A kind of rosin-based silicon-phosphorus synergistic flame retardant, its preparation method and polyurethane foam prepared therefrom

A polyurethane foam, synergistic flame retardant technology, applied in the field of polyurethane foam, can solve the problems of uneven distribution of flame retardants, limited improvement of flame retardant performance, accelerated combustion speed, etc., to achieve enhancement and stability and flame retardant performance, high thermal stability and flame retardancy, the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

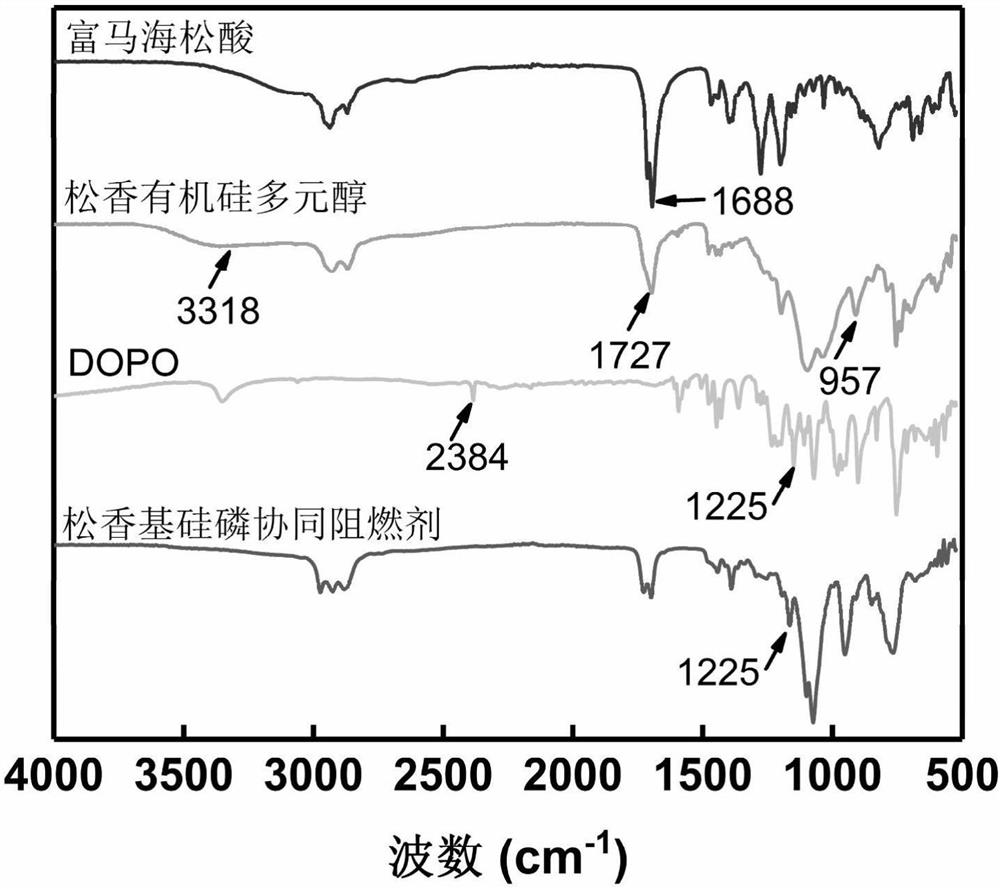

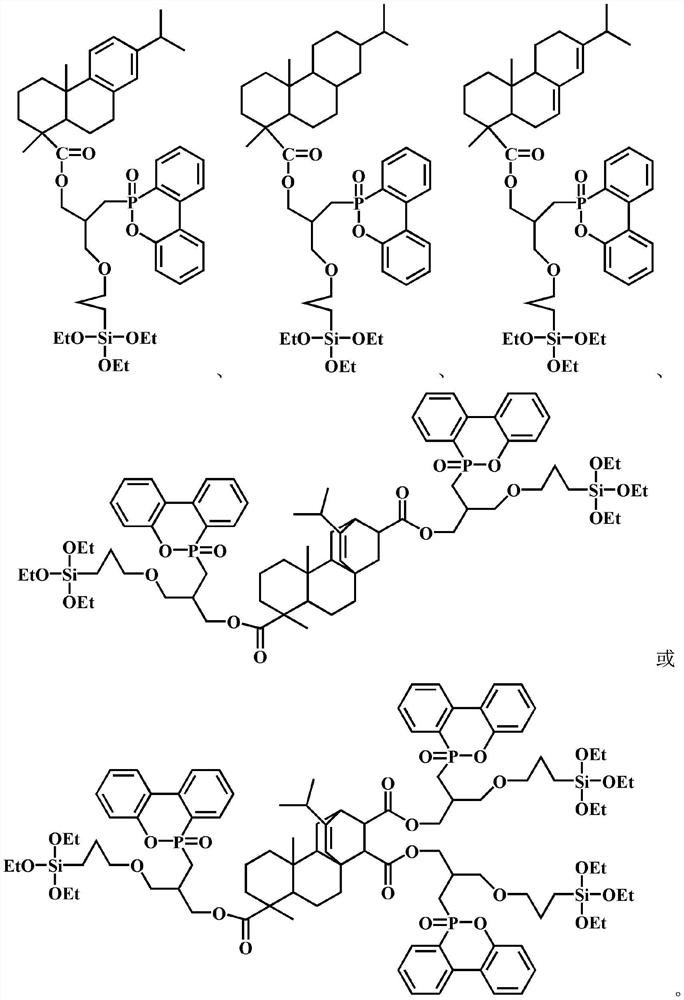

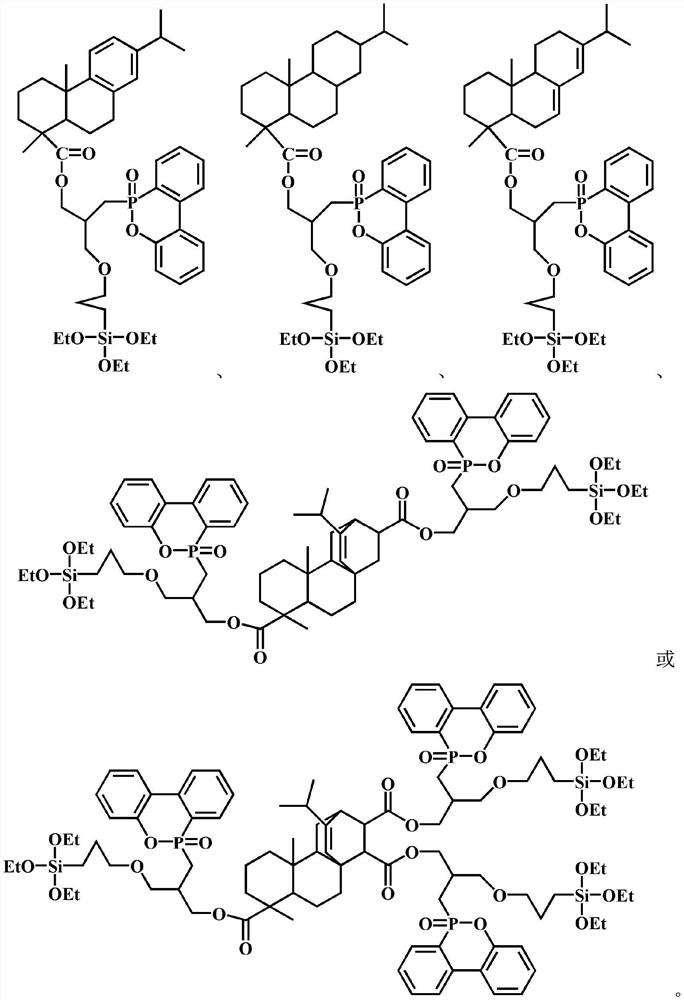

Embodiment 1

[0033] Take by weighing 15 parts by weight of fumopimaric acid and 30 parts by weight of triethoxy (3-epoxypropyloxypropyl) silane (KH-561) in a three-necked flask, add 300 parts by weight of absolute ethanol solvent, under nitrogen Under the conditions of protection and reflux, heat to 90° C., react for 6 hours, and then remove ethanol by rotary evaporation to obtain fumapimaric acid-modified silicone polyol (FASO) in light yellow viscous shape. Weigh 30 parts by weight of fumopimaric acid-modified silicone polyol and dissolve it in 210 parts by weight of methylene chloride in a three-necked flask, weigh 5.1 parts by weight of DOPO (9,10-dihydro-9-oxa-10-phosphorus Heterophenanthrene-10-oxide) and 2.7 parts by weight of triethylamine were dissolved in 30 parts by weight of dichloromethane, and the solution was added to the above-mentioned three-necked flask. Under the condition of an ice bath, the temperature of the system was reduced to between minus 10°C and minus 5°C, and ...

Embodiment 2

[0040]Take by weighing 15 parts by weight of fumopimaric acid and 30 parts by weight of triethoxy (3-epoxypropyloxypropyl) silane (KH-561) in a three-necked flask, add 300 parts by weight of absolute ethanol solvent, under nitrogen Under the conditions of protection and reflux, heat to 90° C., react for 6 hours, and then remove ethanol by rotary evaporation to obtain fumapimaric acid-modified silicone polyol (FASO) in light yellow viscous shape. Weigh 30 parts by weight of fumopimaric acid modified silicone polyol and dissolve it in 210 parts by weight of dichloromethane in a three-necked flask, weigh 5.1 parts by weight of DOPO and 2.7 parts by weight of triethylamine and dissolve it in 30 parts by weight of dichloromethane , and the solution was added to the above-mentioned three-necked flask. Under the condition of an ice bath, the temperature of the system was reduced to between minus 10°C and minus 5°C, and 3.7 parts by weight of carbon tetrachloride was added dropwise wh...

Embodiment 3

[0043] Take by weighing 15 parts by weight of fumopimaric acid and 30 parts by weight of triethoxy (3-epoxypropyloxypropyl) silane (KH-561) in a three-necked flask, add 300 parts by weight of absolute ethanol solvent, under nitrogen Under the conditions of protection and reflux, heat to 90° C., react for 6 hours, and then remove ethanol by rotary evaporation to obtain fumapimaric acid-modified silicone polyol (FASO) in light yellow viscous shape. Weigh 30 parts by weight of fumopimaric acid modified silicone polyol and dissolve it in 210 parts by weight of dichloromethane in a three-necked flask, weigh 5.1 parts by weight of DOPO and 2.7 parts by weight of triethylamine and dissolve it in 30 parts by weight of dichloromethane , and the solution was added to the above-mentioned three-necked flask. Under the condition of an ice bath, the temperature of the system was reduced to between minus 10°C and minus 5°C, and 3.7 parts by weight of carbon tetrachloride was added dropwise w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com