A kind of pet plastic toughening agent and preparation method

A toughening agent and plastic technology, applied in the field of plastic toughening agent, can solve the problems of crystal point, fogging, influence, etc., and achieve good toughening effect and toughness improvement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

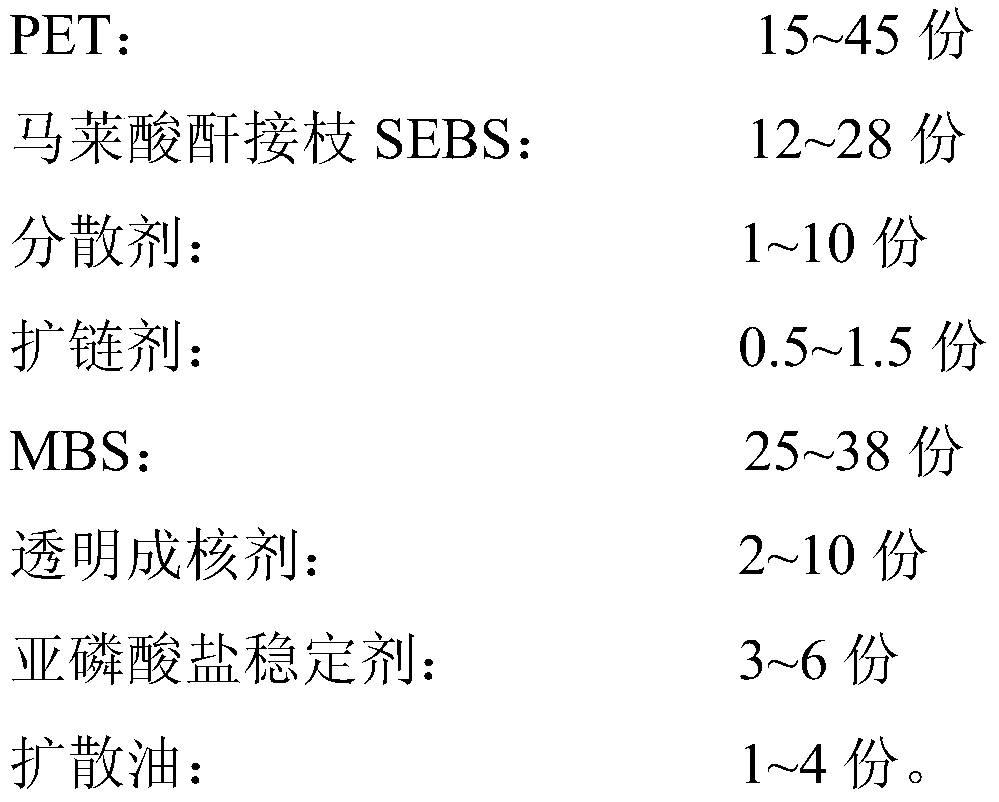

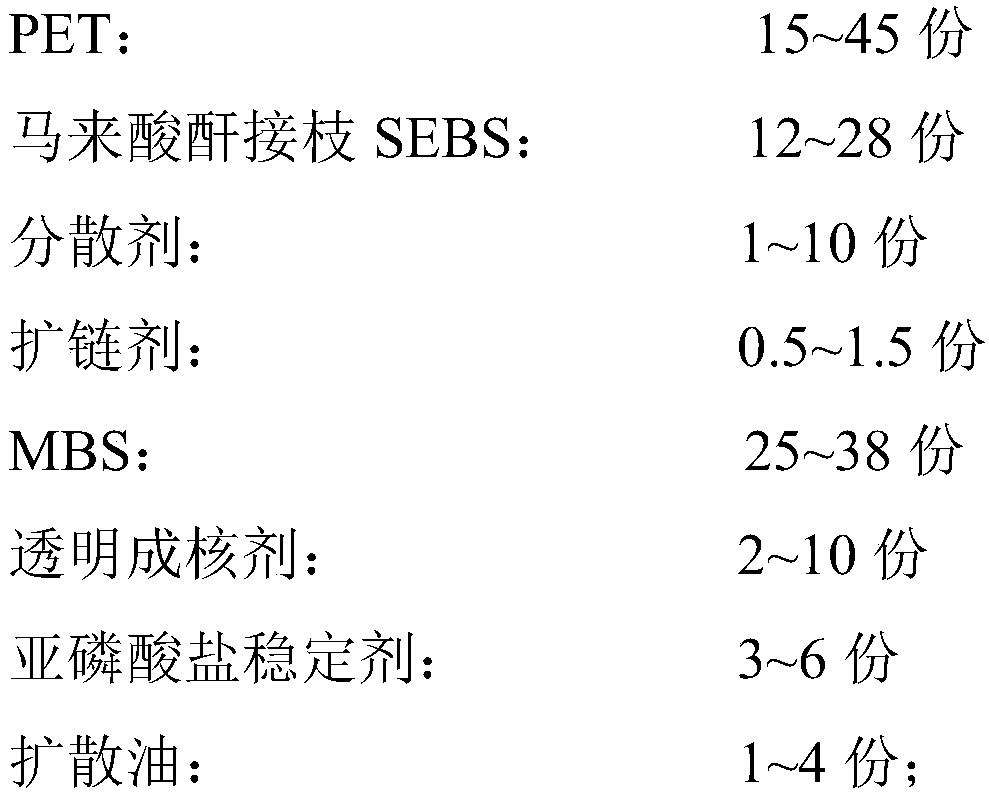

[0031] The PET plastic toughening agent disclosed in this embodiment includes the following components and parts by weight: PET: 15-45 parts; maleic anhydride grafted SEBS: 12-28 parts; dispersant: 1-10 parts; Chain agent: 0.5-1.5 parts; MBS: 25-38 parts; transparent nucleating agent: 2-10 parts; phosphite stabilizer: 3-6 parts; diffusing oil: 1-4 parts.

[0032] The PET is PET slices or granules. In this embodiment, China Resources PET slices are used, and PET is used as the base material to better act on PET products; the maleic anhydride-grafted SEBS is granules, and the maleic anhydride-grafted SEBS is PET Compatibilization between products and additives, better absorption of additives; the dispersant is powdery, and the dispersant can disperse various materials in the formula more evenly; the chain extender is pulverized, The chain agent increases the reaction of functional groups, and the molecular weight increases by 30% to 40%. MBS (methyl methacrylate, butadiene, styr...

Embodiment 2

[0041] The preparation method of the PET plastic toughening agent provided in this embodiment is basically the same as in Example 1, the difference being that it comprises the following steps:

[0042] (1) Take the dispersant, chain extender, transparent nucleating agent, and phosphite stabilizer by parts by weight, mix and stir in a mixer for 1 hour to achieve uniformity, and obtain mixture A;

[0043] Components and parts by weight: dispersant: 10 parts; chain extender: 1.5 parts; transparent nucleating agent: 5 parts; phosphite stabilizer: 5 parts;

[0044] (2) Take PET, maleic anhydride grafted SEBS, MBS by parts by weight, mix and stir in mixer for 30 minutes, obtain mixture B;

[0045] Components and parts by weight: PET: 45 parts; maleic anhydride grafted SEBS: 28 parts; MBS: 30 parts;

[0046] (3) Mix mixture A and mixture B, add 1 part of diffusion oil, put it into a high-speed mixer, and stir for 2 hours at a speed of 500-600r / min to obtain mixture C;

[0047] (4) ...

Embodiment 3

[0051] The preparation method of the PET plastic toughening agent provided in this embodiment is basically the same as in Example 1, the difference being that it comprises the following steps:

[0052] (1) Take the dispersant, chain extender, transparent nucleating agent, and phosphite stabilizer by parts by weight, mix and stir in a mixer for 1 hour to achieve uniformity, and obtain mixture A;

[0053] Components and parts by weight: dispersant: 3 parts; chain extender: 1 part; transparent nucleating agent: 2 parts; phosphite stabilizer: 3 parts;

[0054](2) Take PET, maleic anhydride grafted SEBS, MBS by parts by weight, mix and stir in mixer for 30 minutes, obtain mixture B;

[0055] Components and parts by weight: PET: 15 parts; maleic anhydride grafted SEBS: 20 parts; MBS: 25 parts;

[0056] (3) Mix mixture A and mixture B, add 2 parts of diffusion oil, put it into a high-speed mixer, and stir for 2 hours at a speed of 500-600r / min to obtain mixture C;

[0057] (4) Put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com