Halogen-free fire-retardant foam and preparation method thereof

A foam and flame retardant technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of low environmental protection factor, air pollution, human injury, etc., and achieve the effect of reducing surface energy, reducing combustibility, and flame retardancy excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

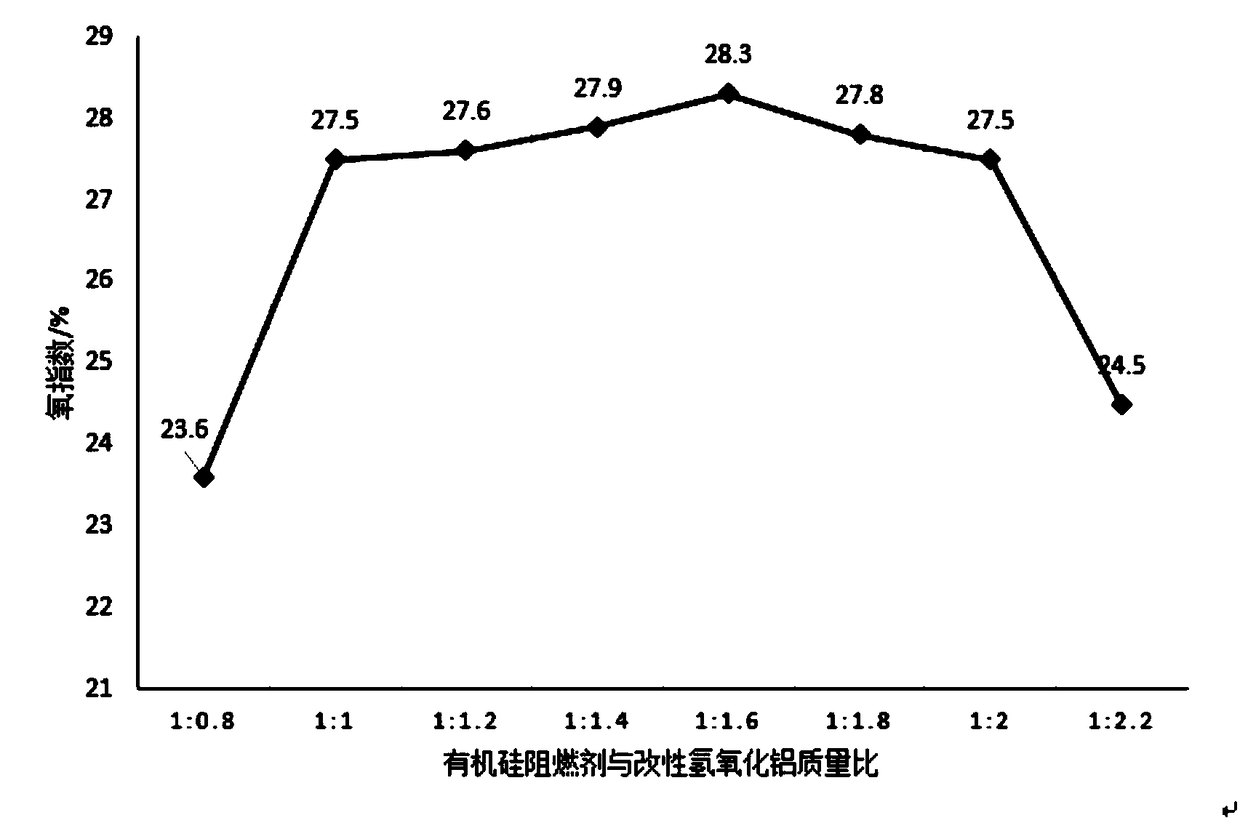

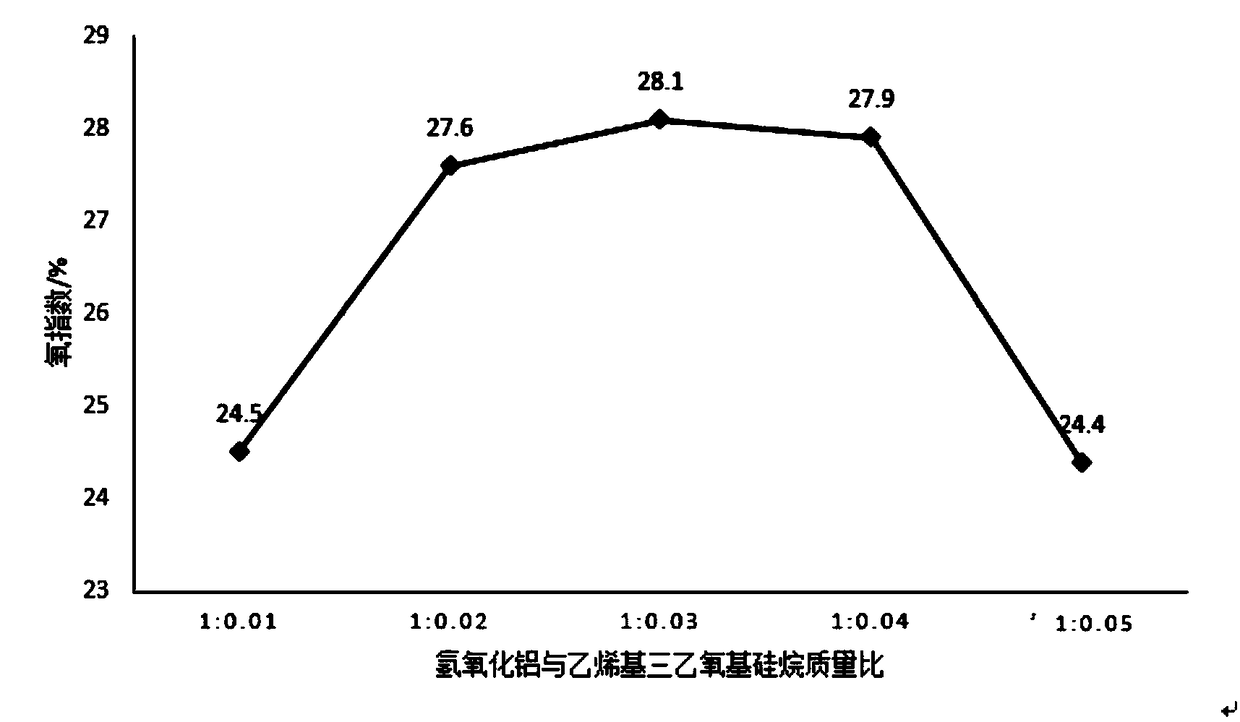

[0037] Preparation example 1: Modified aluminum hydroxide is prepared by the following method: dry aluminum hydroxide at 100°C for 1 hour, then put it in a mixer and stir at 2000 rpm; For the silane coupling agent of 1:0.02, the silane coupling agent dissolved in toluene is evenly sprayed on the aluminum hydroxide being stirred, stirred at 200 rpm for 10 minutes, and then stirred at 2000 rpm for 10 minutes Minutes, take out and dry;

[0038] Wherein the silane coupling agent refers to vinyltriethoxysilane.

preparation example 2

[0039] Preparation example 2: Modified aluminum hydroxide is prepared by the following method: dry aluminum hydroxide at 105°C for 1.2 hours, then put it in a mixer and stir at 2300 rpm; For the silane coupling agent of 1:0.02, spray the silane coupling agent dissolved in toluene evenly on the stirring aluminum hydroxide, stir at 230 rpm for 15 minutes, and then stir at 2300 rpm for 15 minutes , take out to dry.

[0040] Wherein the silane coupling agent refers to vinyltriethoxysilane.

preparation example 3

[0041] Preparation example 3: Modified aluminum hydroxide is prepared by the following method: dry aluminum hydroxide at 110°C for 1.5 hours, then put it in a mixer and stir at 2500 rpm; For the silane coupling agent of 1:0.02, the silane coupling agent dissolved in toluene is evenly sprayed on the aluminum hydroxide being stirred, stirred at 250 rpm for 20 minutes, and then stirred at 2500 rpm for 20 minutes minutes, remove to dry.

[0042] Wherein the silane coupling agent refers to vinyltriethoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com