Tear-resistant, peel-resistant and flame-retardant PVC membrane structural material preparation method and product

A technology of peeling resistance and membrane structure, which is applied in the direction of layered products, flame-retardant fibers, chemical instruments and methods, etc., can solve the problems of flame-retardant stability, water-washing durability decline, etc., and achieve superior tear resistance, Effect of improving flame retardant stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

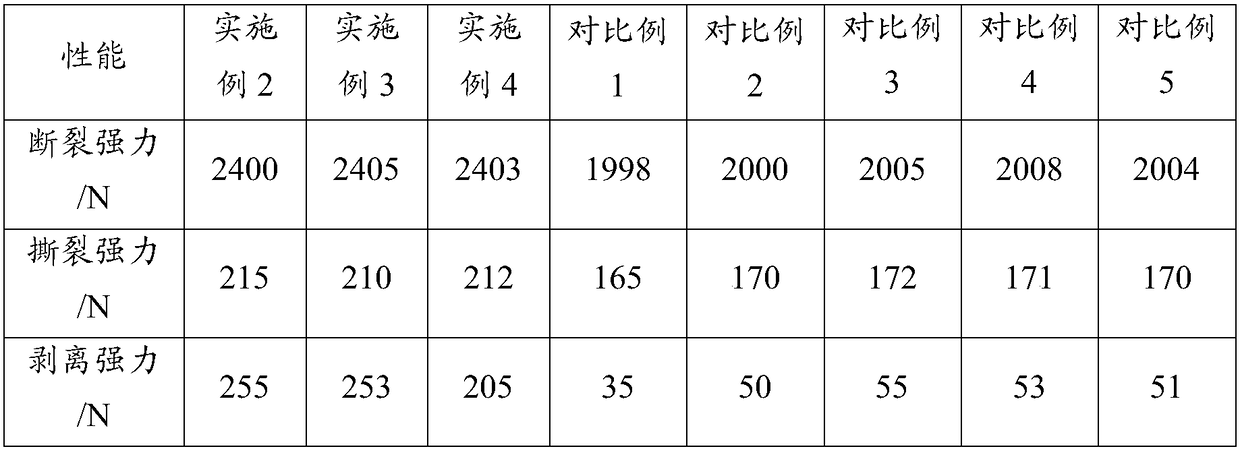

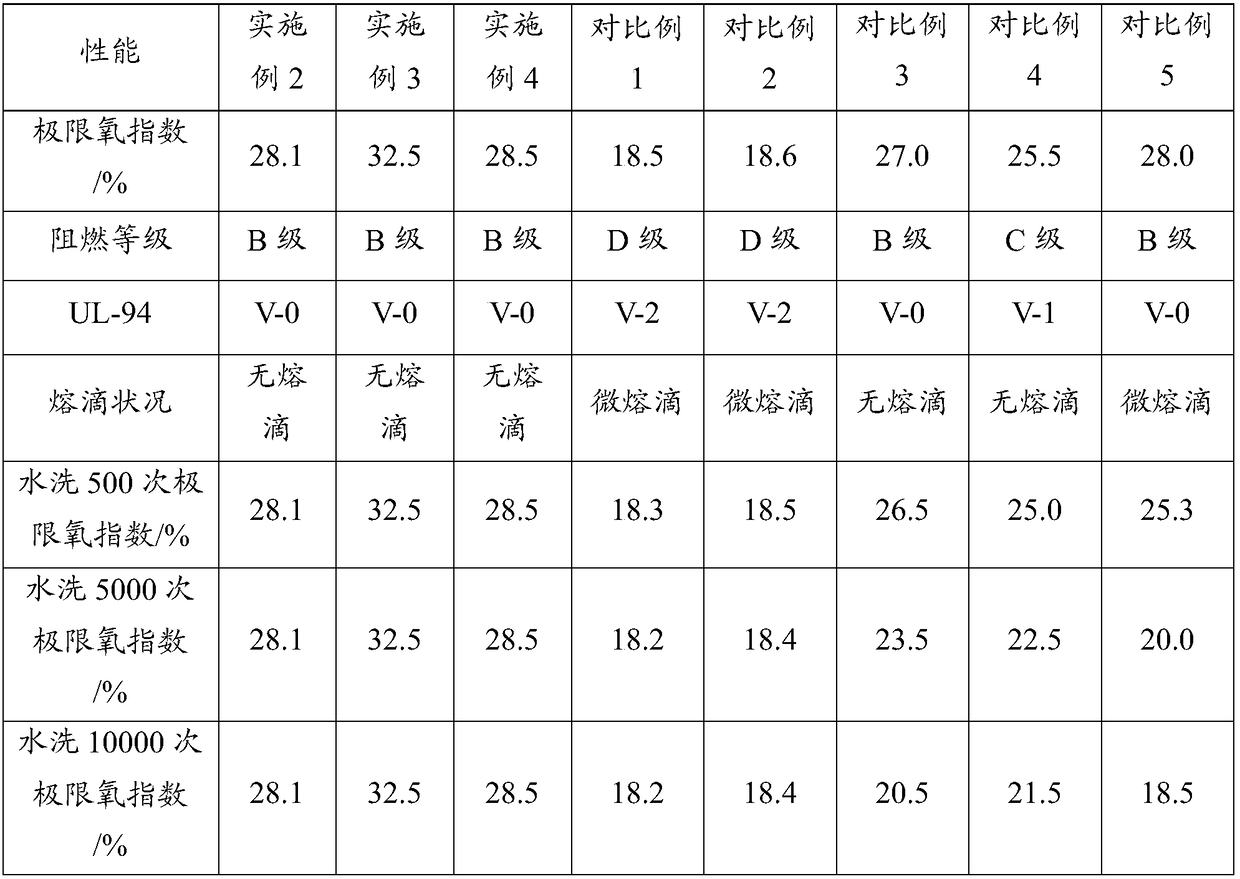

Examples

Embodiment 1

[0036] Embodiment 1: Preparation of modified flame retardant and smoke suppressant

[0037]1) Add 10kg of aluminum sulfate heptahydrate, 10kg of iron sulfate heptahydrate, 10kg of zinc sulfate heptahydrate, 10kg of magnesium sulfate heptahydrate, and 10kg of ammonium polyphosphate into 200kg of water, stir at 25°C for 1 hour until uniformly dispersed, and then add 5wt% Sodium hydroxide, adjust the pH to 10, react at 25°C for 1 h, filter to obtain the precipitate, then wash and dry to obtain the product.

[0038] 2) Add 10kg of the product obtained in step 1 and 10kg of tetraethyl orthosilicate into 200kg of water, add 10kg of absolute ethanol and 1kg of ammonia water, react at 40°C for 8 hours, cool, filter, wash, and dry to obtain the product .

[0039] 3) Add 10kg of the product obtained in step 2) and 2kg of 3-(2,3-epoxypropoxy)propyltrimethoxysilane into 100kg of water, react at 80°C for 3h, cool, filter, Washing and drying to obtain a modified flame retardant and smoke ...

Embodiment 2

[0040] Example 2: Preparation of tear-resistant and peel-resistant flame-retardant PVC film structural material

[0041] 1) With 100kg polyvinyl chloride resin (PSM-31), 60kg diisononyl phthalate, get the 10kg modified flame retardant and smoke suppressant that embodiment 1 prepares, 2.5kg isophorone diisocyanate, 2.5kg Barium zinc heat stabilizer, 2kg fatty alcohol polyoxyethylene ether, 10kg diluent (OS-20), stir at 25°C for 1 hour to obtain PVC impregnation solution.

[0042] 2) Then immerse the industrial high-strength polyester fabric in the PVC impregnation solution of step 1), and then squeeze it through a roller (pressure 5KG, speed 11m / min), dry at 165°C for 1min, and cool to obtain the modified Polyester fabric.

[0043] 3) Preheating the modified polyester fabric obtained in step 2) at 105° C. for 0.75 min.

[0044] 4) Finally, preheat the PVC film with a thickness of 0.1mm at 190°C for 0.75min, then heat press it with the modified polyester fabric obtained in ste...

Embodiment 3

[0045] Example 3: Preparation of tear-resistant and peel-resistant flame-retardant PVC film structural material

[0046] 1) With 100kg polyvinyl chloride resin (PSM-31), 60kg diisononyl phthalate, get the 15kg modified flame retardant and smoke suppressant that embodiment 1 prepares, 2.5kg isophorone diisocyanate, 2.5kg Barium zinc heat stabilizer, 2kg fatty alcohol polyoxyethylene ether, 10kg diluent (OS-20), stir at 25°C for 1 hour to obtain PVC impregnation solution.

[0047] 2) Then immerse the industrial high-strength polyester fabric in the PVC impregnation solution of step 1), and then squeeze it through a roller (pressure 5KG, speed 11m / min), dry at 165°C for 1min, and cool to obtain the modified Polyester fabric.

[0048] 3) Preheating the modified polyester fabric obtained in step 2) at 105° C. for 0.75 min.

[0049] 4) Finally, preheat the PVC film with a thickness of 0.1mm at 190°C for 0.75min, then heat press it with the modified polyester fabric obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com