Flame-retarding and smoke-suppressing polyvinyl chloride membrane structure material

A technology of polyvinyl chloride film and structural material, which is applied in the field of flame retardant and smoke-suppressing polyvinyl chloride film structural material, can solve the problems of low plasticization efficiency, poor durability of flame retardants, and reduced mechanical properties of materials, and achieves anti-melting effect. The effect of improving dripping performance, increasing flame retardant stability, and reducing the use of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

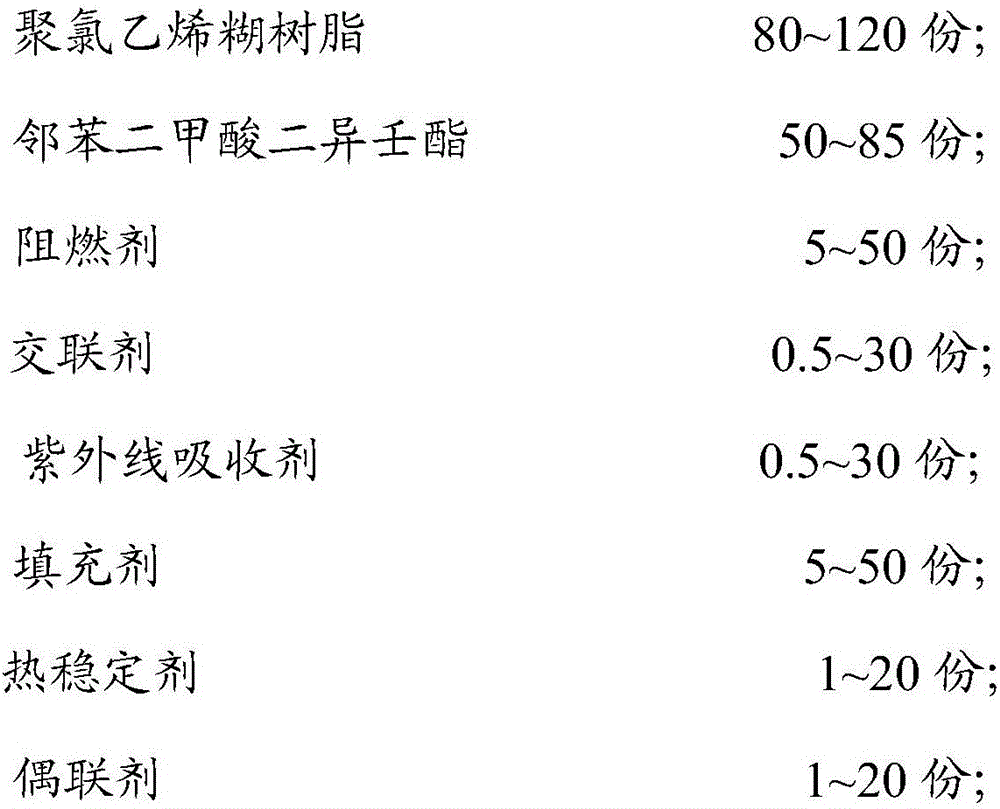

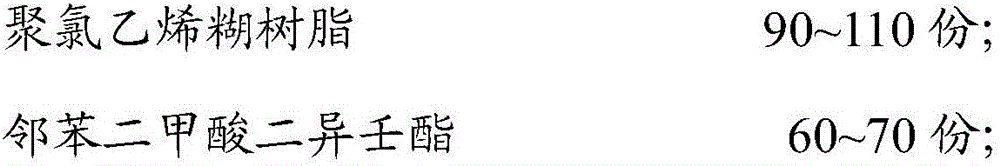

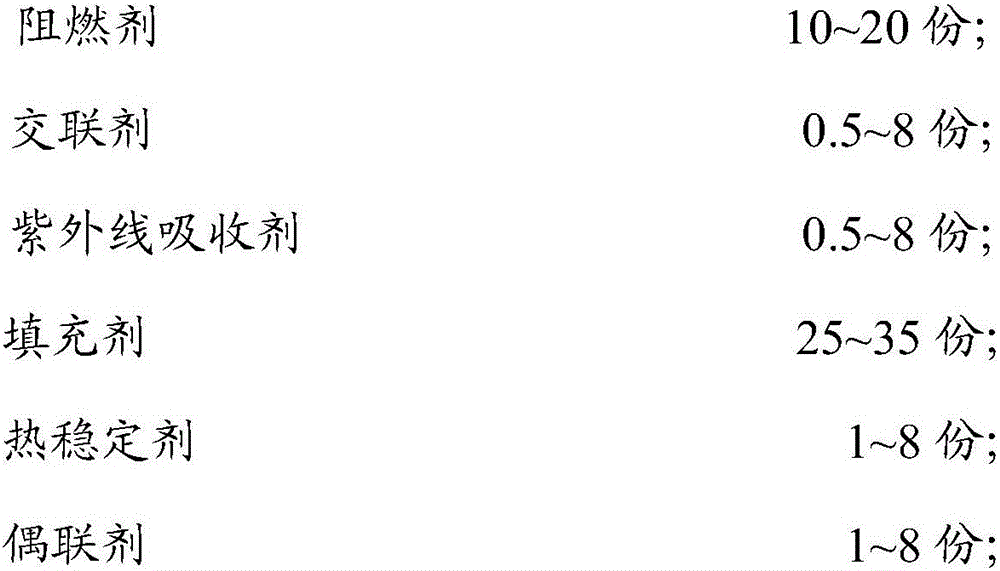

Method used

Image

Examples

Embodiment 1

[0025] The weight ratio of each component of the flame-retardant and smoke-suppressing PVC film structure material is: 100 parts of polyvinyl chloride paste resin, 65 parts of diisononyl phthalate, 9 parts of zinc stannate, 6 parts of molybdenum trioxide, 3 parts of isocyanate, 3.5 parts of 2-hydroxy-4-n-octoxybenzophenone, 30 parts of nano calcium carbonate, 2.5 parts of barium zinc stabilizer, 3 parts of γ-aminopropyltriethoxysilane.

[0026] Preparation method: step one, fully stir and mix the components of the polyvinyl chloride film structure material to obtain a PVC slurry, step two, evenly coat polyester fiber base fabric (polyester fiber base fabric prepared by ordinary polyester industrial yarn ), after drying in an oven at 165°C for 5 minutes, a polyvinyl chloride membrane structure material with a thickness of 1.5 mm is made.

Embodiment 2

[0028] The weight ratio of each component is: 100 parts of polyvinyl chloride paste resin, 65 parts of diisononyl phthalate, 7.5 parts of zinc stannate, 7.5 parts of molybdenum trioxide, 3 parts of isocyanate, 2-hydroxy-4-positive 3.5 parts of octyloxybenzophenone, 30 parts of nano calcium carbonate, 2.5 parts of barium zinc stabilizer, 3 parts of γ-aminopropyltriethoxysilane.

[0029] Preparation method: step one, fully stir and mix the components of the polyvinyl chloride film structure material to obtain a PVC slurry, step two, evenly coat polyester fiber base fabric (polyester fiber base fabric prepared by ordinary polyester industrial yarn ), after drying in an oven at 165°C for 5 minutes, a polyvinyl chloride membrane structure material with a thickness of 1.5 mm is made.

Embodiment 3

[0031] The weight ratio of each component is: 100 parts of polyvinyl chloride paste resin, 65 parts of diisononyl phthalate, 6 parts of zinc stannate, 9 parts of molybdenum trioxide, 3 parts of isocyanate, 2-hydroxy-4-positive 3.5 parts of octyloxybenzophenone, 30 parts of nano calcium carbonate, 2.5 parts of barium zinc stabilizer, 3 parts of γ-aminopropyltriethoxysilane.

[0032] Preparation method: step one, fully stir and mix the components of the polyvinyl chloride film structure material to obtain a PVC slurry, step two, evenly coat polyester fiber base fabric (polyester fiber base fabric prepared by ordinary polyester industrial yarn ), after drying in an oven at 165°C for 5 minutes, a polyvinyl chloride membrane structure material with a thickness of 1.5 mm is made.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com