Expansion type flame-retardant polypropylene composite

A technology of flame retardant polypropylene and composition, applied in the field of intumescent flame retardant polypropylene composition, can solve the problems of unstable flame retardant performance, large content of flame retardant, strong hygroscopicity, etc., to improve the flame retardant stability , The effect of improving crystallization performance and oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

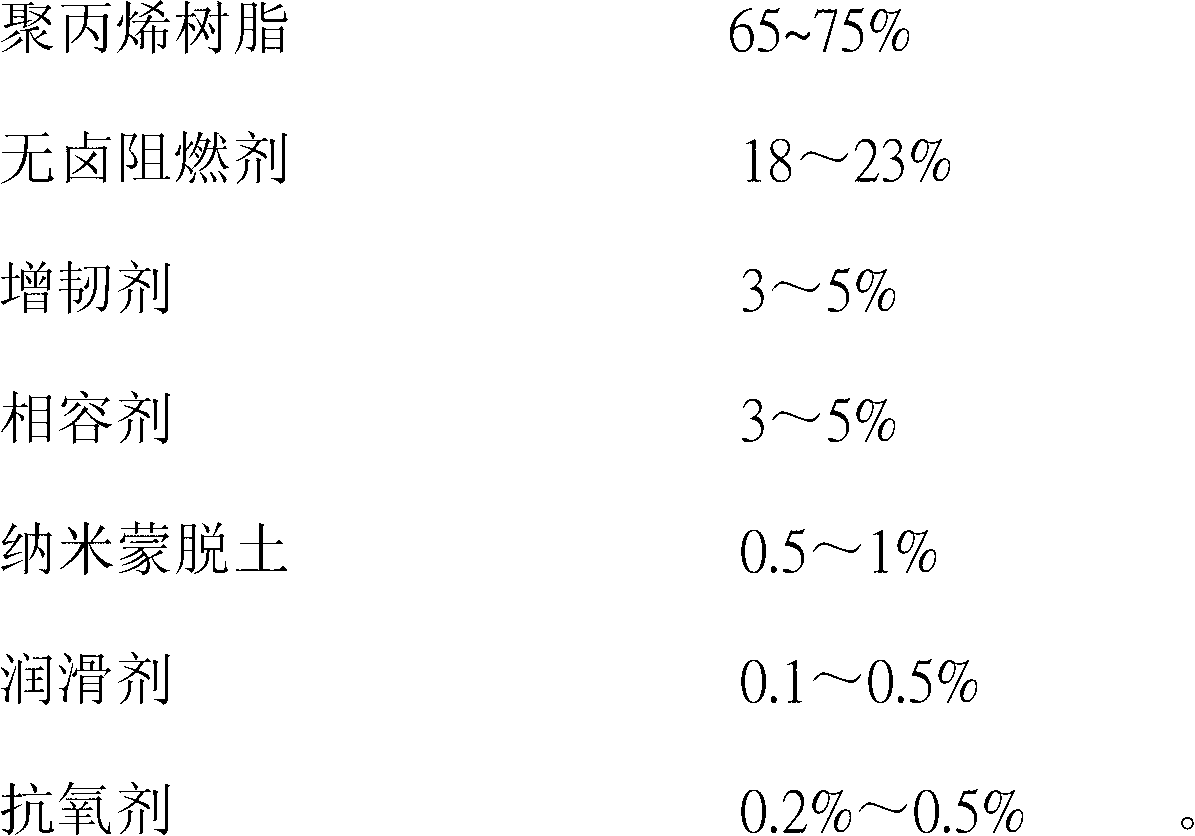

[0026] An intumescent flame-retardant polypropylene composition of the present invention is characterized in that it comprises the following components by weight percentage:

[0027]

[0028] The halogen-free flame retardant of the present invention is obtained by mixing ammonium polyphosphate, polyalcohol and melamine in a weight ratio of 3:1:1 and then performing coating treatment. The coating treatment described therein includes: first mix ammonium phosphate, polyol and melamine evenly with a high-speed mixer, then add PE wax and mix at a high speed at 80±5°C, so that ammonium phosphate, polyol and melamine can be evenly mixed Encased in coating and wax.

Embodiment 2

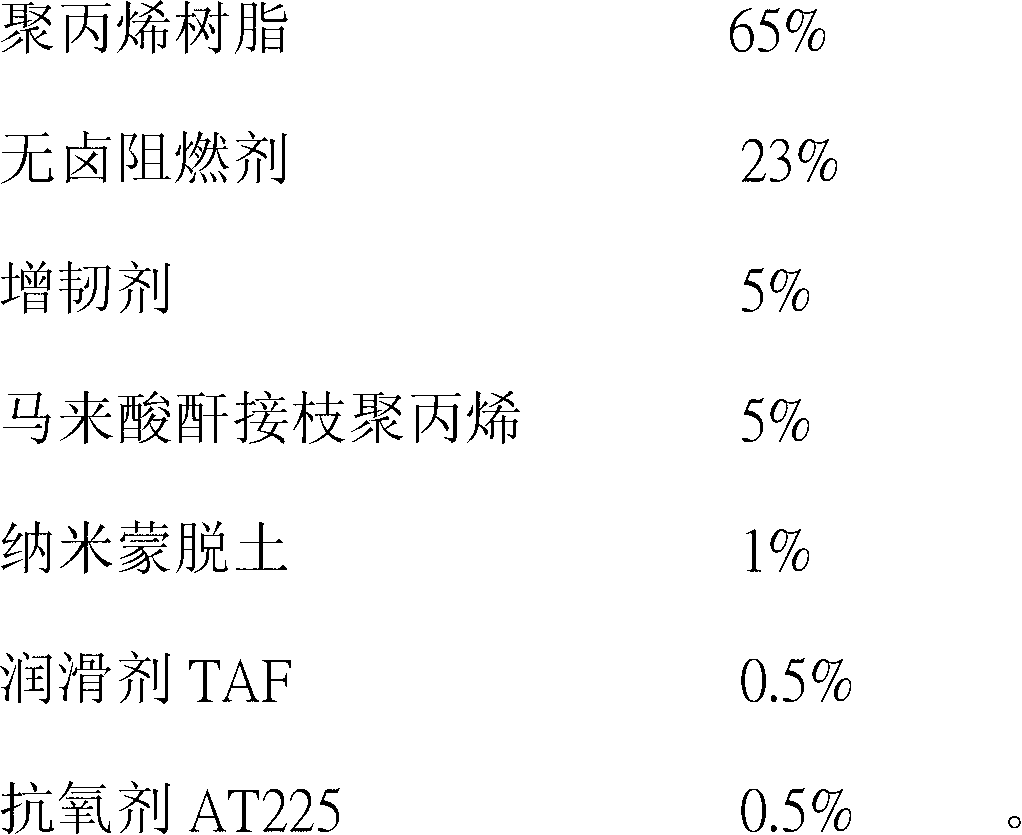

[0030] An intumescent flame-retardant polypropylene composition of the present invention is characterized in that it comprises the following components by weight percentage:

[0031]

[0032] The halogen-free flame retardant of the present invention is obtained by mixing ammonium polyphosphate, polyalcohol and melamine in a weight ratio of 3:1:1 and then performing coating treatment. The coating treatment described therein includes: first mix ammonium phosphate, polyol and melamine evenly with a high-speed mixer, then add PE wax and mix at a high speed at 80±5°C, so that ammonium phosphate, polyol and melamine can be evenly mixed Encased in coating and wax.

Embodiment 3

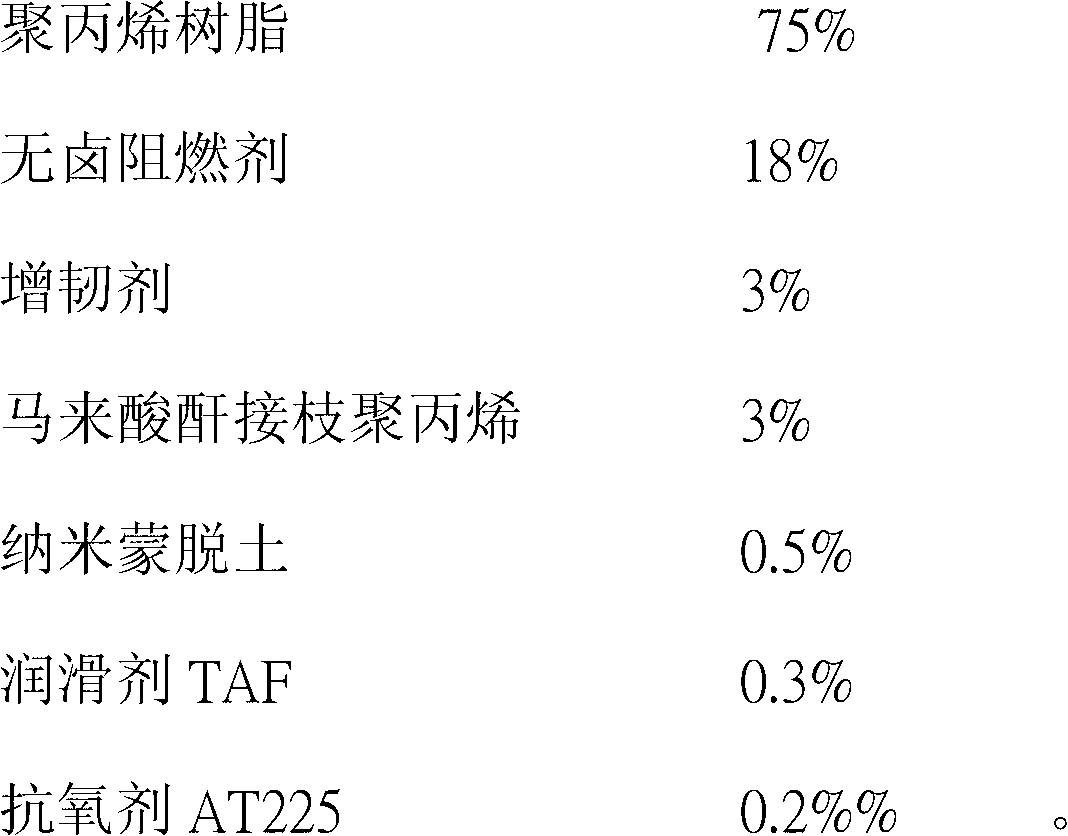

[0034] An intumescent flame-retardant polypropylene composition of the present invention is characterized in that it comprises the following components by weight percentage:

[0035]

[0036]

[0037] The halogen-free flame retardant of the present invention is obtained by mixing ammonium polyphosphate, polyalcohol and melamine in a weight ratio of 3:1:1 and then performing coating treatment. The coating treatment described therein includes: first mix ammonium phosphate, polyol and melamine evenly with a high-speed mixer, then add PE wax and mix at a high speed at 80±5°C, so that ammonium phosphate, polyol and melamine can be evenly mixed Encased in coating and wax.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com