Patents

Literature

45results about How to "Improve flame retardant stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

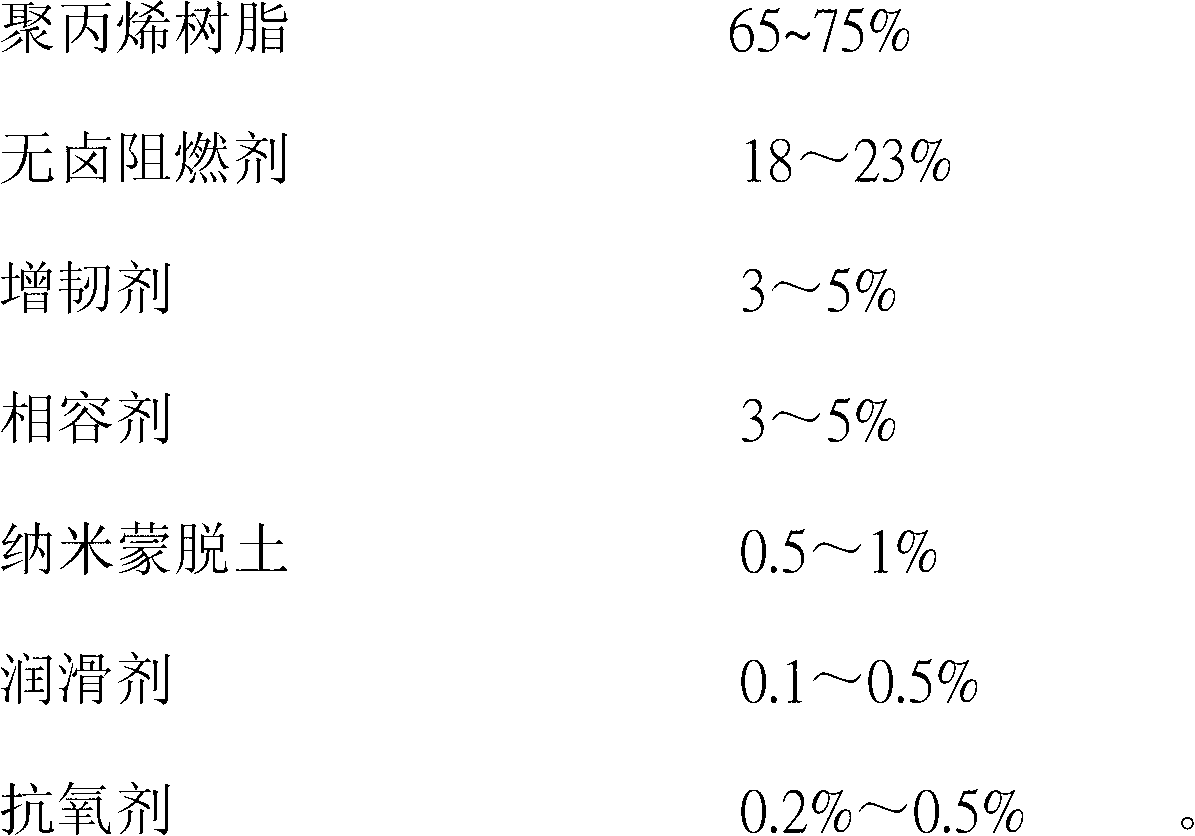

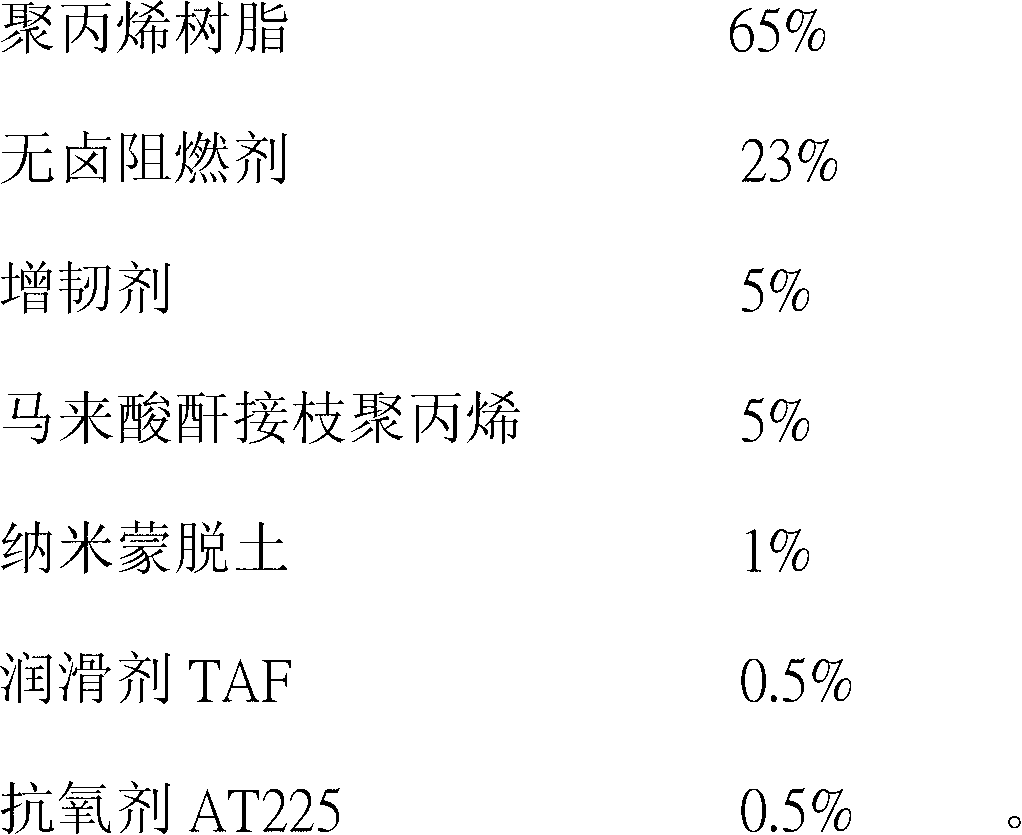

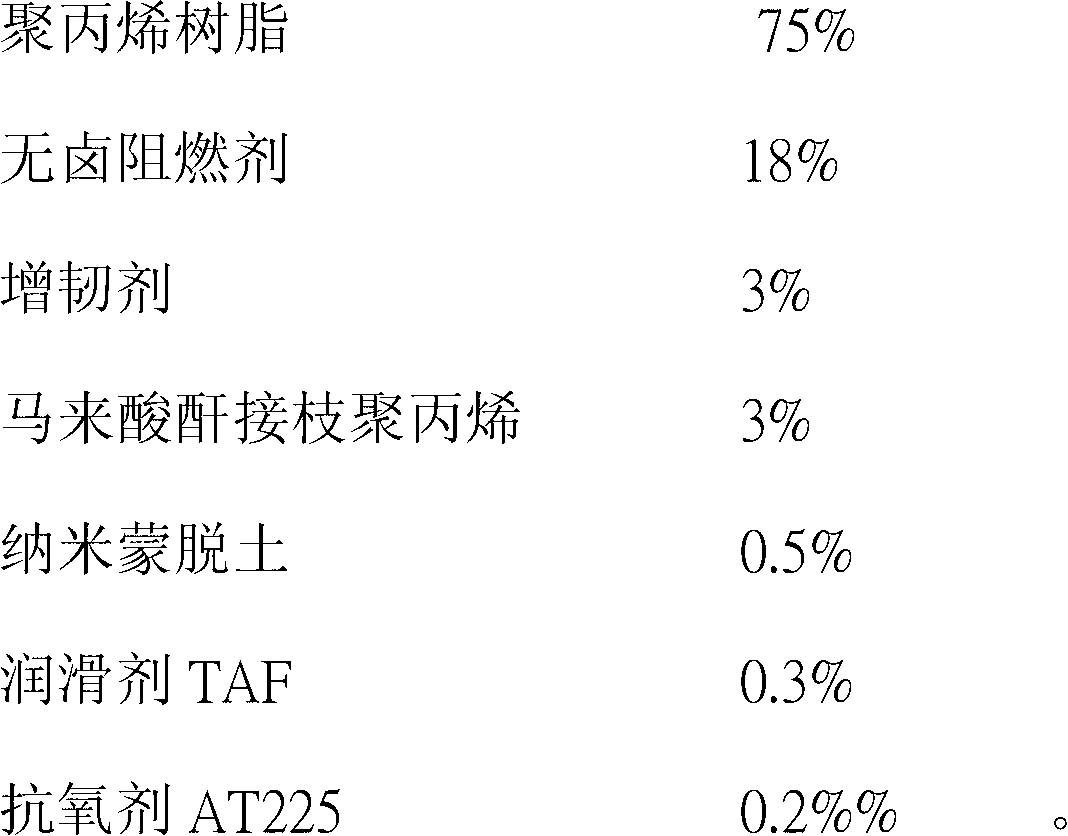

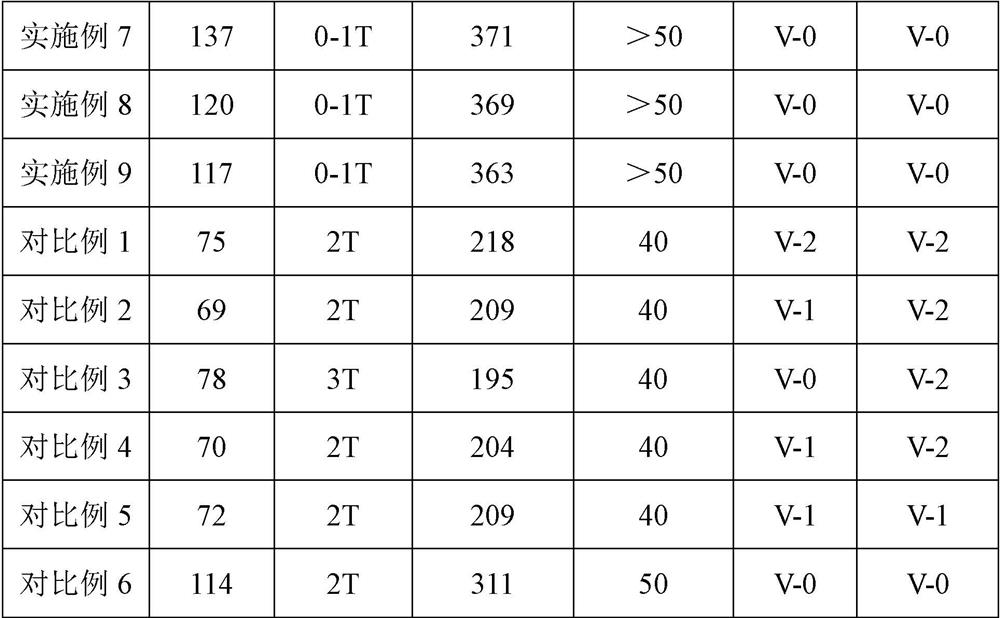

Expansion type flame-retardant polypropylene composite

ActiveCN102796319AReduce flame retardant contentImprove flame retardant stabilityPolypropylene compositesMontmorillonite

The invention discloses an expansion type flame-retardant polypropylene composite, which comprises the following components by weight percentages: 65-75% of polypropylene resin, 18-23% of halogen-free flame retardant, 3-5% of toughening agent, 3-5% of compatibilizing agent, 0.5-1% of nano-montmorillonite, 0.1-0.5% of lubricant and 0.2-0.5% of antioxidant. The expansion type flame-retardant polypropylene composite overcomes the disadvantage of current technology and provides the expansion type flame-retardant polypropylene composite with high toughness which is capable of reducing the content of the flame retardant and effectively preventing hydrolysis.

Owner:武汉顺威赛特工程塑料有限公司

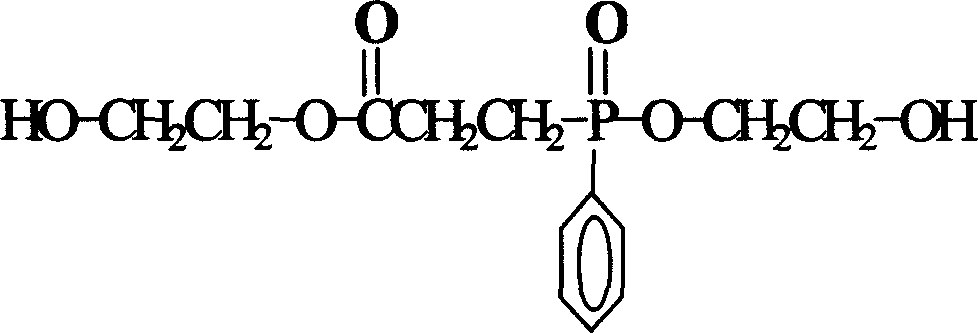

Method for preparing flame-resisting polyester in phosphorus series

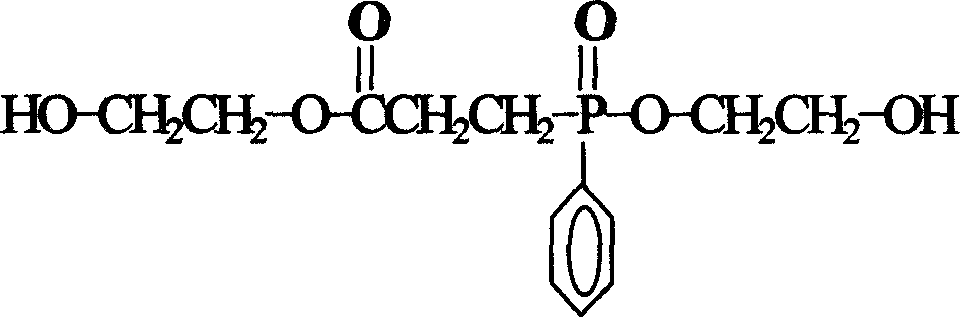

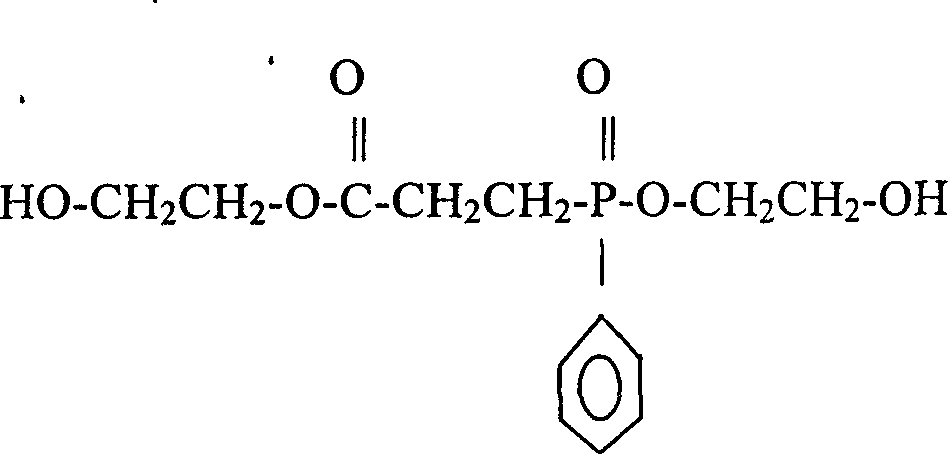

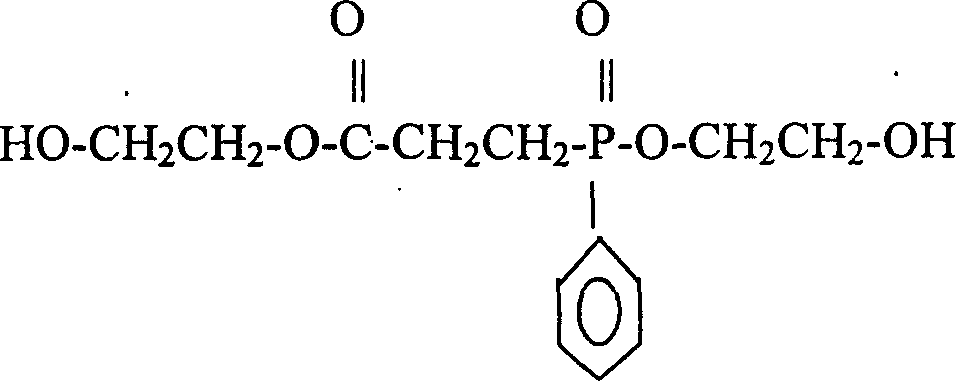

In the prepairng method, fine p-phthalic acid, glycol, catalyst and assistant are used to carry out esterification; fire retardant mixed liquid containing glycol exter radical propionate-phenyl phosphorus acid glycol exter, 2-propyloic phenyl phosphorous acid and glycol is added before polymerization and after exterification; and conventional polycondensation process is applied to obtain fire resistant polyester chip.

Owner:SHAOXING SANLIDA TEXTILE FLAME RETARDANT NEW MATERIALS

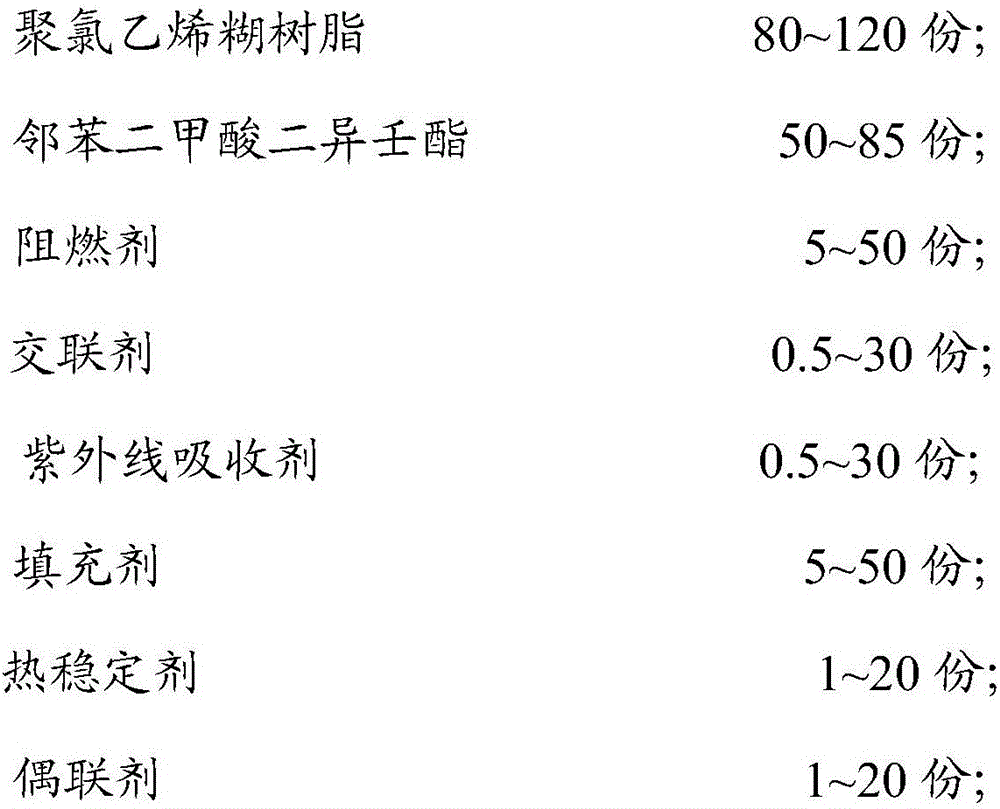

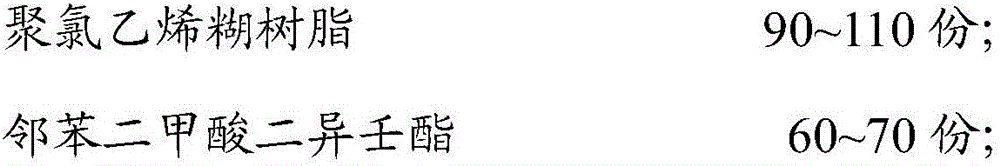

Flame-retarding and smoke-suppressing polyvinyl chloride membrane structure material

The invention relates to a flame-retarding and smoke-suppressing polyvinyl chloride membrane structure material.The material is prepared from, by mass, 80-120 parts of polyvinyl chloride paste resin, 50-85 parts of diisononyl phthalate, 5-50 parts of fire retardant, 0.5-30 parts of a cross-linking agent, 0.5-30 parts of ultraviolet light absorber, 5-50 parts of filler, 1-20 parts of heat stabilizer and 1-20 parts of a coupling agent, wherein the fire retardant is zinc stannate-molybdenum trioxide or zinc stannate-ammonium molybdate.According to the flame-retarding and smoke-suppressing polyvinyl chloride membrane structure material, an efficient flame-retarding and smoke-suppressing agent is added to polyvinyl chloride, so that flame retardation performance, heat resistance and smoke suppression performance of the material are improved.

Owner:ZHEJIANG UNIFULL IND FIBER

Low-density halogen-free flame retardant monocomponent titanate catalyzed room-temperature vulcanized silicone rubber and preparation method thereof

ActiveCN103834172AImprove processing performanceHigh flame retardant efficiencyOther chemical processesCarbon blackMethyl group

The invention relates to a low-density halogen-free flame retardant monocomponent titanate catalyzed room-temperature vulcanized silicone rubber and preparation method thereof, the silicone rubber is prepared from the following components in parts by mass: 100 parts of modified alpha, omega-dihydroxy polydimethyl siloxane, 10-40 parts of modified alpha-hydroxy-omega-methyl polydimethyl siloxane, 10-20 parts of inorganic function filler, 3-10 parts of fumed silica, 0.5-2 parts of carbon black, 1-5 parts of vapor phase method titanium dioxide, 1-15 parts of a crosslinking agent, 1-10 parts of a titanate catalyst and 0-5 parts of a silane coupling agent. The processing property and storage property of the titanate catalyst system are improved, the silicone rubber with low viscosity can be prepared, the compatibility, color uniformity and storage stability and electrical property of the filler and the silicone rubber system are improved, the UL94-V0 level flame retardance is improved, the rubber cannot release any toxic gas in combustion; the prepared silicone rubber has lower density, wider viscosity adjustable range, and lower cost, the contact material cannot be corroded, and the demand on electronics industry is satisfied.

Owner:TONSAN ADHESIVES INC

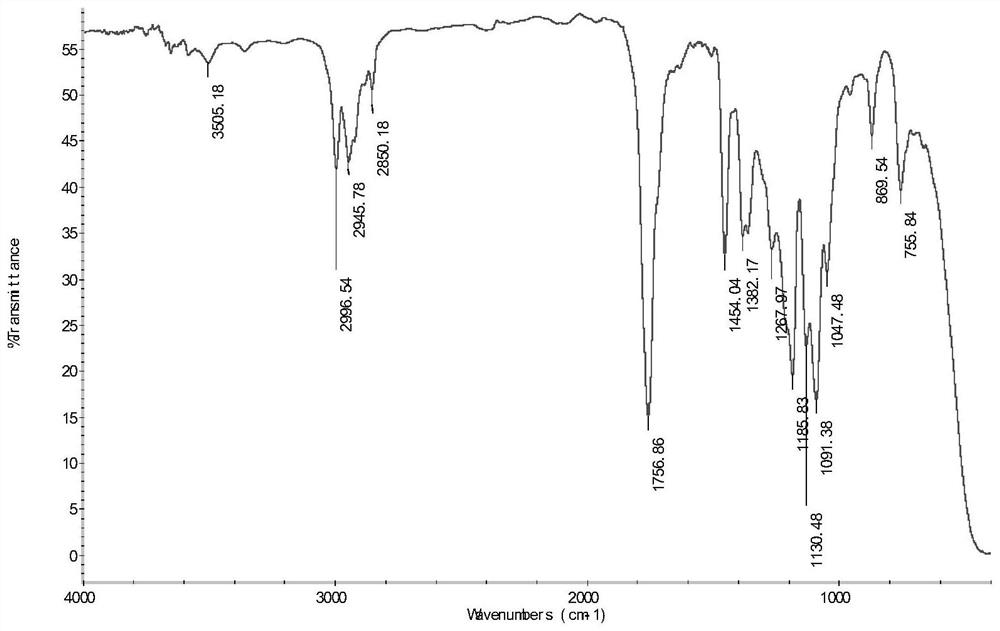

Flame retardant acrylate organic impregnant used for sealing and reinforcing and preparation method of flame retardant acrylate organic impregnant

InactiveCN104387522AImprove flame retardant stabilityImprove flame retardant performanceOther chemical processesChemical industryPolymer science

The invention belongs to the field of chemical industry and in particular relates to a flame retardant acrylate organic impregnant used for sealing and reinforcing and a preparation method of the flame retardant acrylate organic impregnant. The impregnant is prepared from monofunctional acrylate monomers, polyfunctional acrylate monomers, reactive flame retardants, a surfactant, an initiator, a polymerization inhibitor and a chelating agent. The impregnant has the advantages of excellent flame retardance, good flame retardance stability, no toxicity, good sealability and the like.

Owner:NANJING UNIV OF TECH

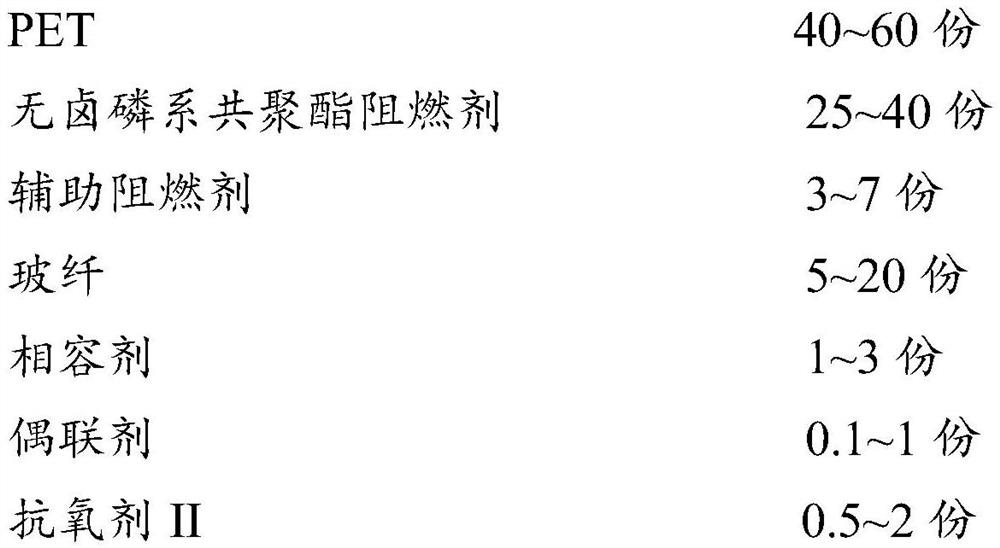

Halogen-free flame-retardant PET (polyethylene terephthalate) material and preparation method thereof

ActiveCN109370172AImprove melt strengthGood physical propertiesGlass fiberPolyethylene terephthalate glycol

The invention provides a halogen-free flame-retardant PET (polyethylene terephthalate) material. The halogen-free flame-retardant PET material contains the following components in parts by weight: 40-60 parts of PET, 25-40 parts of halogen-free phosphorus-based copolyester flame retardant, 3-7 parts of auxiliary flame retardant, 5-20 parts of glass fiber, 1-3 parts of compatibilizer, 0.1-1 part ofcoupling agent and 0.5-2 parts of antioxidant II. A high-efficiency P-containing flame retardant is synthesized through polymerization reaction; and the presence of a P flame retardance element can improve the flame retardance of the polymer in a mode of changing the thermal degradation process of a polymer matrix and the like; the flame retardance stability of the polymer is further improved through the compounding of the P-containing flame retardant, and P and N flame retardance auxiliaries; and then the halogen-free flame-retardant PET material is prepared through the selection and dosagecontrol of reaction auxiliaries and the like. The halogen-free flame-retardant PET material prepared by the method has an excellent flame retardance effect, excellent mechanical property, high and lowtemperature resistance, chemical resistance and excellent resistance to gas, water, oil, peculiar smell and the like.

Owner:BEIJING CO FOUND HIGH TECH INCUBATOR

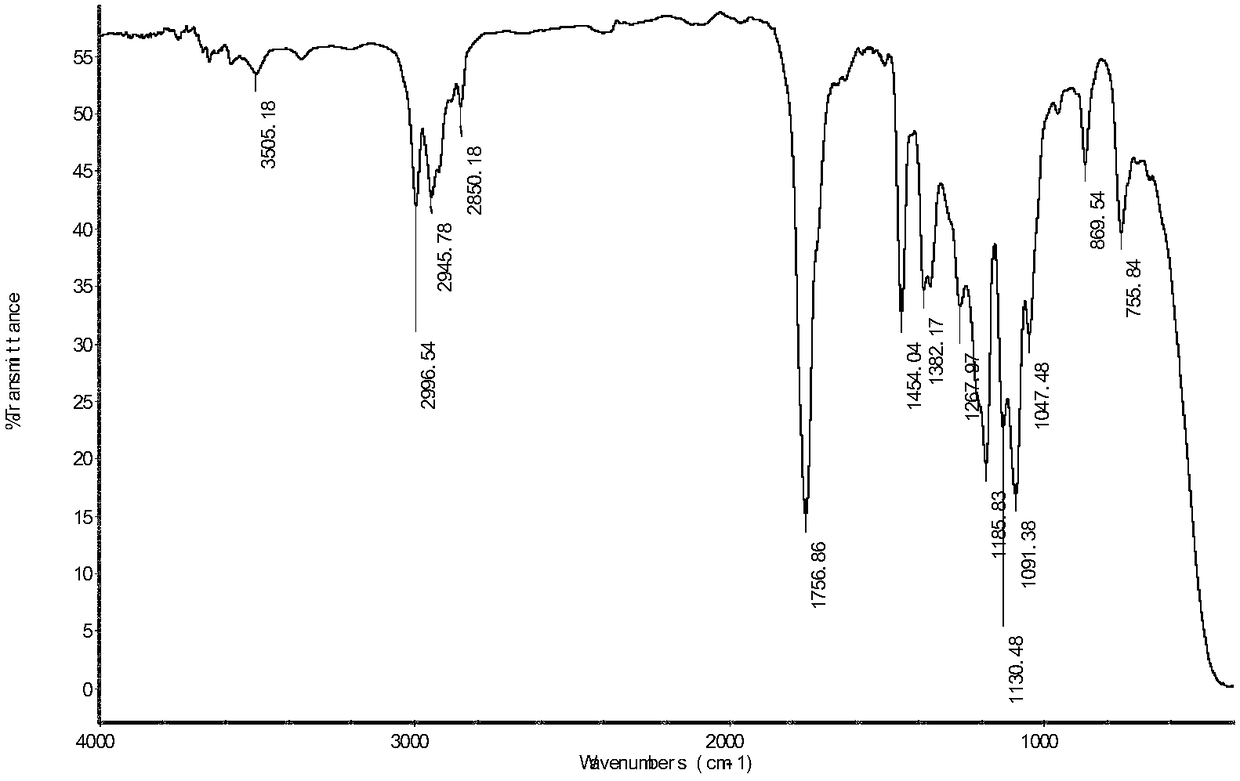

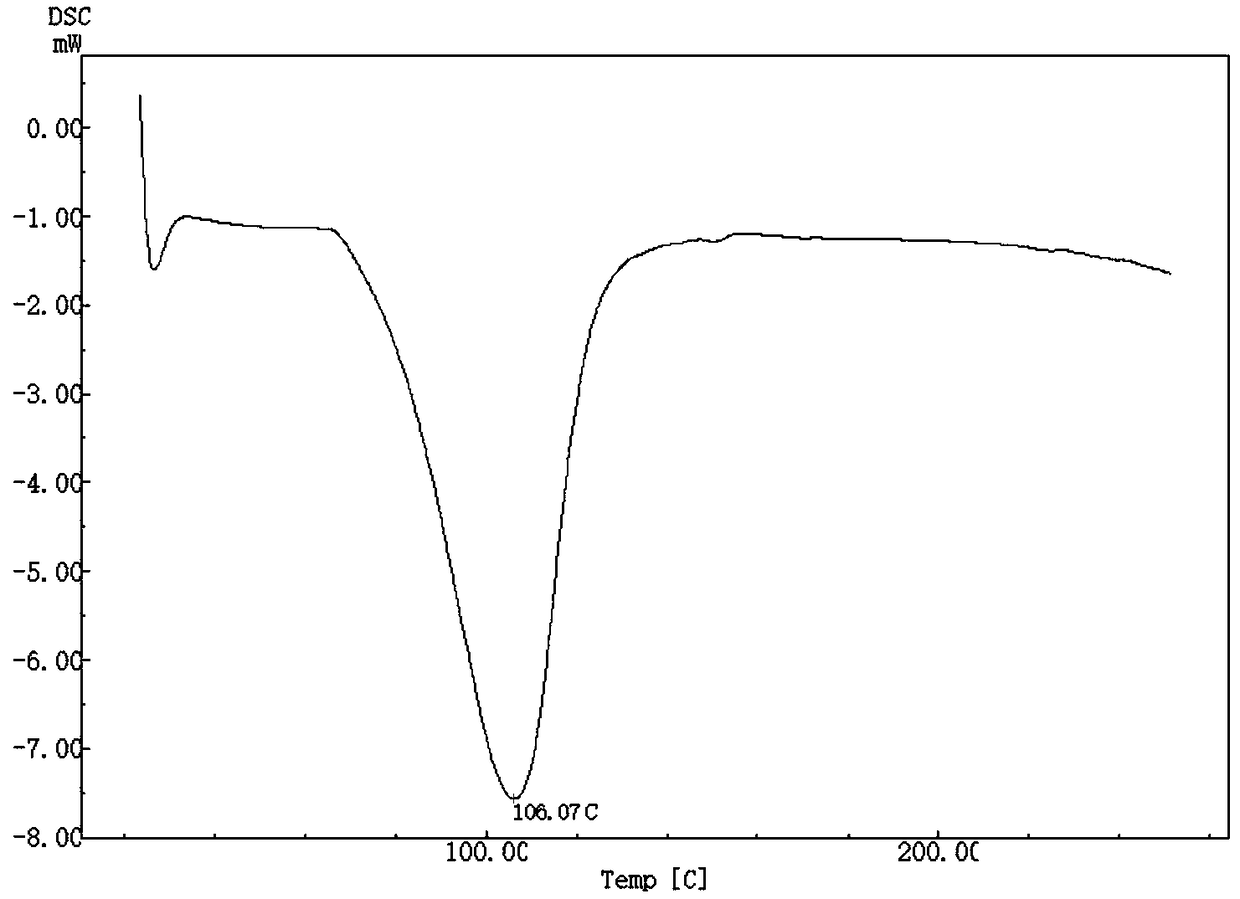

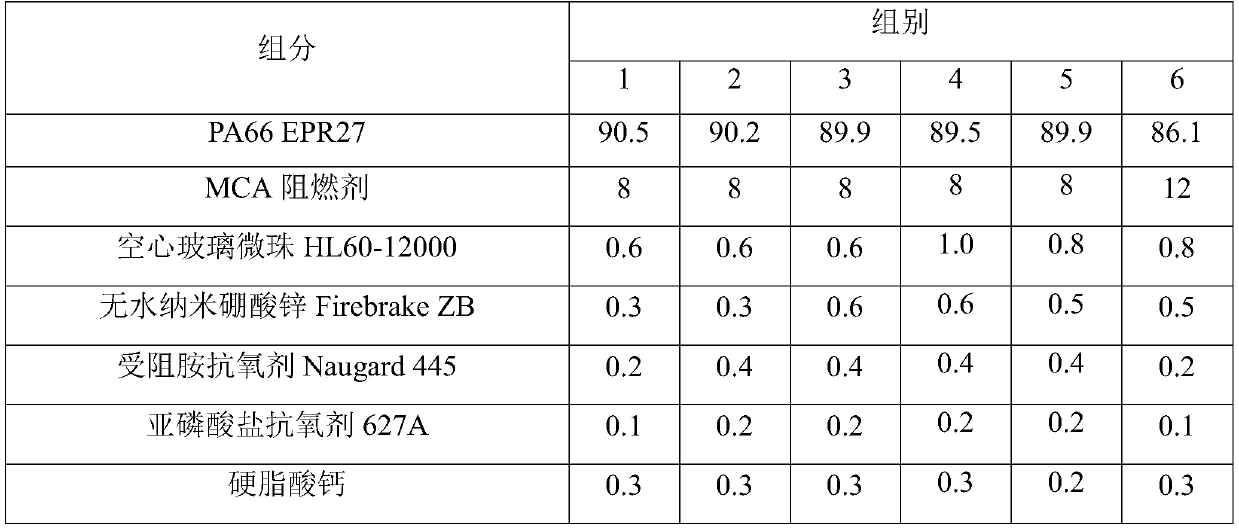

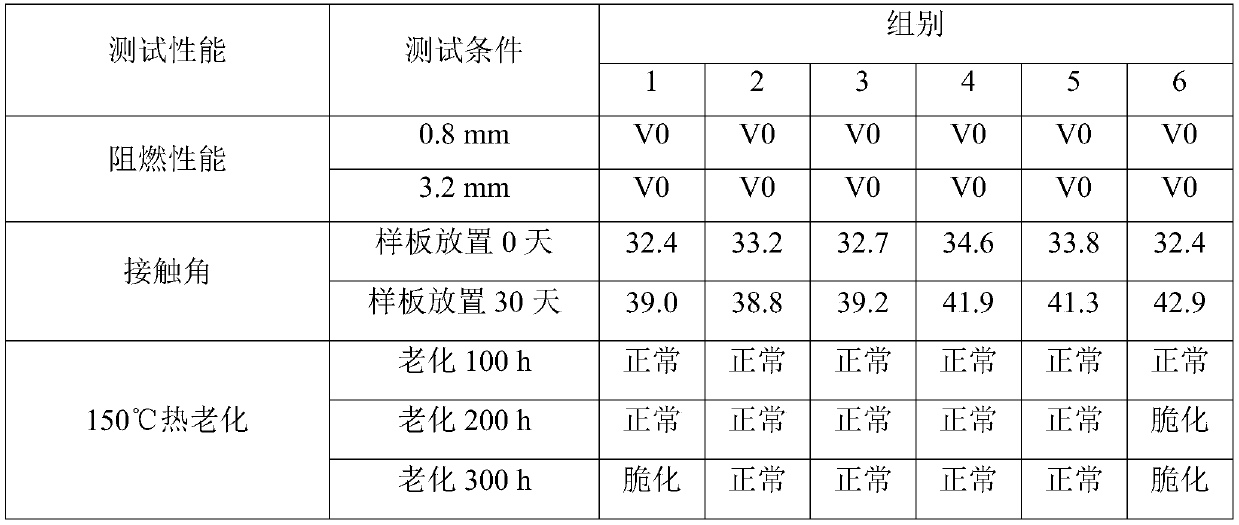

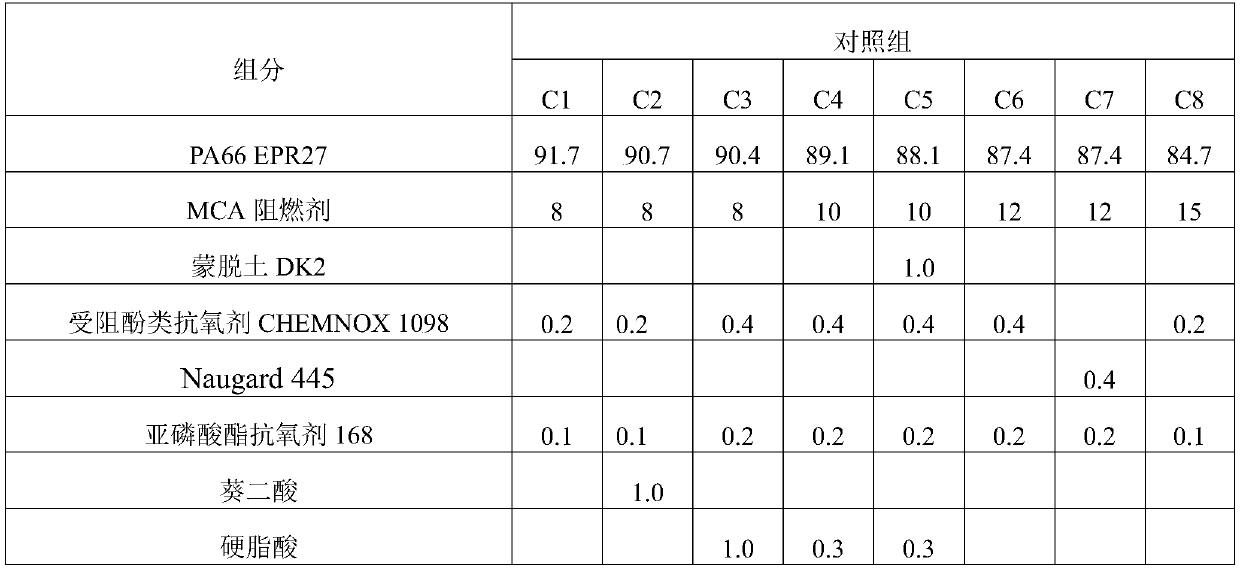

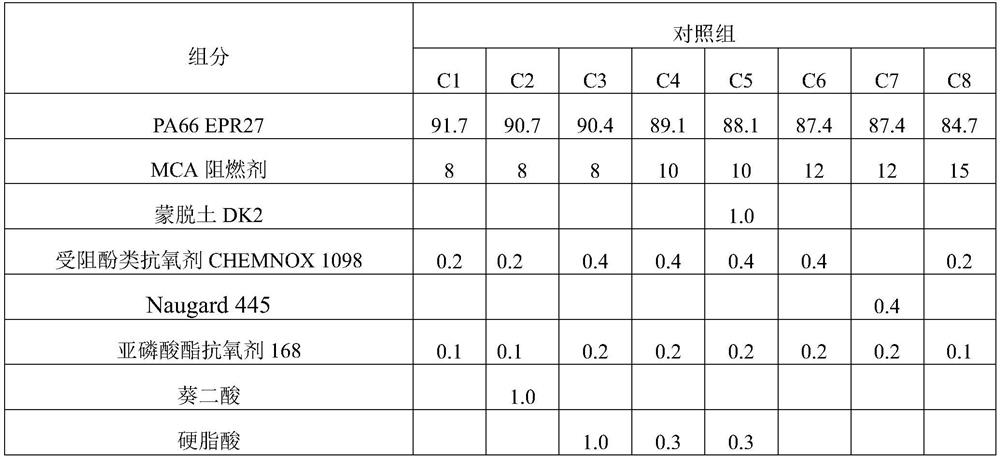

Thermo-oxidative aging-resistant low-precipitation MCA flame-retardant PA66 composite material and application thereof

ActiveCN110698854AHigh flame retardant gradeImprove flame retardant stabilityZinc borateResin matrix

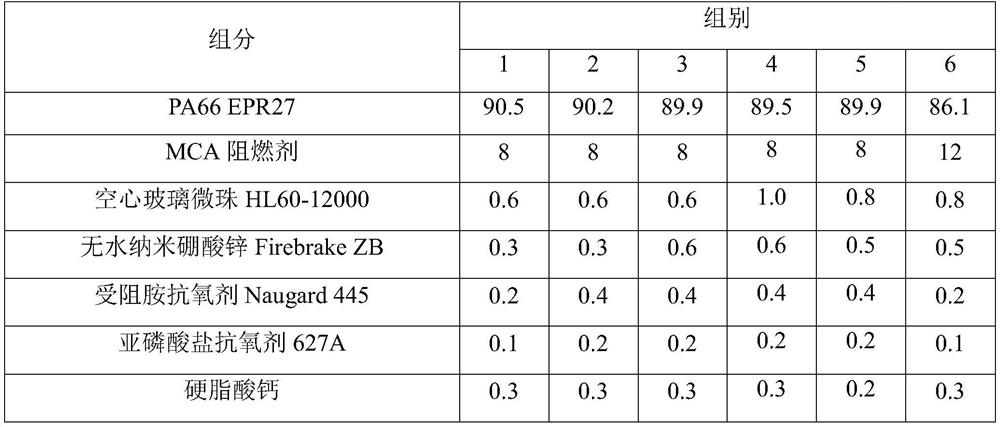

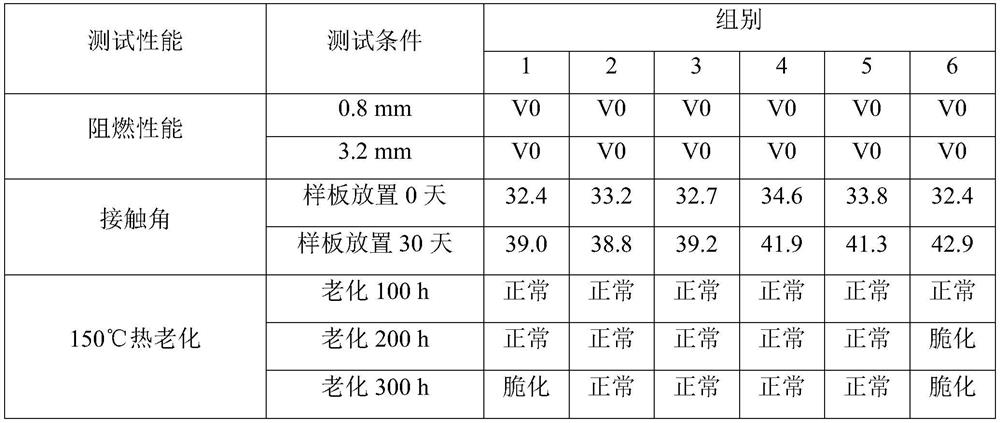

The invention discloses a thermo-oxidative aging-resistant low-precipitation MCA flame-retardant PA66 composite material and application of the thermo-oxidative aging-resistant low-precipitation MCA flame-retardant PA66 composite material. The composite material comprises the following components in parts by weight: 85-91 parts of PA66 resin, 8-12 parts of an MCA flame retardant, 0.6-1.0 part of hollow glass beads, 0.3-0.6 part of an antioxidant, 0.2-0.3 part of a flame retardant stabilizer and 0.3-0.6 part of zinc borate. According to the invention, PA66 is used as a resin matrix, a common MCA flame retardant in the market is adopted, and the hollow glass beads, anhydrous zinc borate and stearate are combined as flame retardant stabilizers, so that the composite material reaches the UL94V0 grade and is less separated out, and the printing effect of a final product is effectively improved; by adding an efficient compound antioxidant system, the performance retention rate of the material in a high-temperature environment is improved, and the material is widely applied to the fields of electronic appliances and connectors, especially the field of wiring terminals.

Owner:合诚技术股份有限公司

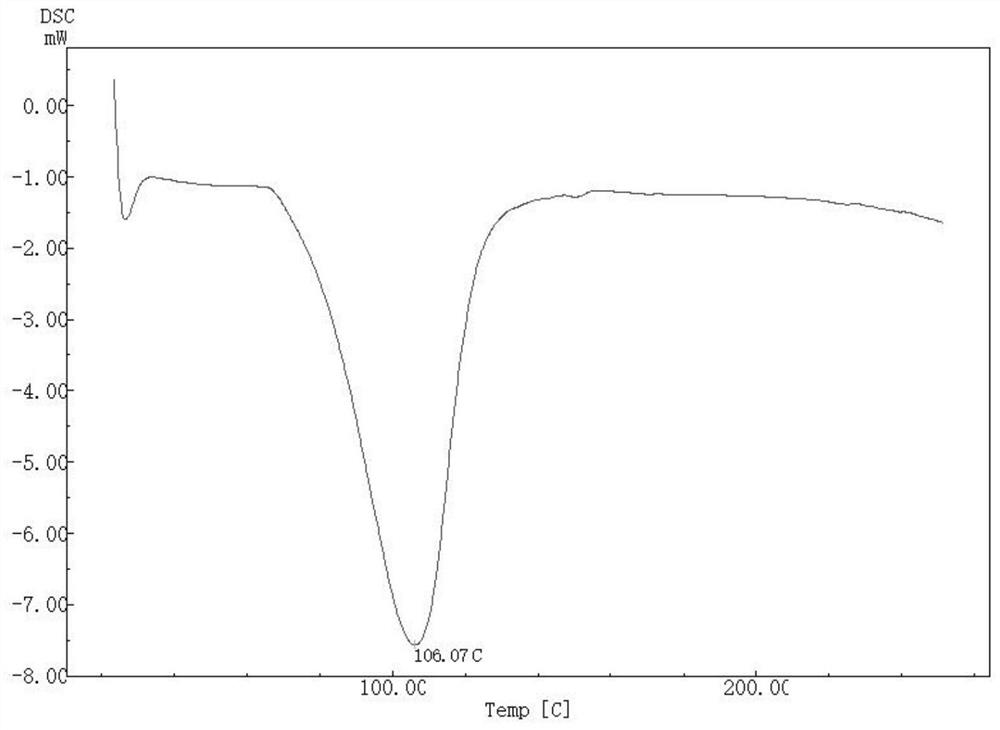

Flame-retardant polycarbonate composite material and preparation method thereof

The invention discloses a flame-retardant polycarbonate composite material which comprises the following components in parts by weight: 60-100 parts of polycarbonate and 1-25 parts of flame retardant,wherein the weight average molecular weight of the polycarbonate is greater than 26000; the molecular weight distribution index PDI is less than 2.2; the pH value of a polycarbonate solution is 6.7-7.1; and the Tg temperature changes in multiple cycles. The invention finds that the flame retardant has less influence on the stability of the polycarbonate when the polycarbonate is within the parameter range.

Owner:KINGFA SCI & TECH CO LTD

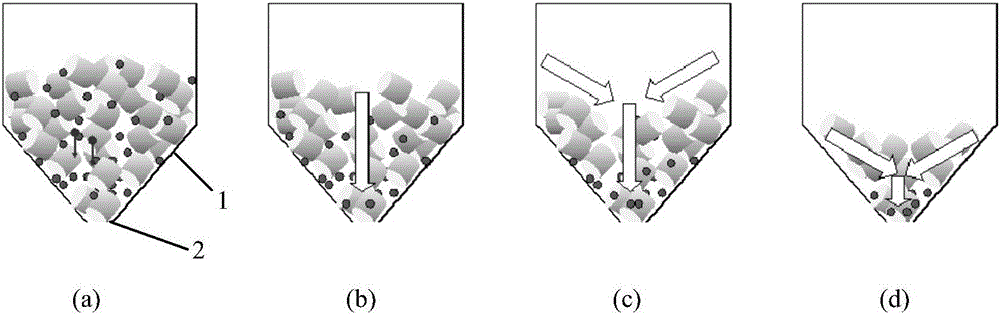

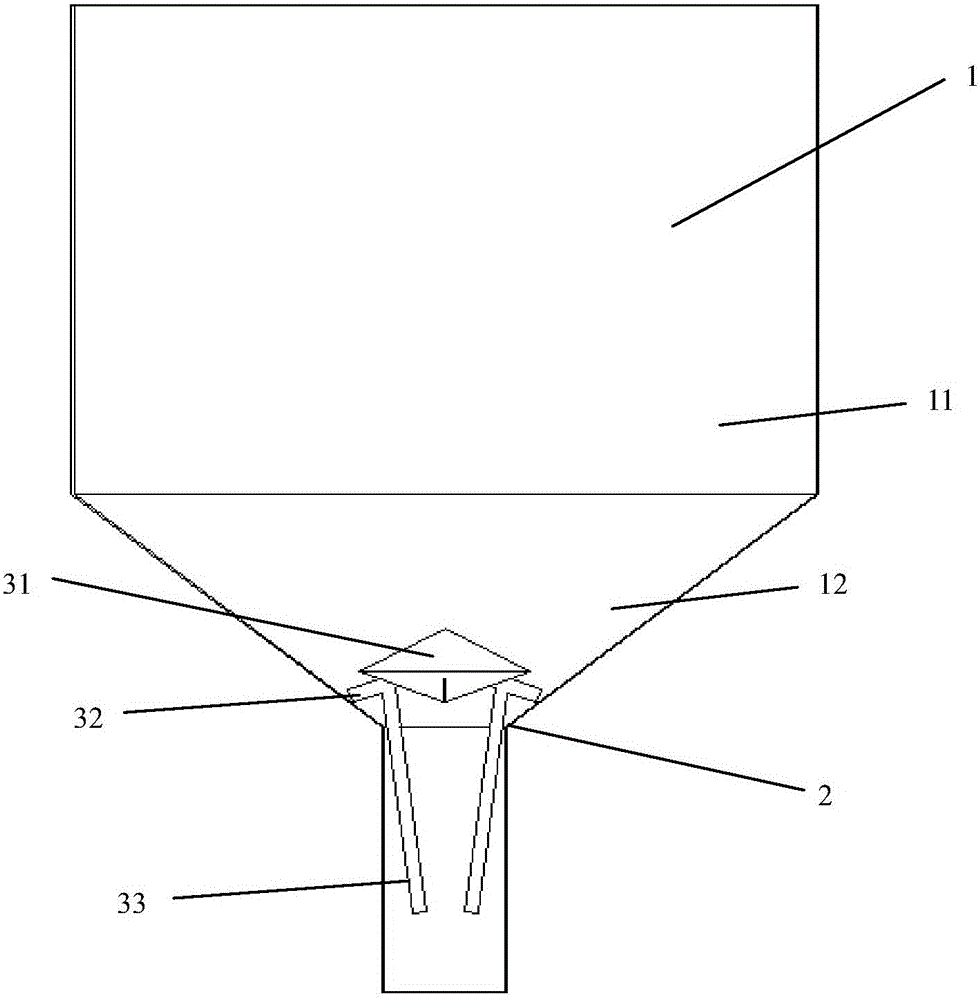

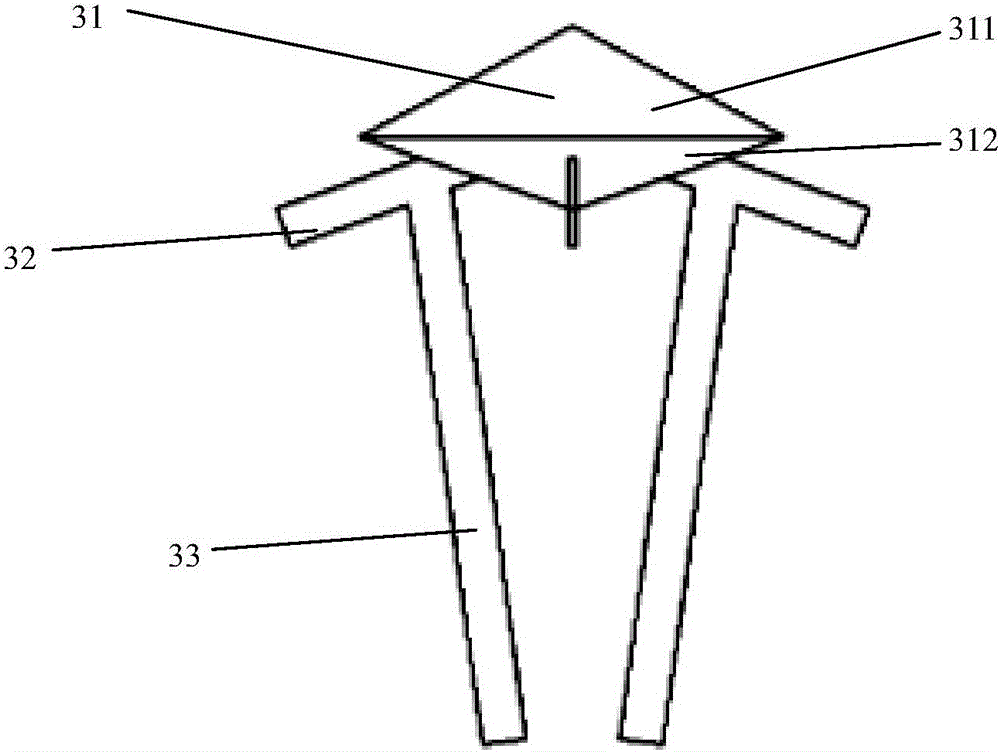

Charging distributor and flame-retardant nylon manufacturing device and method

The invention relates to a charging distributor and a flame-retardant nylon manufacturing device and method, and belongs to the technical field of manufacturing of nylon composites. The charging distributor comprises a distributing body and a supporting mechanism arranged on the distributing body. The supporting mechanism comprises supporting legs used for supporting the distributing body on the corresponding inner walls of a charging container and enabling material channels to be formed between the distributing body and the inner walls of the charging container. Each supporting leg is provided with a pushing end matched with the corresponding inner wall of the charging container in a pushing-fit mode. The charging distributor is characterized in that the supporting mechanism further comprises a positioning structure used for being inserted into a discharge outlet of the charging container to prevent the axis of the distributing body from deviating from the vertical direction. The charging distributor can be placed in a charging bin and is convenient to overhaul and replace, and the positioning structure is adopted, so that the distributor is prevented from deviating under material impact.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC +4

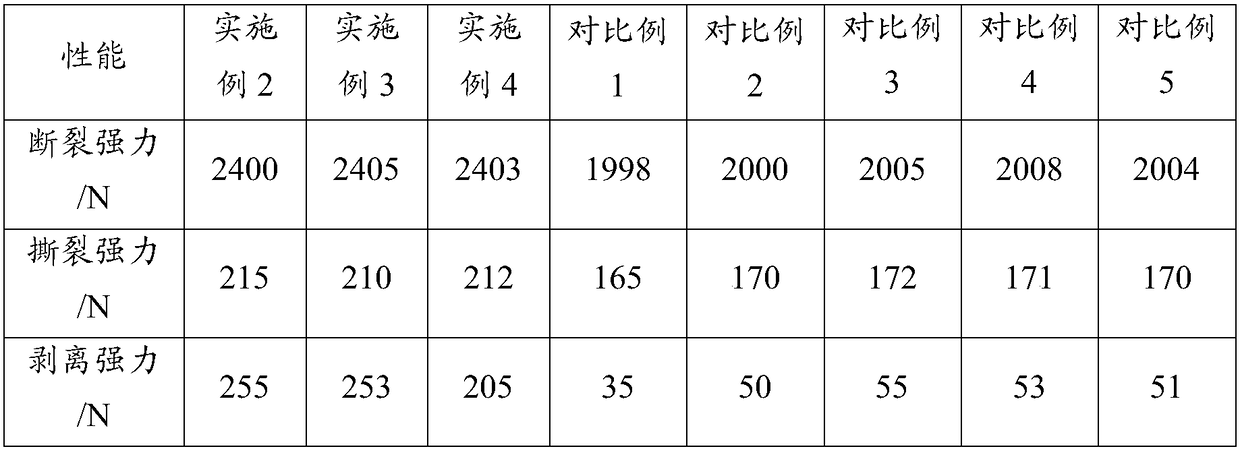

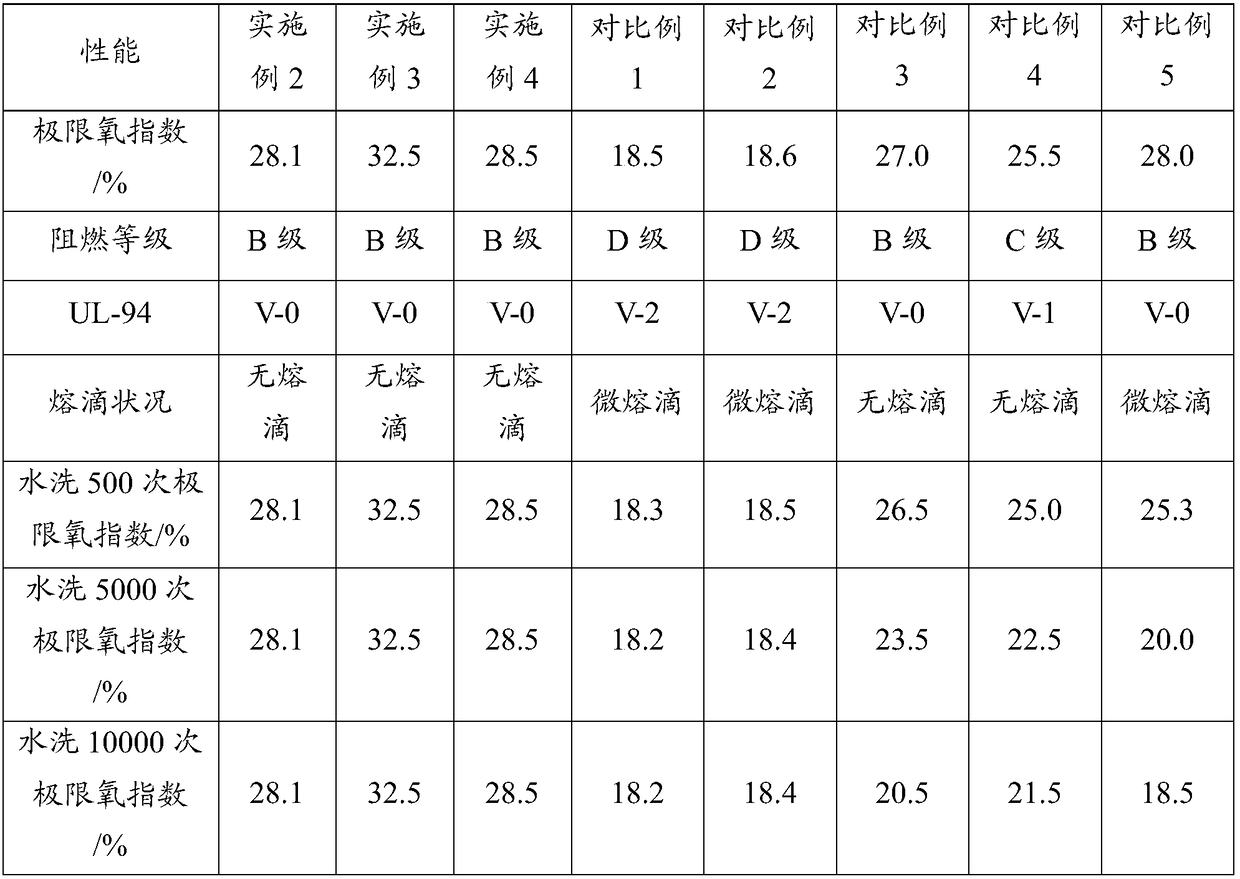

Tear-resistant, peel-resistant and flame-retardant PVC membrane structural material preparation method and product

ActiveCN109203612AImprove tear resistanceEnhanced resistance to peelingSynthetic resin layered productsLaminationPolyesterPolyvinyl chloride

The invention relates to a tear-resistant, peel-resistant and flame-retardant PVC membrane structural material preparation method and a product, wherein the preparation method includes the steps: mixing and stirring 100 parts of polyvinyl chloride resin, 55-65 parts of diisononyl ortho-phthalate, 5-25 parts of a modified flame-retardant smoke suppressant, 1-5 parts of isophorone diisocyanate, 1-5parts of a barium-zinc thermal stabilizer, 1-5 parts of fatty alcohol-polyoxyethylene ether, and 5-20 parts of a diluent, to obtain a PVC impregnating solution; immersing a polyester fabric in the PVCimpregnating solution, extruding by a rolling drum, drying, and cooling, to obtain a modified polyester fabric; preheating the modified polyester fabric under a condition of the temperature of 90-125DEG C; preheating a 0.1-0.5 mm thick PVC film under a condition of the temperature of 150-205 DEG C, then carrying out hot pressing with the modified polyester fabric, and cooling to obtain the tear-resistant, peel-resistant and flame-retardant PVC membrane structural material. The method modifies the PVC impregnating solution and the flame-retardant smoke suppressant in the PVC impregnating solution, so that the product has more superior tear resistance and peeling resistance, and further improves flame retardant stability, water scrubbing resistance and durability.

Owner:HAININ JINDA COATING

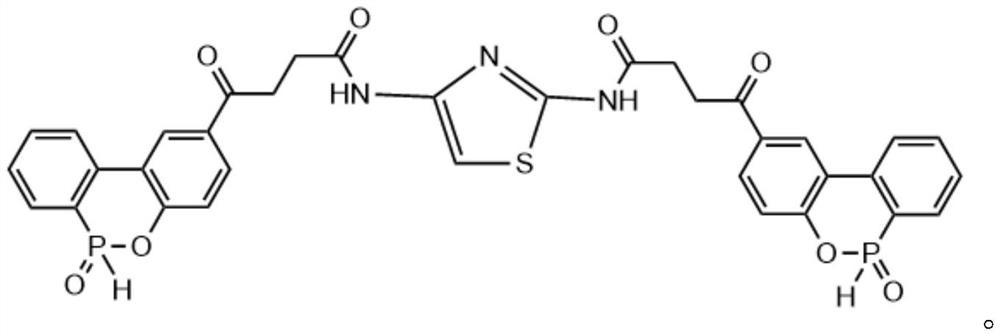

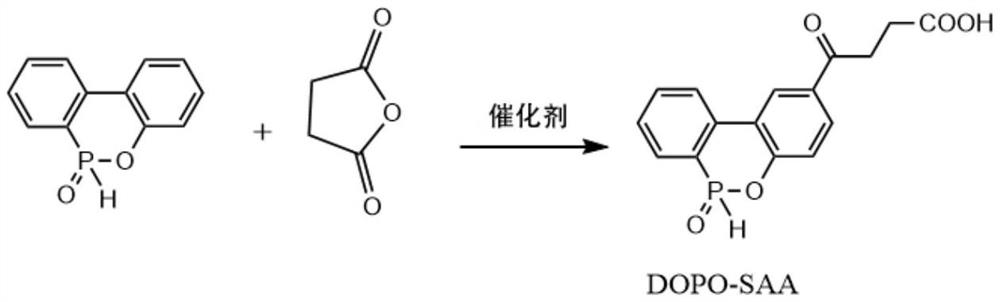

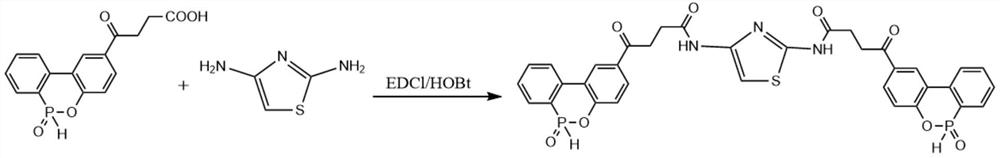

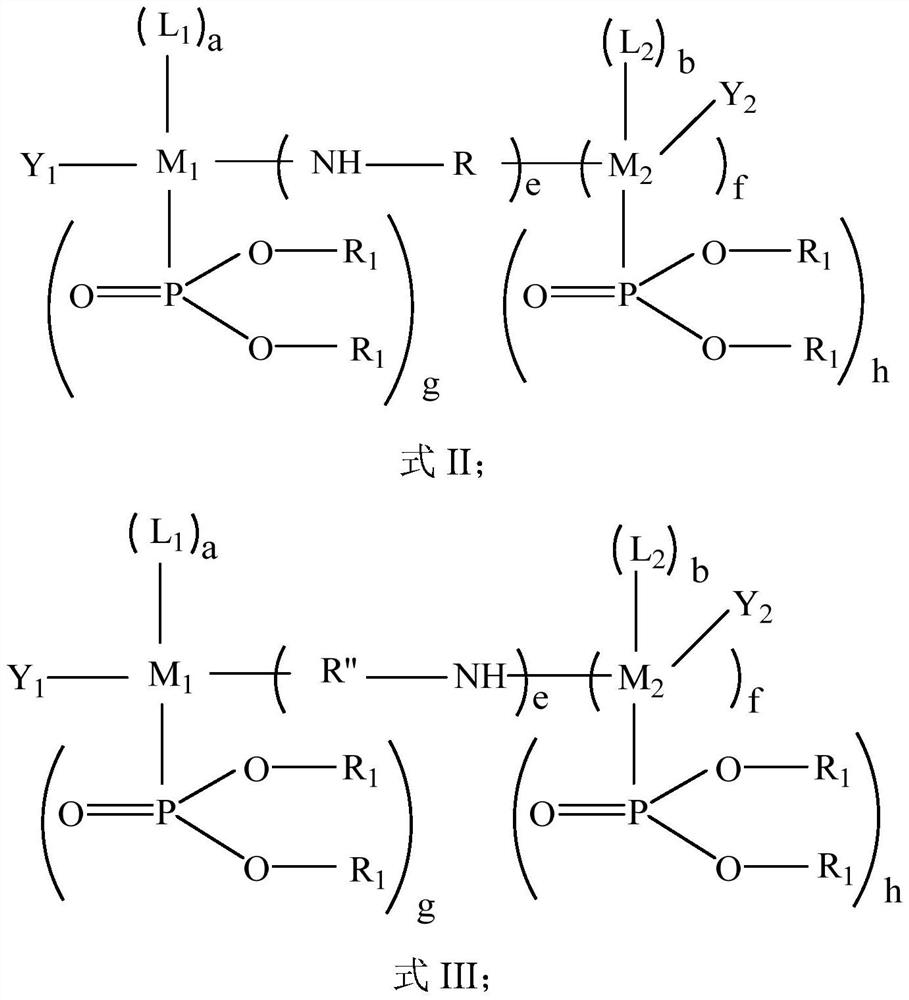

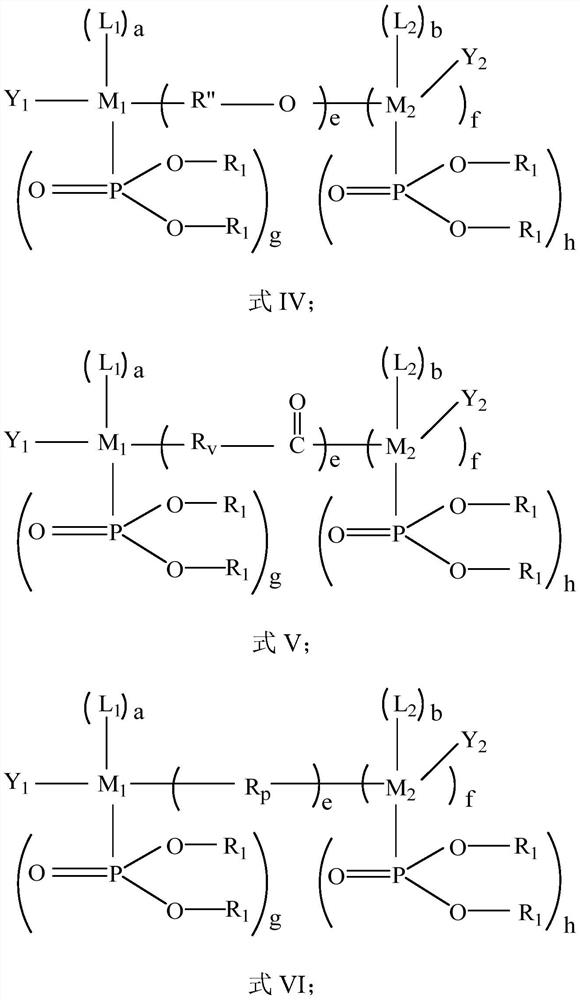

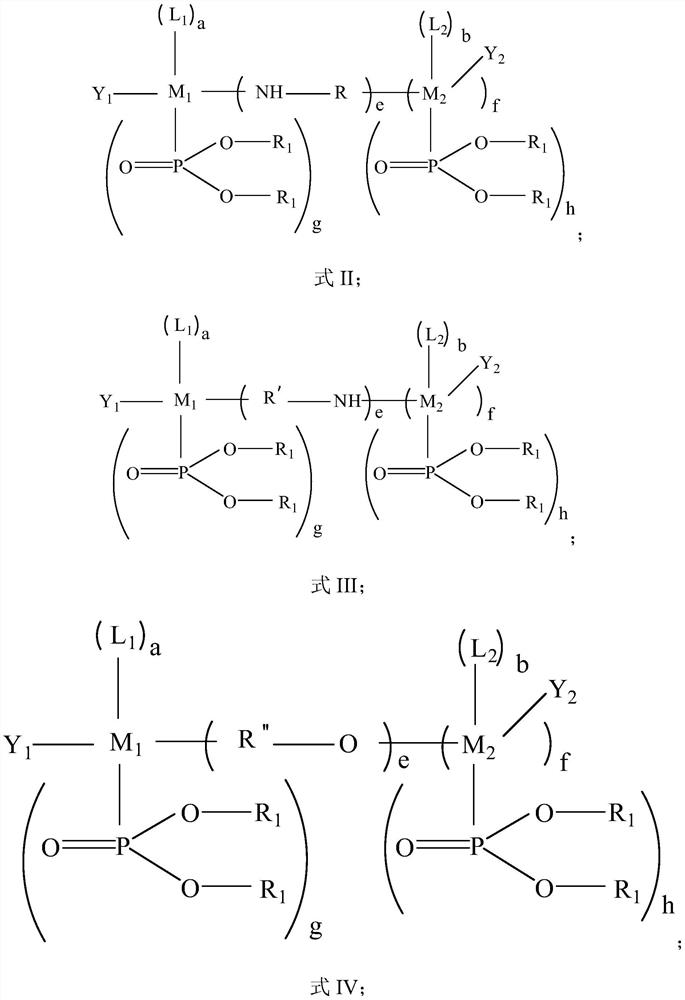

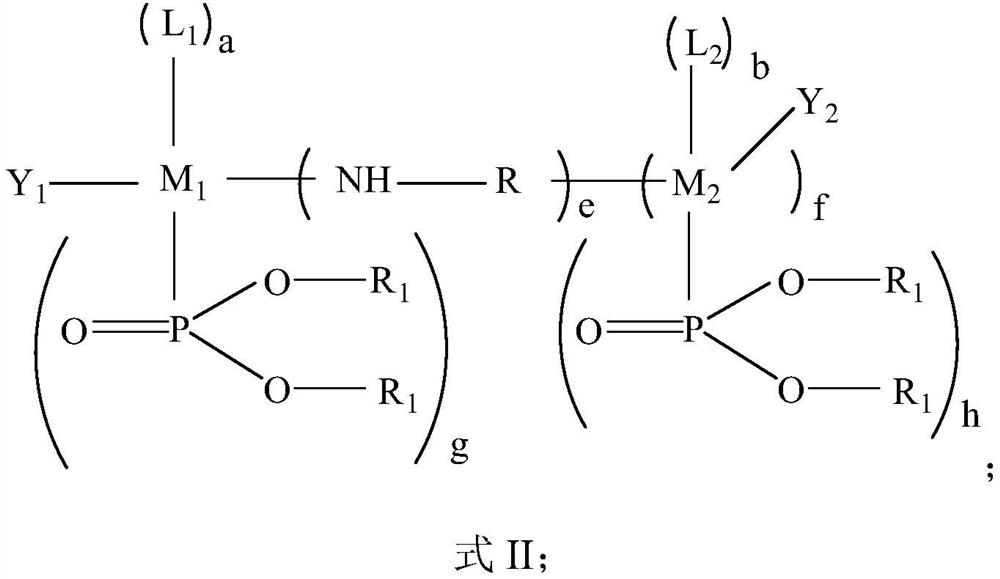

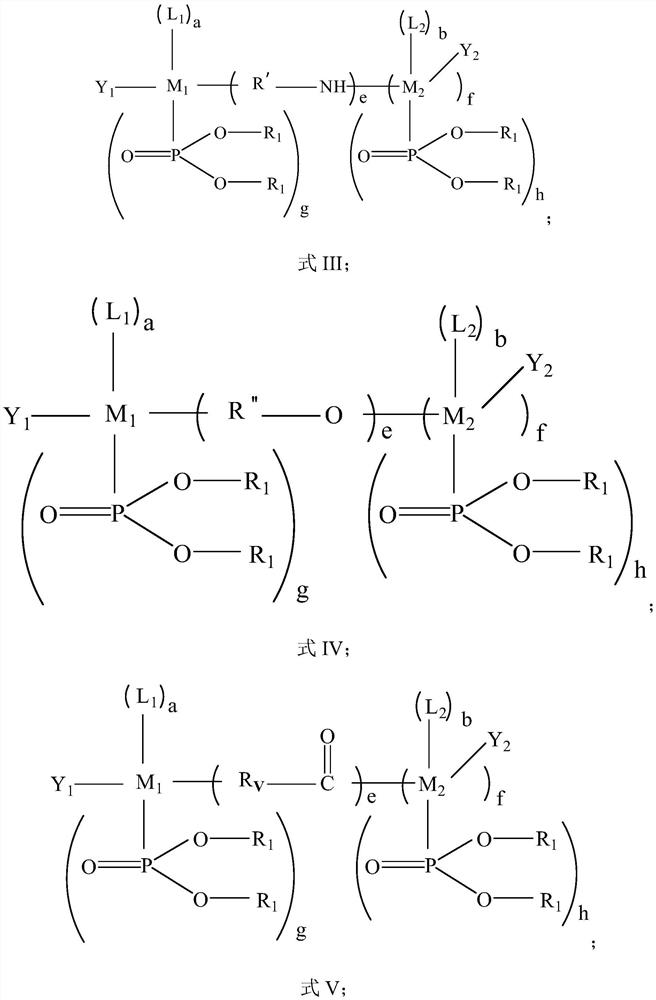

Reactive flame retardant for epoxy resin as well as preparation method and application of reactive flame retardant

ActiveCN112300369AImprove flame retardant performanceImprove flame retardant stabilityGroup 5/15 element organic compoundsEpoxyPolymer science

The invention provides a reactive flame retardant for epoxy resin as well as a preparation method and application of the reactive flame retardant. The reactive flame retardant comprises a first synthetic product obtained by reacting 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide with succinic anhydride, and a second synthetic product obtained by reacting the 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide with 2,4-diaminothiazole. The flame retardant provided by the invention can effectively improve the flame retardant property of the epoxy resin, and can enable the epoxy resin to maintain good transparency and mechanical properties.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

High-temperature-resistant and high-pressure-resistant thin-wall insulated wire cable for railway passenger car

InactiveCN112820450AReduce thicknessImprove insulation performanceInsulated cablesCable/conductor manufactureSODIUM METAPHOSPHATEElectrical conductor

The invention belongs to the technical field of wire and cable materials, particularly relates to a high-temperature-resistant and high-pressure-resistant thin-wall insulated wire and cable for a railway passenger car, and solves the problems of heavy overall weight, large size, low tensile strength, poor electrical property, poor physical and mechanical properties, poor cable safety performance and the like of the wire and cable for the railway passenger car in the prior art. The high-temperature-resistant and high-pressure-resistant thin-wall insulated wire cable for the railway passenger car comprises a conductor, an insulating layer wrapped outside the conductor, a wrapping layer wrapped outside the insulating layer, a braid layer wrapped outside the wrapping layer and an outer sheath wrapped outside the braid layer, and the outer sheath comprises the following raw materials: polyvinyl chloride, polyester resin, sodium metaphosphate, phthalate, butylated hydroxytoluene and a flame retardant. The outer sheath material for the electric wire and cable of the railway passenger car has the advantages of simple and easily available raw materials, simple preparation, excellent high-temperature and high-pressure resistance, flame retardance, tensile strength and elongation at break.

Owner:河北亿正线缆有限公司

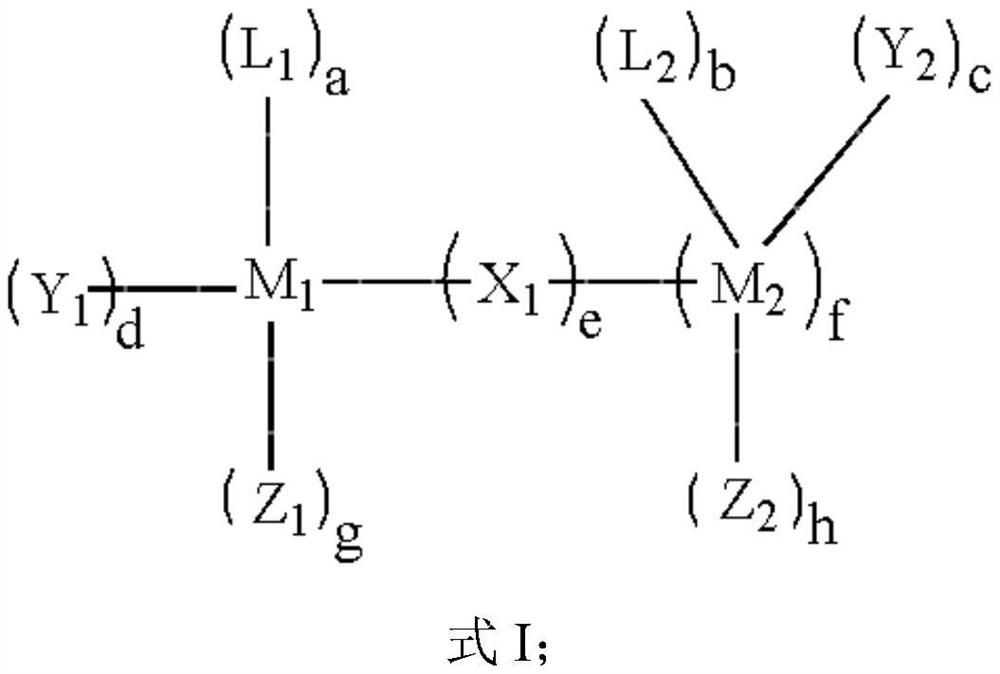

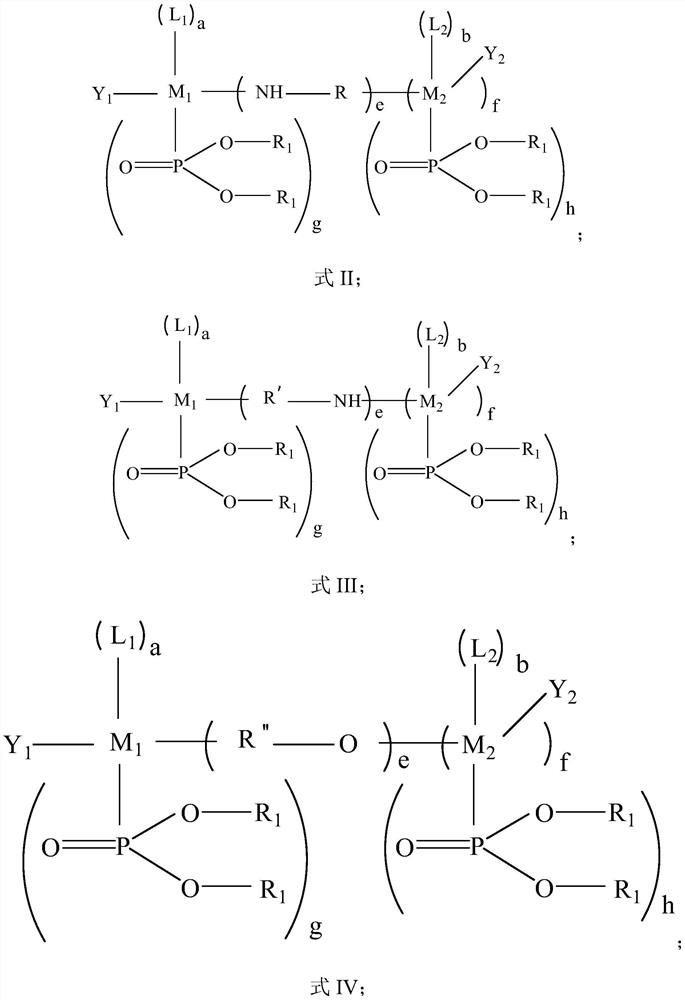

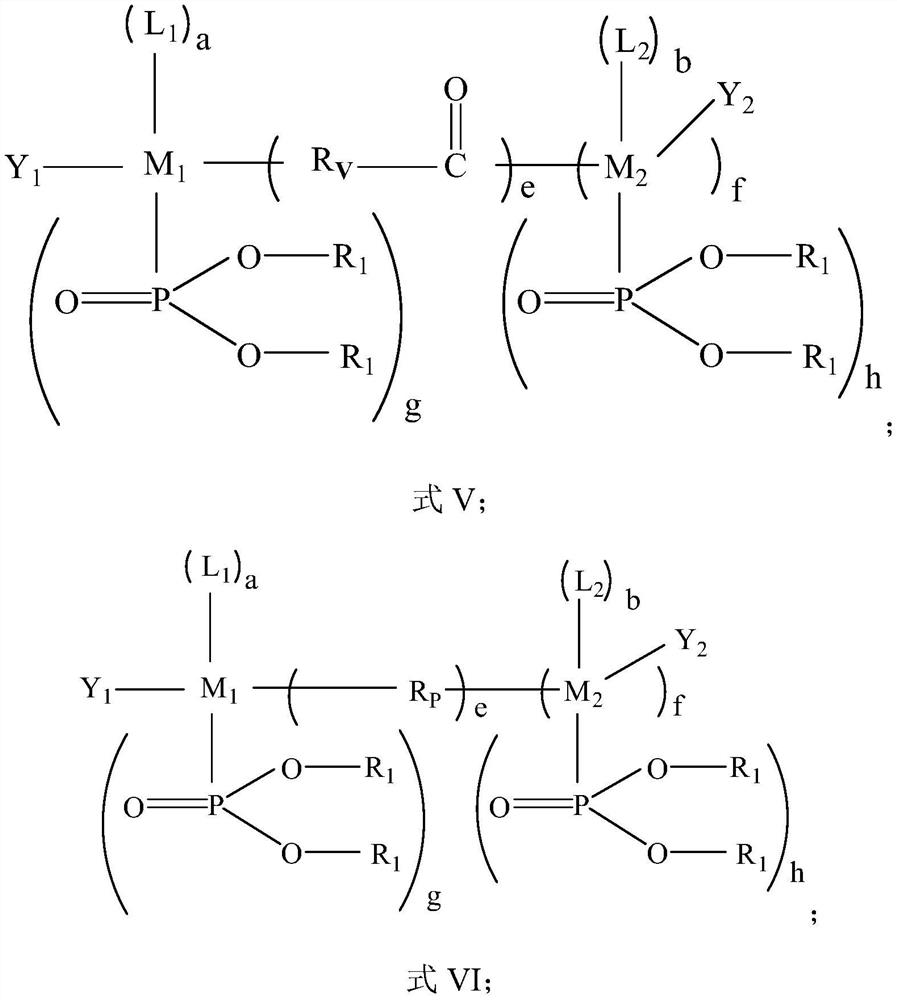

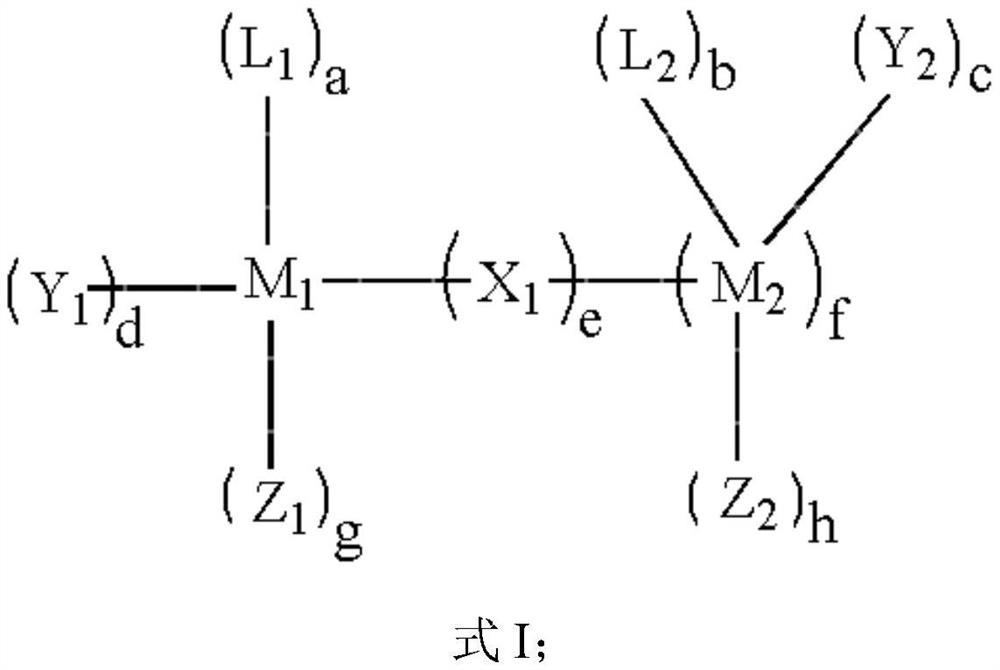

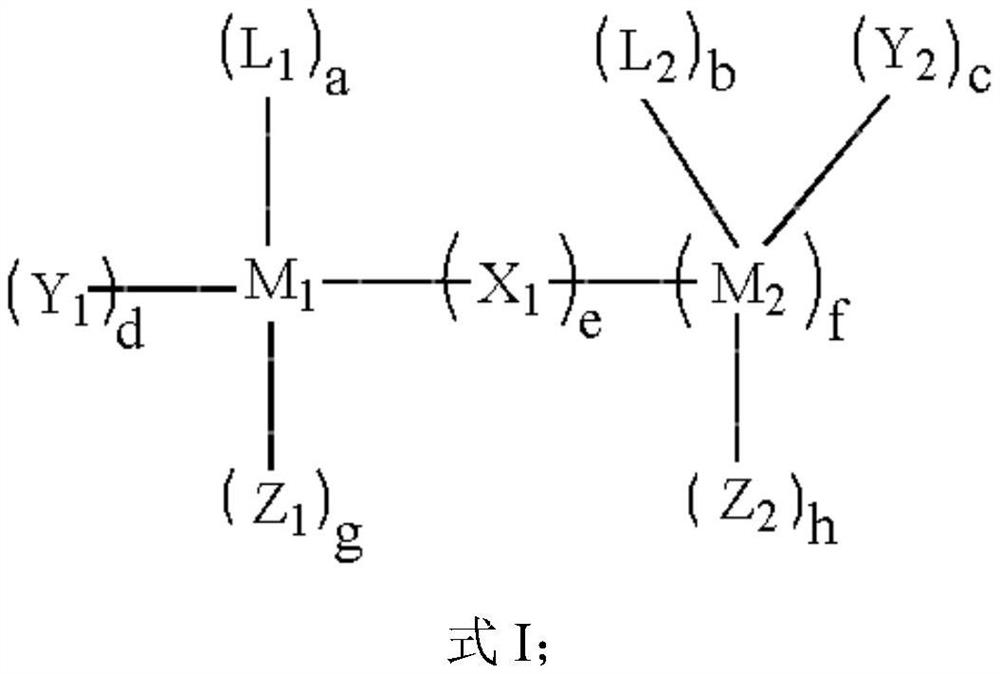

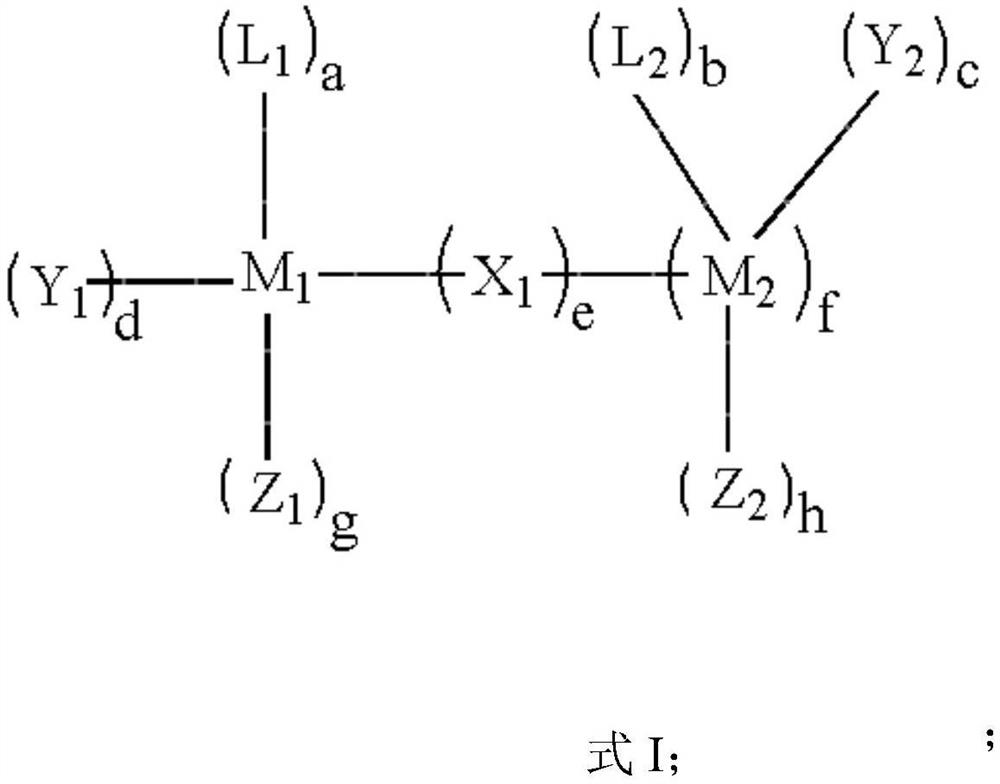

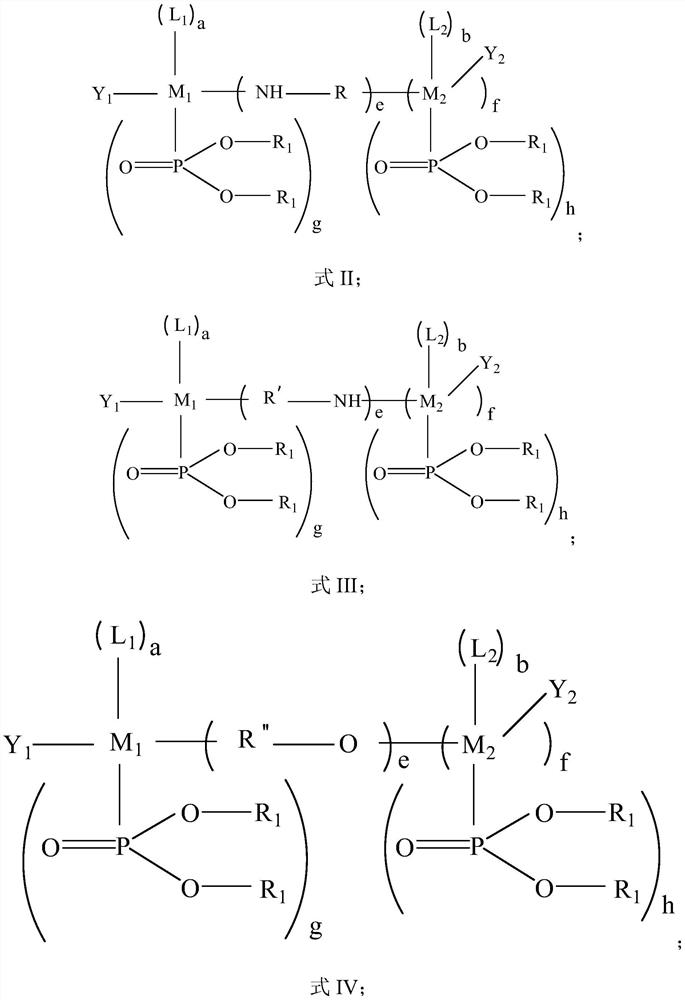

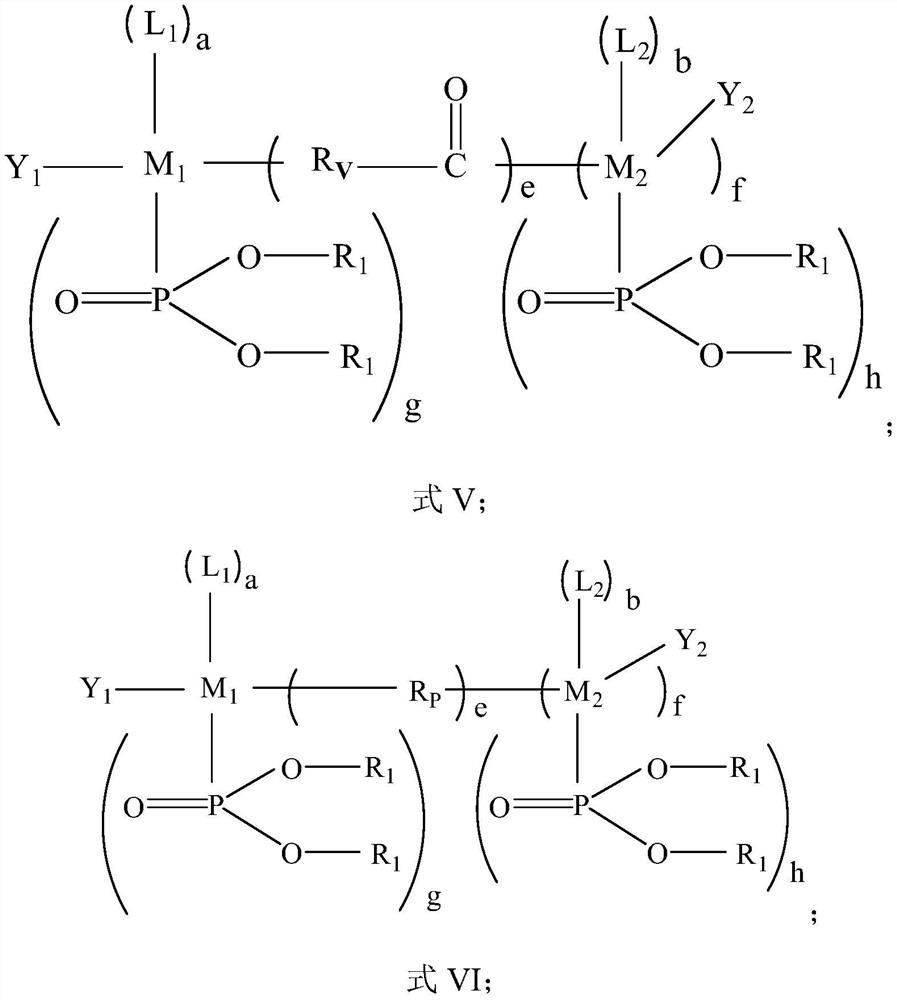

Macromolecular flame retardant, preparation method and application thereof

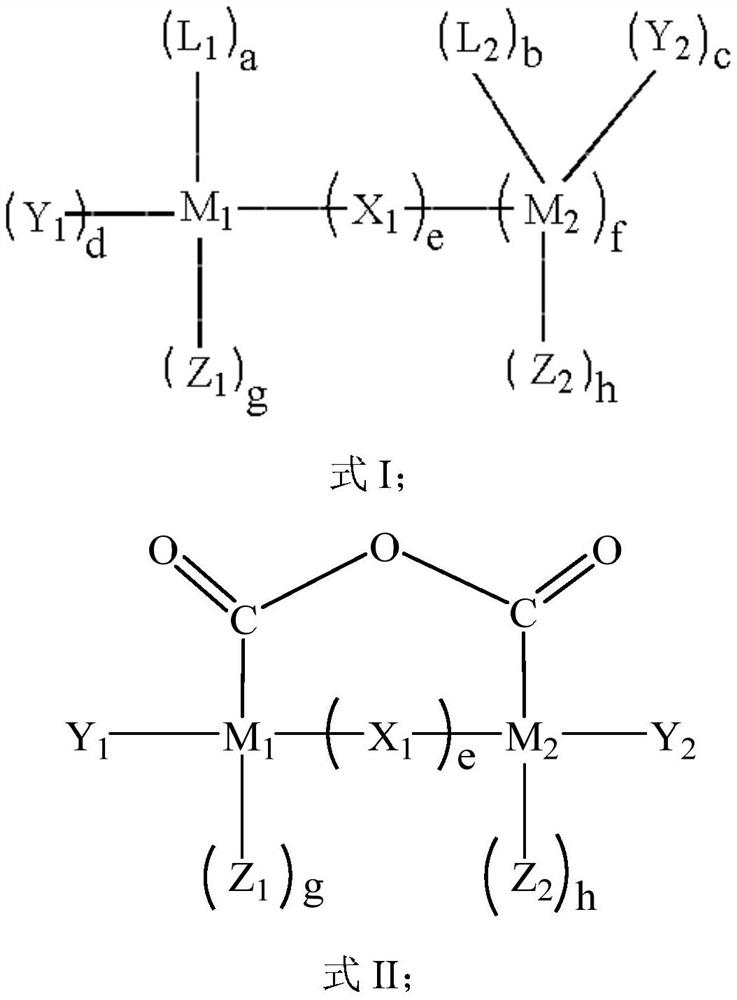

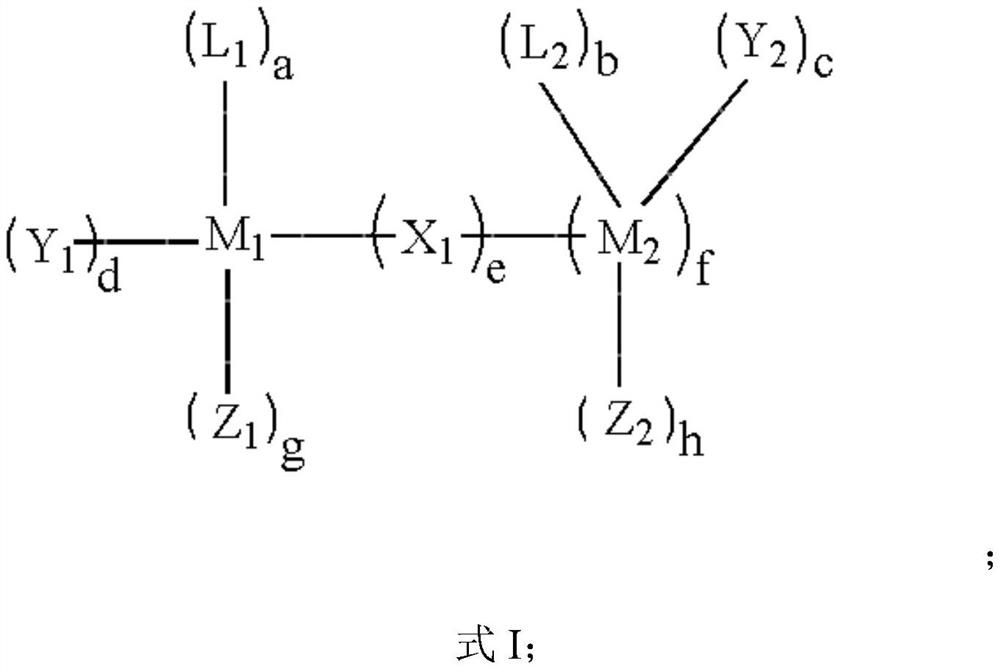

PendingCN112480294AImprove flame retardant performanceGood light stabilityActive agentStructural unit

The invention provides a macromolecular flame retardant, a preparation method and application thereof. The macromolecular flame retardant comprises a light stabilizer, an initiator, an active agent and a phosphorus-containing flame retardant with a structure shown in a formula I. According to the invention, in a preparation process of a macromolecular flame retardant, under the action of an initiator and an active agent, a phosphorus-containing flame retardant is used as a monomer structure unit for polymerization, so that the finally obtained macromolecular flame retardant has better flame retardance, micromolecule migration and precipitation cannot be generated, safety and environmental protection are truly realized, the obtained macromolecular flame retardant also has light stability byin combination with the light stabilizer, and the specific phosphorus-containing flame retardant and the light stabilizer are matched for use, so that the light stability of the flame retardant can be further improved; and the preparation method of the polymer flame retardant is simple, the raw materials are easy to obtain, the price is low, implementation is convenient, and wide industrial application prospects are achieved.

Owner:GUANGDONG GUANGSHAN NEW MATERIALS CO LTD

Method for preparing flame-resisting polyester in phosphorus series

The invention relates to a method for manufacturing phosphorus-based flame-retardant polyester, which comprises the use of purified terephthalic acid, ethylene glycol, catalysts, and auxiliary agents for esterification, and adding ethylene glycol propionate before polymerization after esterification The mixture of ester group ethylene glycol phenylphosphate, 2-carboxyethylphenylphosphoric acid and ethylene glycol flame retardant is polycondensed according to a conventional polycondensation process to obtain flame retardant polyester chips. The fibers and fabrics made of flame-retardant polyester chips produced by this method have good flame-retardant stability, and can keep the flame-retardant performance basically unchanged after dyeing. The flame-retardant performance LOI of curtain fabric products exceeds 32%. There are few kinds of raw materials, the process flow is simple, and the economic cost can be reduced.

Owner:SHAOXING SANLIDA TEXTILE FLAME RETARDANT NEW MATERIALS

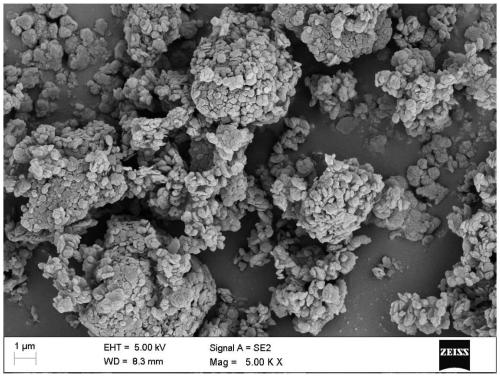

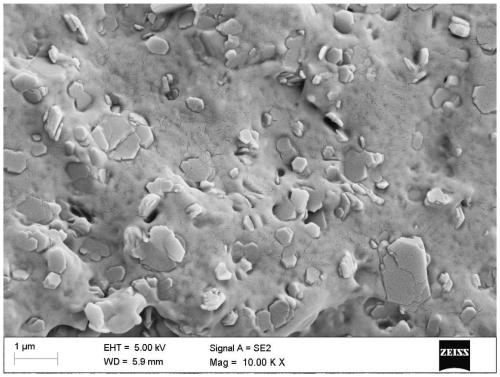

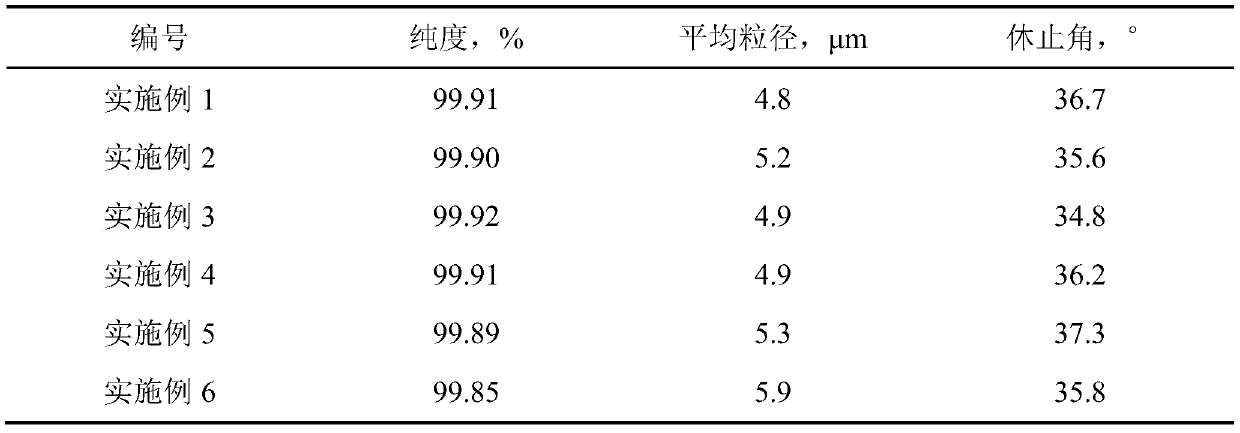

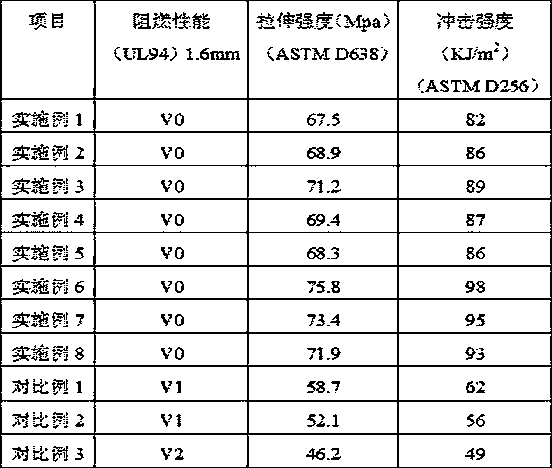

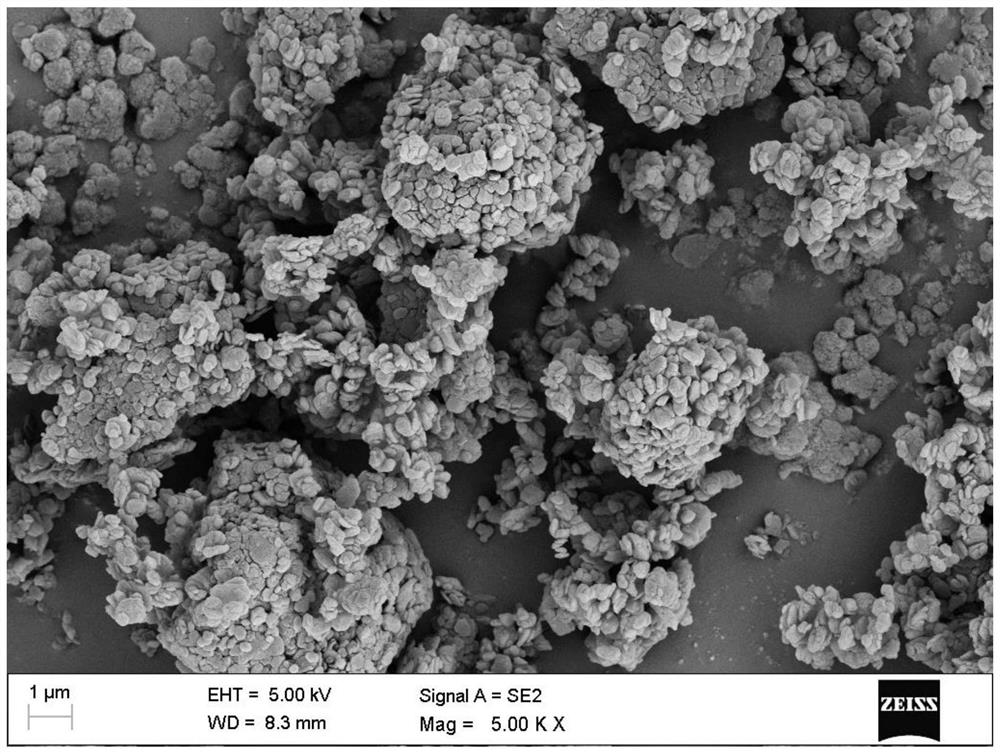

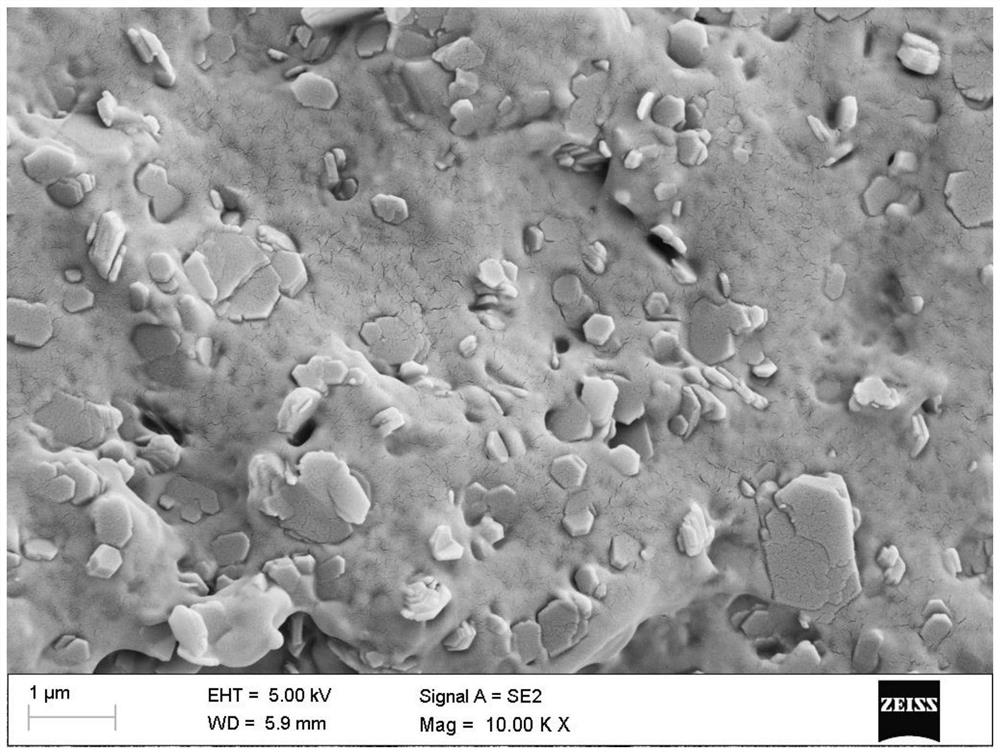

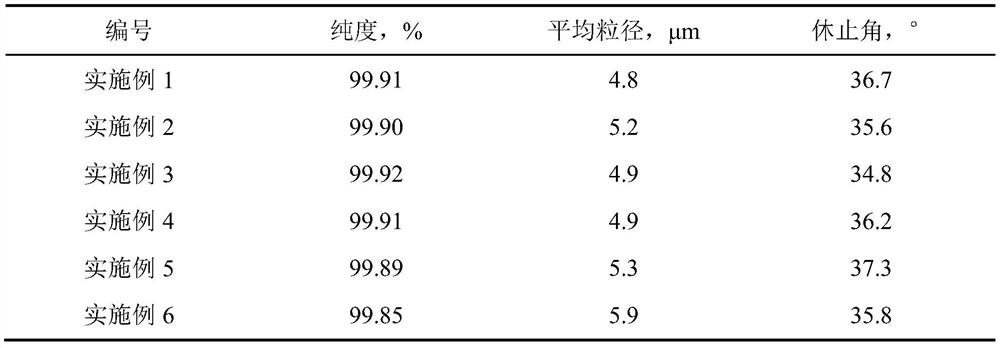

Preparation method for melamine cyanurate nanosheet microsphere and application thereof

The invention discloses a preparation method for a melamine cyanurate nanosheet microsphere and an application thereof. The preparation method comprises the following steps: performing a mixing reaction on a cyanuric acid, melamine, water and a dispersant in a double-planetary-type mixing machine and preparing melamine cyanurate, adding the dispersant in a reaction process, reducing interface freeenergy, and reducing a hydrogen bond binding force between nanosheets, thereby controlling agglomeration between the nanosheets, and forming 4-6 um of nanosheet microspheres. A product prepared by the preparation method has the advantages of good powder flowability, easy dispersion and high inflaming retarding efficiency, and is easy to feed and process in a PA66 application process. The nanosheet has a very large specific surface area, so the flame retarding effect of the melamine cyanurate is promoted to be developed, and flame retarding efficiency is improved.

Owner:JINAN TAIXING FINE CHEM

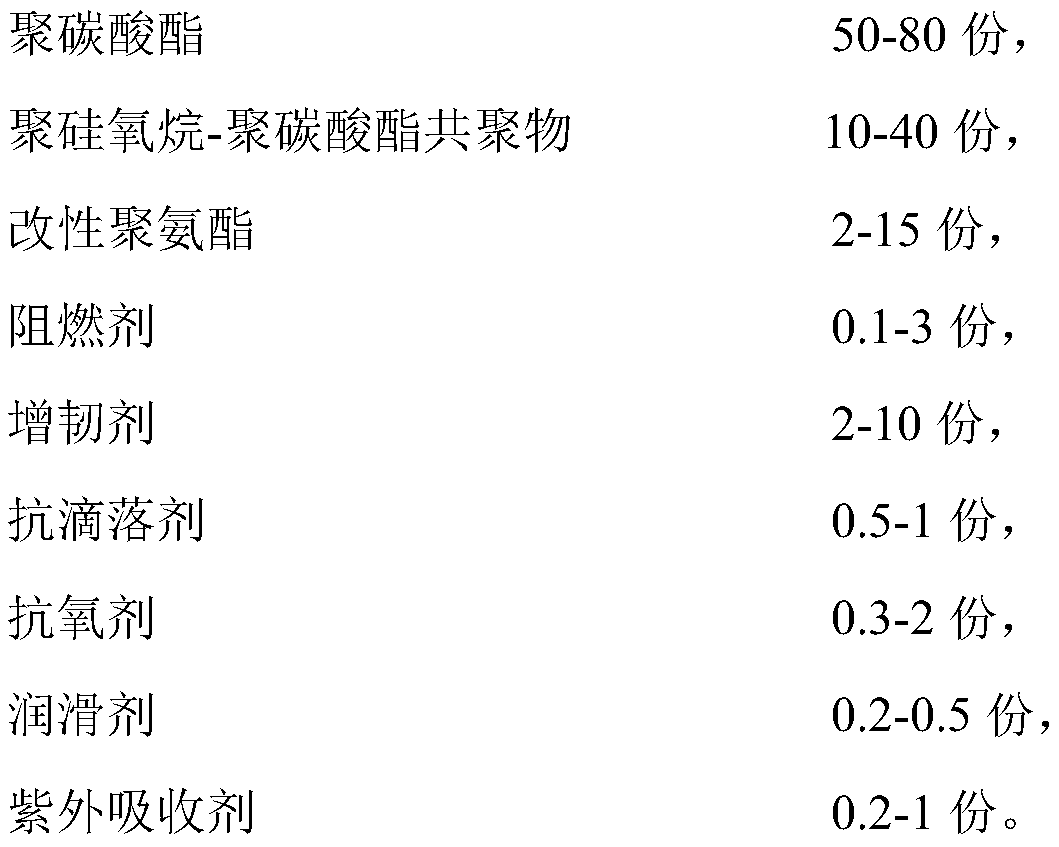

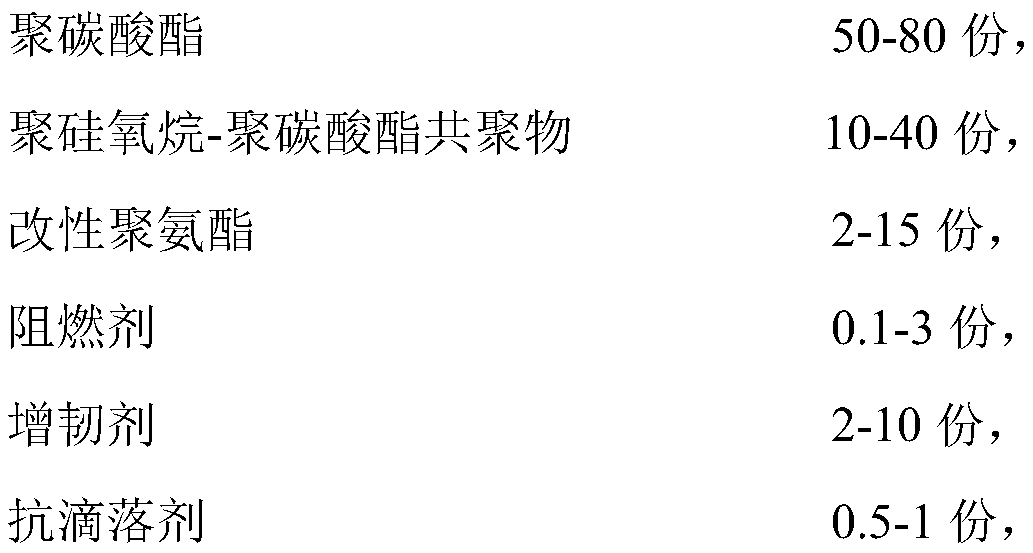

Halogen-free flame-retardant polycarbonate alloy resistant to cold and hot alternation and preparation method thereof

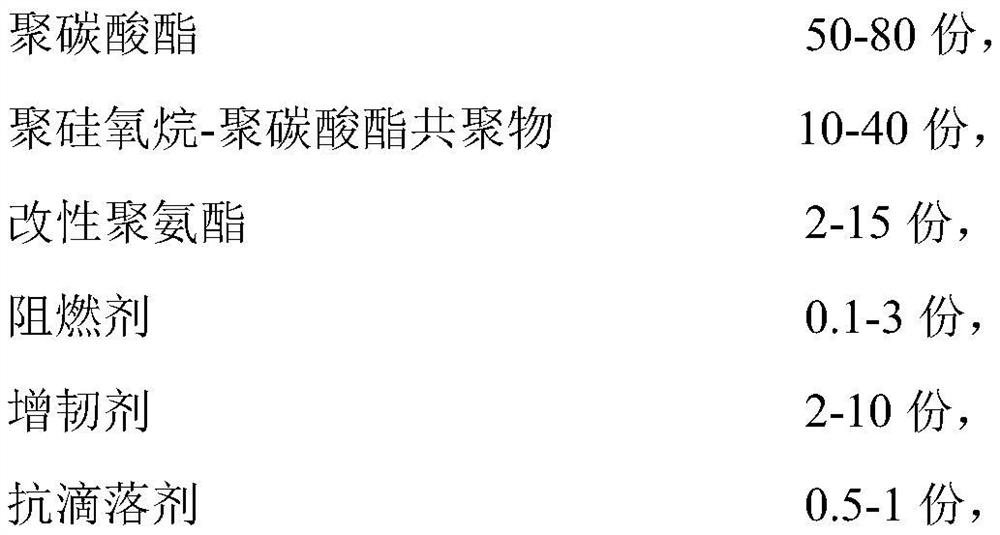

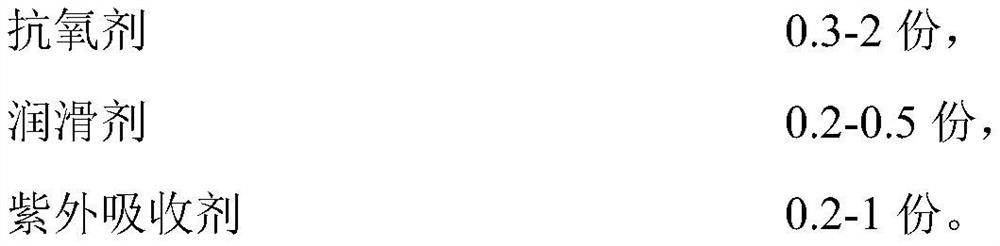

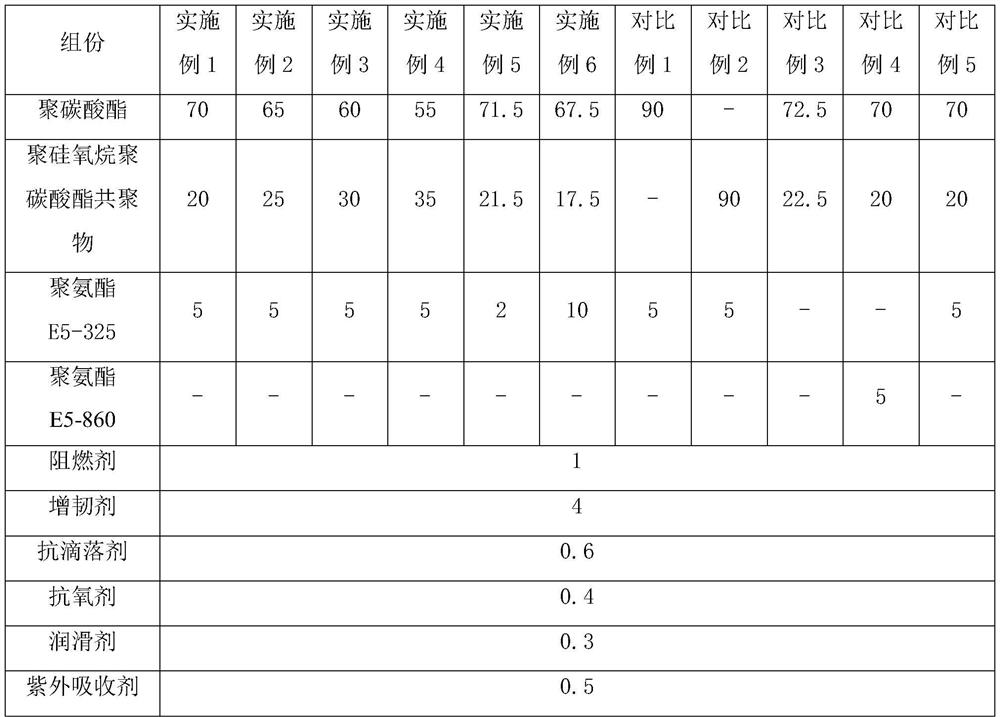

The invention discloses a halogen-free flame-retardant polycarbonate alloy resistant to cold and hot alternation and a preparation method thereof. The halogen-free flame-retardant polycarbonate alloyis prepared from 50 to 80 parts of polycarbonate, 10 to 40 parts of a polysiloxane-polycarbonate copolymer, 2 to 15 parts of a modified polyurethane, 0.1 to 3 parts of a flame retardant, 2 to 10 partsof a toughening agent, 0.5 to 1 part of an anti-dripping agent, 0.3 to 2 parts of an antioxidant, 0.2 to 0.5 part of a lubricating agent and 0.2 to 1 part of an ultraviolet absorbent. The halogen-free flame-retardant polycarbonate alloy has excellent flame retardant property, and the flame retardant level of a sample strip with the thickness of 1.6 mm reaches the UL94-V0 level. Meanwhile, the polysiloxane-polycarbonate copolymer and the modified polyurethane are added into conventional polycarbonate raw materials; while good processing fluidity is guaranteed, the internal stress of the material is reduced, the impact performance of the material under the cold and hot alternating condition is improved, and the material can be applied to occasions with high requirements on cold resistance,heat resistance and flame retardance in the construction industry, the industry, electronics, electrics and the like, and has wide market application prospects.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Flame-retardant epoxy resin composition, preparation method and application thereof

PendingCN112480373AEfficient and environmentally friendly flame retardant effectImprove mechanical propertiesPolymer scienceFirming agent

The invention provides a flame-retardant epoxy resin composition, a preparation method and application thereof. The flame-retardant epoxy resin composition is prepared from epoxy resin, a flame-retardant curing agent and a curing accelerator, wherein the flame-retardant curing agent has a structure shown in a formula I and contains phenolic hydroxyl and phosphorus-containing flame-retardant groups. According to the invention, phenolic hydroxyl in the flame-retardant curing agent and epoxy resin are subjected to a curing reaction, the curing efficiency is high, flame-retardant groups finally exist in the flame-retardant epoxy resin composition in the form of molecular fragments, the phenomenon that small molecules are separated out is avoided, the phenomenon that some additive flame retardants are easily dissolved in water to be separated out or hydrolyzed is also avoided, and high-efficiency environment-friendly flame retardance is truly realized; and the flame-retardant epoxy resin composition provided by the invention has excellent flame-retardant performance and mechanical performance, a copper-clad plate prepared from the flame-retardant epoxy resin composition has high flame-retardant performance and dielectric performance, the preparation process is simple, the raw materials are easy to obtain, and the flame-retardant epoxy resin composition has a wide industrial application prospect.

Owner:GUANGDONG GUANGSHAN NEW MATERIALS CO LTD

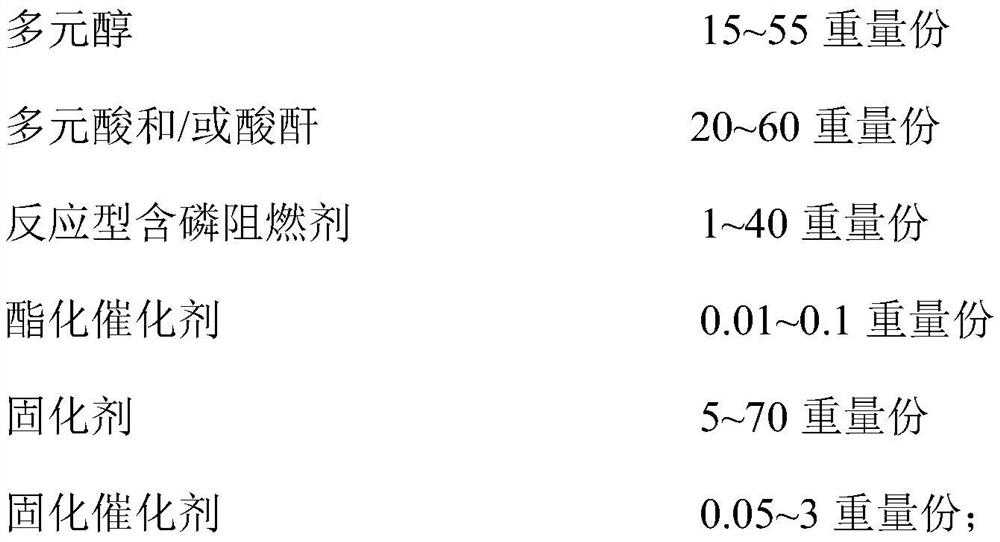

Polyester resin composition, preparation method and application thereof

The invention provides a polyester resin composition, a preparation method and application thereof. The polyester resin composition is prepared from polyol, polybasic acid and / or anhydride, a reactivephosphorus-containing flame retardant, an esterification catalyst, a curing agent and a curing catalyst, wherein the reactive phosphorus-containing flame retardant has a structure shown in a formulaI or a formula II, and contains carboxyl or anhydride reaction groups. According to the invention, the reactive phosphorus-containing flame retardant is used as a reaction monomer to participate in esterification reaction of polyester resin synthesis, and finally exists in a polyester resin composition in the form of molecular chain segments, so that the phenomena of micromolecule precipitation, water dissolution or hydrolysis are avoided, and efficient and stable environment-friendly flame retardance is truly realized; and the polyester resin composition provided by the invention has excellent flame retardant property, mechanical property and chemical resistance, the preparation process is simple, the raw materials are easy to obtain, and the polyester resin composition has a wide industrial application prospect.

Owner:GUANGDONG GUANGSHAN NEW MATERIALS CO LTD

High-stability halogen-free environmental-friendly fire retardant used for plastic, and preparation method thereof

ActiveCN109897357AOvercome resilienceImprove heat resistanceBulk chemical productionHeat resistanceFumed silica

The invention relates to a high-stability halogen-free environmental-friendly fire retardant used for plastic, and a preparation method thereof. The high-stability halogen-free environmental-friendlyfire retardant used for plastic is prepared from, by weight, 45 to 80 parts of modified polyorganosiloxane, 20 to 32 parts of fumed silica, 8 to 15 parts of modified diatomite, 2 to 5 parts of a surface treatment agent, and 1 to 2 parts of polyethylene wax. Compared with the prior art, the high-stability halogen-free environmental-friendly fire retardant is excellent in flame resistance, smoking inhibition effect, and plastifying effect, is safe and reliable, is low in cost, contains no toxic additive, is capable of improving mechanical process performance, flame resistance, and heat resistance of base materials, reducing smoke formation amount effectively, inhibiting generation of carbon dioxide, and satisfying novel type fire retardant halogen-free phosphorus-free environmental-protection requirements; the raw materials are widely available.

Owner:东莞浩联新材料科技有限公司

A kind of preparation method and application of melamine cyanurate nano sheet microsphere

The invention discloses a method for preparing melamine cyanurate nanosheet microspheres and its application. In the invention, cyanuric acid, melamine, water and a dispersant are mixed and reacted in a double planetary mixer to prepare melamine cyanurate. A dispersant is added during the reaction to reduce the interfacial free energy and the hydrogen bonding force between the nanosheets, thereby controlling the agglomeration between the nanosheets and forming 4-6 μm nanosheet microspheres. The product of the present invention has the advantages of good powder fluidity, easy dispersion, and high flame retardant efficiency; it is easy to cut and process PA66 in the application process; the nanosheet has a very large specific surface area, which promotes the flame retardant effect of melamine cyanurate The play, improve the flame retardant efficiency.

Owner:JINAN TAIXING FINE CHEM

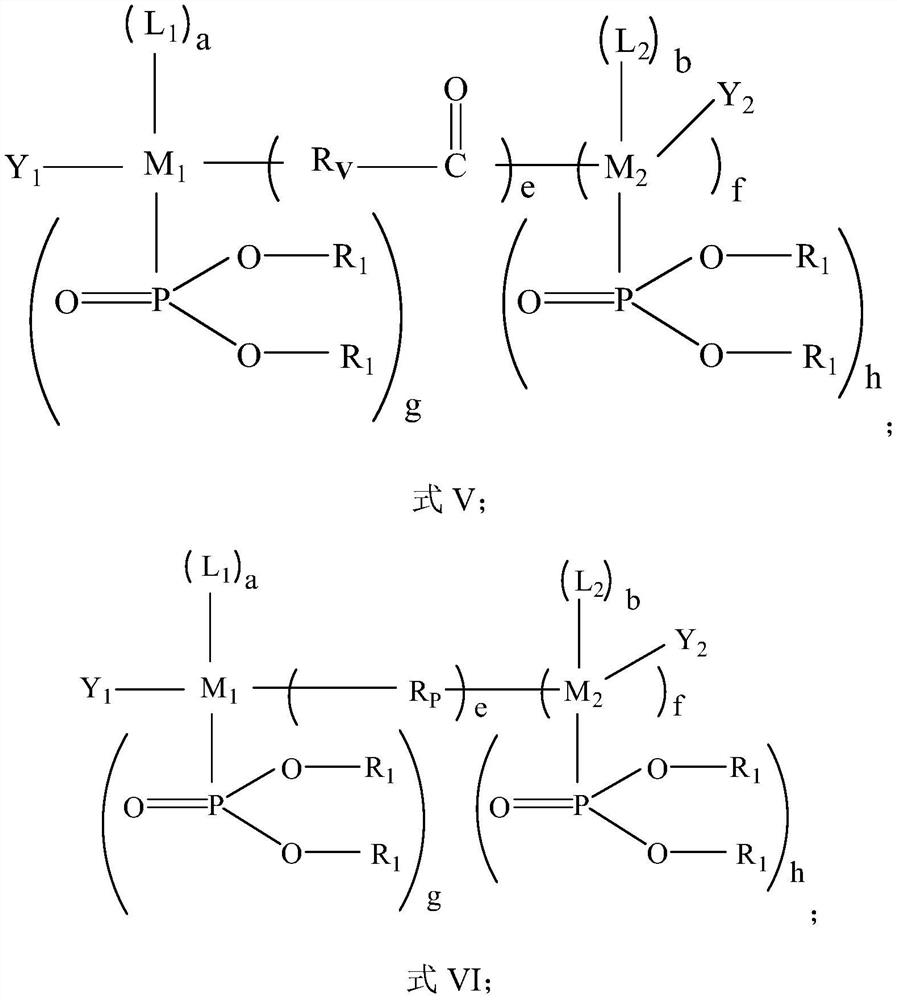

Acrylate copolymer, preparation method and application thereof

The invention provides an acrylate copolymer, a preparation method and application thereof. The acrylate copolymer comprises acrylate, methacrylic acid, an initiator and a phosphorus-containing flameretardant with a structure as shown in a formula I, and has relatively good flame retardant property and flame retardant stability on the premise of having proper bonding strength and flexibility. According to the invention, a phosphorus-containing flame retardant is creatively used as a polymer monomer, and a flame retardant group is grafted into an acrylate copolymer in the form of a stable chemical bond, so that the acrylate copolymer has better flame retardancy, the flame retardant is prevented from being separated out in the form of small molecules in the reuse process, the phenomena thatthe flame retardant is dissolved in water to be separated out or hydrolyzed and the like are avoided, and efficient environment-friendly flame retardance is truly achieved; and the acrylate copolymerhas the advantages of simple preparation method, accessible raw materials, low price and wide industrial application prospects, and is convenient to implement.

Owner:GUANGDONG GUANGSHAN NEW MATERIALS CO LTD

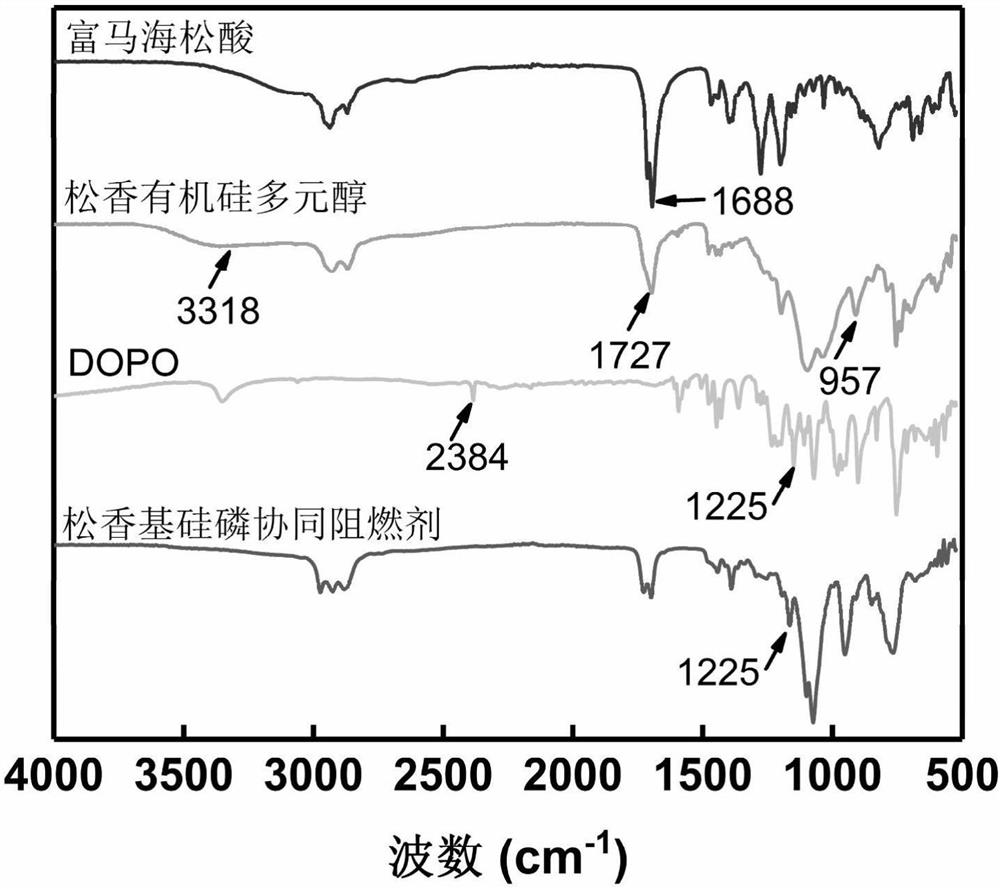

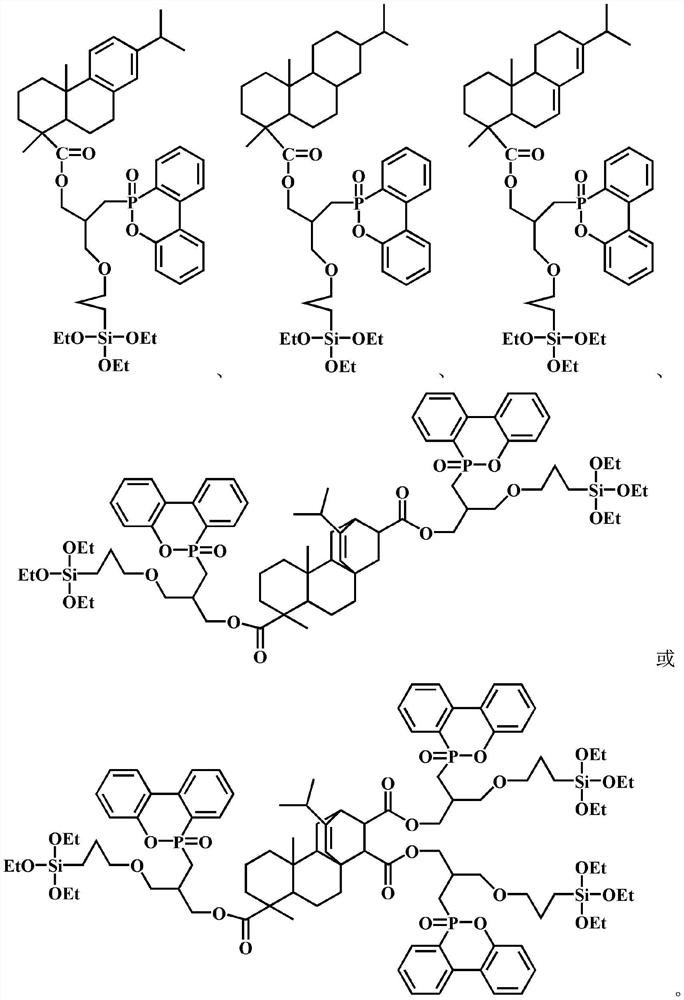

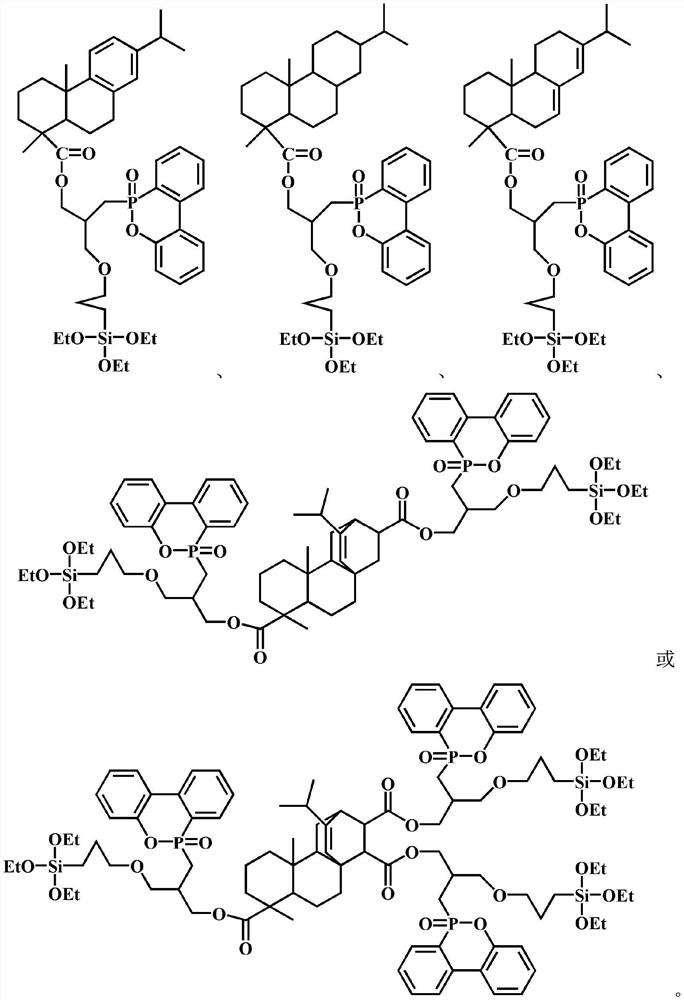

A kind of rosin-based silicon-phosphorus synergistic flame retardant, its preparation method and polyurethane foam prepared therefrom

ActiveCN112341495BTo achieve an organic combinationImprove thermal stabilityGroup 5/15 element organic compoundsChemical reactionHeat stability

The invention discloses a rosin-based silicon-phosphorus synergistic flame retardant, the structural formula of which is: etc. The present invention realizes the organic combination of silicon-phosphorus elements through the chemical reaction of rosin and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, and under the action of synergistic mechanism, the preparation The obtained flame retardant has higher thermal stability and flame retardancy; the introduction of rosin-based silicon-phosphorus synergistic flame retardant enhances the stability and flame retardancy of rigid foam polyurethane, and also enhances the rigid foam polyurethane Excellent mechanical properties, meet the application requirements of building insulation boards, box packaging and other fields, and the dosage is small, the introduction of polyurethane through chemical combination, no flame retardant overflow phenomenon, good flame retardant stability.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

A kind of halogen-free flame retardant polycarbonate alloy resistant to alternating heat and cold and preparation method thereof

The invention discloses a halogen-free flame retardant polycarbonate alloy resistant to alternating cold and heat and a preparation method thereof; the alloy comprises: 50-80 parts of polycarbonate, and 10-10 parts of polysiloxane-polycarbonate copolymer 40 parts, 2-15 parts of modified polyurethane, 0.1-3 parts of flame retardant, 2-10 parts of toughening agent, 0.5-1 part of anti-drip agent, 0.3-2 parts of antioxidant, 0.2-0.5 part of lubricant , 0.2‑1 part of UV absorber. The alloy has excellent flame retardant properties, and the flame retardant level of the 1.6mm thickness spline reaches the UL94‑V0 level. At the same time, polysiloxane-polycarbonate copolymer and modified polyurethane are added to the conventional polycarbonate raw materials, which not only ensures good processing fluidity, but also helps to reduce the internal stress of the material and improve the material's performance under alternating cold and heat conditions. It can be used in construction, industry, electronic and electrical and other occasions with high requirements for cold resistance, heat resistance and flame retardant, and has a wide range of market application prospects.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

A kind of heat-resistant oxygen aging low-precipitation MCA flame-retardant pa66 composite material and its application

ActiveCN110698854BHigh flame retardant gradeImprove flame retardant stabilityZinc borateResin matrix

Owner:合诚技术股份有限公司

Alkyd resin composition, preparation method and application thereof

The invention discloses an alkyd resin composition, a preparation method and application thereof. The alkyd resin composition comprises anhydride, tricyclic diterpene resin acid, epoxy resin, an initiator, a catalyst and a phosphorus-containing flame retardant with a structure shown in a formula I. According to the invention, the phosphorus-containing flame retardant is connected with acid anhydride through tricyclic diterpene resin acid by chemical bonds, and epoxy resin is added, so that the obtained alkyd resin composition has higher hardness and better flame retardance, cannot be separatedout due to migration of small molecules, cannot be separated out due to high solubility in water, and is environment-friendly, safe and harmless; and the alkyd resin composition has the advantages ofsimple preparation method, low price and accessible raw materials, and is suitable for industrial large-scale production and application.

Owner:GUANGDONG GUANGSHAN NEW MATERIALS CO LTD

Polyamide resin composition, preparation method and application thereof

The invention discloses a polyamide resin composition, a preparation method and application thereof, wherein the polyamide resin comprises 1,4-cyclohexane dicarboxylic acid, glass fiber, styrene-isoprene copolymer, a vulcanizing agent and a phosphorus-containing flame retardant with a structure as shown in a formula I. According to the invention, the phosphorus-containing flame retardant is connected with maleic anhydride and terephthalic acid through chemical bonds, and is matched with other substances for use, so that the obtained polyamide resin composition has better tensile strength, elongation at break, air and moisture permeability and flame retardance, cannot be separated out due to migration of small molecules, cannot be dissolved in water easily, is environment-friendly and pollution-free, and does not need to consider the compatibility of the flame retardant and the base material and whether the properties of the polyamide resin are influenced when the flame retardant is added as an additive.

Owner:GUANGDONG GUANGSHAN NEW MATERIALS CO LTD

A kind of halogen-free flame-retardant pet material and preparation method thereof

The invention provides a halogen-free flame-retardant PET material, which comprises the following components in parts by weight: 40-60 parts of PET, 25-40 parts of halogen-free phosphorus copolyester flame retardant, and 3-7 parts of auxiliary flame retardant , 5-20 parts of glass fiber, 1-3 parts of compatibilizer, 0.1-1 part of coupling agent, 0.5-2 parts of antioxidant II. The present invention synthesizes a high-efficiency P-containing flame retardant through a polymerization reaction. The existence of P flame-retardant elements can improve the flame retardancy of polymers by changing the thermal degradation process of the polymer matrix, and by combining with P and N The compounding of combustion aids further improves the flame-retardant stability of the polymer, and then through the selection and dosage control of reaction aids, a halogen-free flame-retardant PET material is prepared. The flame retardant PET material prepared by the invention has excellent flame retardant effect, excellent mechanical properties, high and low temperature resistance, chemical resistance and excellent gas, water, oil, odor and other performances.

Owner:BEIJING CO FOUND HIGH TECH INCUBATOR

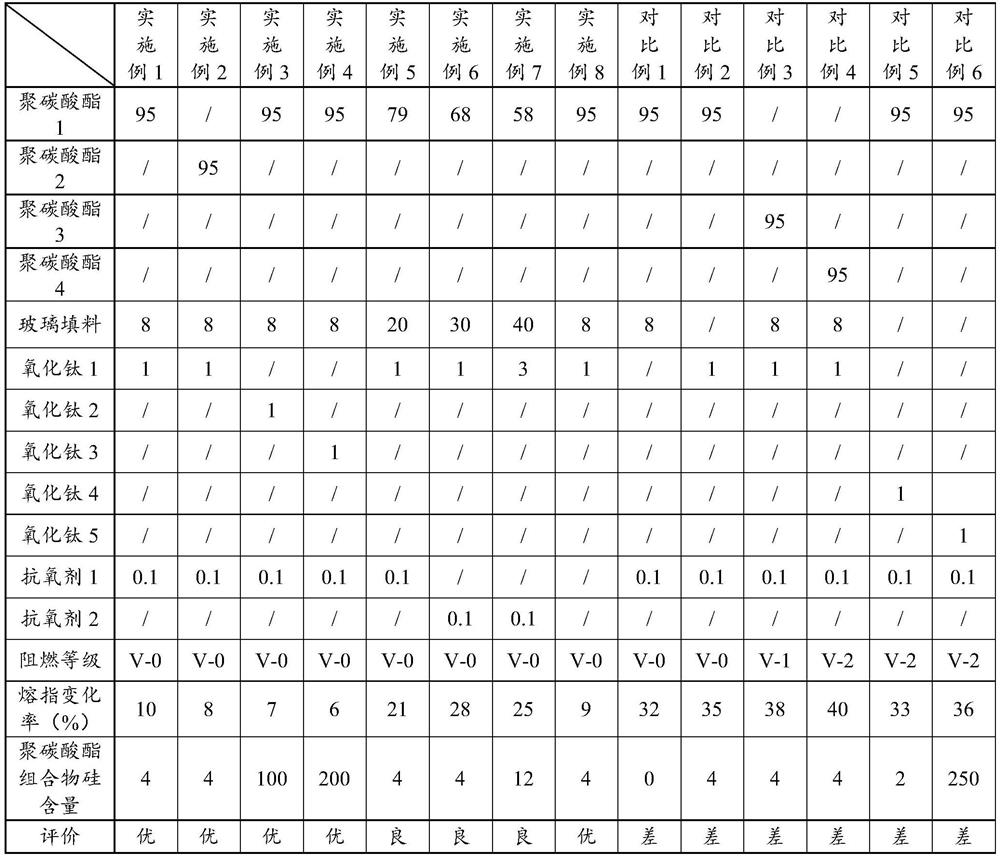

Polycarbonate composition as well as preparation method and application thereof

PendingCN114773818AImprove flame retardant stabilityReduce negative impactPolymer scienceEngineering plastic

The invention belongs to the technical field of engineering plastics, and discloses a polycarbonate composition as well as a preparation method and application thereof. The polycarbonate composition disclosed by the invention is prepared from the following components in parts by weight: 58 to 95 parts of polycarbonate, 8 to 40 parts of glass filler and 0.1 to 1 part of titanium oxide. The invention also provides a preparation method of the polycarbonate composition, and application of the polycarbonate composition in outdoor CPE (chlorinated polyethylene). According to the polycarbonate composition disclosed by the invention, the distribution interval of the glass filler is regulated and controlled by using the titanium oxide with specific silicon content, the negative influence of the length of the glass filler on flame retardance is reduced, stress concentration is dispersed, and internal stress is reduced, so that the flame-retardant stability of the material is improved, and the performance can be kept stable in a humid and hot environment.

Owner:KINGFA SCI & TECH CO LTD

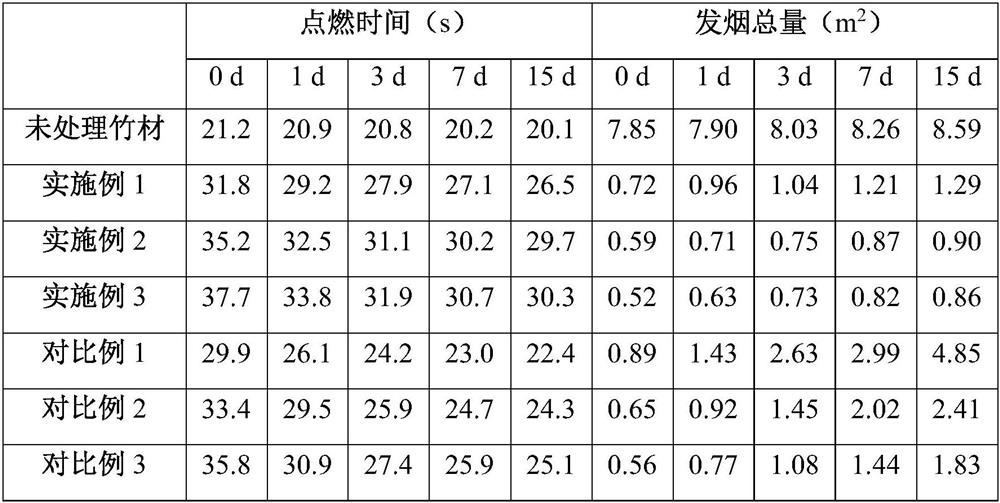

A kind of flame retardant modification treatment method of bamboo

ActiveCN110587759BGood dispersionImprove stabilityWood treatment detailsReed/straw treatmentDi-isocyanateDiphenylmethane diisocyanate

The invention discloses a bamboo material flame-retardant modification treatment method, and belongs to the technical field of bamboo product flame-retardant treatment. The bamboo material flame-retardant modification treatment method comprises the steps that: firstly, a 4, 4'-diphenylmethane diisocyanate solution is used for conducting primary modification treatment on bamboo wood, and then a 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide solution is used for conducting secondary modification treatment on the bamboo wood. According to the bamboo wood flame-retardant modification treatment method, the flame retardance and flame-retardant stability of the bamboo wood can be remarkably improved, the treatment process is simple to operate and easy to control, and industrial large-batch production can be conveniently achieved.

Owner:福建省顺昌县升升木业有限公司

A kind of flame-retardant polycarbonate composite material and preparation method thereof

The invention discloses a flame-retardant polycarbonate composite material, which comprises the following components in parts by weight: 60-100 parts of polycarbonate; 1-25 parts of flame retardant; the weight-average molecular weight of the polycarbonate Greater than 26000, the molecular weight distribution index PDI is less than 2.2, the pH of the polycarbonate solution is 6.7-7.1, and the Tg temperature changes after multiple cycles. The present invention finds that when the polycarbonate is within the above parameter range, the flame retardant has less influence on the stability of the polycarbonate.

Owner:KINGFA SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com