Reactive flame retardant for epoxy resin as well as preparation method and application of reactive flame retardant

A technology of reactive flame retardant and epoxy resin, which is applied in the field of polymer flame retardants, can solve the problems of epoxy resin transparency and unsatisfactory mechanical properties, and achieve good flame retardant stability, good transparency and mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

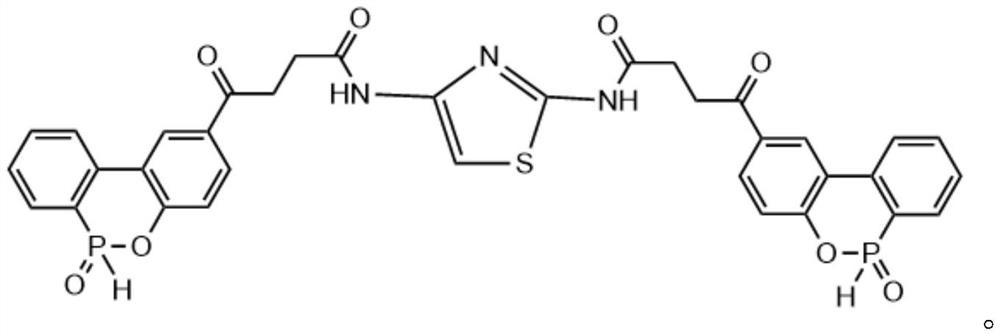

Image

Examples

Embodiment 1

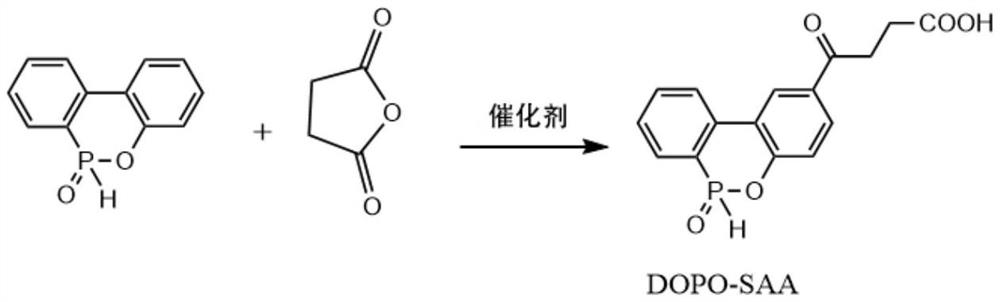

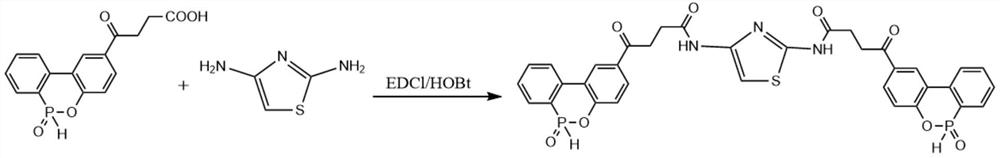

[0031] The reactive flame retardant provided in this example is the second synthetic product prepared as follows:

[0032] Under nitrogen protection, 21.60g (0.10mol) DOPO, 26.67g (0.20mol) anhydrous aluminum trichloride, 300mL dichloromethane are added in the there-necked flask, and the first solution is obtained after mixing uniformly; Slowly add a mixed solution of 12.00g (0.12mol) of succinic anhydride and absolute ethanol dropwise in the first solution, after the dropwise addition is completed, the first mixed system is obtained; the first mixed system is slowly warmed up to 50°C, and the reaction is continued with stirring for 3 Hours later, cool to room temperature, collect the filtrate by suction filtration, wash the filtrate with acetone, then remove the solvent by rotary evaporation and dry in vacuo to obtain the first synthetic product (DOPO-SAA), with a yield of 72.43%;

[0033] Under nitrogen protection, 2.30g (0.02mol) of 2,4-diaminothiazole, 7.67g (0.04mol) of E...

Embodiment 2

[0035] The reactive flame retardant provided in this example is the second synthetic product prepared as follows:

[0036] Under the protection of nitrogen, 21.60g (0.10mol) DOPO, 33.33g (0.25mol) anhydrous aluminum trichloride, 200mL nitrobenzene were added into the three-necked flask, and the first solution obtained after mixing evenly; under stirring in an ice-water bath, Slowly add a mixture of 15.00g (0.15mol) of succinic anhydride and absolute ethanol dropwise to the first solution. After the dropwise addition is completed, the first mixed system is obtained; the temperature of the first mixed system is slowly raised to 40°C, and the reaction is continued with stirring After 5 hours, cool to room temperature, collect the filtrate by suction filtration, wash the filtrate with acetone, then remove the solvent by rotary evaporation and dry in vacuo to obtain the first synthetic product (DOPO-SAA), with a yield of 78.9%;

[0037] Under nitrogen protection, 2.30g (0.02mol) of...

Embodiment 3

[0039] The reactive flame retardant provided in this example is the second synthetic product prepared as follows:

[0040] Under the protection of nitrogen, 21.60g (0.10mol) DOPO, 35.16g (0.30mol) anhydrous boron trichloride, 300mL dichloromethane were added in the three-necked flask, and the first solution was obtained after mixing uniformly; Slowly add a mixed solution of 10.00g (0.10mol) of succinic anhydride and absolute ethanol dropwise in the first solution, after the dropwise addition is completed, the first mixed system is obtained; the first mixed system is slowly warmed up to 60°C, and the reaction is continued with stirring 2 Hours later, cool to room temperature, collect the filtrate by suction filtration, wash the filtrate with acetone, remove the solvent by rotary evaporation and dry in vacuo to obtain the first synthetic product (DOPO-SAA), with a yield of 74.82%;

[0041] Under nitrogen protection, 2.30g (0.02mol) of 2,4-diaminothiazole, 5.75g (0.03mol) of EDCl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com