A kind of flame retardant modification treatment method of bamboo

A treatment method, bamboo technology, applied in wood treatment, wood treatment details, reed/straw treatment, etc., can solve the problems of bamboo easy to burn and loss resistance, so as to facilitate mass production, improve flame retardancy and flame retardancy stability permanent, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

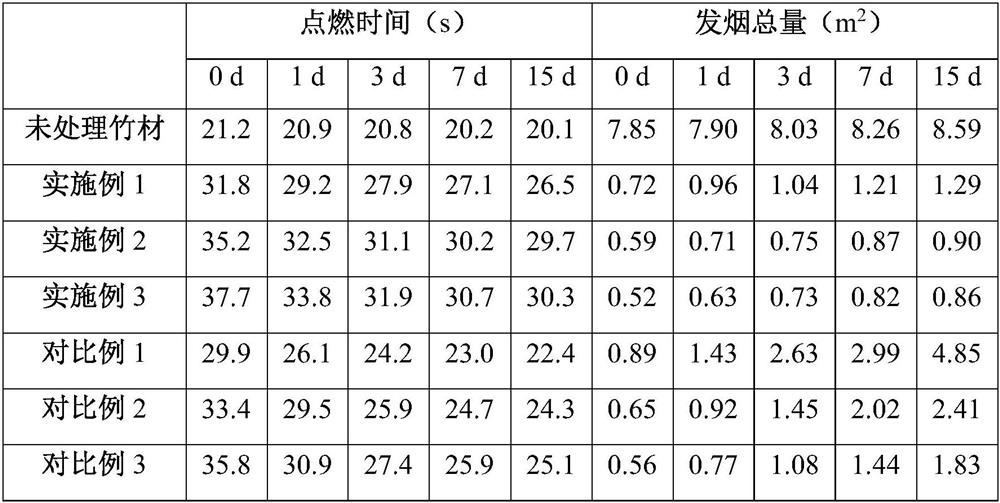

Examples

Embodiment 1

[0016] (1) Place the dried bamboo sample in an automatic vacuum pressure tank, evacuate to a vacuum of 0.05 MPa, and after holding the pressure for 30 minutes, inject 5% by weight of 4,4'-diphenyl Dioxane solution of methane diisocyanate, pressurized to 1MPa, kept the pressure for 2 hours, and released the pressure; after continuing to impregnate for 2 hours under normal pressure, take out the bamboo sample, and vacuum dry it at 60°C for 24 hours to obtain a primary modified bamboo. sample;

[0017] (2) Place the primary modified bamboo sample in an automatic vacuum pressurized tank, evacuate to a vacuum degree of 0.04MPa, and after holding the pressure for 20min, inject 10% by weight of 9,10-dihydro-9- Oxa-10-phosphaphenanthrene-10-oxide in dioxane solution, pressurized to 1MPa, kept the pressure for 2h, and released the pressure; after continuing to impregnate for 3h under normal pressure, take out the bamboo sample, and put it at 60℃ Dry in vacuum for 24 hours to obtain a ...

Embodiment 2

[0019] (1) Place the dried bamboo sample in an automatic vacuum pressure tank, evacuate to a vacuum of 0.07 MPa, and after holding the pressure for 60 minutes, inject 8% by weight of 4,4'-diphenyl Dioxane solution of methane diisocyanate, pressurize to 1.2MPa, keep the pressure for 1.5h, and release the pressure; continue impregnating under normal pressure for 3h, take out the bamboo sample, and dry it in vacuum at 60°C for 24h to obtain a primary modification Handling of bamboo samples;

[0020] (2) Place the primary modified bamboo sample in an automatic vacuum pressurized tank, evacuate to a vacuum degree of 0.06MPa, and after holding the pressure for 30min, inject 15% by weight of 9,10-dihydro-9- The dioxane solution of oxa-10-phosphaphenanthrene-10-oxide was pressurized to 1.5MPa, maintained for 1.5h, and then released; the bamboo sample was taken out after continuing to impregnate for 4.5h under normal pressure, and the Vacuum dry at 60°C for 24 hours to obtain a second...

Embodiment 3

[0022] (1) Place the dried bamboo sample in an automatic vacuum pressurized tank, evacuate to a vacuum degree of 0.09MPa, and after holding the pressure for 90min, inject 10% by weight of 4,4'-diphenyl Dioxane solution of methane diisocyanate, pressurize to 1.5MPa, keep the pressure for 1h, and release the pressure; continue impregnation under normal pressure for 4h, take out the bamboo sample, and vacuum dry at 60°C for 24h to obtain a primary modification treatment Bamboo samples;

[0023] (2) Place the primary modified bamboo sample in an automatic vacuum pressurized tank, evacuate to a vacuum degree of 0.08MPa, and after holding the pressure for 40min, inject 20% by weight of 9,10-dihydro-9- Oxa-10-phosphaphenanthrene-10-oxide in dioxane solution, pressurized to 2MPa, kept the pressure for 1h, and released the pressure; after continuing to impregnate for 6h under normal pressure, take out the bamboo sample, at 60°C Dry in vacuum for 24 hours to obtain a secondary modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com