A spray-coated flame-retardant polyurethane composite material and its preparation method and use method

A technology of polyurethane composite material and flame-retardant polyether, which is applied in the field of polyurethane, can solve the problems that additive flame retardants are difficult to meet the use requirements, cannot maintain the flame-retardant effect for a long time, and destroy the physical properties of foam, so as to achieve a long-lasting flame-retardant effect , No adverse effects on physical properties, enhanced mechanical properties and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

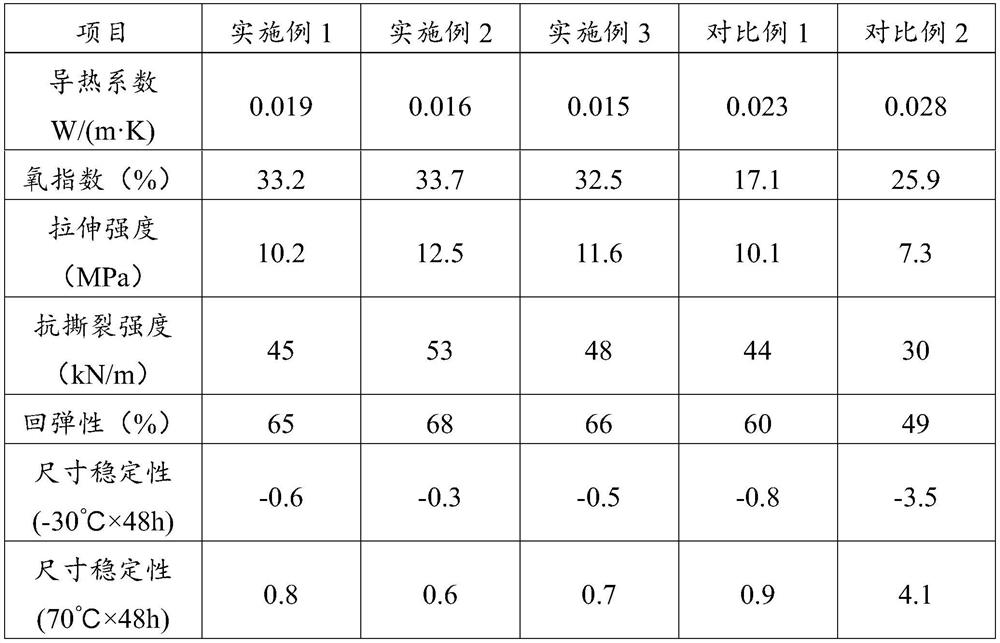

[0038] Examples 1 to 3 provide a spray-on flame-retardant polyurethane composite material, the formula composition of which is shown in Table 1.

[0039] Comparative Examples 1-2 provide a spray-on polyurethane composite material, the formula composition of which is shown in Table 1.

[0040] Table 1

[0041] Component (part) Example 1 Example 2 Example 3 Comparative example 1 Comparative example 2 PCL2000 25 32 40 32 32 CP-2055 25 32 40 32 32 POP3628H 7.5 5 2.5 - - YB-3028 7.5 5 2.5 - - ippp35 - - - - 10 MDI 20 35 50 35 35 Triethanolamine 10 8 5 8 8 stannous octoate 0.8 0.5 0.3 0.5 0.5 1,3-Propanediol 5 8 12 8 8 water 5 8 10 8 8 HY-193 1 0.8 0.5 0.8 0.8

[0042] Note: "-" in the table means that the component is not added.

[0043] The method of using the above-mentioned polyurethane composite material is: put polyester polyol, flame retardant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com