Preparation method for melamine cyanurate nanosheet microsphere and application thereof

The technology of melamine cyanurate and melamine is applied in the field of preparation of nano-sheet micro-spherical melamine cyanurate, which can solve the problems of uneven dispersion, bridging of feeding materials, poor fluidity of powder, etc. The effect of preventing feeding bridging and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

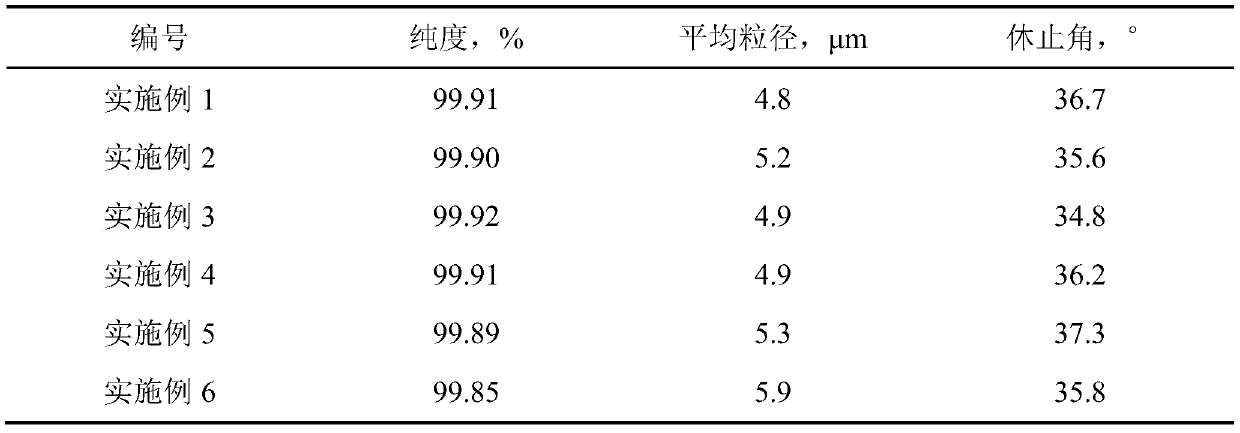

Embodiment 1

[0040] Add 20kg cyanuric acid (purity 98.5%) and 19.2kg melamine (purity 99.5%) in 50L reactor, after stirring and mixing evenly, add 23.5kg water, heat up to 90~95 ℃. After 1 hour, 31.36 g of sodium alkylphenol phenyl ester disulfonate was added, and the reaction was continued for 2 hours. Dry to obtain melamine cyanurate nanosheet microspheres with an average particle diameter of 4.8 μm.

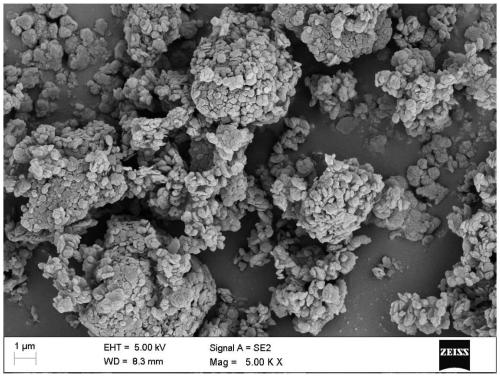

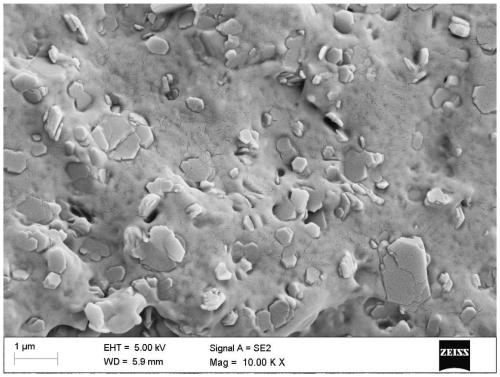

[0041] figure 1 Shown is the SEM collection of illustrative plates of the melamine cyanurate nano sheet microsphere prepared by the present embodiment, by figure 1 It can be seen that the microsphere is composed of nanosheets with a thickness of about 30 nm and a width of about 200 nm.

Embodiment 2

[0043] Add 39.2 g of sodium alkylphenol phenyl ester disulfonate after heating up to 90-95°C for 1 hour. The rest are the same as embodiment 1.

Embodiment 3

[0045] Add 31.6g fatty alcohol polyoxyethylene 30 ether methyl silane after heating up to 90-95°C for 0.5h. The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com