Filling machine with dripping and leaking prevention device

An anti-drip, canning machine technology, applied in packaging, liquid bottling, transportation and packaging, etc., can solve the problem of reducing the accuracy and service life of the filling head, residual liquid flowing back into the filling machine, and high repair and maintenance costs and other problems, to achieve the effect of good dripping effect, reduce manpower, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

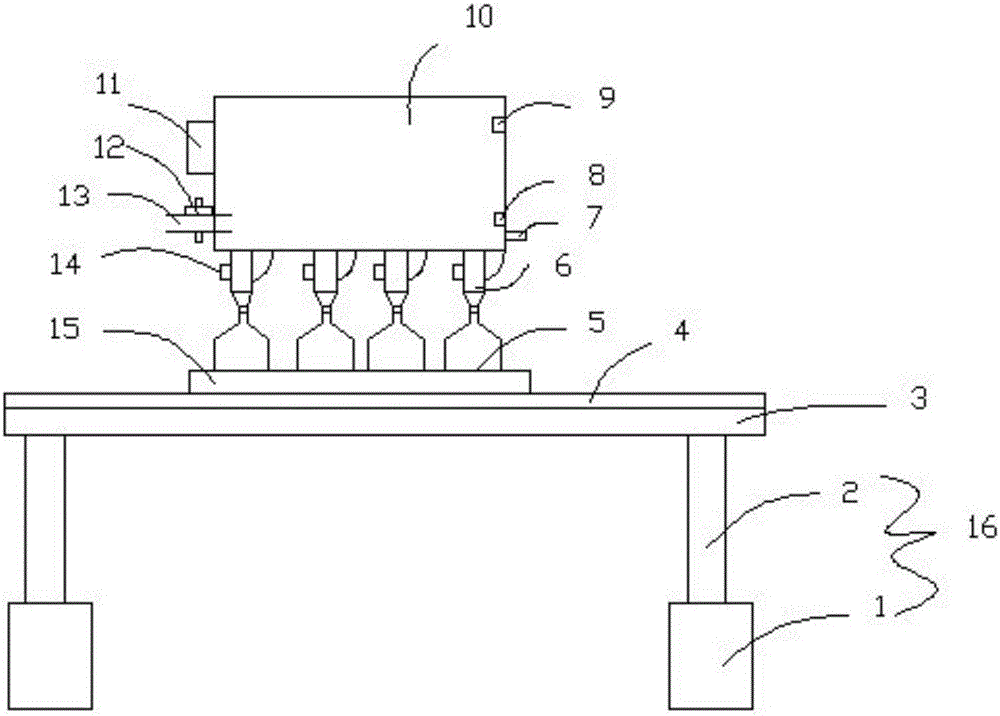

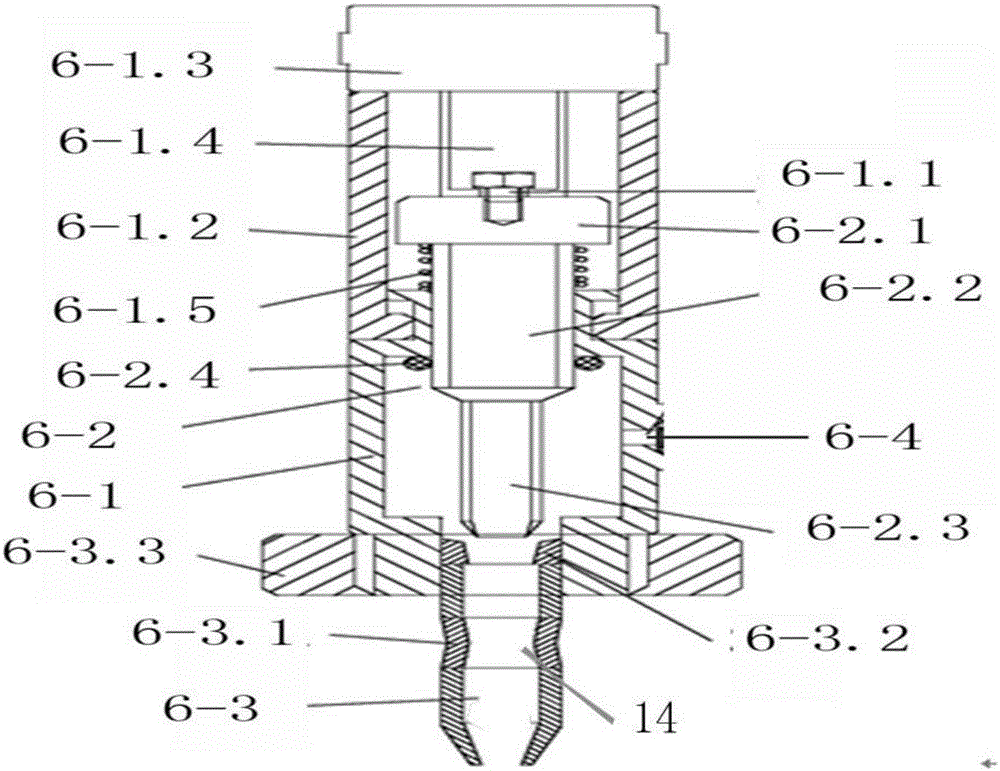

[0018] Such as Figures 1 to 2 As shown, the present embodiment provides a canning machine with an anti-drip device, comprising an oil storage tank 10, characterized in that the bottom of the oil storage tank 10 is provided with several filling heads 6, and each filling head 6 Both include a filling head housing 6-1, a cut-off rod 6-2, a needle 6-3 and a liquid inlet 6-4, and the upper side of the filling head housing 6-1 is fixedly connected with a mounting seat 6-1.2 , the installation seat 6-1.2 is provided with a fixed installation cylinder 6-1.3, the top of the installation seat 6-1.2 is fixed on the bottom of the oil storage tank 10, and the lower side of the filling head housing 6-1 is connected with a needle 6-3, said A conveyor frame 3 is arranged below the oil storage tank 10, a conveyor belt 4 is arranged on the conveyor frame 3, a fixed bar groove 15 is arranged on the conveyor belt 4, and a plurality of fixed grooves are arranged on the fixed bar groove 15, and ea...

Embodiment 2

[0021] This embodiment is further optimized on the basis of embodiment 1 or 2, specifically:

[0022] The bottom of the filling head housing 6-1 is provided with a needle reinforcement mounting part 6-3.3, and the cylinder rod 6-1.4 and the cut-off rod 6-2 are connected by screws 6-1.6. The extrusion part 6-3.1 is a rubber hose.

[0023] Each filling head 6 is respectively equipped with a filling valve 14, the lower part of the oil storage tank 10 is provided with an oil replenishment sensor 8, and the upper part is provided with an oil overflow sensor 9, and one side of the oil storage tank 10 is also provided with An oil supply pipe 13 is provided, and an electromagnetic valve 12 is arranged on the oil supply pipe 13. A control box 11 is also provided on one side of the oil storage tank 10, and the input end of the control box 11 is respectively connected with the oil replenishment sensor 8 and the oil spill. The sensor 9 is connected, and the output end of the control box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com