Polyamide resin composition, preparation method and application thereof

A technology of polyamide resin and composition, applied in the field of polyamide resin composition and preparation thereof, can solve the problems of poor flame retardant stability, affect the mechanical properties of polyamide resin, and the wear resistance needs to be improved, and achieve good tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

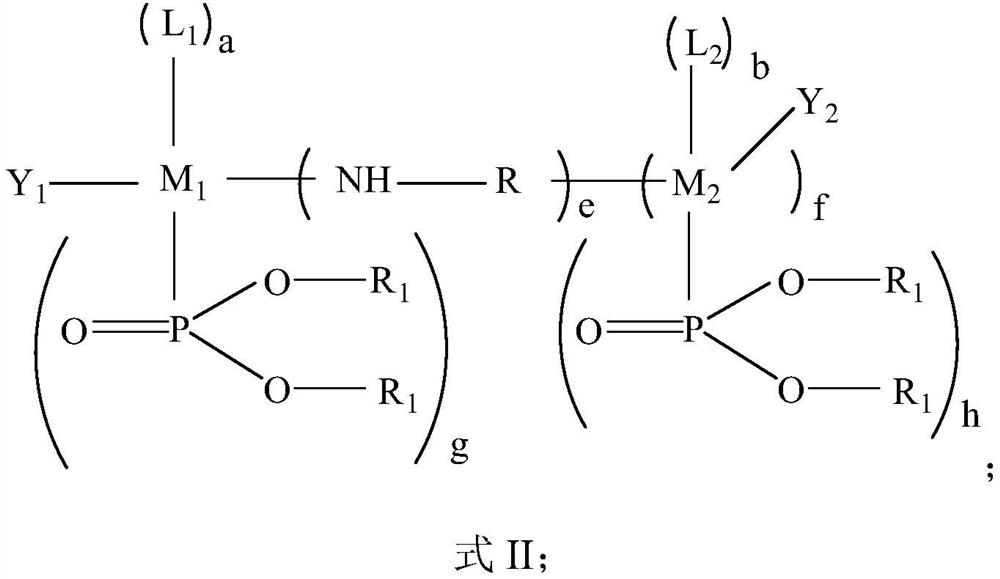

[0089] A phosphorus-containing flame retardant with the following structure:

[0090]

[0091] The preparation method is as follows:

[0092]Add 1 mol of diethylenetriamine and 1 mol of dimethyl hydroxymethyl phosphite, 200 mL of ethanol, 0.1 mol of sodium hydroxide, and 0.1 g of DMAP into a three-necked flask equipped with magnetic stirring and a thermometer, heat up to ethanol reflux, and react for 12 hours. Then add hydrochloric acid until the pH is 7, filter and wash to remove impurities, and obtain the phosphorus-containing flame retardant with the above structure.

[0093] 1 H NMR (400MHz, DMSO-d6): δ=5.00-5.03(s, 2H, -N H 2 ),3.48-3.50(d,6H,-P-O-CH 3 ),3.03-3.06(s,2H,-P-C H 2 -),2.85-2.88(t,2H,-NH-CH 2 -C H 2 -NH 2 ),2.65-2.68(t,2H,-NH-C H 2 -CH 2 -NH 2 ),2.51-2.55(s,4H,-NH-C H 2 -C H 2 -NH-).

preparation example 2

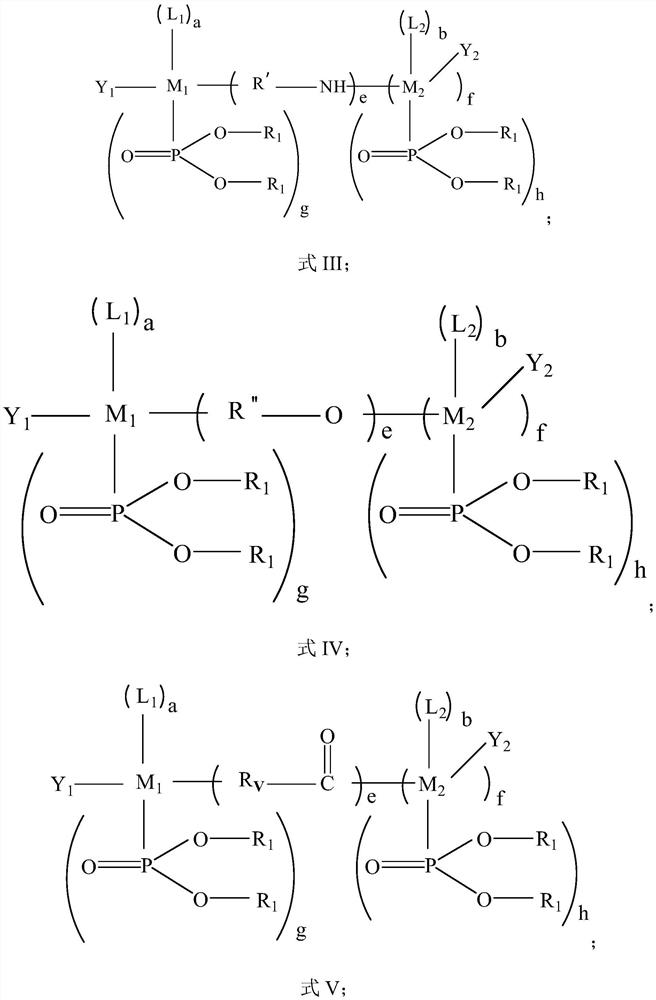

[0095] A phosphorus-containing flame retardant with the following structure:

[0096]

[0097] The preparation method is as follows:

[0098] (1) Under a nitrogen atmosphere, put 200mL glacial acetic acid, 0.5mol dimethyl phosphite and 0.5mol maleic acid into a three-port 500mL glass reactor with a stirring device and stir. At a stirring temperature of 60°C, 0.5mmol The Pb catalyst was dissolved in 20mL of glacial acetic acid, then added dropwise to the reaction system, reacted for 12h, and then separated the product;

[0099] 1 H NMR (400MHz, DMSO-d6) δ = 13.52-13.54 (s, 1H, -CH-CO-O H ),12.98-13.00(s,1H,-CH 2 -CO-O H ),3.47-3.49(d,6H,-P-O-CH 3 ),2.85-2.90(t,1H,-CH-),2.78-2.81(d,2H,-C H 2 -).

[0100] (2) Mix 1 mol of the product obtained in step (1), 2 mol of thionyl chloride and 200 mL of chloroform, react at reflux temperature, then add 1 mol of ethylenediamine and 0.1 mol of triethylamine to react for 30 minutes to obtain product B;

[0101] 1 H NMR (400MHz...

preparation example 3

[0108] A phosphorus-containing flame retardant with the following structure:

[0109]

[0110] The preparation method is as follows:

[0111] (1) Under a nitrogen atmosphere, put 200mL glacial acetic acid, 0.5mol dimethyl phosphite and 0.5mol maleic acid into a three-port 500mL glass reactor with a stirring device and stir. At a stirring temperature of 60°C, 0.5mmol The Pb catalyst was dissolved in 20mL of glacial acetic acid, then added dropwise to the reaction system, reacted for 12h, and then separated the product;

[0112] 1 H NMR (400MHz, DMSO-d6) δ = 13.52-13.54 (s, 1H, -CH-CO-O H ),12.98-13.00(s,1H,-CH 2 -CO-O H ),3.47-3.49(d,6H,-P-O-C H 3 ),2.85-2.90(t,1H,-CH-),2.78-2.81(d,2H,-C H 2 -).

[0113] (2) Mix 3 mol of the product obtained in step (1), 2 mol of thionyl chloride and 600 mL of chloroform, react at reflux temperature, then add 3 mol of ethylenediamine and 0.3 mol of triethylamine to react for 0.5 h to obtain the product;

[0114] (3) 1mol of diethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com