Anti-dribble method for steamer and dribble-free inner steam chamber

An anti-drip and steam chamber technology, which is applied to steam cooking utensils and other directions, can solve the problems of wetting food, affecting the appearance and quality of steamed food, etc., and achieves the effect of preventing the lid from dripping, having excellent anti-drip effect, and being convenient to manufacture and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

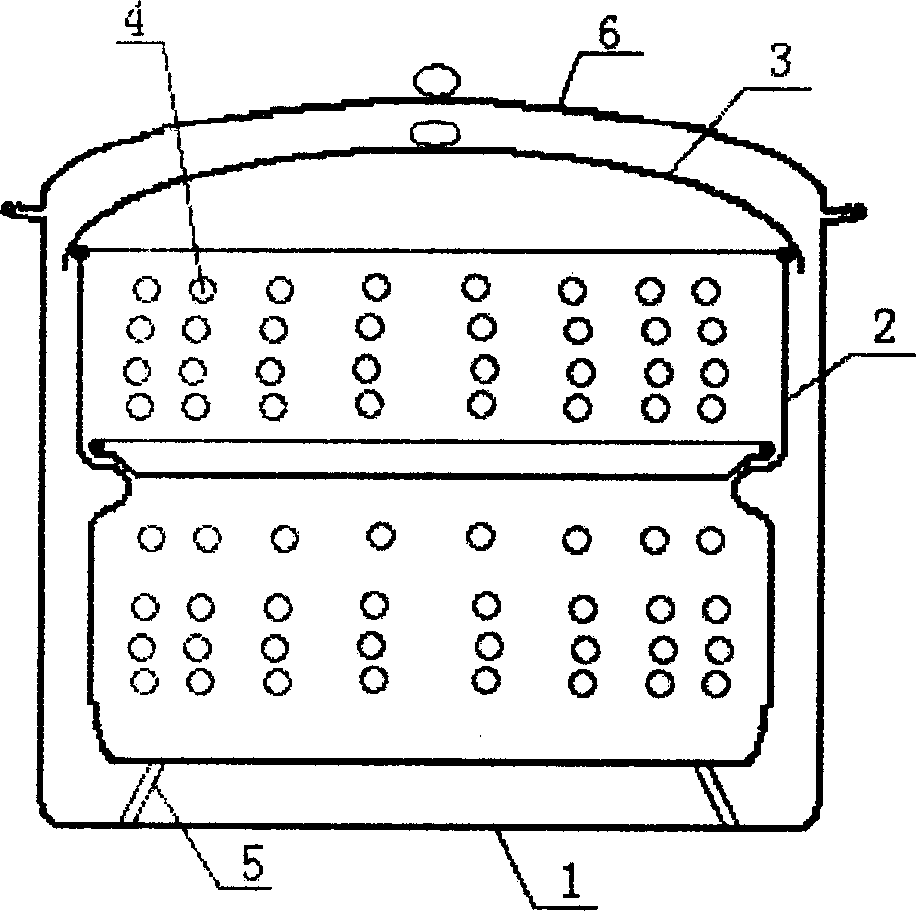

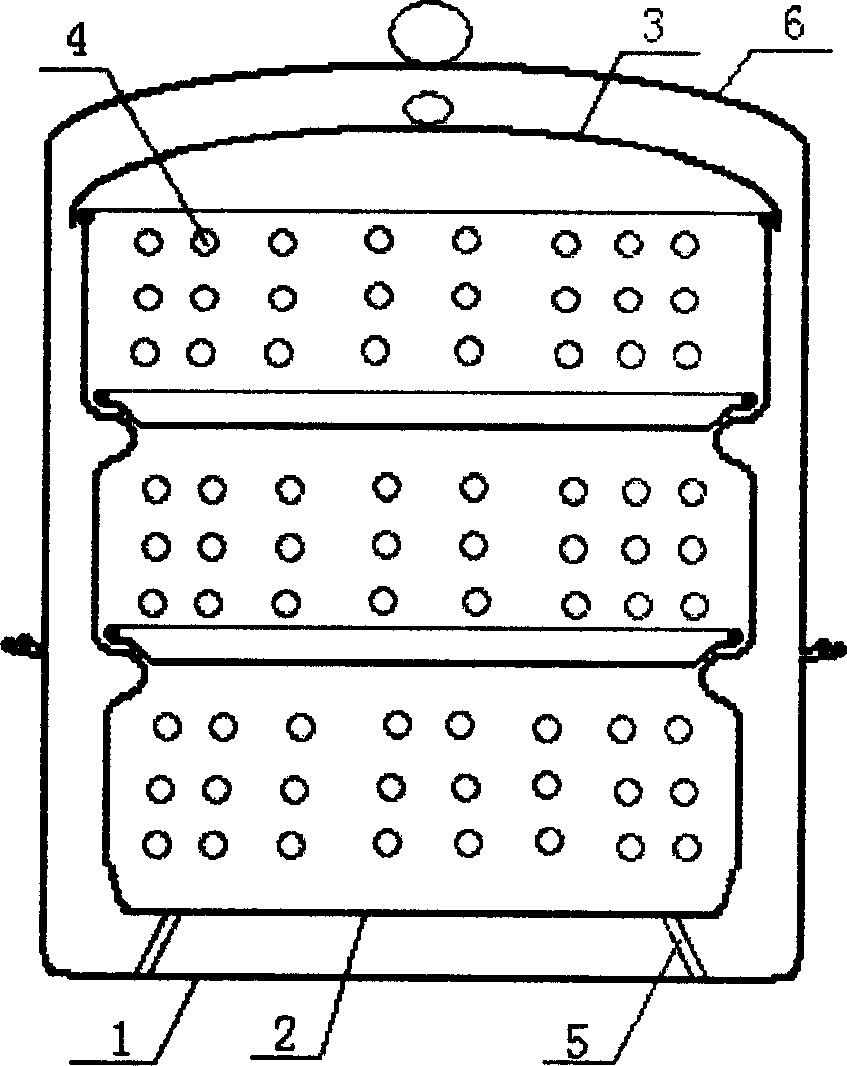

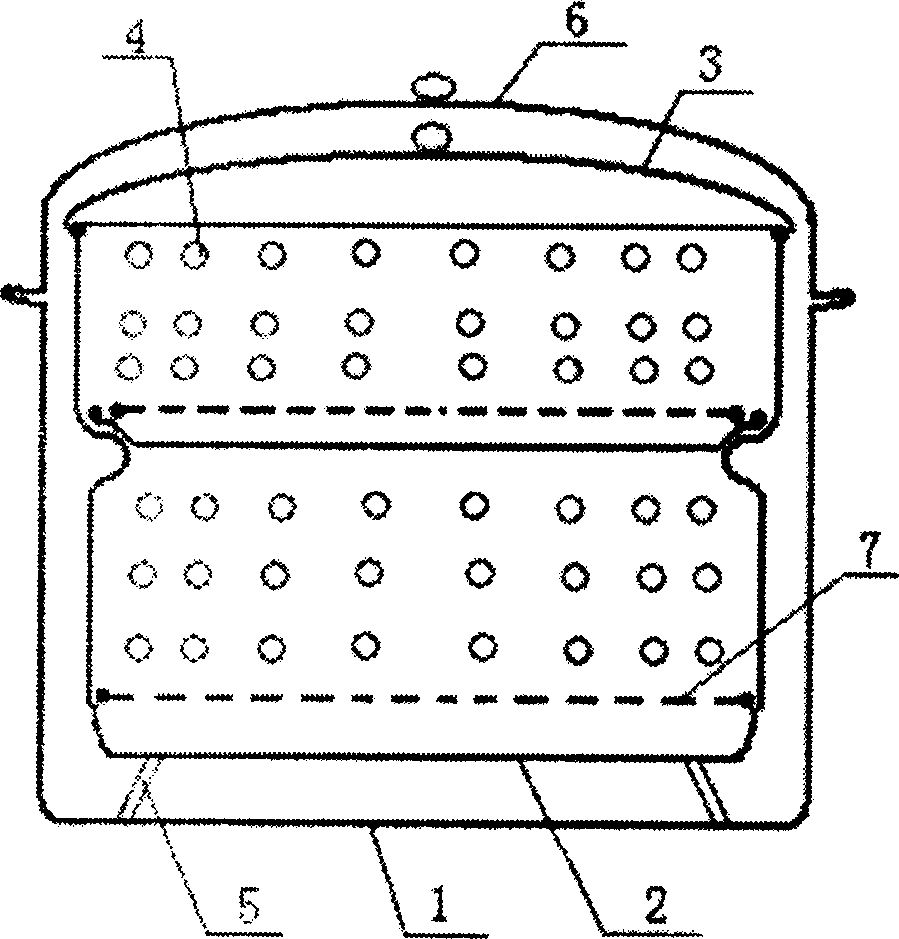

[0021] The anti-dripping method for the steamer of the present invention adopts an internal steaming chamber sealed at the bottom and top of the pot, so that an air passing space is formed between the internal steaming chamber and the pot body, and the internal steaming chamber exchanges heat with the passing air space through the side wall steam channel.

[0022] 1. The inner steaming chamber can be composed of one or more layers of steaming plates with a closed bottom and an upper cover. 2. The steaming tray can be equipped with porous grates. 3. The multi-layer steaming tray can be used: the side wall of the bottom steaming tray extends upwards and the inner wall is made with a boss for placing the upper steaming tray, or the lower end of the upper steaming tray is placed on the upper end of the lower steaming tray. 4. The configuration of the inner steaming chamber and the pot body can be as follows: the bottom of the bottom layer of the steaming plate is equipped with sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com