Phosphorus-nitrogen-containing vegetable oil polyol as well as preparation method and application thereof

A vegetable oil polyol and reaction technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc. It is difficult to meet the needs of practical applications and other problems to achieve the effects of high flame retardant efficiency, excellent chemical stability, and improved chemical stability and thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

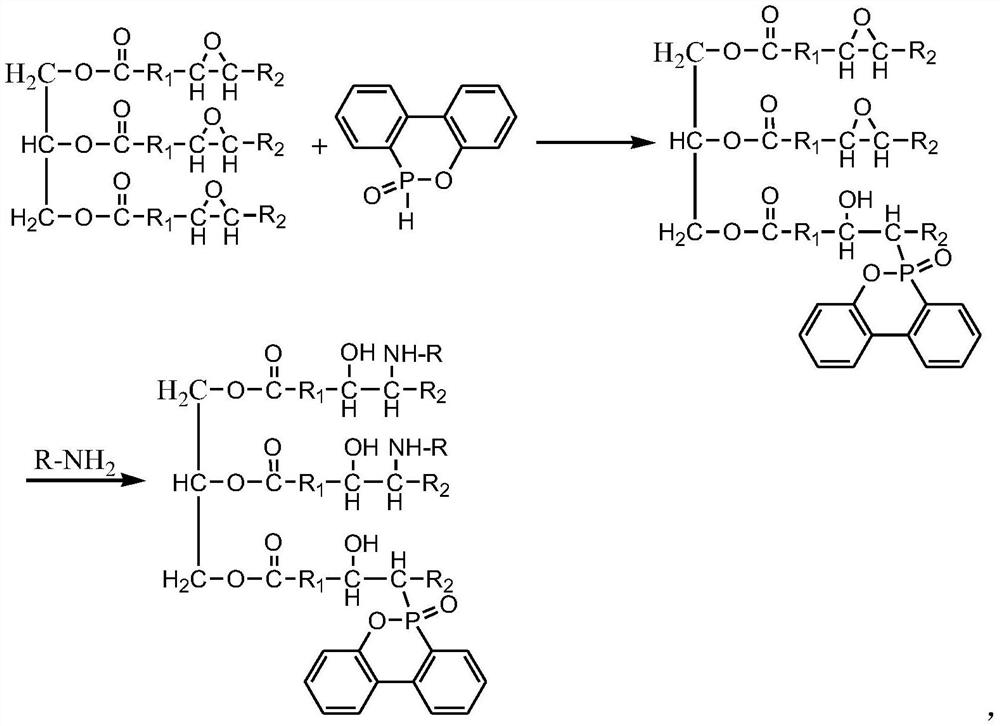

[0033] A kind of phosphorus nitrogen-containing vegetable oil polyol, its preparation method comprises the following steps:

[0034] 1) Mix 500g of epoxidized soybean oil with an epoxy value of 6.20%, 100g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and 0.2g of KOH, stir and heat up to 120 °C, heat preservation reaction for 5 hours, and then naturally cool to 40 °C to obtain phosphorus-containing vegetable oil polyol;

[0035] 2) Add 60g of ethylenediamine to the phosphorus-containing vegetable oil polyol in step 1), keep the temperature at 40°C for 6 hours, then heat up to 100°C and vacuumize for 2 hours to obtain phosphorus-nitrogen-containing vegetable oil polyol (hydroxyl value: 372mgKOH / g ).

Embodiment 2

[0037] A kind of phosphorus nitrogen-containing vegetable oil polyol, its preparation method comprises the following steps:

[0038] 1) 500g epoxy value 6.22% epoxidized soybean oil, 150g 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and 0.4g mass fraction 98% concentrated sulfuric acid are mixed , stir and heat up to 130°C, heat preservation reaction for 4 hours, and then naturally cool to 50°C to obtain phosphorus-containing vegetable oil polyol;

[0039] 2) Add 140g of 2,6-toluenediamine to the phosphorus-containing vegetable oil polyol in step 1), heat-retain and react at 50°C for 5h, then heat up to 100°C and vacuumize for 2h to obtain phosphorus-nitrogen-containing vegetable oil polyol (hydroxyl value : 368mgKOH / g).

Embodiment 3

[0041] A kind of phosphorus nitrogen-containing vegetable oil polyol, its preparation method comprises the following steps:

[0042] 1) Mix 500g of epoxidized soybean oil with an epoxy value of 6.25%, 200g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and 0.6g of NaOH, stir and heat up to 140 ℃, keep it warm for 3 hours, and then cool naturally to 50 ℃ to obtain phosphorus-containing vegetable oil polyol;

[0043] 2) Add 150 g of 2,6-toluenediamine to the phosphorus-containing vegetable oil polyol in step 1), heat-preserve at 50°C for 4 hours, then heat up to 100°C and vacuumize for 2 hours to obtain phosphorus-nitrogen-containing vegetable oil polyol (hydroxyl value : 375mgKOH / g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com