Hyperbranched polymer flame retardant and preparation method and application thereof

A technology of hyperbranched polymers and flame retardants, applied in the field of flame retardant materials, can solve the problems of cellulose being flammable and limited in use, and achieve the effects of simple synthesis process, simple purification process, and improved anti-dripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

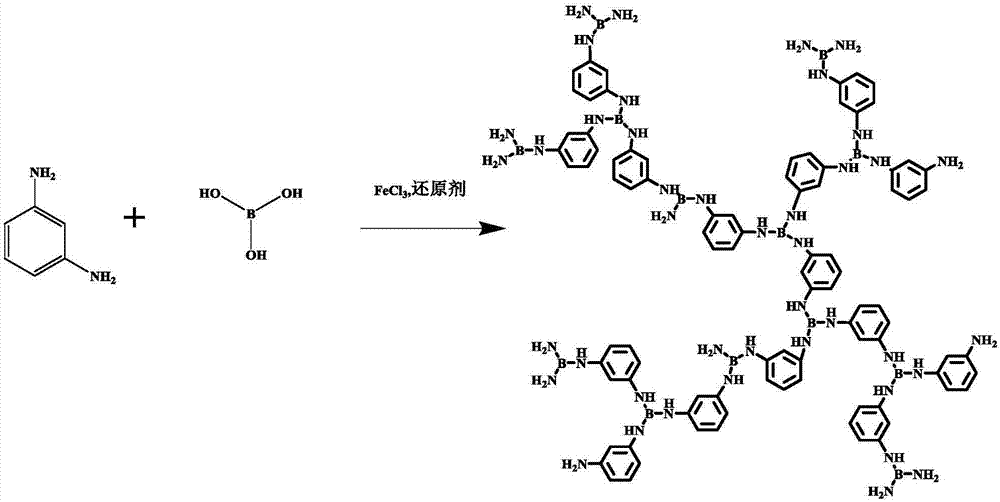

[0027] Add 32.4g of m-phenylenediamine, 12.35g of boric acid and 4g of ferric chloride into a three-necked flask in sequence, dissolve with 100ml of NMP and 30ml of toluene as solvents, stir at 100°C for 8h, then add 30ml of xylene, and then raise the temperature , stirred at 150°C and 180°C for 5h and 2h in turn. Then carry out purification treatment, dissolve the reaction product with acetone, add a large amount of ether to precipitate it and filter it with suction, repeat the above operation three times, and finally put it in a vacuum oven at 140°C for 10 hours to finally obtain the hyperbranched polymer flame retardant p-PNB .

[0028] The synthesis reaction formula of hyperbranched polymer flame retardant p-PNB in the present embodiment is as figure 1 shown.

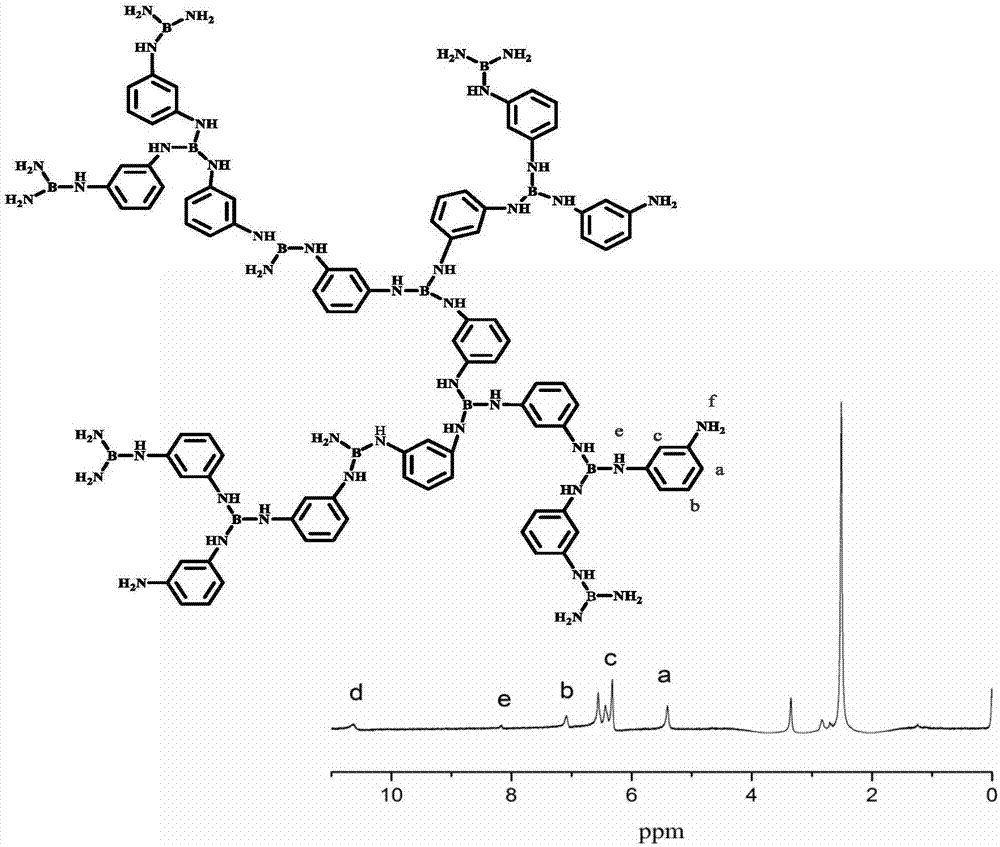

[0029] The hyperbranched polymer flame retardant p-PNB that present embodiment prepares 1 H NMR as figure 2 As shown, the results show that: chemical shift δ5.4-7.2ppm is H on the benzene ring (as shown in a...

Embodiment 2

[0032] The hyperbranched polymer flame retardant p-PNB synthesized in Example 1 was melt-blended with PET at a mass ratio of 3:100 in a twin-screw extruder at 206-280°C, then extruded and cooled to obtain the flame-retardant p-PNB PNB composite PET.

[0033] Injection molded into a standard sample with an injection molding machine, test its limiting oxygen index (LOI) and disposal combustion grade (UL-94) with a limiting oxygen tester and a vertical combustion instrument respectively, the flame-retardant p-PNB composite PET obtained in the present embodiment The LOI is 28.5, and its UL-94 rating is V-0.

Embodiment 3

[0035] The hyperbranched polymer flame retardant p-PNB synthesized in Example 1 was melt-blended with PET at a mass ratio of 5:100 in a twin-screw extruder at 206-280°C, then extruded and cooled to obtain the flame-retardant p-PNB PNB composite PET.

[0036] Injection molded into a standard sample with an injection molding machine, test its limiting oxygen index (LOI) and disposal combustion grade (UL-94) with a limiting oxygen tester and a vertical combustion instrument respectively, the flame-retardant p-PNB composite PET obtained in the present embodiment The LOI is 29.5, and its UL-94 rating is V-0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com