Optical fiber drawing technology

A wire drawing and process technology, applied in the direction of manufacturing tools, glass manufacturing equipment, etc., can solve the problems affecting the cooling effect of helium gas, and achieve the effects of improving the cooling effect of helium gas, the structure is simple, and the heat conduction efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

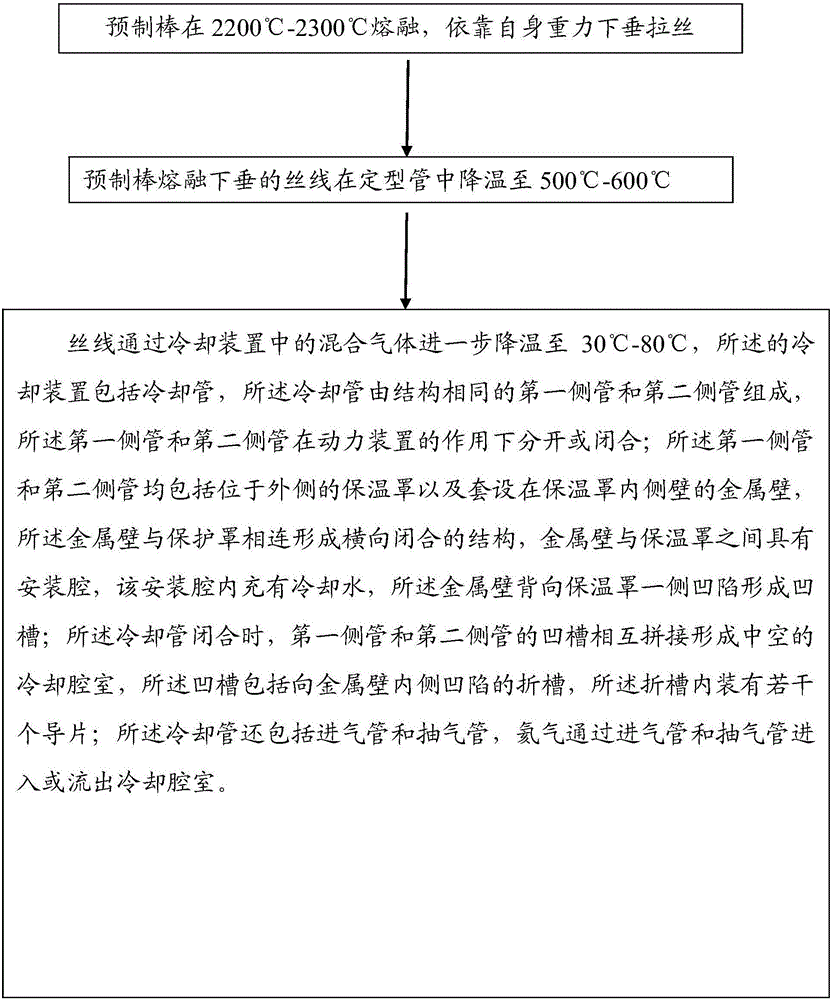

Method used

Image

Examples

Embodiment 1

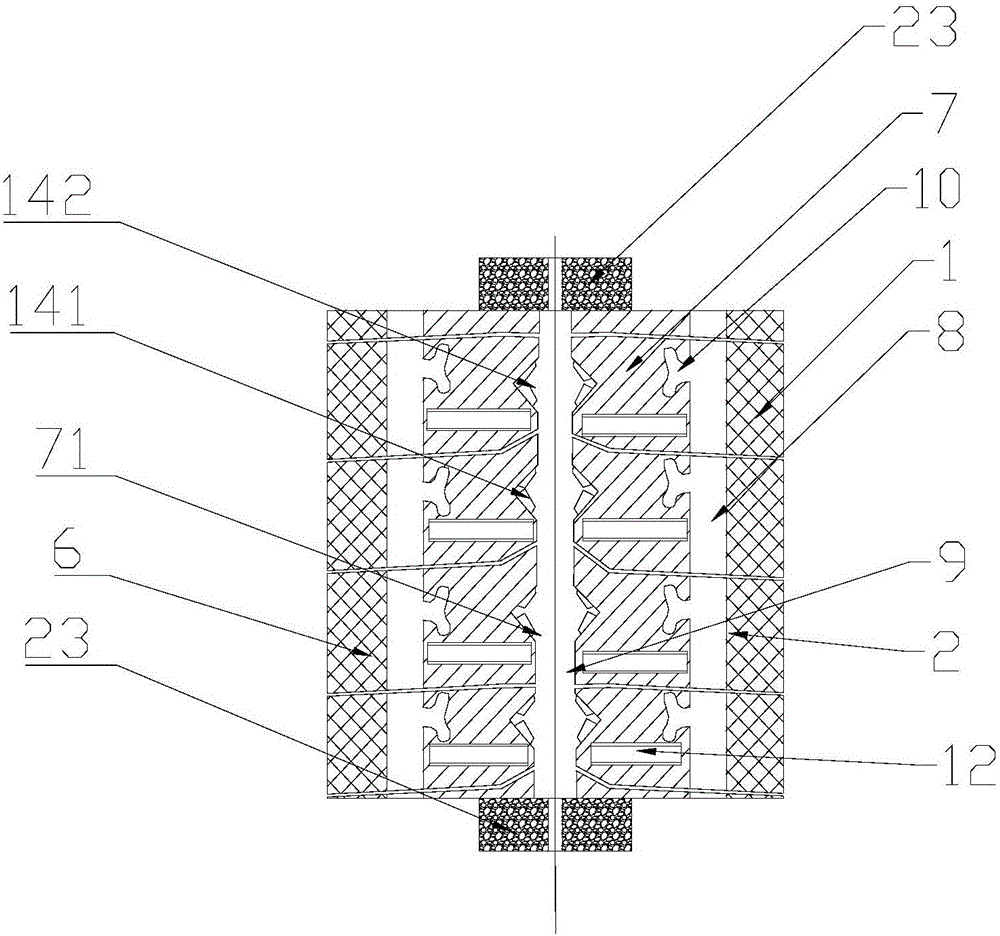

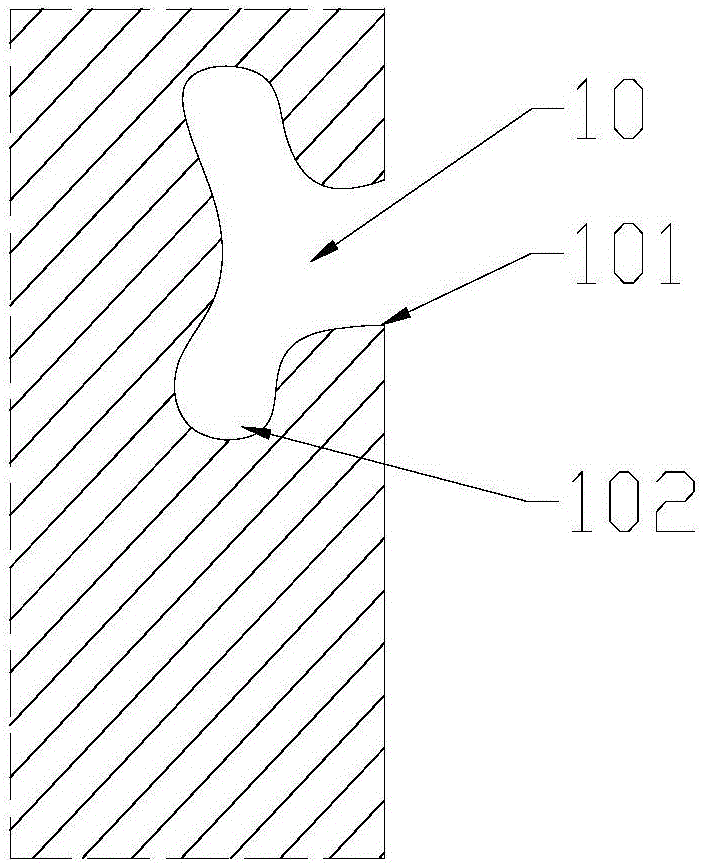

[0050] Embodiment 1: The embodiment of the present invention provides a cooling device 1 (see attached figure 2 , 3 , 4, 5, 6, 7), applied to step 3), the cooling device 1 cooling device includes a cooling pipe 2, and the cooling pipe is composed of a first side pipe 3 and a second side pipe 4 with the same structure , the first side pipe 3 and the second side pipe 4 are vertically separated or closed under the action of the power unit 5; On the metal wall 7 on the inner wall of the heat preservation cover 6, the metal wall 7 is connected with the protective cover 6 to form a horizontally closed structure. There is an installation cavity 8 between the metal wall 7 and the heat preservation cover 6, and the installation cavity 8 is filled with cooling water. The side of the metal wall 7 facing away from the insulation cover 6 is recessed to form a groove 71; when the cooling pipe 2 is closed, the grooves 71 of the first side pipe 3 and the second side pipe 4 are spliced tog...

Embodiment 2

[0054] Embodiment 2: The temperature of the helium is 15°C. A drying device is installed at both ends of the cooling chamber. The drying device is equipped with a desiccant to effectively reduce the moisture in the cooling chamber. Under the condition that the temperature of the helium is controlled at 5°C-15°C, the condensation of the cooling water to The impact on the physical properties of the fiber on the fiber.

[0055] During the implementation of the embodiment of the present invention, helium gas at 5°C-15°C enters the cooling chamber through the intake pipe, and under the action of the groove and its folded grooves and guide vanes, a turbulent flow is formed to destroy the optical fiber and bring it into the bottom layer of the air laminar flow, Helium is drawn out of the cooling chamber through the extraction tube. The drying device dries the air entering the cooling chamber to reduce the moisture entering the cooling chamber. The hot helium in the cooling chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com