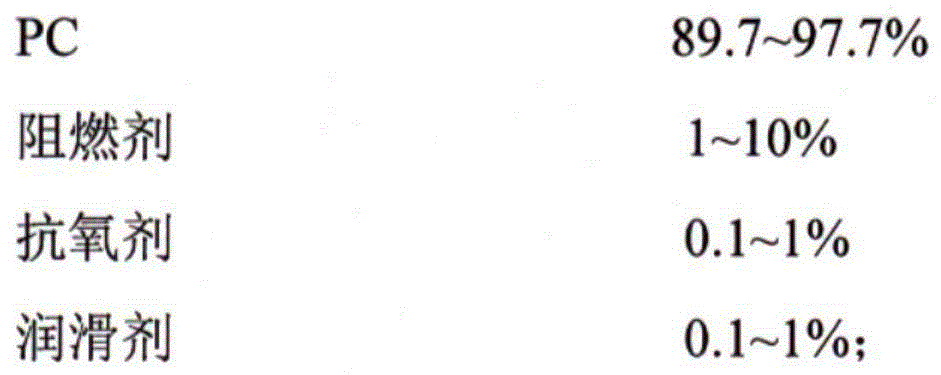

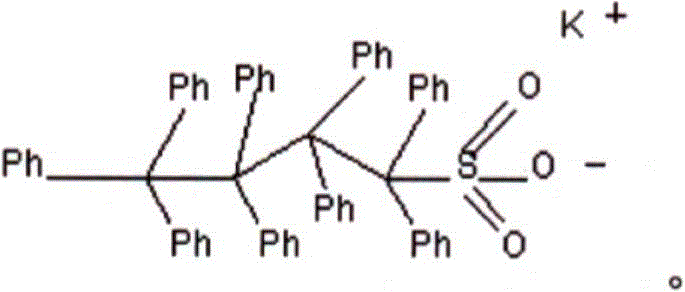

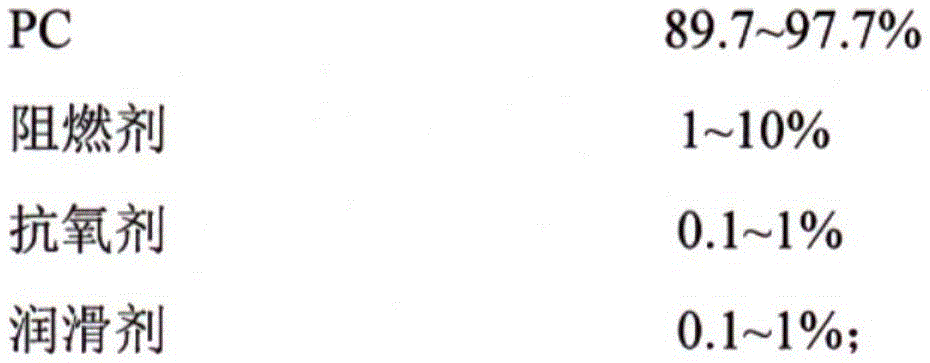

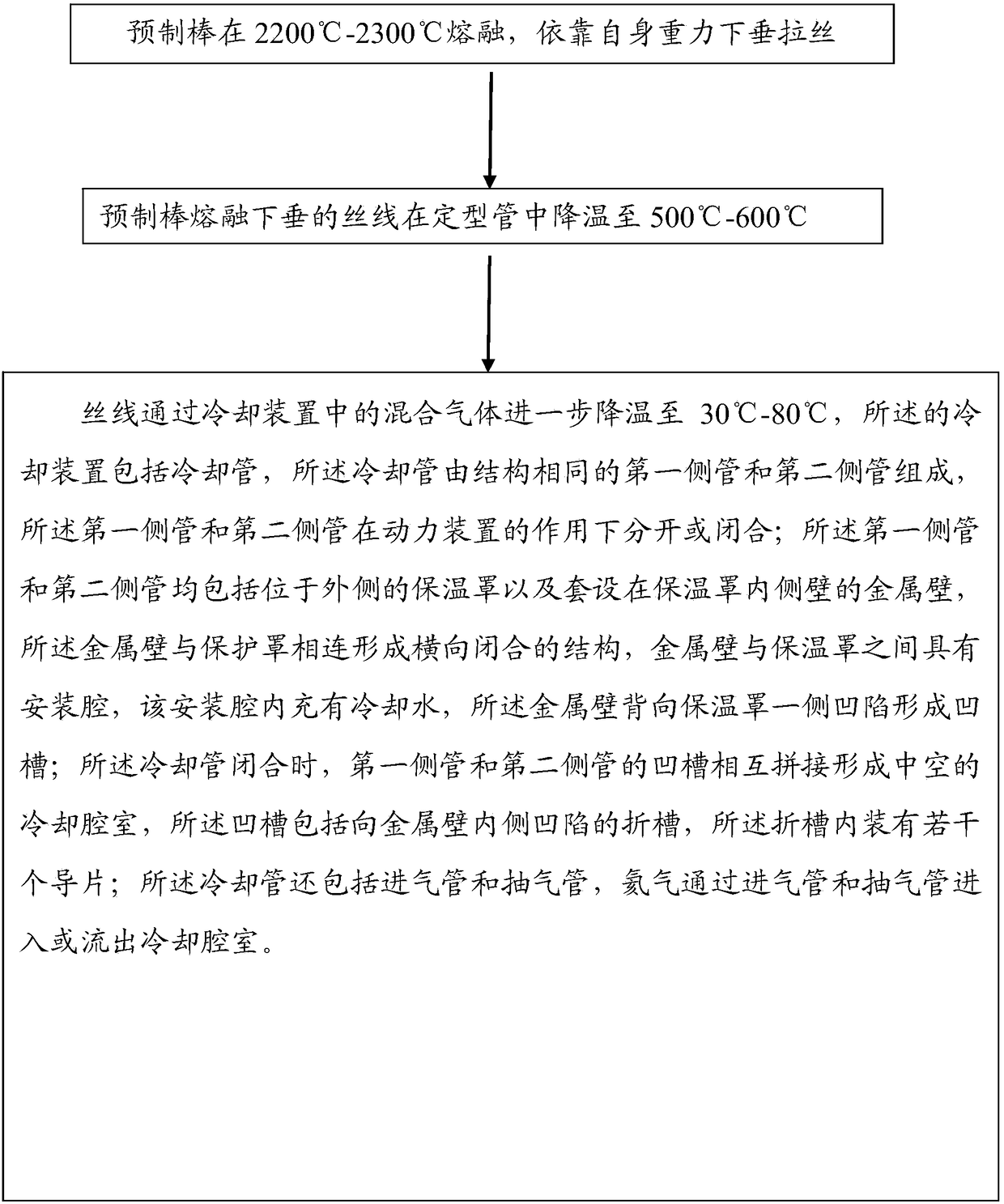

Transparent halogen-free flame-retardant polycarbonate resin and preparation method thereof

The invention relates to a transparent halogen-free flame-retardant polycarbonate resin. The resin comprises the following components in percentage by weight: 98.4-99.75% of flame-retardant master batches, 0.05-0.6% of a fire retardant, 0.1-0.5% of an antioxidant and 0.1-0.5% of a lubricant. The preparation method comprises the following steps: preparing materials according to the components, adding PC, the fire retardant, the antioxidant and the lubricant in percentage by weight into a high-speed mixing machine, sufficiently mixing the PC, the fire retardant, the antioxidant and the lubricant, and placing the PC, the fire retardant, the antioxidant and the lubricant, which are mixed, into a screw rod machine for extruding and pelleting so as to obtain flame-retardant master batches; adding the flame-retardant master batches and the rest of the components into the high-speed mixing machine together, sufficiently mixing the flame-retardant master batches and the rest of the components, and then placing the flame-retardant master batches and the rest of the components, which are sufficiently mixed, into the screw rod machine for extruding and pelleting so as to obtain products. Compared with the prior art, the method disclosed by the invention fully uses phenyl butyl sulfonic acid potassium as the fire retardant, after the fire retardant, the antioxidant, the lubricant and the flame-retardant master batches are mixed, extruded and pelleted, the whole preparation technology is simple, a complex ladder temperature control step is not needed, the obtained products have the characteristics of transparence, thin walls, high impact strength, excellent flame retardant property, zero toxicity and zero harm, and the application range is wide.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

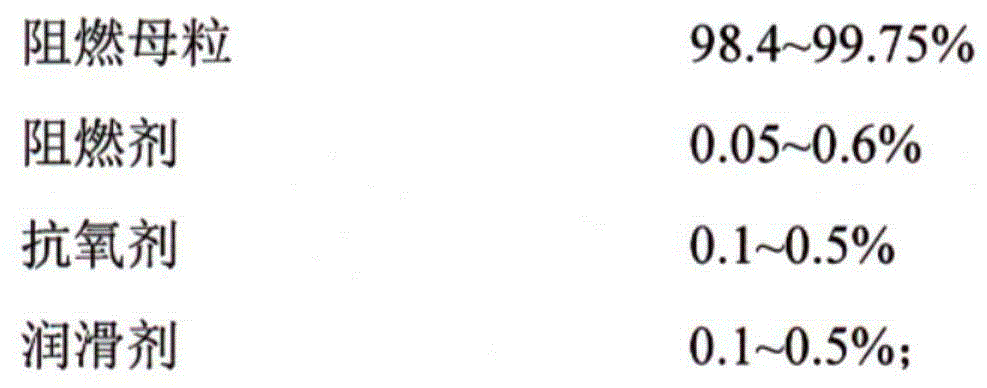

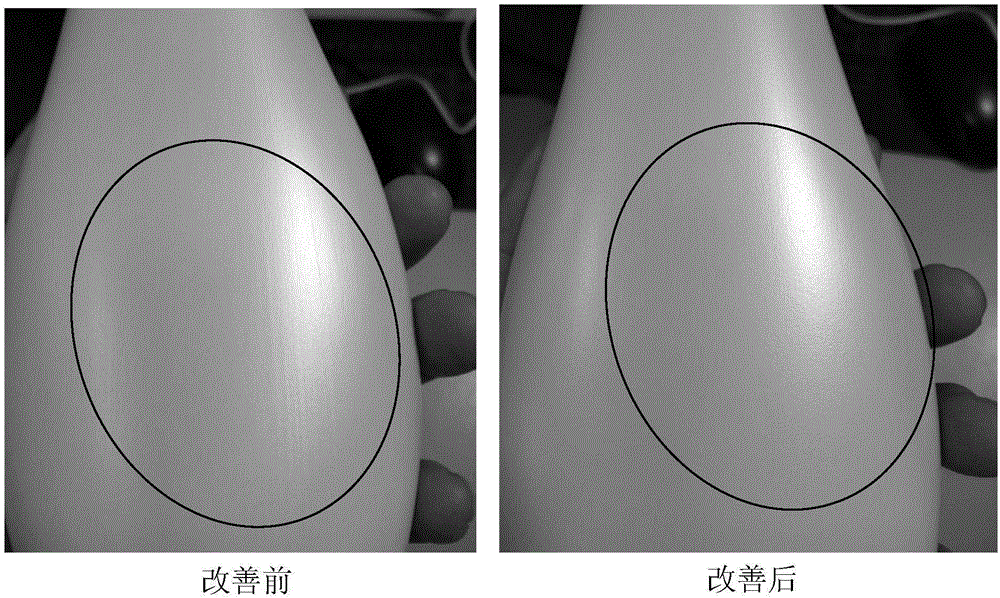

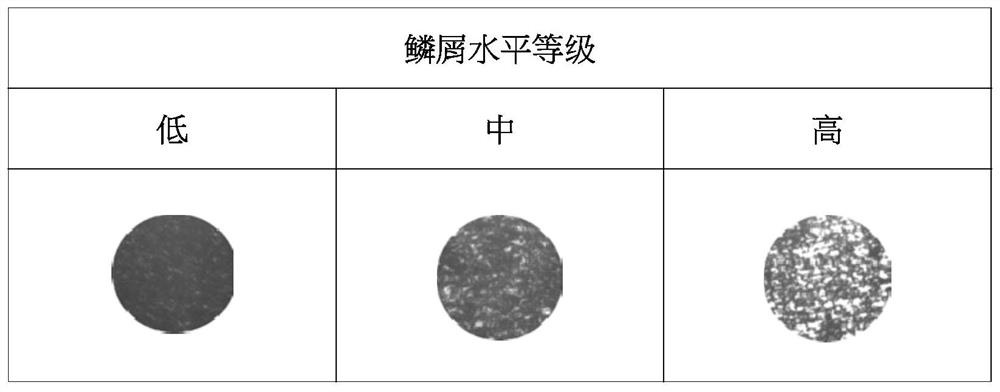

HDPE modified material for improving pearly luster color masterbatch forming line and application of material

The invention discloses an HDPE modified material for improving the pearly luster color masterbatch forming line and application of the material, and belongs to the field of material application. The HDPE modified material is prepared from, by mass, 50-90% of extrusion blow molding grade HDPE and 10-50% of LDPE or LLDPE. The HDPE modified material has the advantages that the effect of improving the pearly luster line and the flow line in forming is good, production efficiency is improved, only a pouring cup needs to be detached to be polished during production, the time for cleaning mold head parts is greatly shortened, and production efficiency is improved; the color and luster of the material are improved, and the material is helpful for improving the pearl luster line and the flow line; the production cost of the product is not increased, and the product performance is not influenced; component compatibility is good, no special requirements exist during machining, so the production cost of the product can not be increased; the mechanical performance of the LDPE is weak, but co-mixture only needs to be used on the outer layer, so the ratio of the co-mixture in the product is small, and the physical performance of the product is not remarkably influenced.

Owner:GUANGZHOU BEAUTY STAR CO LTD

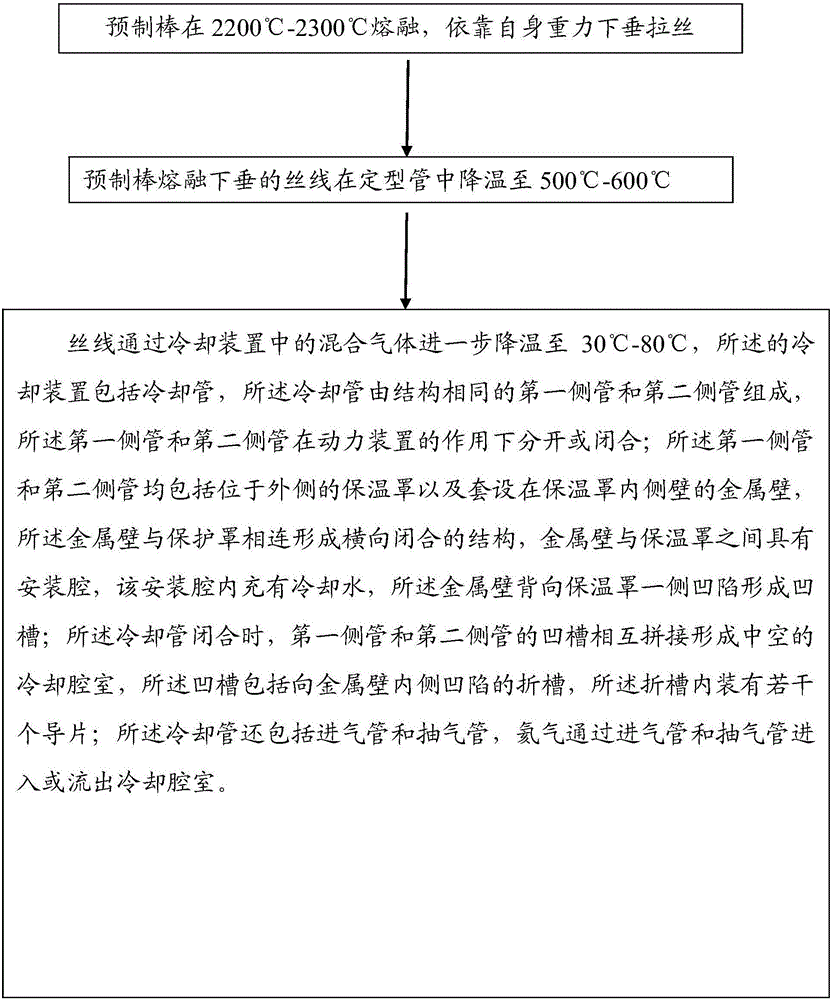

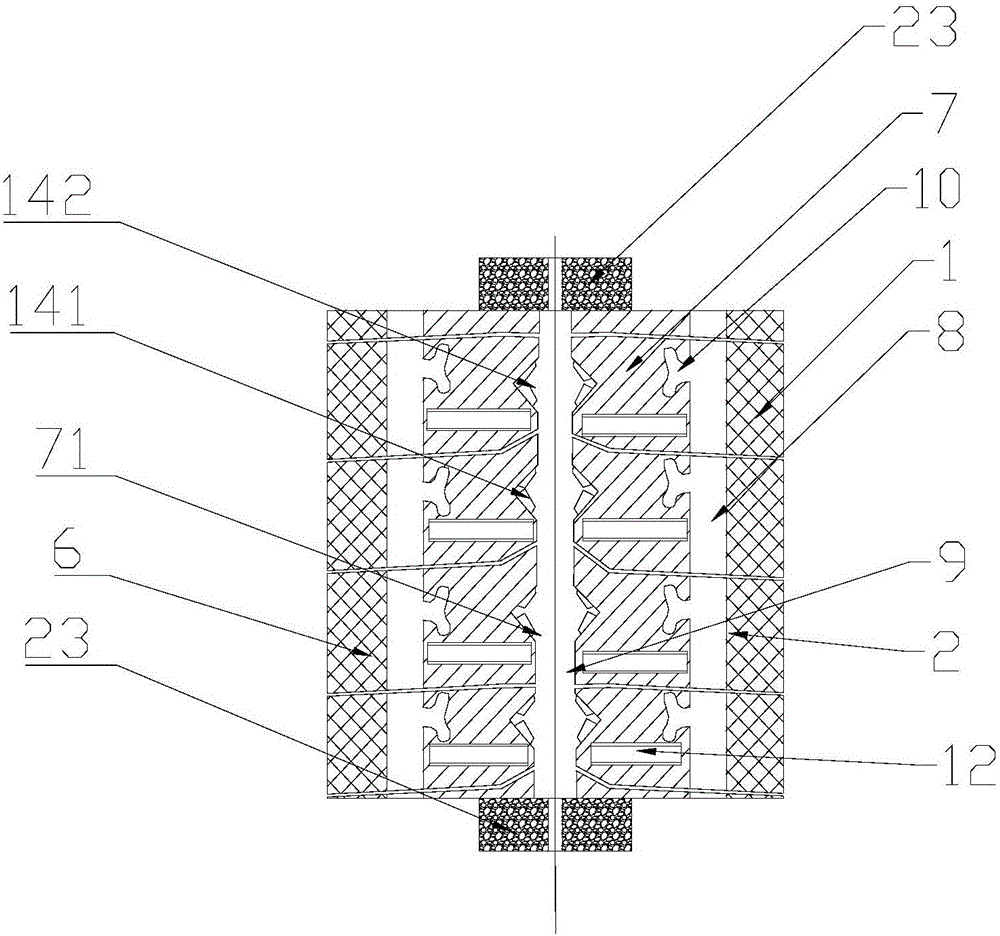

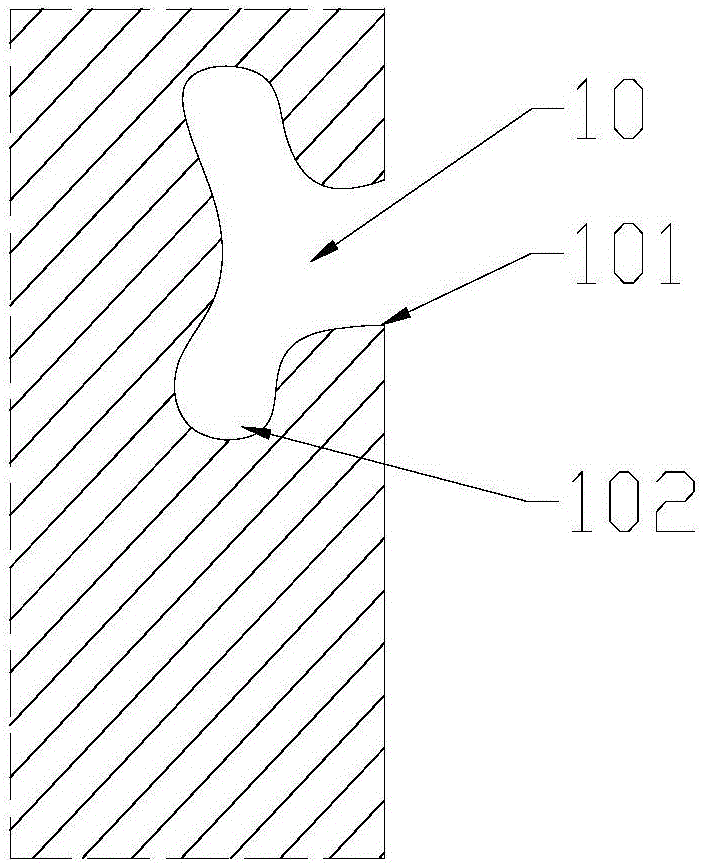

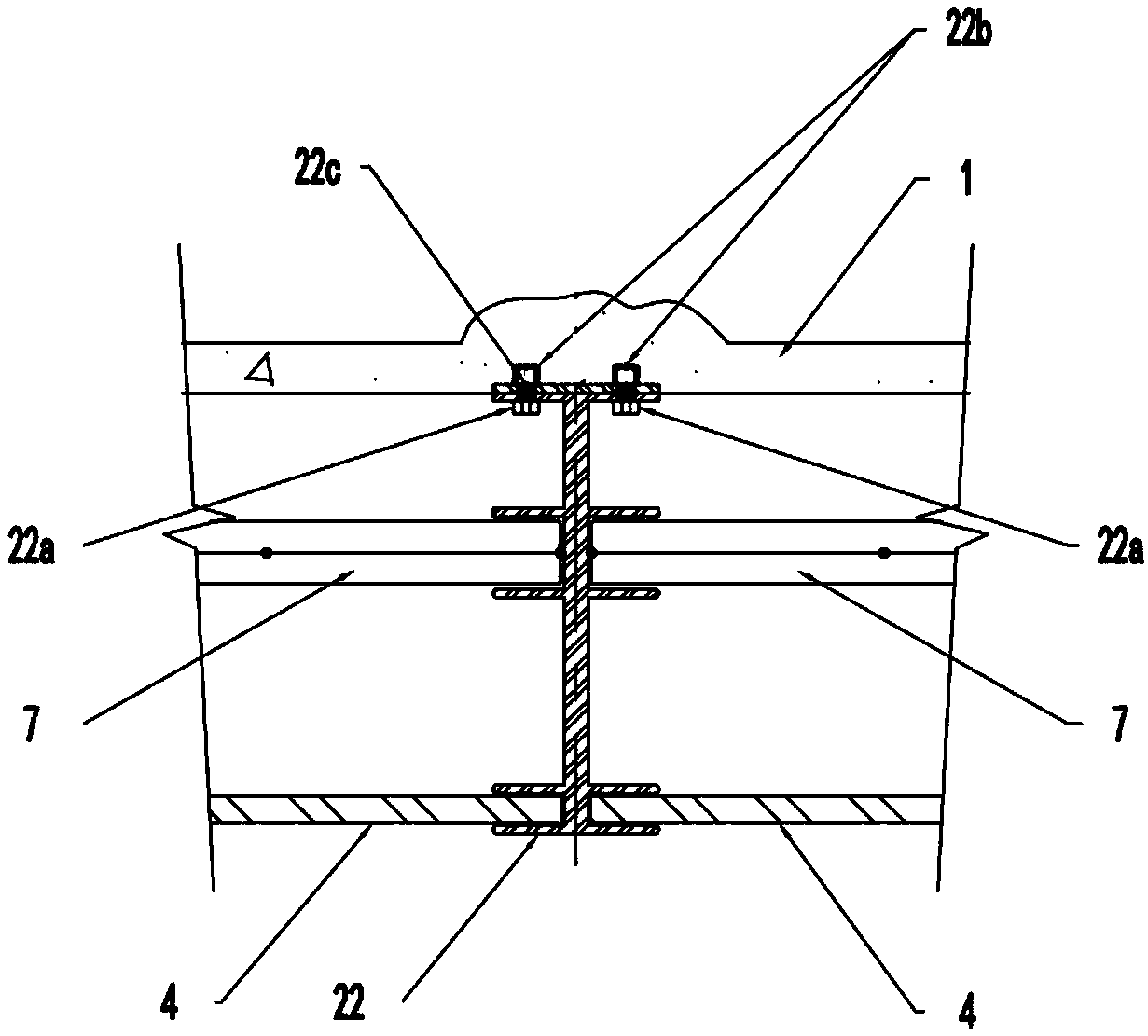

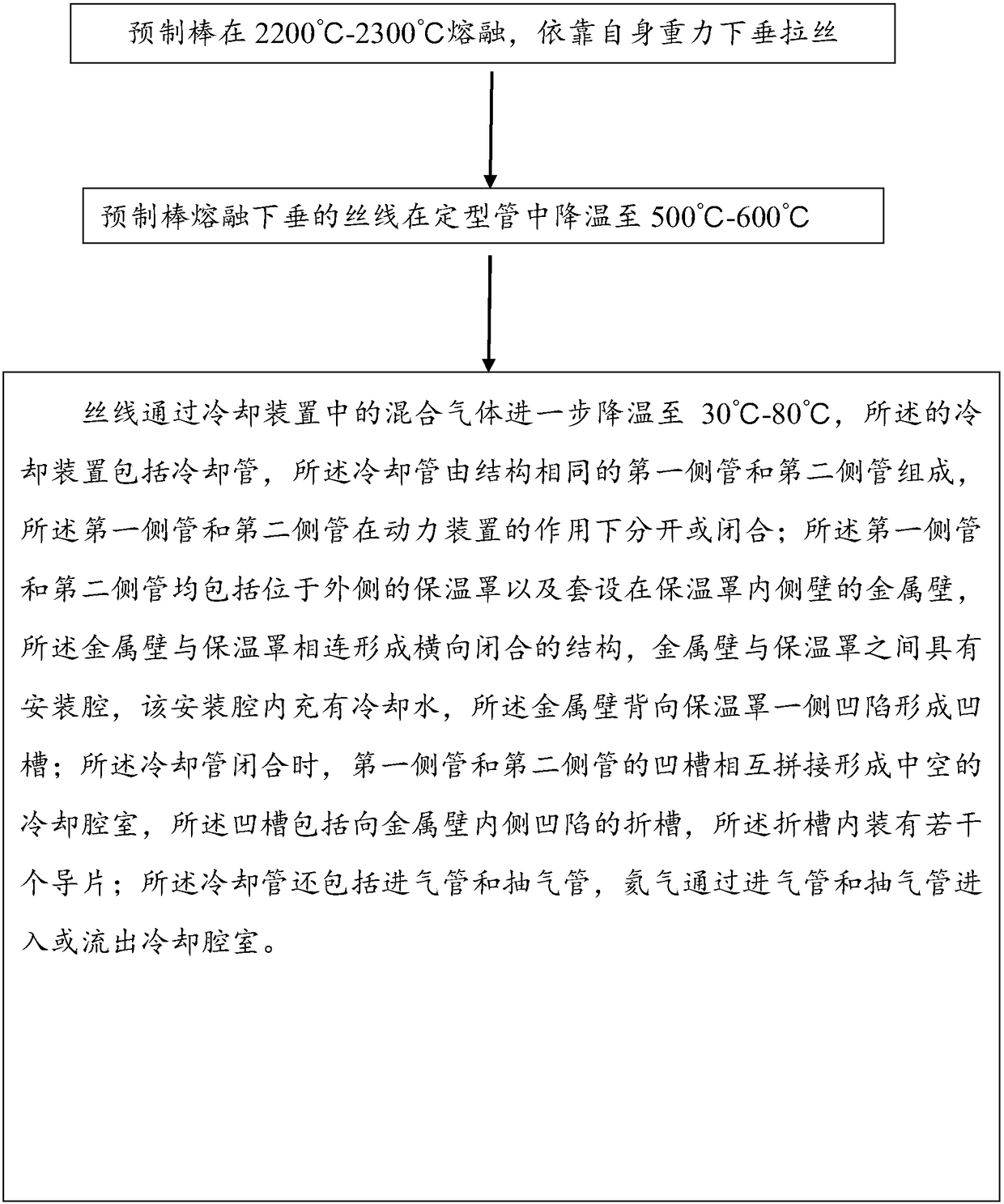

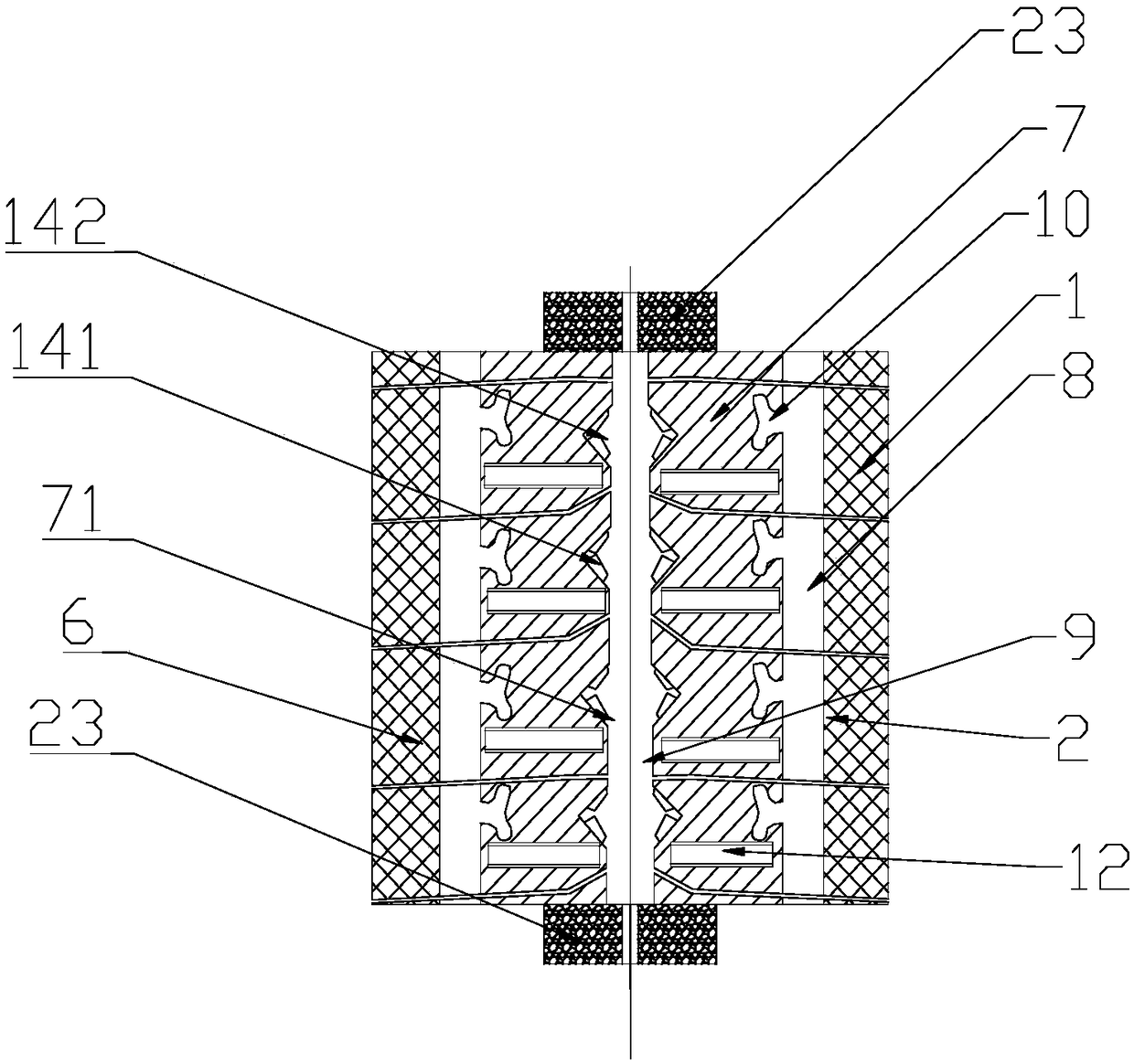

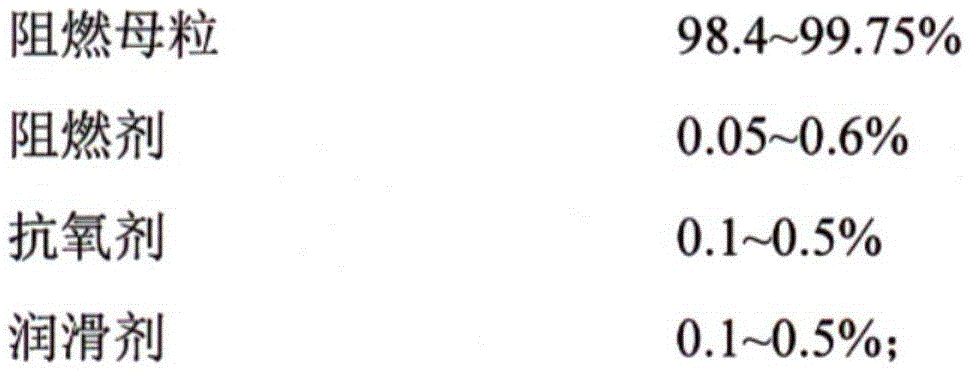

Optical fiber drawing technology

ActiveCN105884187AImprove cooling effectIncrease the Reynolds numberGlass making apparatusCooling effectHelium

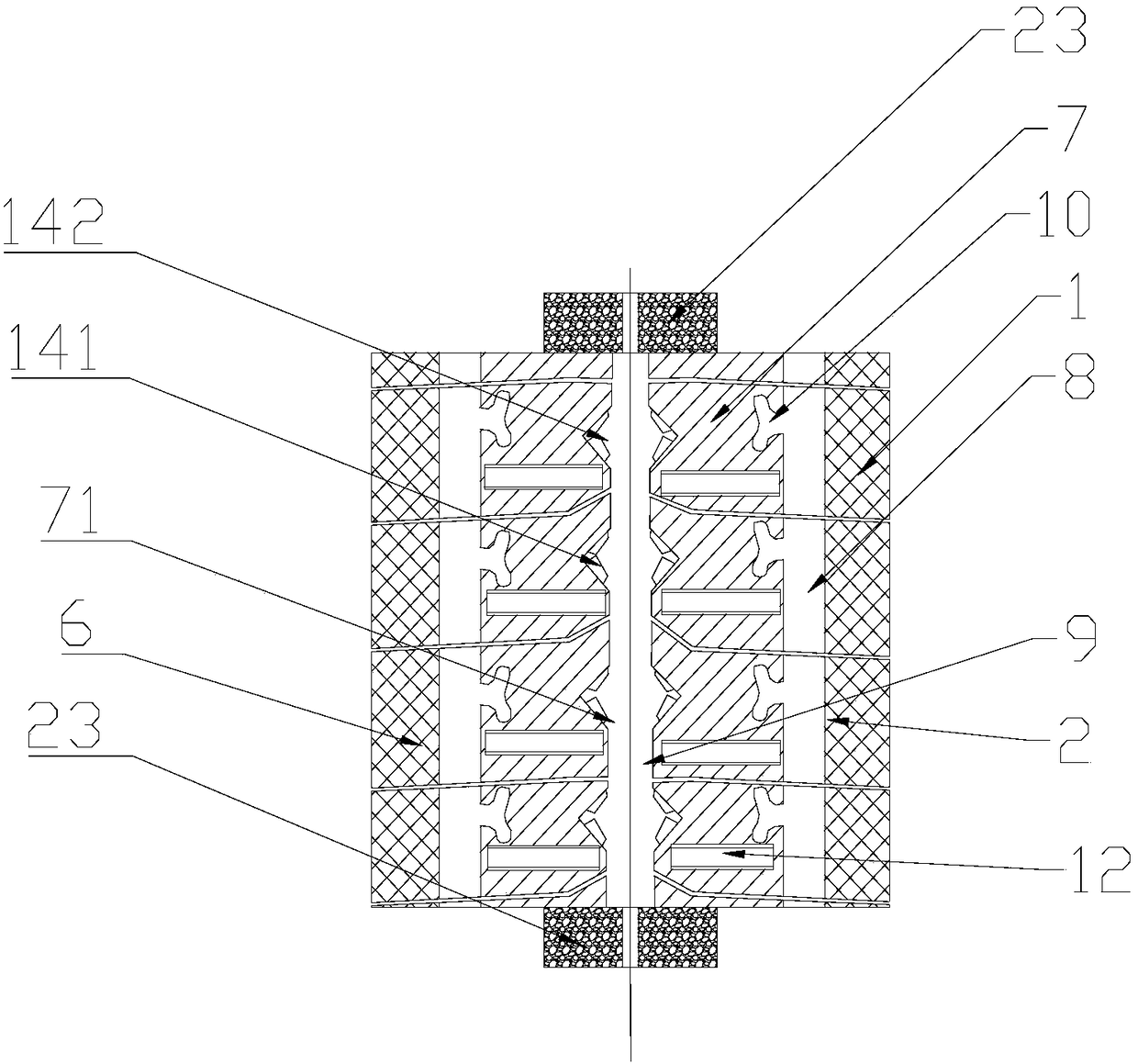

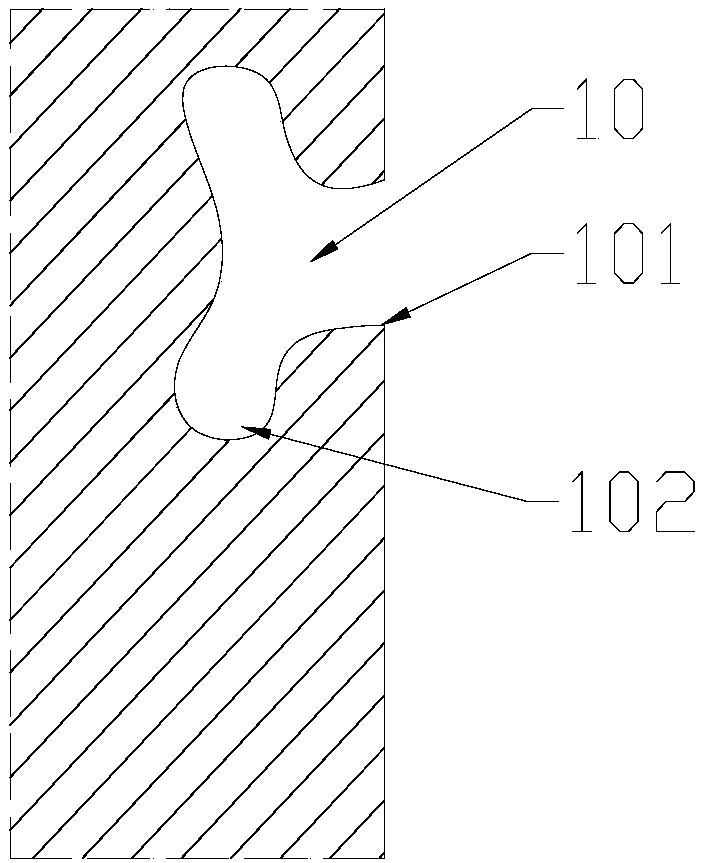

The invention discloses an optical fiber drawing technology. The optical fiber drawing technology comprises steps as follows: 1), a melt drawing process: a preform rod is molten at the temperature of 2,200-2,300 DEG C, droops and is drawn by means of own gravity; 2), a shaping cooling process: drooping wires formed after melting of the preform rod are cooled to 500-600 DEG C in a shaping tube; 3), drawn wire cooling process: the wires are further cooled to 30-80 DEG C under the action of helium in a cooling device, and the cooling device in the step 3) comprises a cooling tube, the cooling tube comprises a first side tube and a second side tube with the same structure, a mounting cavity is formed between each metal wall and a corresponding heat insulation cover, and one side, opposite to the heat insulation cover, of the metal wall is recessed to form a groove; the grooves of the pair of side tubes are spliced to form a cooling cavity, each groove comprises a folding slot, and guide vanes are arranged in the folding slot. According to the optical fiber drawing technology, the cooling cavity formed by the grooves, the folding slots, the guide vanes and the like is arranged, turbulence is increased, the thickness of a laminar sublayer formed by downward movement of the optical fiber wires is effectively reduced, and a helium cooling effect is further improved.

Owner:HANGZHOU FUTONG COMM TECH CO LTD

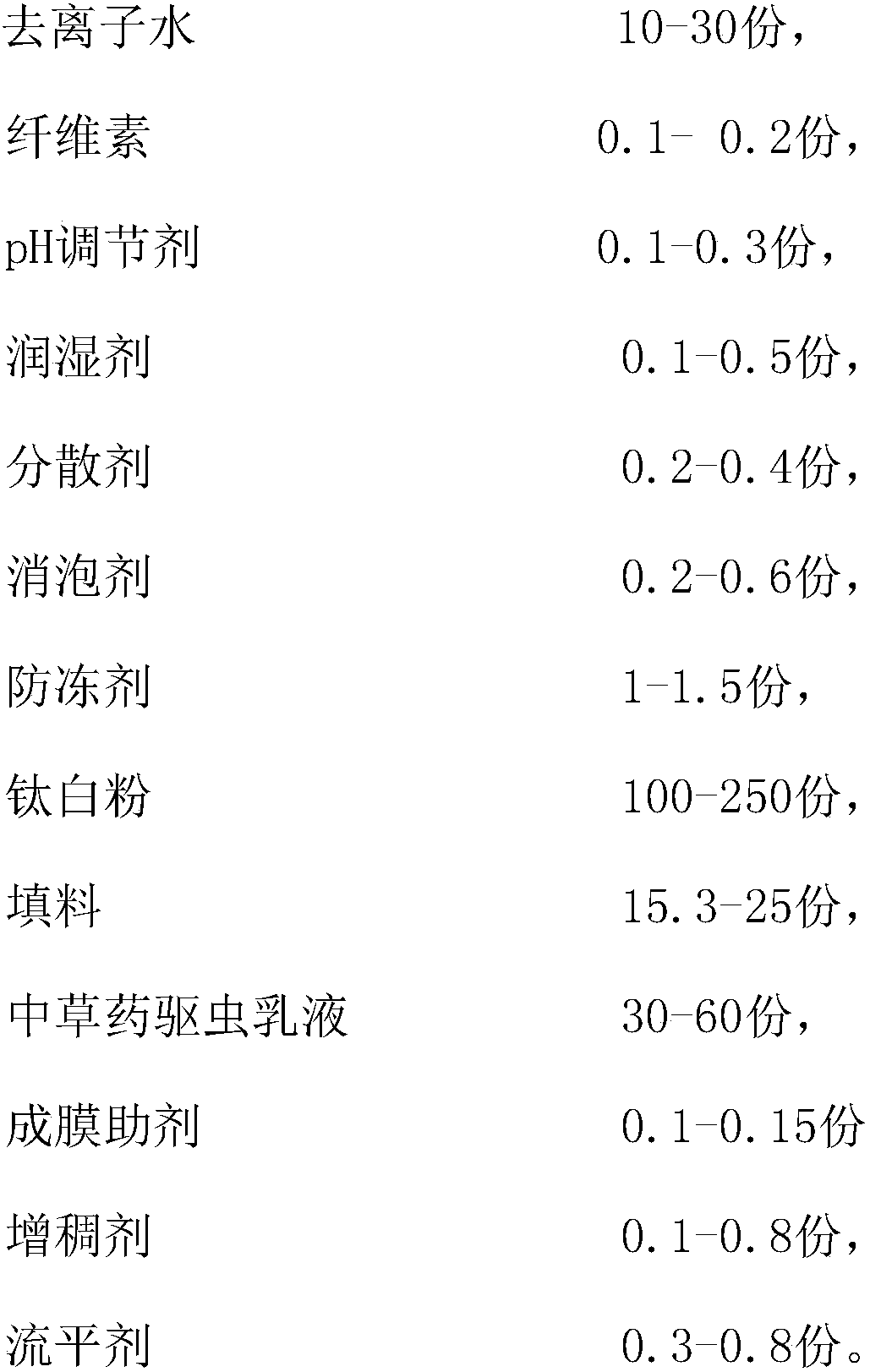

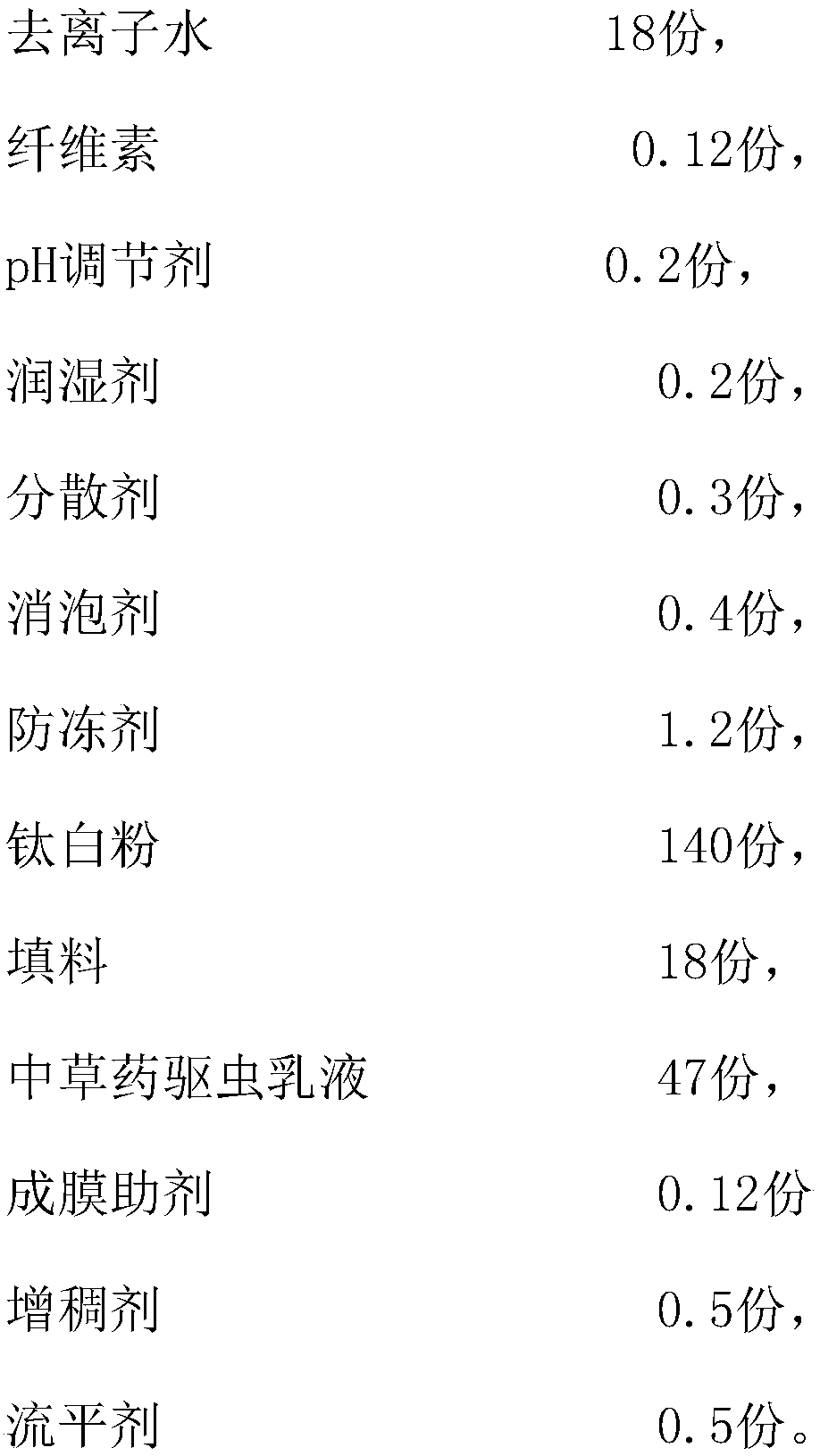

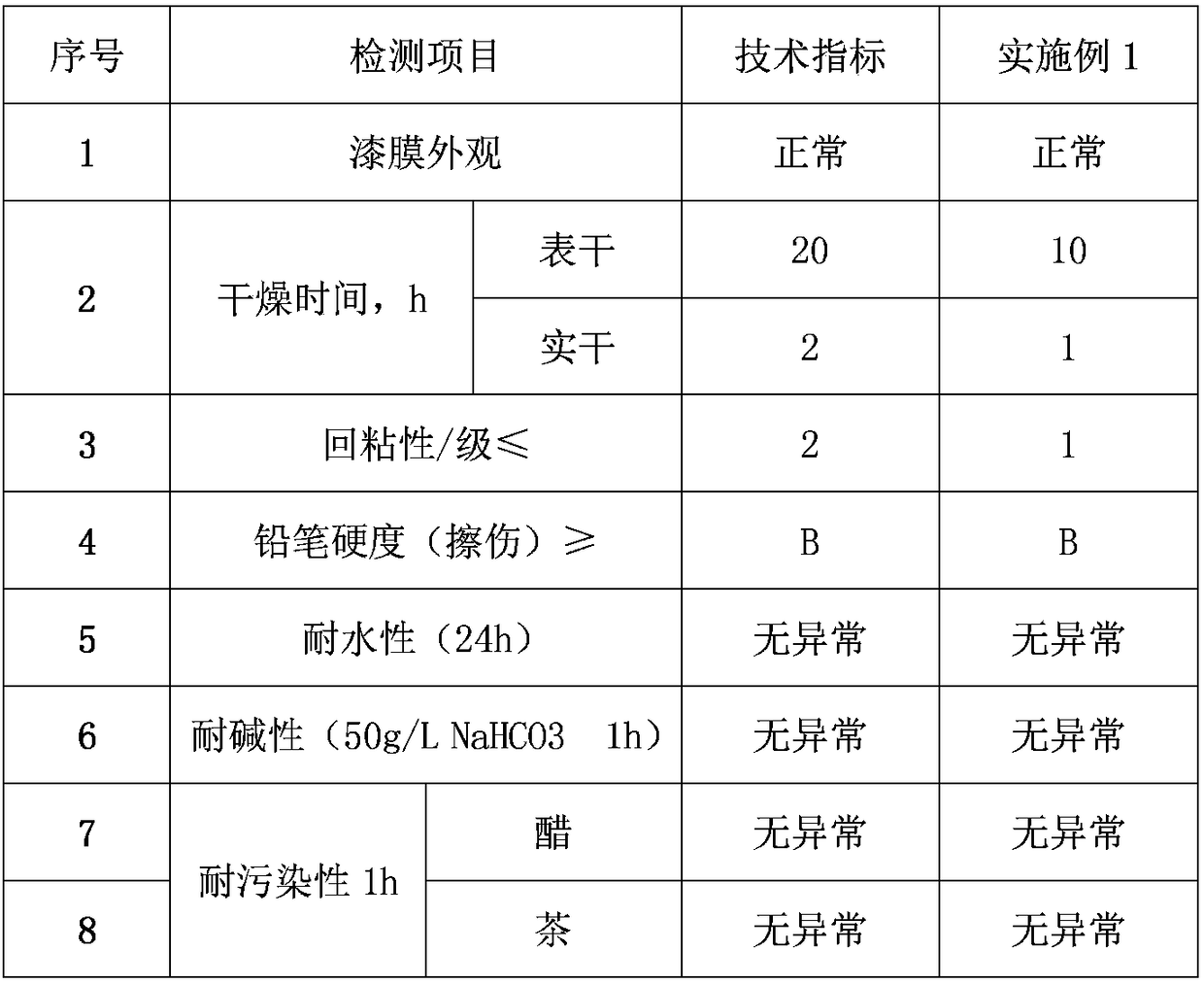

Chinese herbal medicine insect-prevention woodenware paint and preparation method thereof

InactiveCN108359283AImprove insect repellent effectEffect on physical propertiesAntifouling/underwater paintsPaints with biocidesCelluloseEmulsion

The invention provides a Chinese herbal medicine insect-prevention woodenware paint and a preparation method thereof, which belong to the technical field of a paint. The Chinese herbal medicine insect-prevention woodenware paint comprises the following components in parts by weight: 10-30 parts of deionized water, 0.1-0.2 parts of cellulose, 0.1-0.3 parts of a pH conditioning agent, 0.1-0.5 partsof a wetting agent, 0.2-0.4 parts of a dispersing agent, 0.2-0.6 parts of a antifoaming agent, 1-1.5 parts of an antifreezing agent, 100-250 parts of titanium dioxide, 15.3-25 parts of a filling material, 30-60 parts of a Chinese herbal medicine insect-repellent emulsion, 0.1-0.15 parts of a membrane-forming auxiliary agent, 0.1-0.8 parts of a thickening agent, and 0.3-0.8 parts of a levelling agent.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

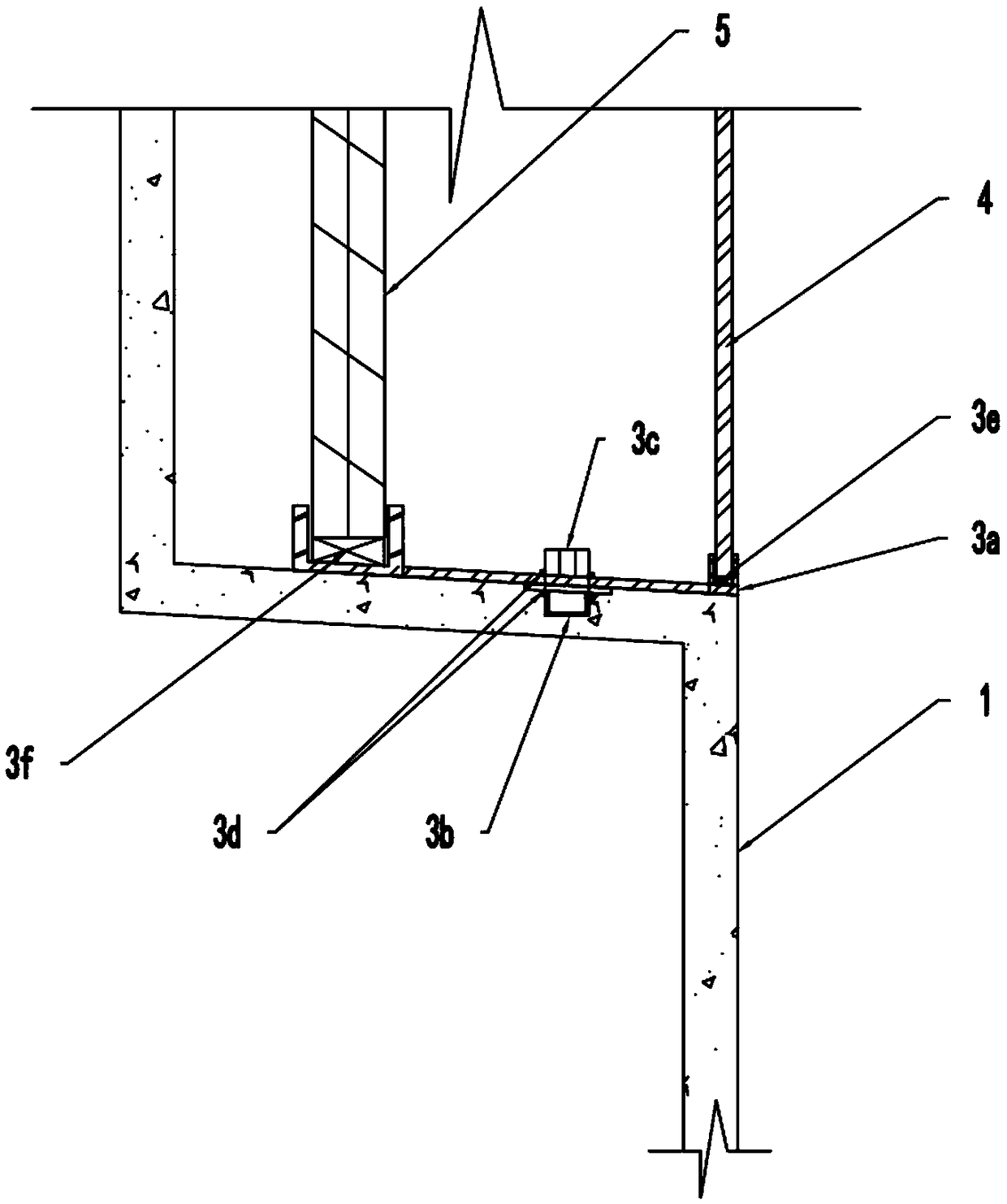

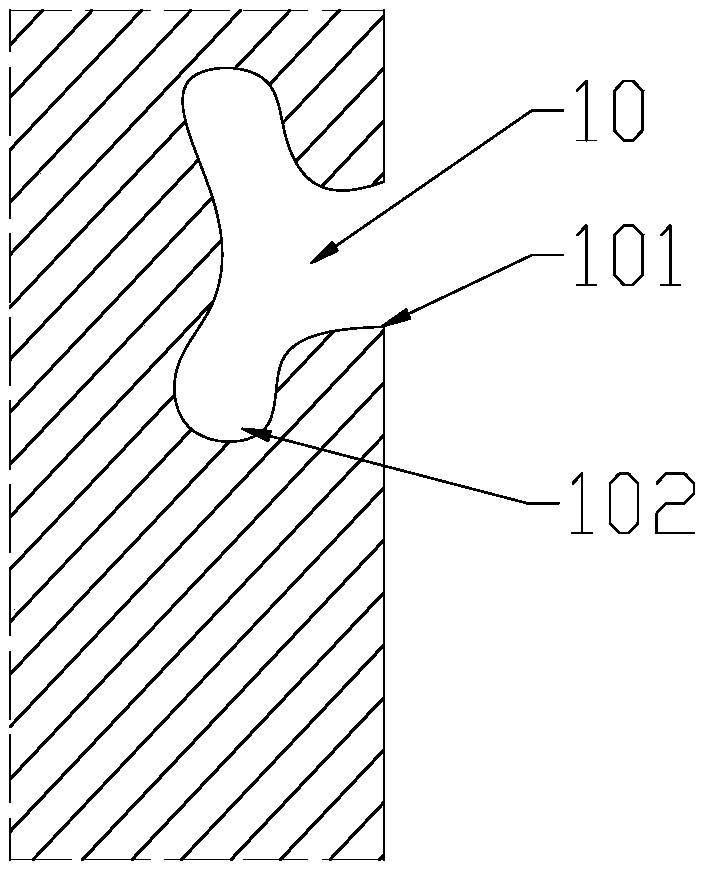

Ecological plant outer wall

PendingCN108824677AGood sunshineEffect on physical propertiesWallsSelf-acting watering devicesThermal insulationPlant cultivation

The invention discloses an ecological plant outer wall which comprises a steel framework and a wall board fixed to one side of the steel framework. The wall board is provided with a bearing part whichextends inwards and is provided with a stud or an internal thread connector in an embedded mode. An inserting fixing part is fixed on the bearing part through the stud or the internal thread connector. Inserting grooves are formed in the two ends of the inserting fixing part. A cultivation plate rack and an outer cover are connected into the inserting grooves correspondingly. An overturning coverplate is rotatably connected to the wall board at one side of the bearing plate, and plant through holes are formed. The steel formwork is fixedly connected with cultivation containers. According tothe technical scheme, plants can gain sunlight well, the physical performance of a curtain wall is not influenced, and the wind resistance, thermal insulation, and watertight and airtight performanceof the curtain wall are not influenced. Mounting, maintaining and plant cultivation are more convenient, and popularization is facilitated.

Owner:NANJING AOJIE WALL MATERIAL

Optical fiber wiredrawing technology

ActiveCN108383371AImprove cooling effectIncrease the Reynolds numberGlass making apparatusCooling effectCooling chamber

The invention discloses an optical fiber wiredrawing technology. The optical fiber wiredrawing technology comprises the following steps: 1) a melting and wiredrawing procedures: melting a preformed rod at 2200 DEG C to 2300 DEG C, drooping by self gravity and carrying out wiredrawing; 2) a shaping and cooling procedure: cooling melted and drooped wires of the preformed rod in a shaping pipe to 500to 600 DEG C; 3) a wiredrawing cooling procedure: further cooling the wires through helium gas in a cooling device to 30 DEG C to 80 DEG C, wherein the cooling device in step 3) comprises a cooling pipe, the cooling pipe is composed of a first side pipe and a second side pipe, which have the same structure, a mounting cavity is formed between a metal wall and a heat-insulation cover, the metal wall is concave in a direction opposite to the heat-insulation cover, the grooves of one pair of the side pipes are spliced to form a cooling chamber, each groove comprises a foldable groove and each foldable groove is internally provided with a guide blade. According to the optical fiber wiredrawing technology disclosed by the invention, the cooling chamber formed by structures including the grooves, the foldable grooves, the guide blades and the like is arranged, so that the turbulent flow is increased and the thickness of a laminar flow bottom layer formed by downward movement belts of optical fiber wires is effectively reduced, and furthermore, the helium gas cooling effect is improved.

Owner:FUTONG GROUP CO LTD

High-flame-retardant PVC product containing hyperbranched polymer

InactiveCN111793307AFast plasticizing speedEffect on physical propertiesPOLYETHYLENE WAXPolymer chemistry

The invention belongs to the field of PVC products, and particularly discloses a high-flame-retardant PVC product containing a hyperbranched polymer. The high-flame-retardant PVC product containing the hyperbranched polymer, disclosed by the invention, contains 90 to 110 parts by weight of a polyvinyl chloride resin, 20 to 40 parts of dioctyl terephthalate, 30 to 50 parts of light calcium carbonate, 20 to 30 parts of hydroxide, 3 to 5 parts of a calcium-zinc stabilizer, 0.3 to 0.7 part of polyethylene wax and 1 to 3 parts of a hyperbranched polymer. According to the invention, the hyperbranched polymer is used as an additive and is added into the PVC product containing a large amount of magnesium hydroxide / aluminum hydroxide, so that the plasticizing speed of the PVC product is effectivelyincreased, the flowability of the PVC product melt is obviously improved, and the physical properties of the PVC product are not influenced.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

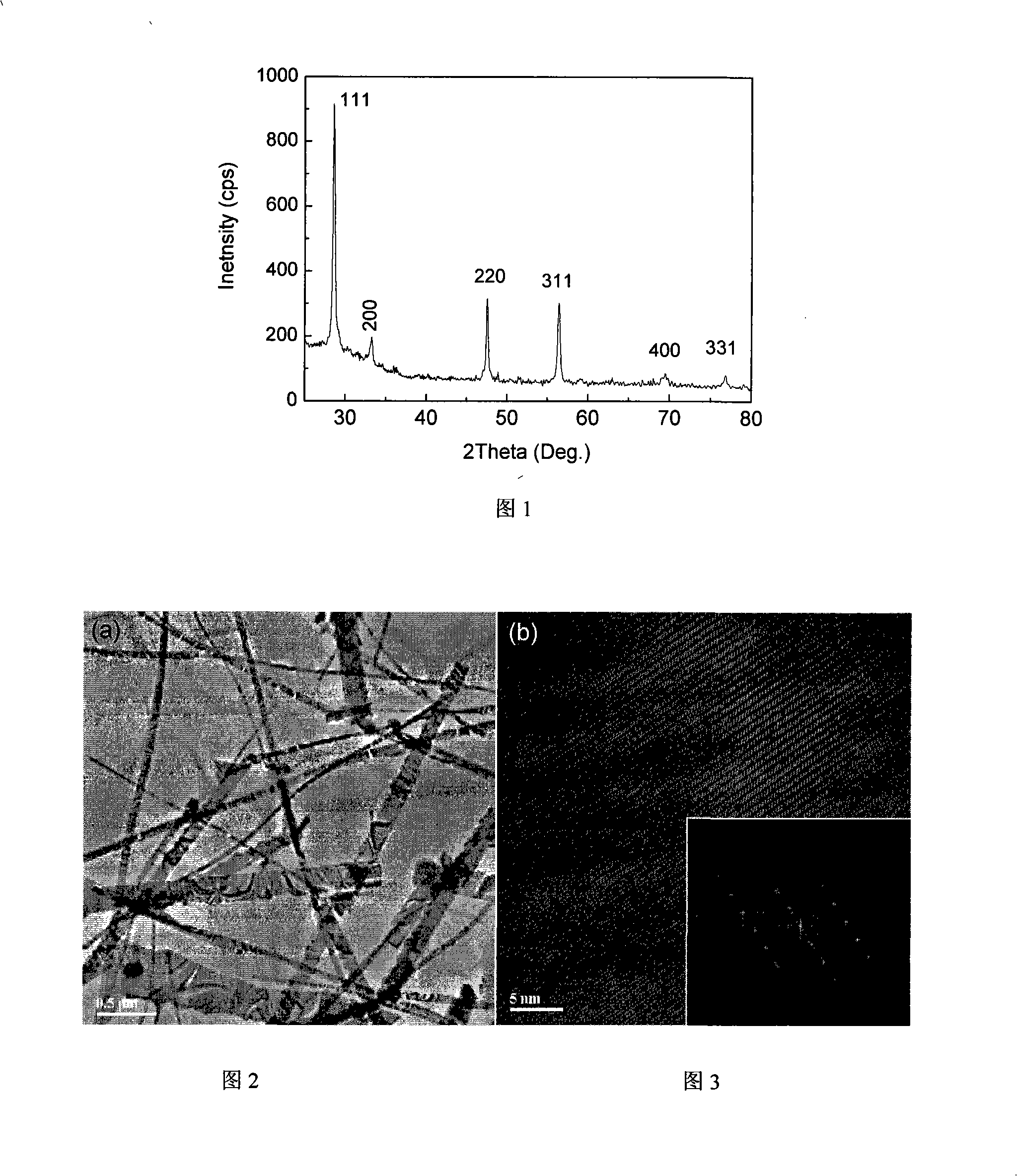

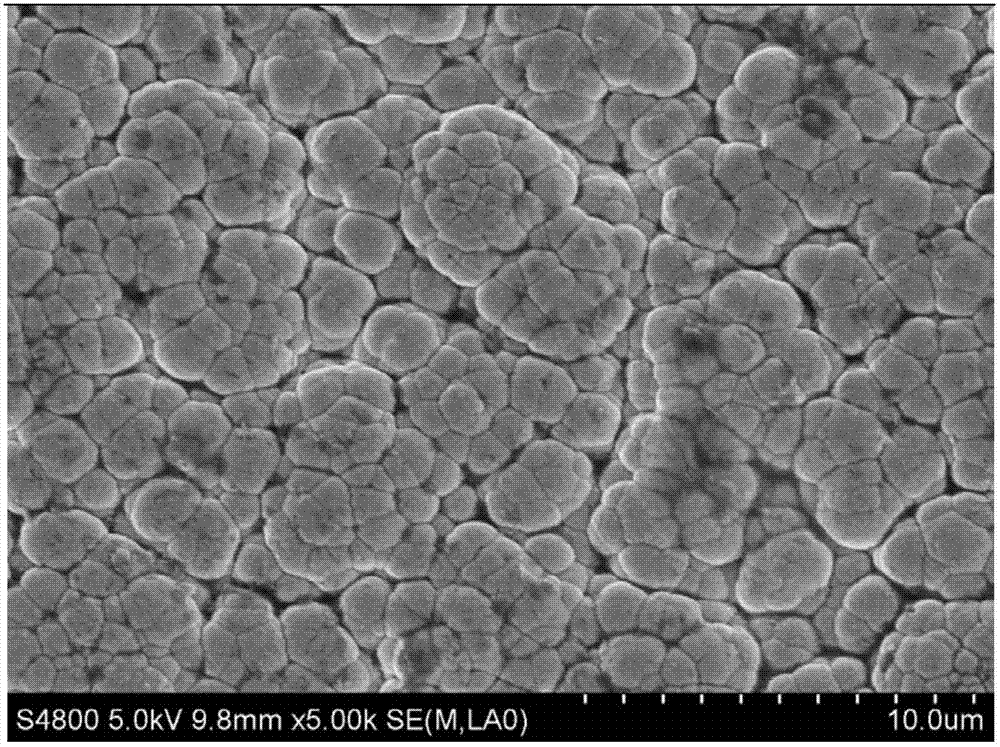

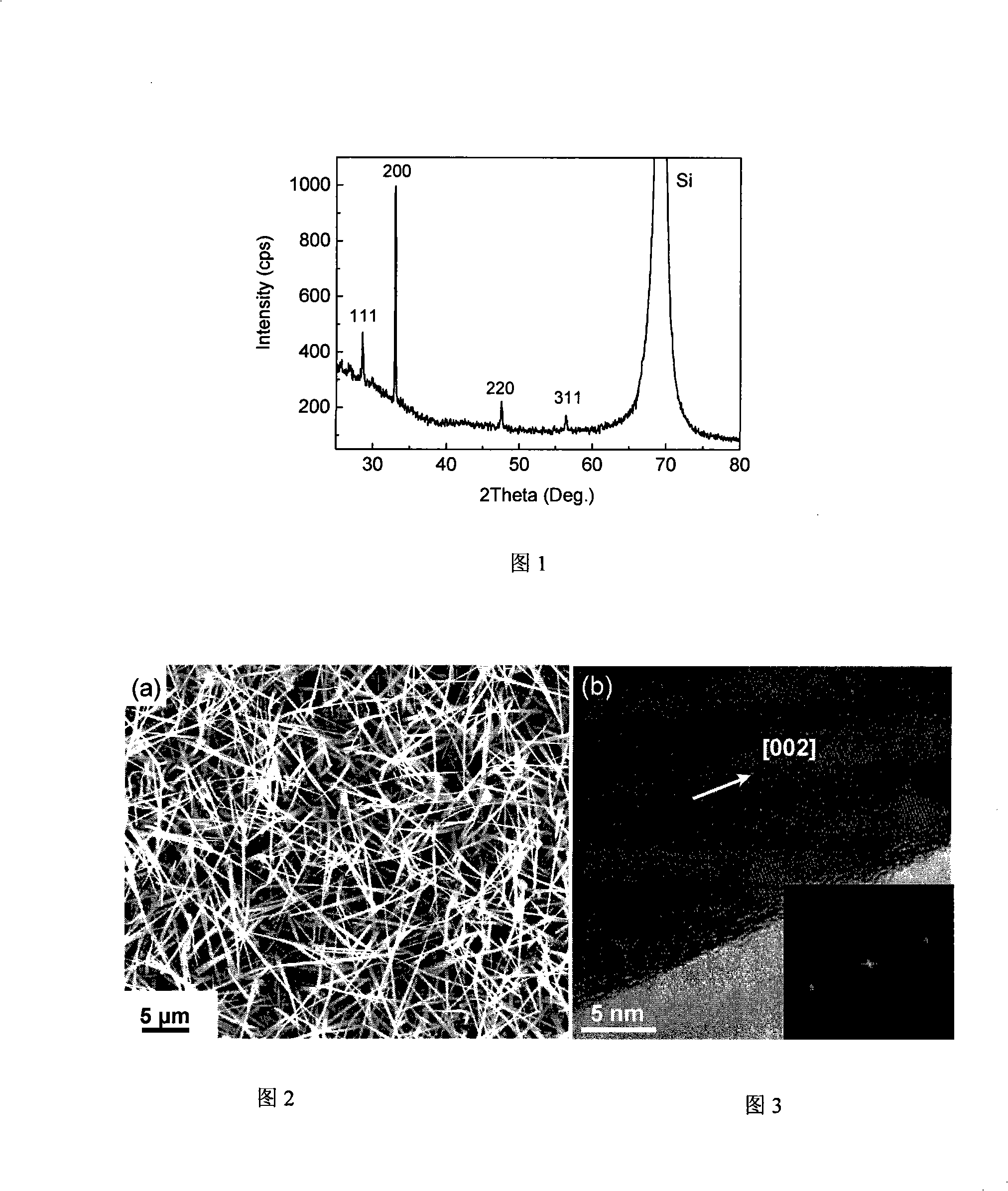

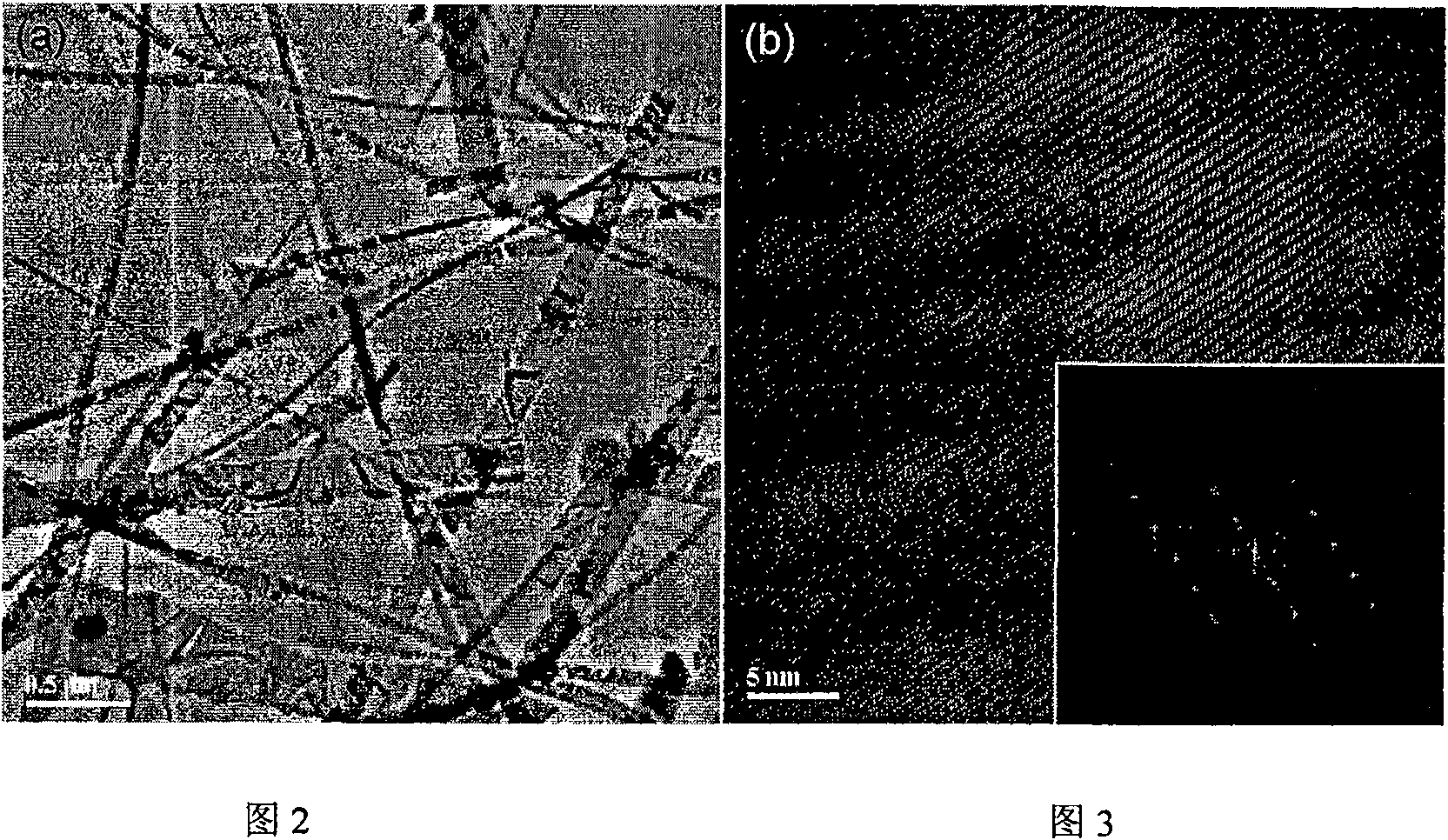

Method for preparing single crystal zinc blende nano-wire

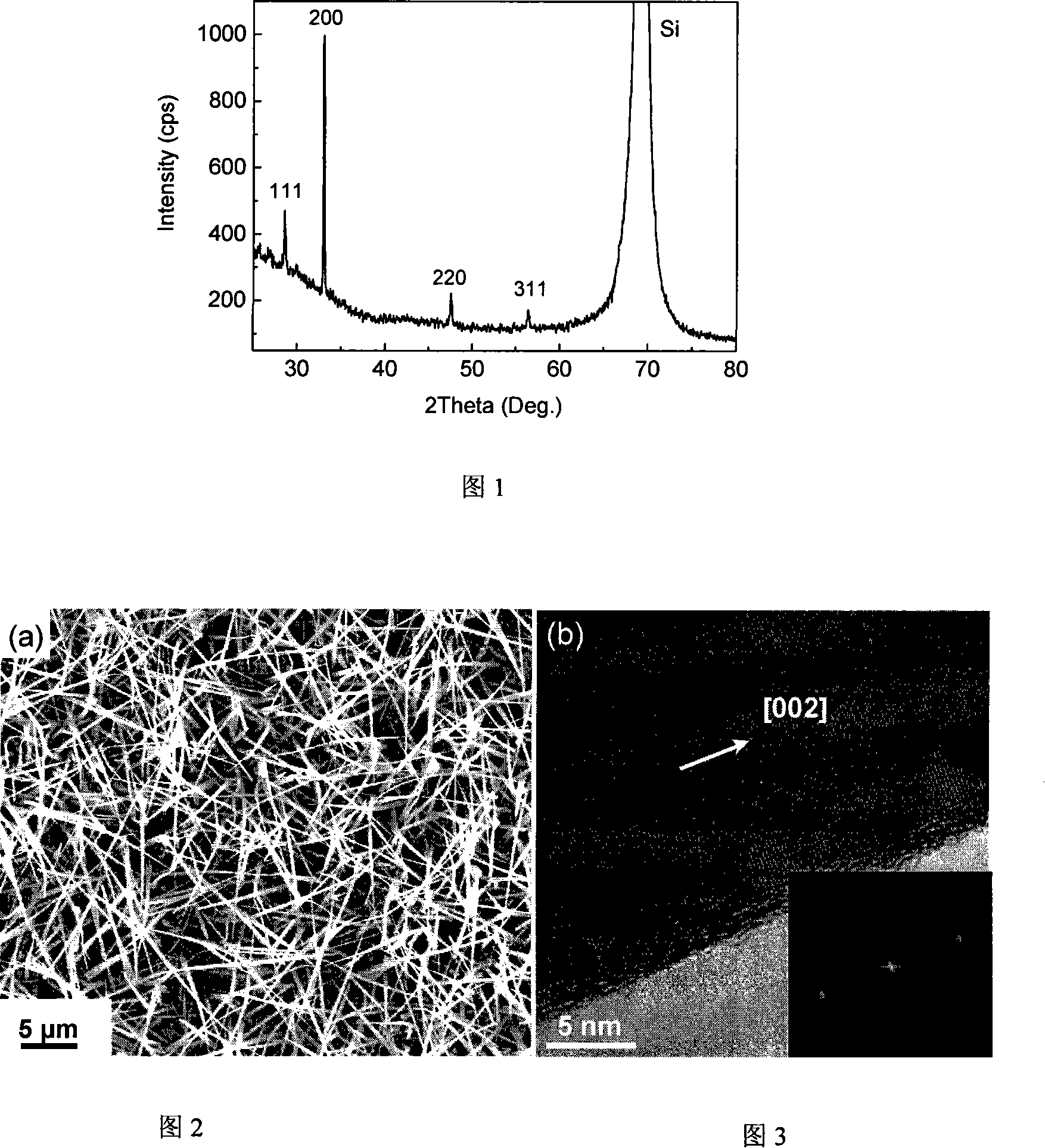

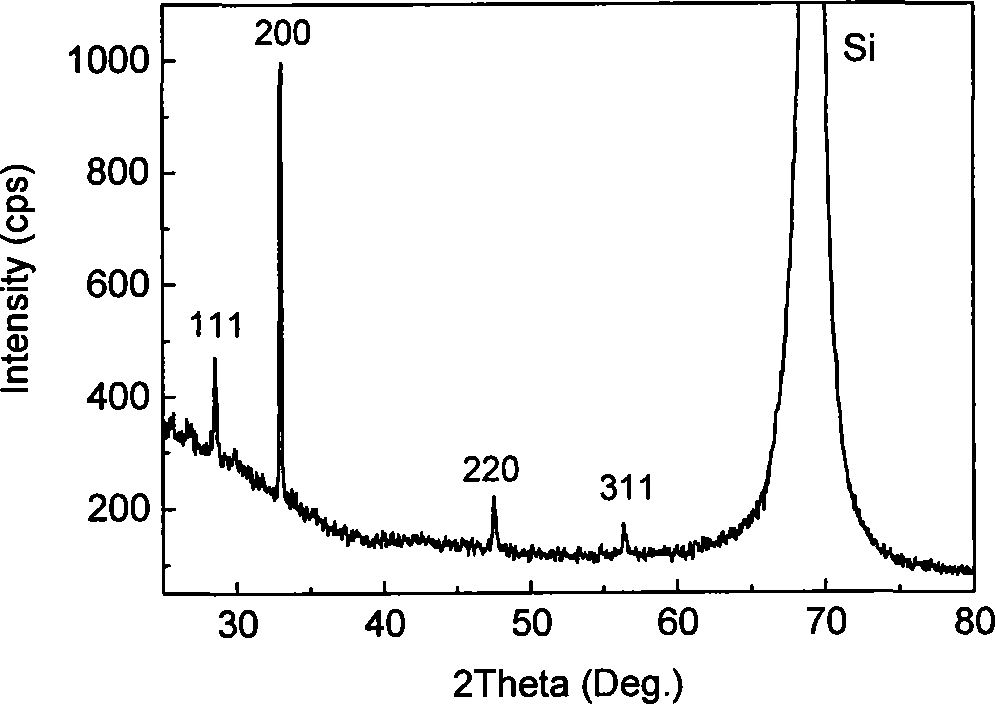

InactiveCN101311386AEasy to operateRaw materials are easy to getPolycrystalline material growthFrom condensed vaporsSemiconductor materialsEvaporation

The invention relates to a preparation method of a single crystal ZnS nano-wire, which belongs to the field of preparative technique of semiconductor material. The method comprises the following steps: inletting the mixed gas of argon and hydrogen with a flow rate of 108 to 113ml / min into a tube furnace; putting the ZnS powder in a quartz boat as a evaporation source, and putting the ZnS powder together with the boat in the tube furnace, and putting a cleaned silicon chip in the furnace, which is 25 to 30mm from the evaporation source, wherein the evaporation source is in the direction of inlet airflow while and the silicon chip is in the direction of outlet airflow; heating the tube furnace to 890 to 910 DEG C with the holding time of 80 to 120min and a pressure of 0.015 to 0.03MPa in the furnace. A layer of white ZnS nano-wire film is deposited on the silicon chip when the temperature of the furnace drops to a room temperature. The method requires a low synthesis temperature and does not apply a foreign catalyst. The prepared ZnS nano-wire has a face-centered cubic structure; the length of 10 to 15Mum and a diameter of only 20 to 30nm at the tip. The nano-wire is single crystal with a higher crystalline quality. The preparation method has the advantages of simple and convenient operating process, available raw material, low cost and easy scale production.

Owner:UNIV OF SCI & TECH BEIJING

Silicon carbide composite material and preparation method therefor

InactiveCN110451976AImprove high temperature stabilityImprove high temperature resistanceCross-linkHeat conducting

The invention discloses a silicon carbide composite material. The silicon carbide composite material comprises the following ingredients in parts by mass: 60% to 80% of silicon carbide powder, 10% to30% of organic metal salt and 1% to 15% of binder. The invention further discloses a preparation method for the silicon carbide composite material. The method comprises the steps: subjecting the silicon carbide powder, the organic metal salt and the binder to ultrasonic treatment; placing the uniform-mixed raw materials in a cross-linking pyrolyzer, heating the temperature of the cross-linking pyrolyzer to 200 DEG C to 1,000 DEG C at a heating rate of 1 DEG C / min to 2 DEG C / min under argon shield, and carrying out heat preservation for 2 to 3 hours at the temperature of 1,000 DEG C; subjectinga solid matter obtained through cross-linking pyrolysis to ball milling; and placing the solid matter obtained through ball milling into a high-temperature heat-treatment furnace under argon shield,thereby obtaining the silicon carbide composite material. The silicon carbide composite material prepared by the method has the advantages of excellent corrosion resistance, heat conducting efficiencyand oxidation resistance, and the cost is reduced effectively.

Owner:湖南太子新材料科技有限公司

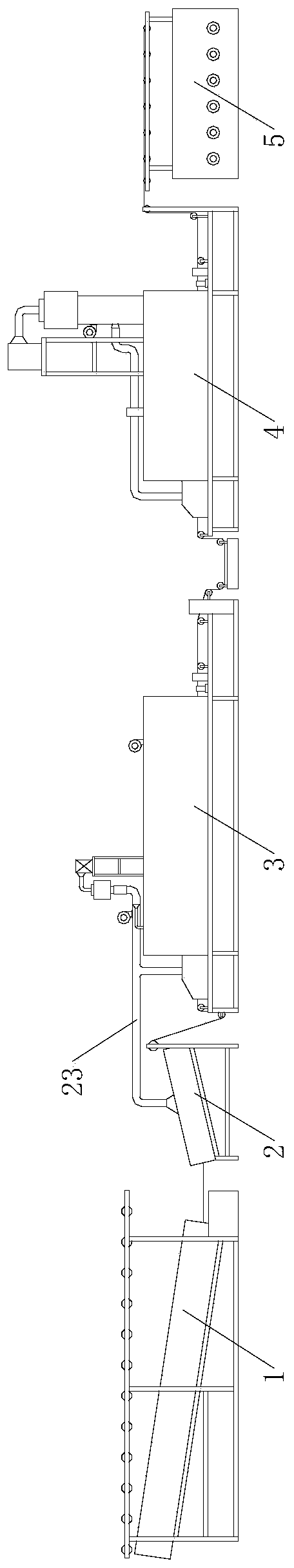

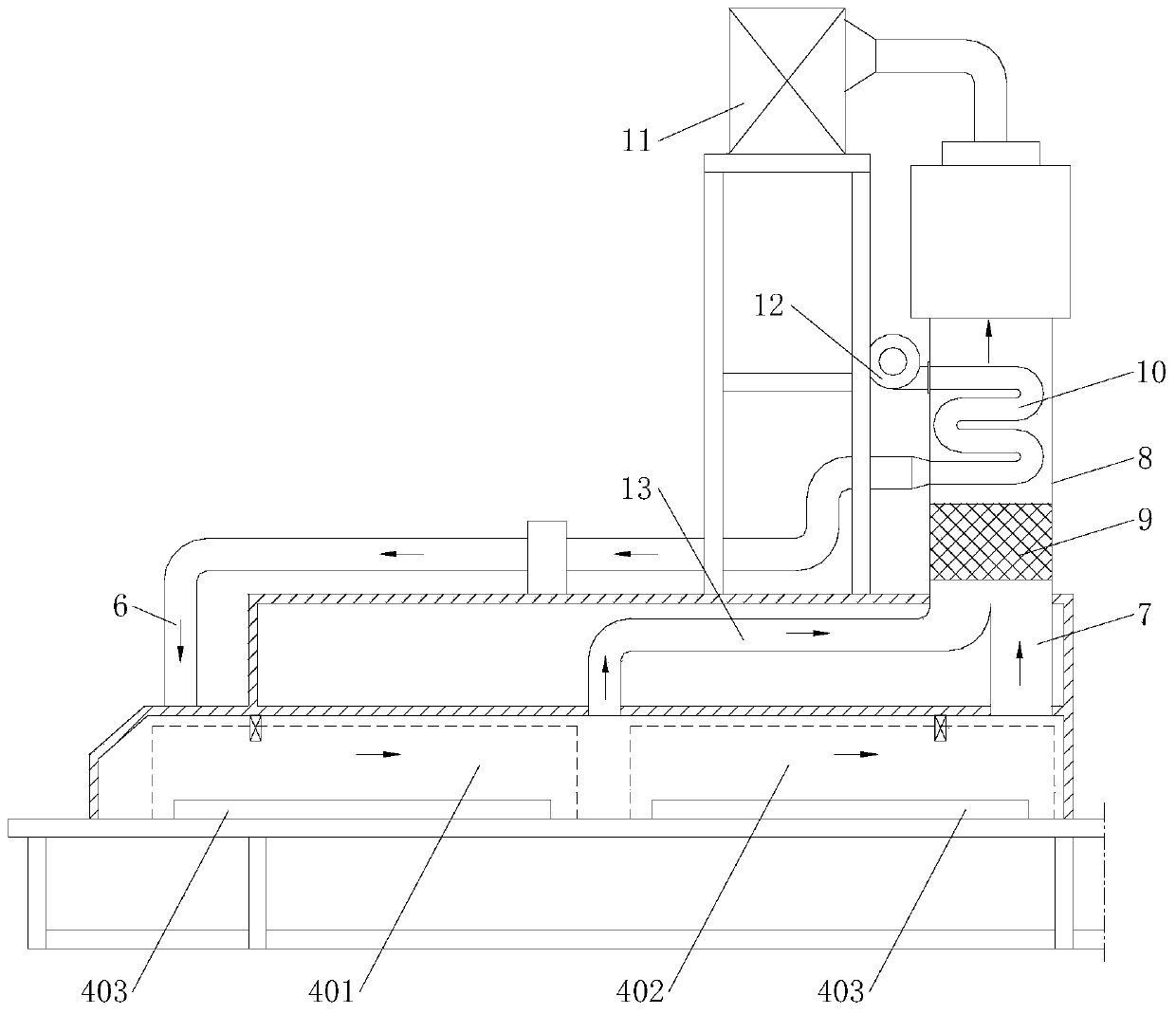

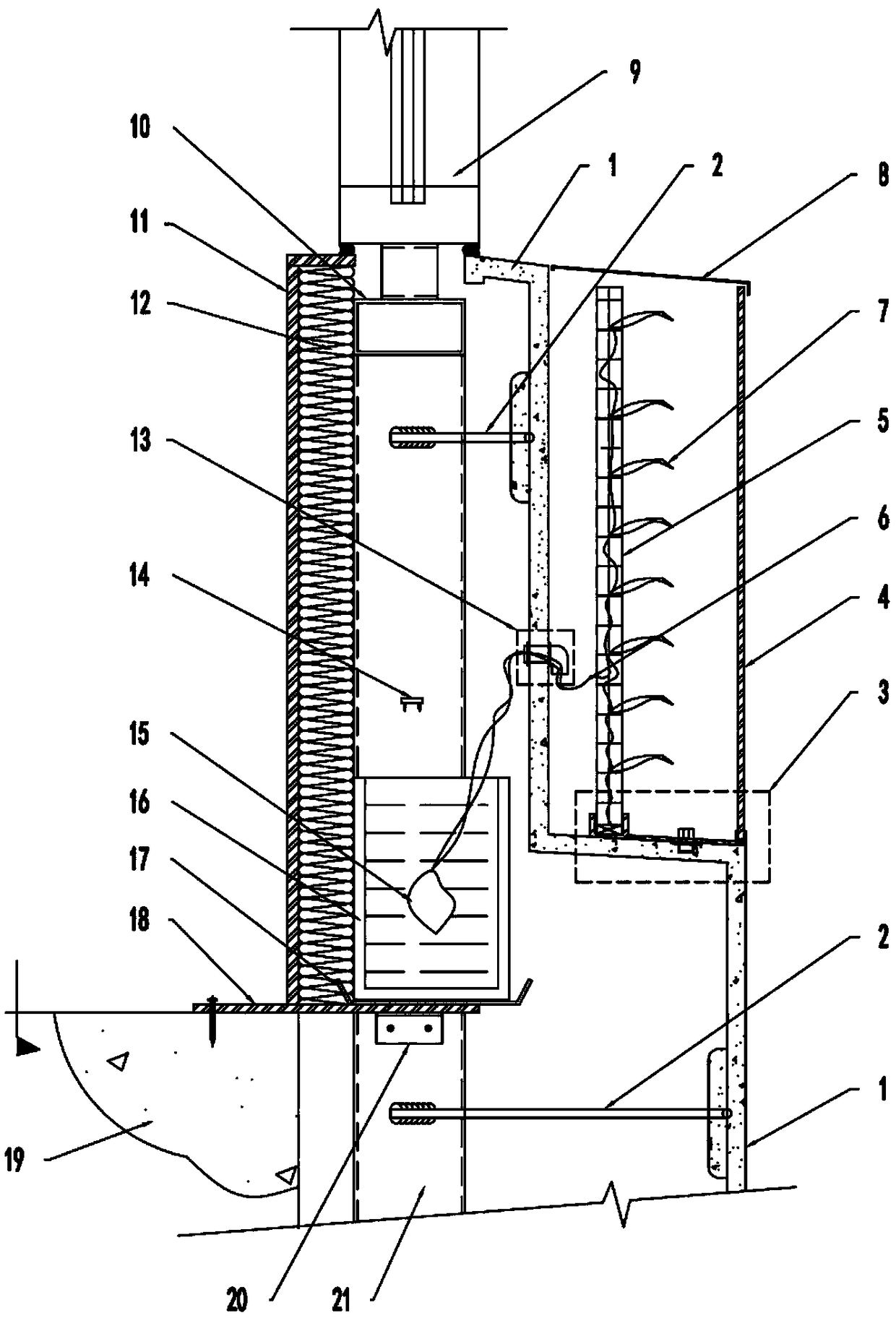

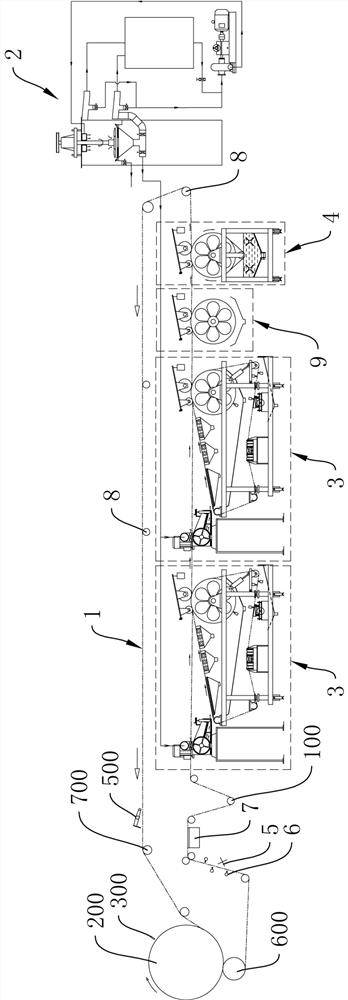

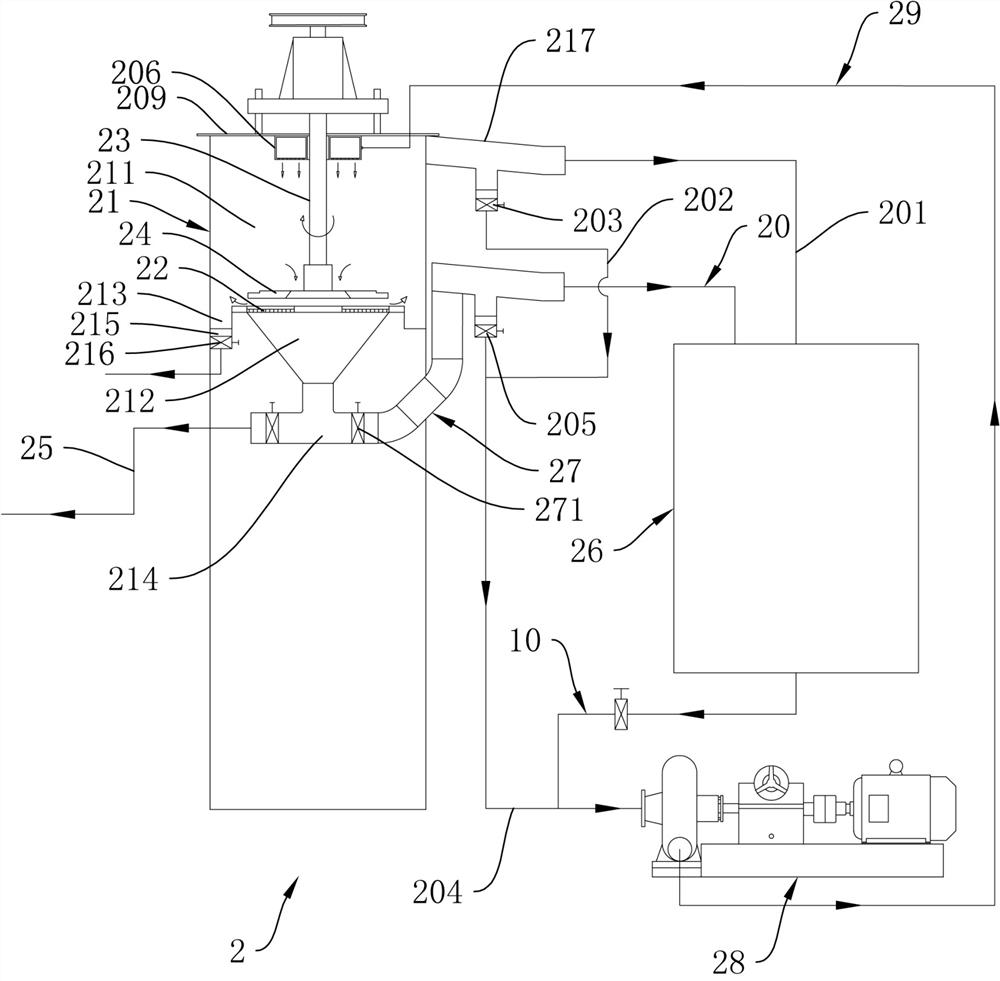

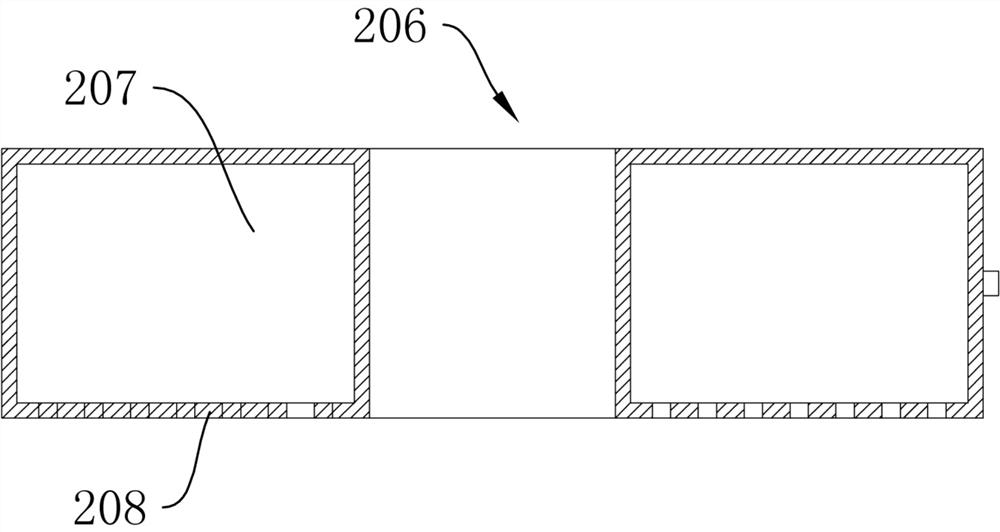

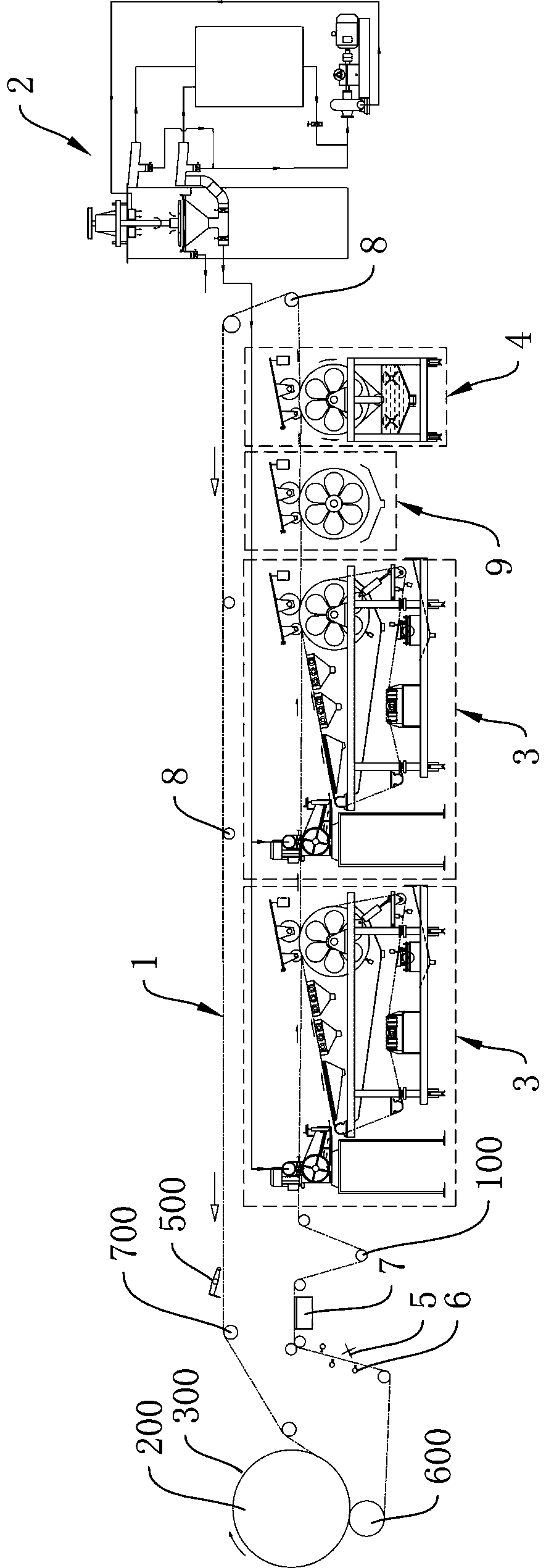

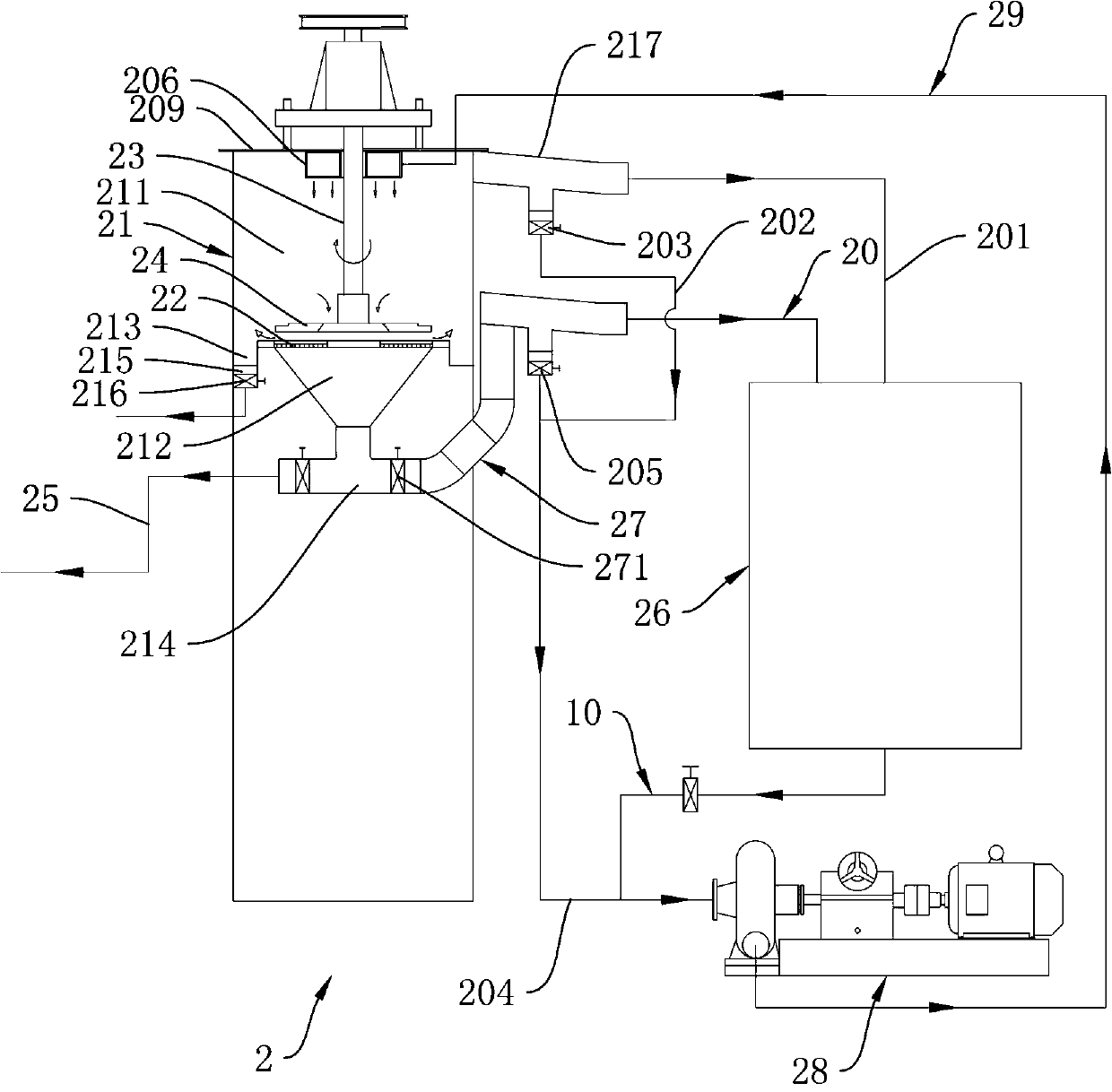

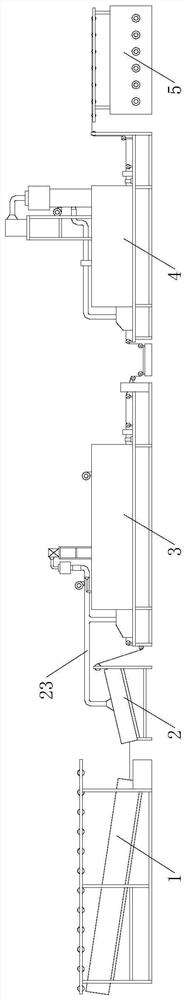

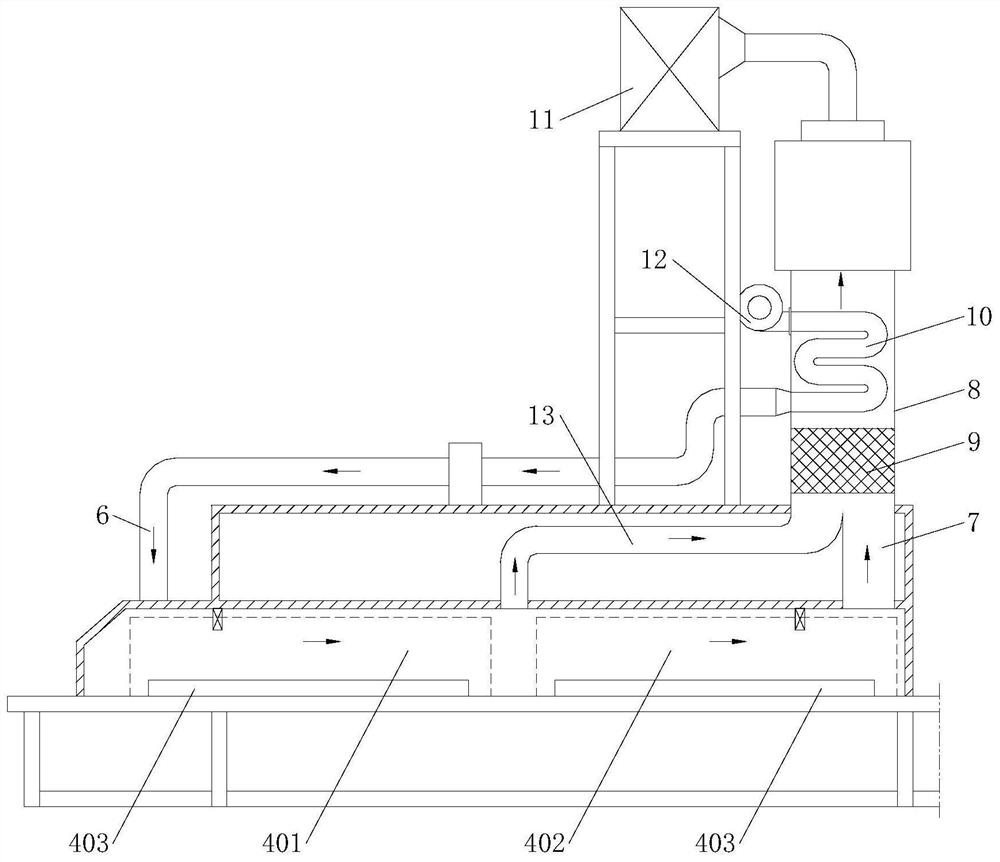

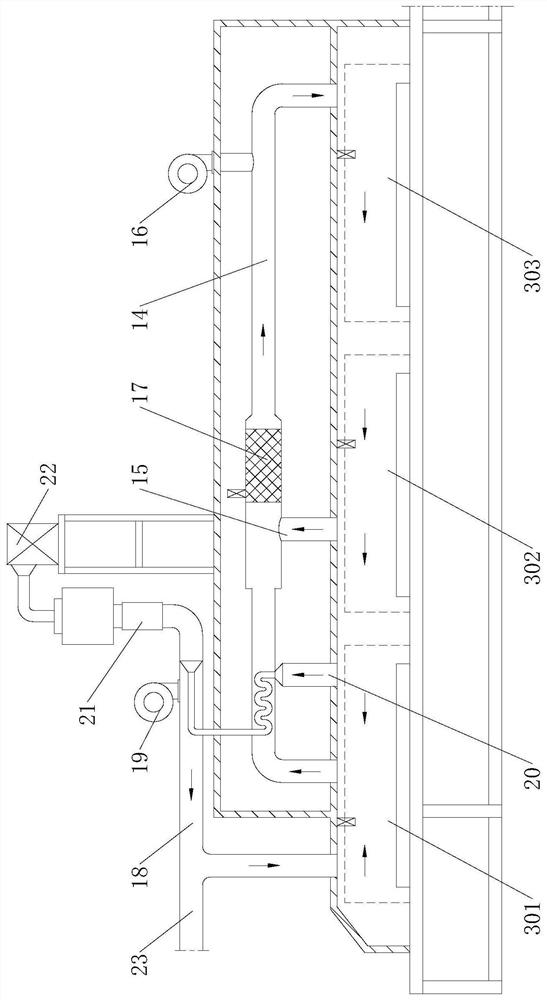

A jet lay-up board system

ActiveCN110004759BImprove reliabilityGuaranteed reliabilityInorganic fibres/flakesPaper-making machinesMolding machineElectric machine

The invention relates to a jet layup board-producing system. The jet layup board-producing system comprises a woolen blanket, a slurry stabilizing filter tank, a plurality of jet-type slurry spreadingmoulding machines, a colorant adding machine, a cloth puncher, a woolen blanket flushing assembly, a vacuum water suction box and a plurality of supporting rolls, wherein the slurry stabilizing filter tank is arranged beside the woolen blanket; each jet-type slurry spreading moulding machine comprises a jetting device and a moulding device; each jetting device comprises a support, a driving motor, a feed pipe, a balancing valve, a stirring propeller, a slurry jetting head, a dispersing component and a flow control assembly; each moulding device comprises a machine frame, a first dewatering assembly, at least one second dewatering assembly, a first cylindrical net cage, a first couch roll, a moulding cloth belt, an upper water receiving tank body, a lower water receiving tank body, a flushing assembly and a plurality of guide rolls; the colorant adding machine comprises a colorant tank, a second cylindrical net cage, a swinging rod, a colorizing roll, colorizing net cloth and a secondcouch roll; and the cloth puncher, the woolen blanket flushing assembly and the vacuum water suction box are arranged beside the woolen blanket. The jet layup board-producing system has the advantagesof a good shaping effect, low production cost, high reliability, high processing quality and the like.

Owner:FOSHAN JINFU PANEL

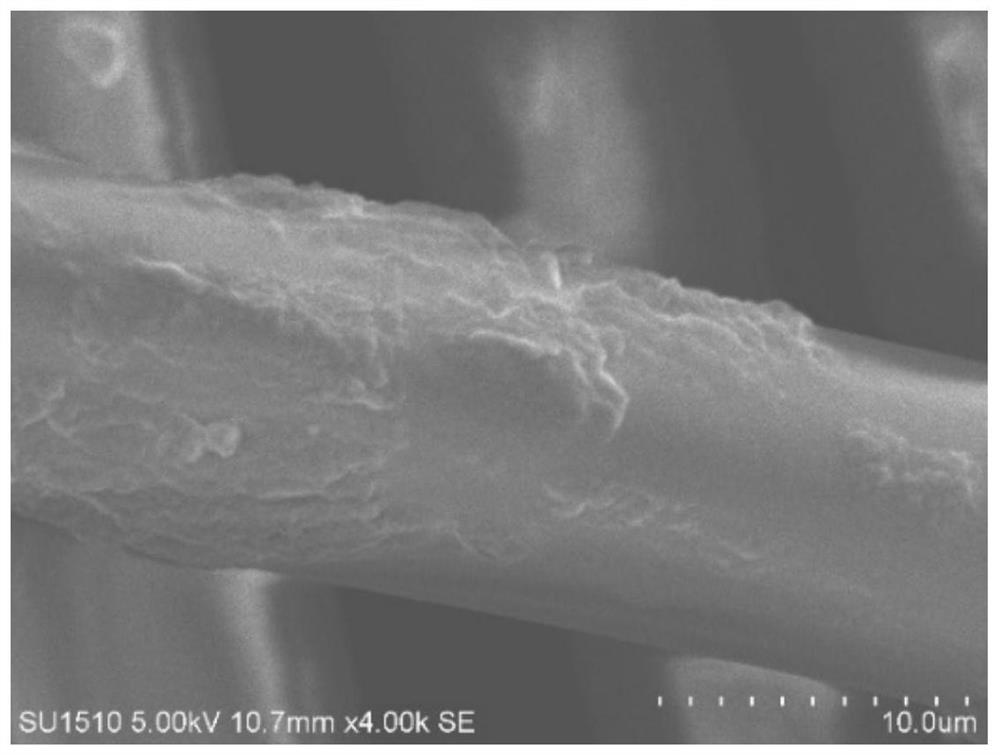

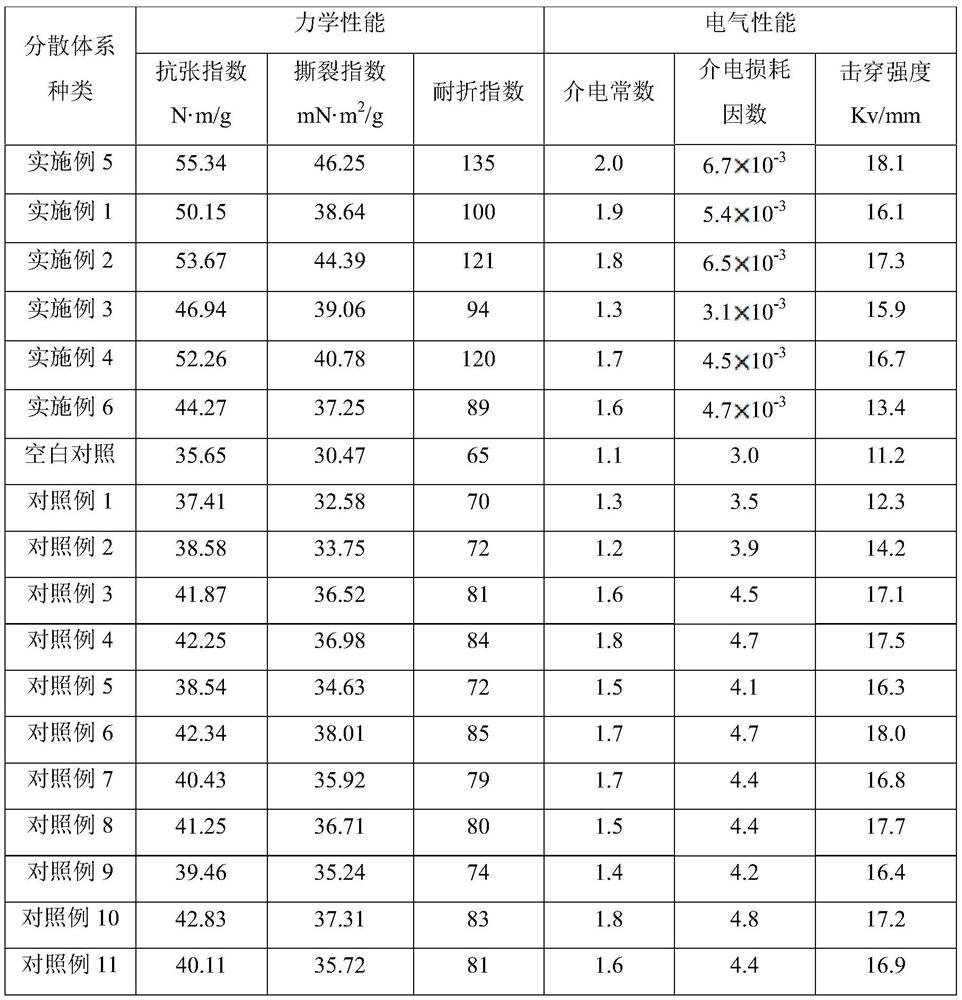

A composite dispersion method for polyimide chopped fibers

ActiveCN111996789BStrong acid resistanceEffect on physical propertiesRadio/micro wave fibre treatmentFibre typesFiberPolymer science

The invention discloses a composite dispersion method for polyimide chopped fibers, which belongs to the technical field of dispersion mechanism. The dispersing method of the present invention comprises the following steps: (1) adopt acid to carry out surface modification: polyimide chopped fiber is added in the acid solution to carry out surface modification, afterwards washing, drying; (2) use hexamethylenediamine Carry out surface grafting: add cationic surfactant to hexamethylenediamine solution, mix well to obtain a mixed solution; add polyimide chopped fibers treated with acid surface modification to the mixed solution for surface grafting, after the reaction , to obtain a fiber suspension; (3) ultrasonically treating the fiber suspension to obtain a uniformly dispersed polyimide chopped fiber suspension. The dispersion degree of the fiber suspension obtained by the invention can be as high as 45%, which is beneficial to the preparation of high-performance polyimide paper.

Owner:JIANGSU AOSHEN HI TECH MATERIALS CO LTD +3

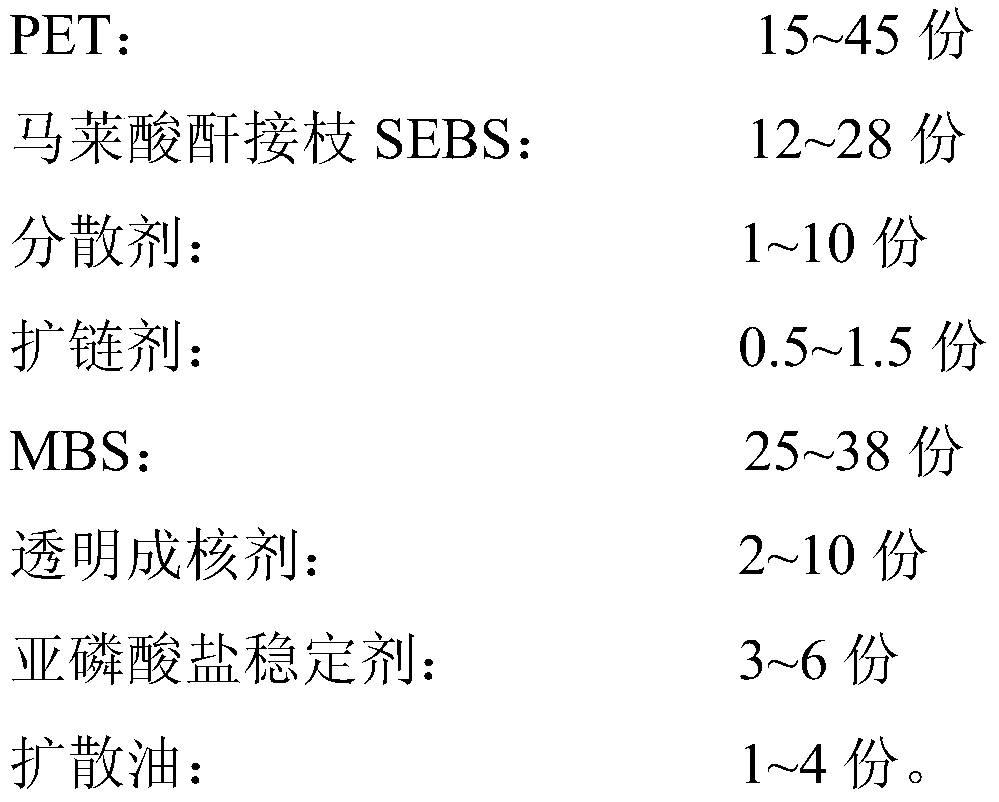

A kind of pet plastic toughening agent and preparation method

The invention discloses a PET plastic toughening agent comprises the following components in parts by weight: 15-45 parts of PET, 12-28 parts of maleic anhydride grafted SEBS, 1-10 parts of a dispersant, 0.5-1.5 parts of a chain extender, 25-38 parts of MBS, 2-10 parts of a transparent nucleating agent, 3-6 parts of a phosphite stabilizer and 1-4 parts of diffusion oil. The mass fraction of the PET plastic toughening agent added into a PET product is 0.2-1%. The invention also discloses a preparation method of the PET plastic toughening agent. The PET plastic toughening agent disclosed by the invention does not influence the transparency of the PET product and can achieve a very good toughening effect on the PET product, and the toughness of the PET product is improved by 15-30%; a small amount of the PET plastic toughening agent is added and cannot influence the physical property of subsequent processing of PET; the PET plastic toughening agent is environmentally friendly and non-toxic, cannot generate a separation phenomenon for the PET product, is highly compatible with PET by taking PET as a base material, and can better act on the PET product.

Owner:东莞鸿冠新材料科技有限公司

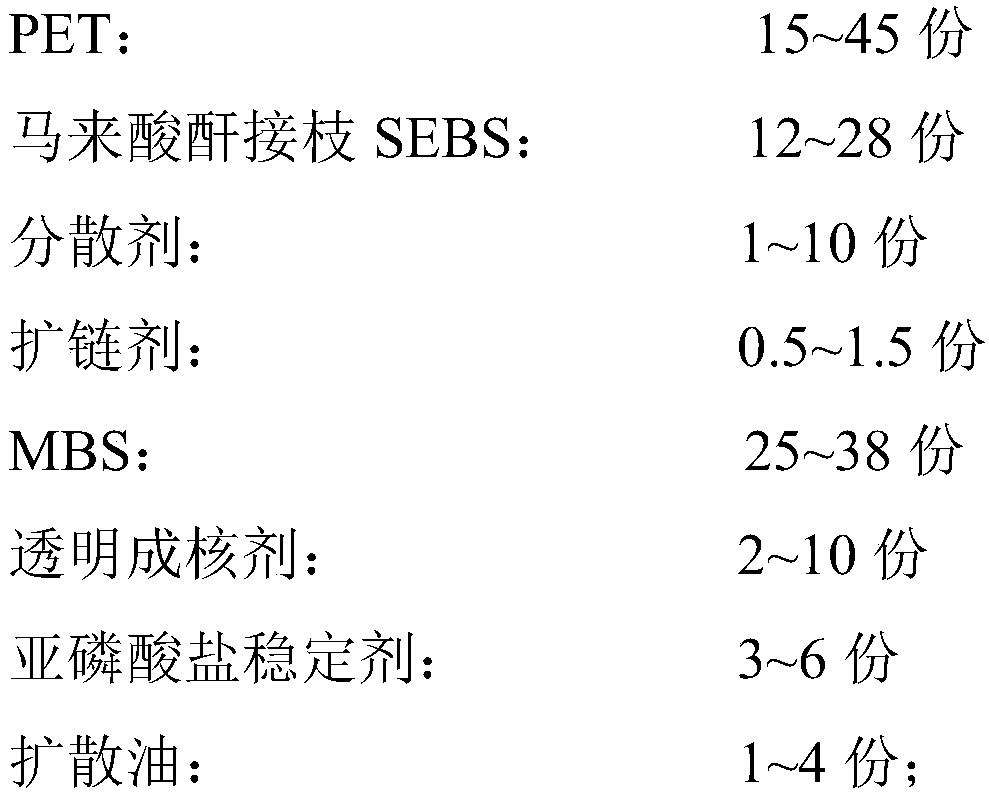

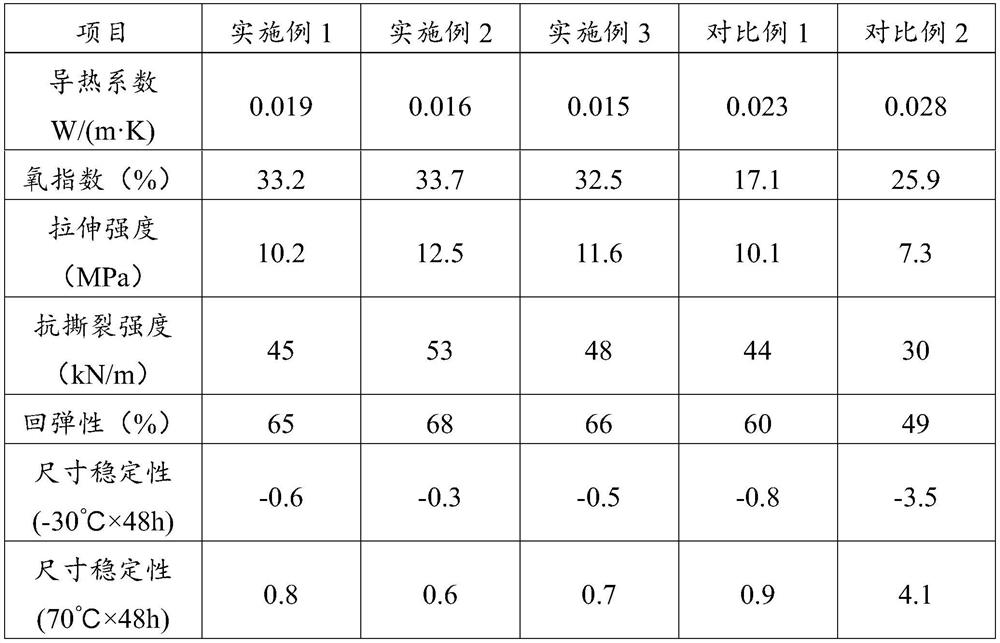

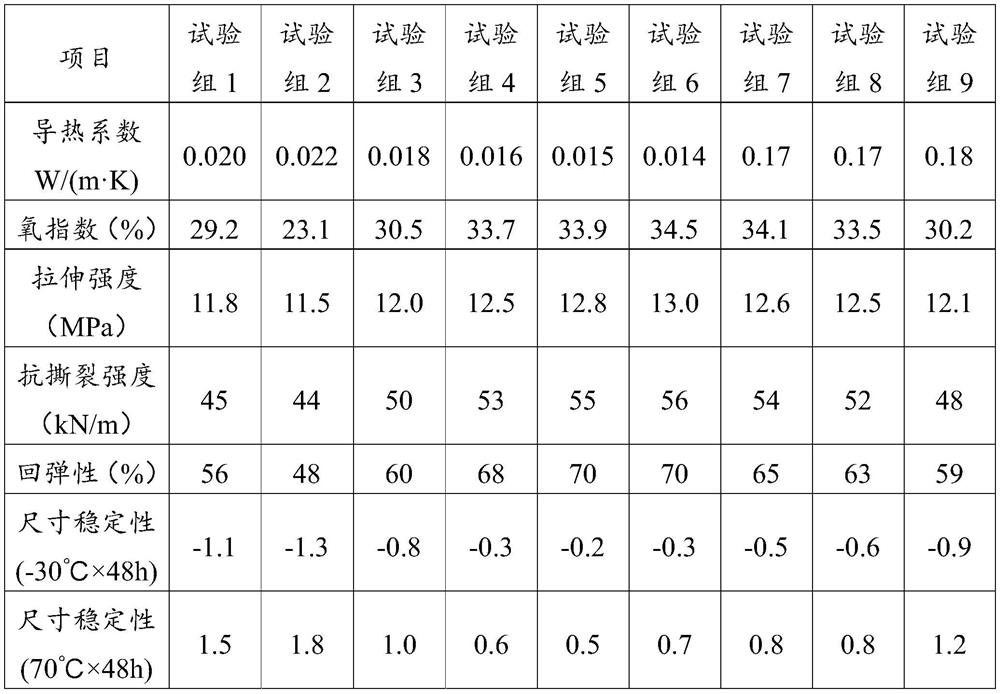

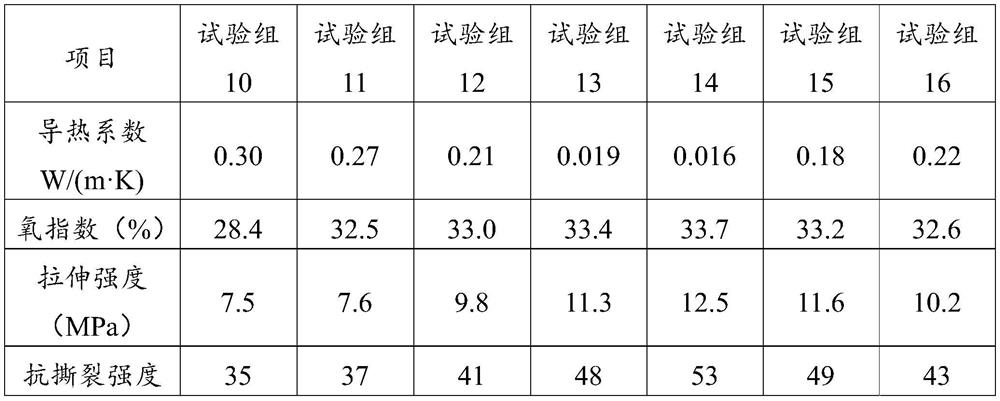

Phosphorus-nitrogen-containing vegetable oil polyol as well as preparation method and application thereof

PendingCN114133414AEffect on physical propertiesHigh flame retardant efficiencyGroup 5/15 element organic compoundsPolymer scienceVegetable oil

The invention discloses plant oil polyol containing phosphorus and nitrogen as well as a preparation method and application of the plant oil polyol. The preparation method of the plant oil polyol containing phosphorus and nitrogen comprises the following steps: 1) mixing epoxidized soybean oil, 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and an acidic / basic catalyst, and carrying out a reaction so as to obtain the plant oil polyol containing phosphorus; and 2) mixing the phosphorus-containing vegetable oil polyol with an amine compound, and reacting to obtain the phosphorus-nitrogen-containing vegetable oil polyol. The plant oil polyol containing phosphorus and nitrogen simultaneously contains two elements P and N with a synergistic flame retardant effect, is high in flame retardant efficiency, does not have a flame retardant precipitation phenomenon when being used for a polyurethane product, and does not influence the physical properties of the polyurethane product.

Owner:NANTONG HAIERMA TECH CO LTD +1

A kind of transparent halogen-free flame-retardant polycarbonate resin and preparation method thereof

Owner:SHANGHAI KUMHO SUNNY PLASTICS

A kind of method of small molecule phenol modification pbat

The invention provides a small molecular phenol modified PBAT method, which belongs to the technical field of polymer modification. The method comprises the following steps: (1) esterification reaction: placing the reactant in a reactor, stirring evenly, adding a catalyst to carry out esterification reaction to obtain a prepolymer; (2) melt polycondensation reaction: adding to step (1 ) in the prepolymer obtained by adding a modifying agent to carry out melt polycondensation reaction, after cooling, modified PBAT is obtained; The mixture of methane acts as a modifier to form hydrogen bonds with the ester groups in the prepolymer to improve the physical properties of the polymer. By controlling 2,2-bis(4-hydroxyphenyl)propane and 4,4-bis The mass ratio of hydroxydiphenylmethane is 1:1, which obviously improves the elongation at break, impact strength and transparency of the polymer; the process of the method is simple and can realize industrialization.

Owner:JIANGSU CHINA NUCLEAR IND HUAWEI ENGDESIGN & RES

Fiber drawing process

ActiveCN105884187BImprove cooling effectIncrease the Reynolds numberGlass making apparatusCooling chamberCooling effect

The invention discloses an optical fiber drawing process, which comprises the following steps: 1) melting and drawing process: the preform is melted at 2200°C-2300°C, and draws sagging by its own gravity; 2) shaping cooling process: the sagging thread of the preform is Cool down to 500°C-600°C in the shaping tube; 3) wire drawing cooling process: the wire passes through the helium in the cooling device to further cool down to 30°C-80°C; in step 3), the cooling device includes a cooling tube, which consists of the first Composed of side pipes and second side pipes; there is an installation cavity between the metal wall and the heat preservation cover, and the side of the metal wall facing away from the heat preservation cover is recessed to form a groove; the grooves of a pair of side pipes are spliced to form a cooling chamber, and the groove includes folding Groove, guide piece is housed in folding groove. The invention designs a kind of optical fiber drawing process, and sets the cooling chamber formed by grooves, folding grooves, guide plates and other structures, which increases the turbulence and effectively reduces the thickness of the laminar bottom layer formed by the downward movement of the optical fiber wire, and further improves the Helium cooling effect.

Owner:HANGZHOU FUTONG COMM TECH CO LTD

Method for preparing single crystal zinc blende nano-wire

InactiveCN101311386BLow costEffect on physical propertiesPolycrystalline material growthFrom condensed vaporsSemiconductor materialsEvaporation

Owner:UNIV OF SCI & TECH BEIJING

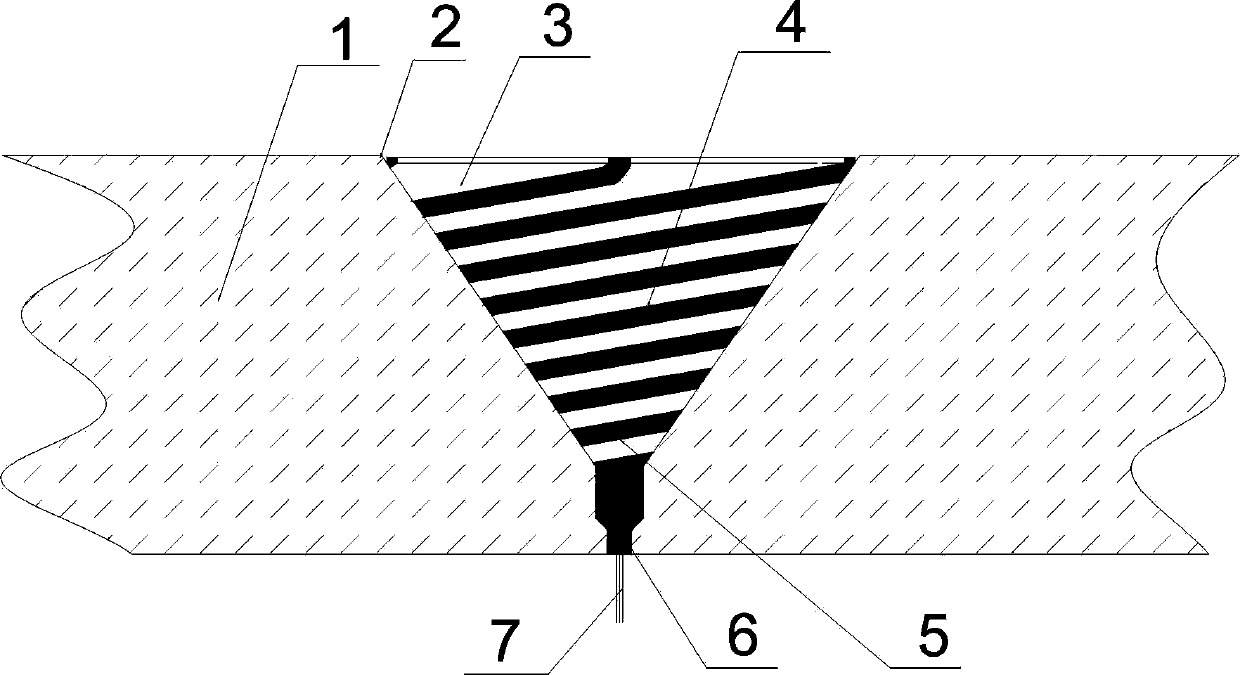

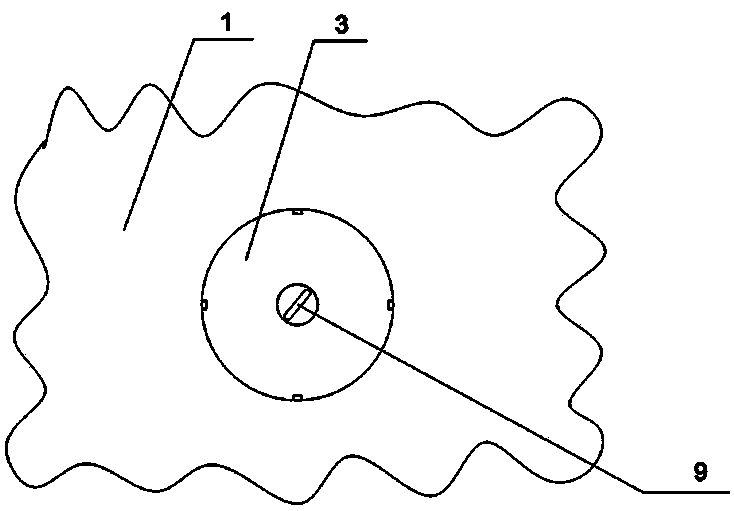

Spinning method and device of single-component sheath-core fiber

ActiveCN102493006BRealize spinningEffect on physical propertiesFilament/thread formingFiberEngineering

The invention provides a spinning method and device of a single-component sheath-core fiber. The spinning device comprises a spinneret plate with a spinneret orifice guide hole; a cone with a spiral smelting channel is installed in the spinneret orifice guide hole of the spinneret plate; the spiral melting channel on the side surface of the cone is of a single-spiral structure, or a double-spiral structure, a three-spiral structure, a four-spiral structure, or a multiple-spiral structure; and the spinneret end part of the spiral melting channel is connected with a spinneret micropore. The spinning method comprises the steps of feeding a spinning melt with functional particles into the spinneret micropore through the high-speed rotation and flowing of the spiral melting channel on the surface of the cone installed in the spinneret orifice guide hole of the spinneret plate, and then injecting and solidifying to obtain the single-component sheath-core fiber. The spinning method and device disclosed by the invention have the characteristics of simpler process and equipment, small energy consumption, low cost and good effect.

Owner:JIANGSU WENFENG CHEM FIBER GROUP

Jet layup board-producing system

ActiveCN110004759AImprove reliabilityGuaranteed reliabilityInorganic fibres/flakesPaper-making machinesPropellerElectric machinery

The invention relates to a jet layup board-producing system. The jet layup board-producing system comprises a woolen blanket, a slurry stabilizing filter tank, a plurality of jet-type slurry spreadingmoulding machines, a colorant adding machine, a cloth puncher, a woolen blanket flushing assembly, a vacuum water suction box and a plurality of supporting rolls, wherein the slurry stabilizing filter tank is arranged beside the woolen blanket; each jet-type slurry spreading moulding machine comprises a jetting device and a moulding device; each jetting device comprises a support, a driving motor, a feed pipe, a balancing valve, a stirring propeller, a slurry jetting head, a dispersing component and a flow control assembly; each moulding device comprises a machine frame, a first dewatering assembly, at least one second dewatering assembly, a first cylindrical net cage, a first couch roll, a moulding cloth belt, an upper water receiving tank body, a lower water receiving tank body, a flushing assembly and a plurality of guide rolls; the colorant adding machine comprises a colorant tank, a second cylindrical net cage, a swinging rod, a colorizing roll, colorizing net cloth and a secondcouch roll; and the cloth puncher, the woolen blanket flushing assembly and the vacuum water suction box are arranged beside the woolen blanket. The jet layup board-producing system has the advantagesof a good shaping effect, low production cost, high reliability, high processing quality and the like.

Owner:FOSHAN JINFU PANEL

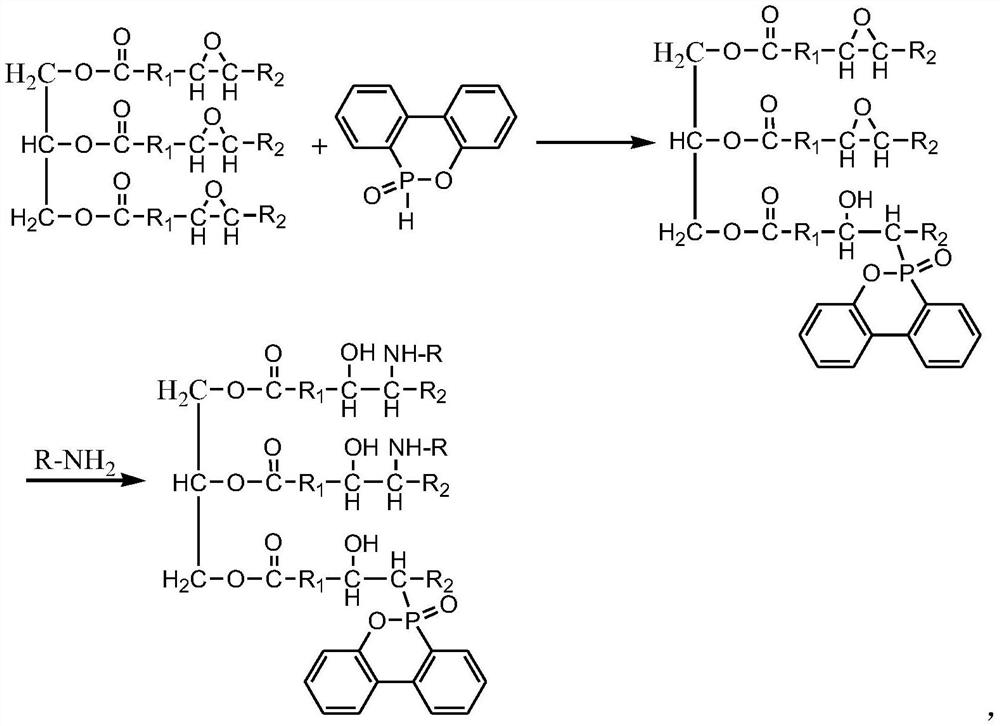

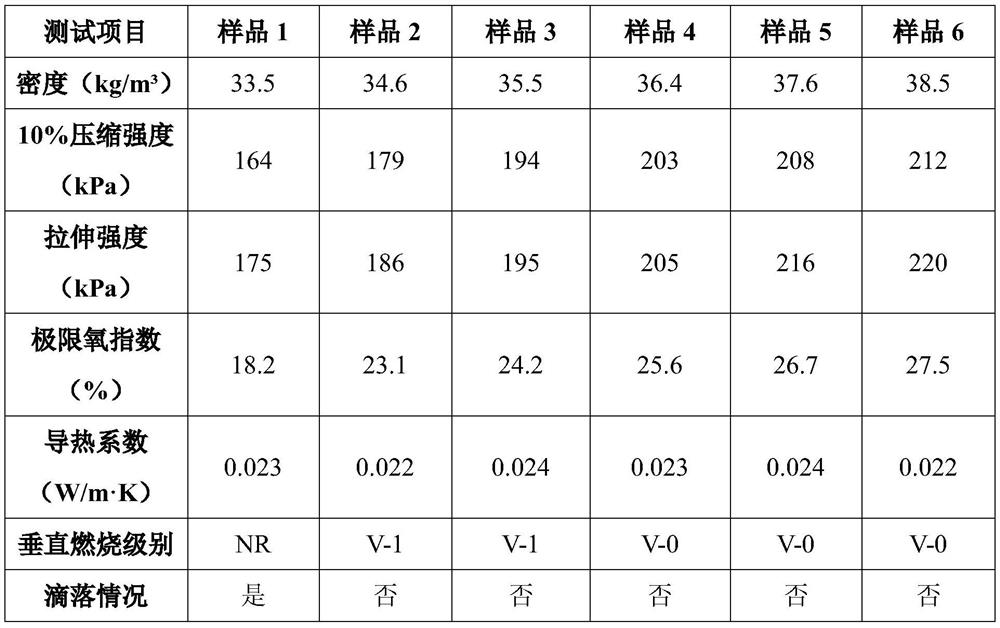

A spray-coated flame-retardant polyurethane composite material and its preparation method and use method

ActiveCN113637142BWell mixedImprove flame retardant performanceFireproof paintsPolyurea/polyurethane coatingsPolyesterPolyol

The invention discloses a spray-coating flame-retardant polyurethane composite material, which comprises the following components in parts by weight: 50-80 parts of polyester polyol, 5-15 parts of flame-retardant polyether polyol, 20-50 parts of isocyanate, 5-10 parts of joint agent, 0.1-1 part of catalyst, 5-12 parts of chain extender, 3-10 parts of foaming agent and 0.5-1 part of foam stabilizer; the flame-retardant polyether polyol includes flame-retardant polyether Polyol POP3628H and flame-retardant polyether polyol YB-3028, in terms of mass ratio, the mass ratio of the flame-retardant polyether polyol POP3628H to flame-retardant polyether polyol YB-3028 is 1:1 to 3:1 . The flame-retardant polyether polyol is introduced into the polyurethane composite material of the present invention, and the flame-retardant elements are stably combined into the polyurethane matrix, and by optimizing and screening the types and proportions of the flame-retardant polyether polyol, the performance of the polyurethane is significantly improved. Flame retardant performance, and reduce the preparation cost of the flame retardant polyurethane foam material, good flame retardant stability, can maintain the flame retardant effect for a long time, and has no adverse effect on the physical properties of polyurethane.

Owner:广东图恩新材料有限公司

A processing technology and device for self-adhesive enameled wire special for household motors

ActiveCN110310782BImprove processing stabilityGood coating effectInsulating conductors/cablesCopper wireElectric machine

The invention discloses a processing technology of a special self-adhesive enameled wire for a household motor and a device. The processing technology comprises the steps of softening a copper bare wire through an annealing oven to obtain a copper wire A; sensing the copper wire A into a drying furnace for drying to obtain a copper wire B; coating the surface of the copper wire B with primer, sending the copper wire B into a first enamelling furnace, and drying the copper wire B for the first time in different temperature environments through the first enamelling furnace to obtain an enameledwire C; coating the surface of the enameled wire C with finish paint, then sending the enameled wire C into a second enamelling furnace, and drying the enameled wire C for the second time in differenttemperature environments through the second enamelling furnace to obtain an enameled wire D; and winding the enameled wire D to obtain a finished enameled wire. The working stability and the bondingeffect of the self-adhesive paint after being coated can be effectively improved according to the invention.

Owner:浙江郎立电工器材有限公司

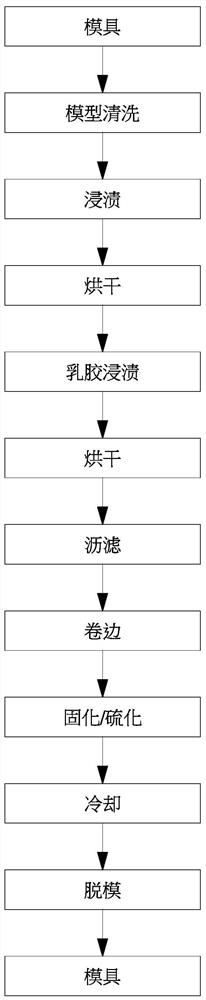

Skin contact elastomer product and preparation method thereof

The invention discloses a skin contact elastomer product and a preparation method thereof, and the elastomer product is characterized in that a skin-friendly coating composition layer is coated on a skin contact surface (also called as a wearing surface) of an elastomer layer, the coating composition layer includes a combination of a primary water-soluble humectant having a high boiling point and a secondary water-soluble humectant having a high boiling point, and a skin protectant. The coating composition layer is used as an isolation medium between the elastomer layer and the skin, the viscosity between the surface of the elastomer layer and the skin can be reduced during wearing, a more convenient wearing effect is provided for a wearer, and the coating composition layer is activated and transferred to the skin after the wearer wears and makes contact with the skin, so that the comfort of the wearer is improved. The skin of a wearer is optimized, and a higher skin care effect is provided. The invention can be used for preparing medical gloves (such as examination gloves and surgical gloves) and non-medical gloves (such as industrial and livelihood gloves). The invention has a very wide prospect in preparation of examination gloves and surgical gloves.

Owner:华毅企业股份有限公司 +2

Method for preparing Mn-doped ZnS nanostructure

The invention provides a preparation method of Mn-doped ZnS nano-structure, which belongs to the technology field of semiconductor nano-material preparation. The method is characterized in including adopting a manner of chemical gas deposition, charging mixed gas of the argon gas and the hydrogen gas at a flow rate of 108-113 ml / min into a pipe heater, and evaporating the ZnS powder and the MnCl2 powder in the mixed atmosphere of the argon gas and the hydrogen gas; and heating the pipe heater to 900-920 DEG C, maintaining the temperature for 60-200min and furnace-in pressure of 0.015-0.03MPa, and depositing Mn-doped ZnS nano-structure on a blank silicon wafer. An evaporation source is arranged in an inlet direction of mixed gas stream of the argon gas and the hydrogen gas, the silicon wafer is arranged in an outlet direction of the mixed gas stream of the argon gas and the hydrogen gas, and horizontal distance between the silicon wafer and the evaporation source is 3-6mm. The method is capable of obtaining high purity and high crystalline quality Mn-doped ZnS nano-material without catalyst, and has simple preparation, low cost and easy operation.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com