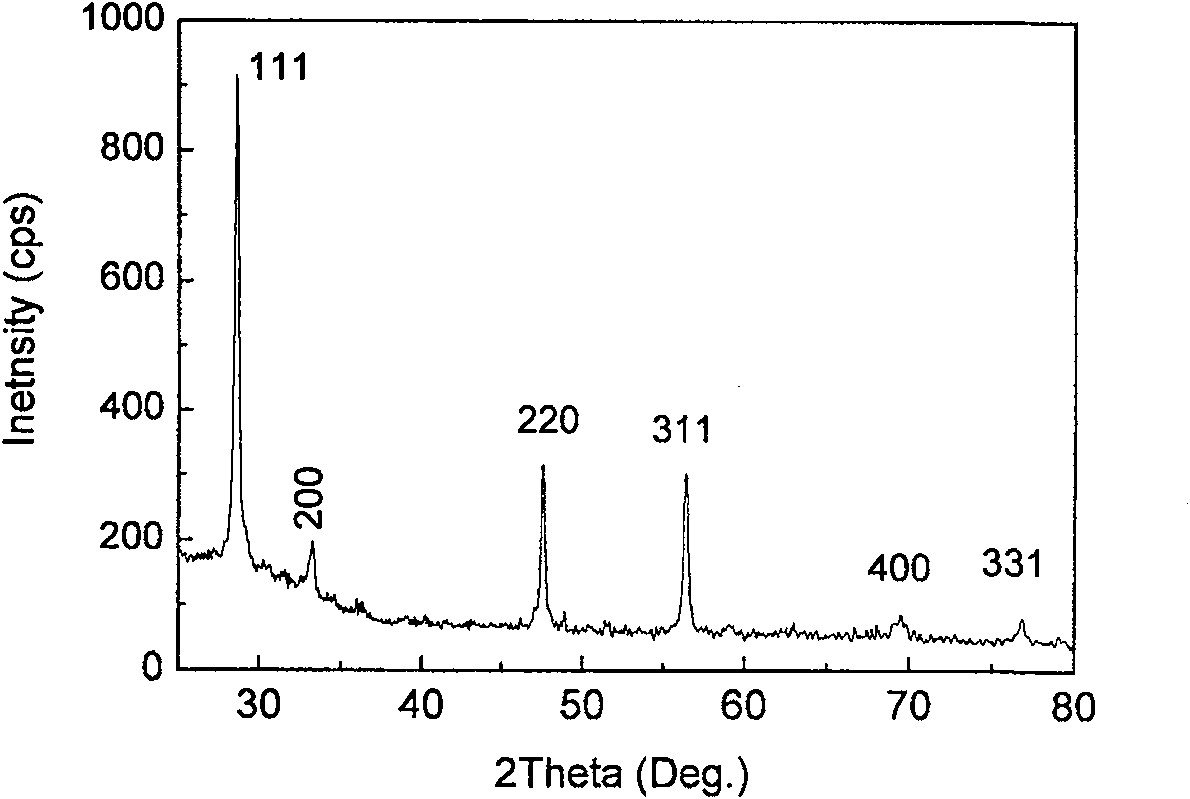

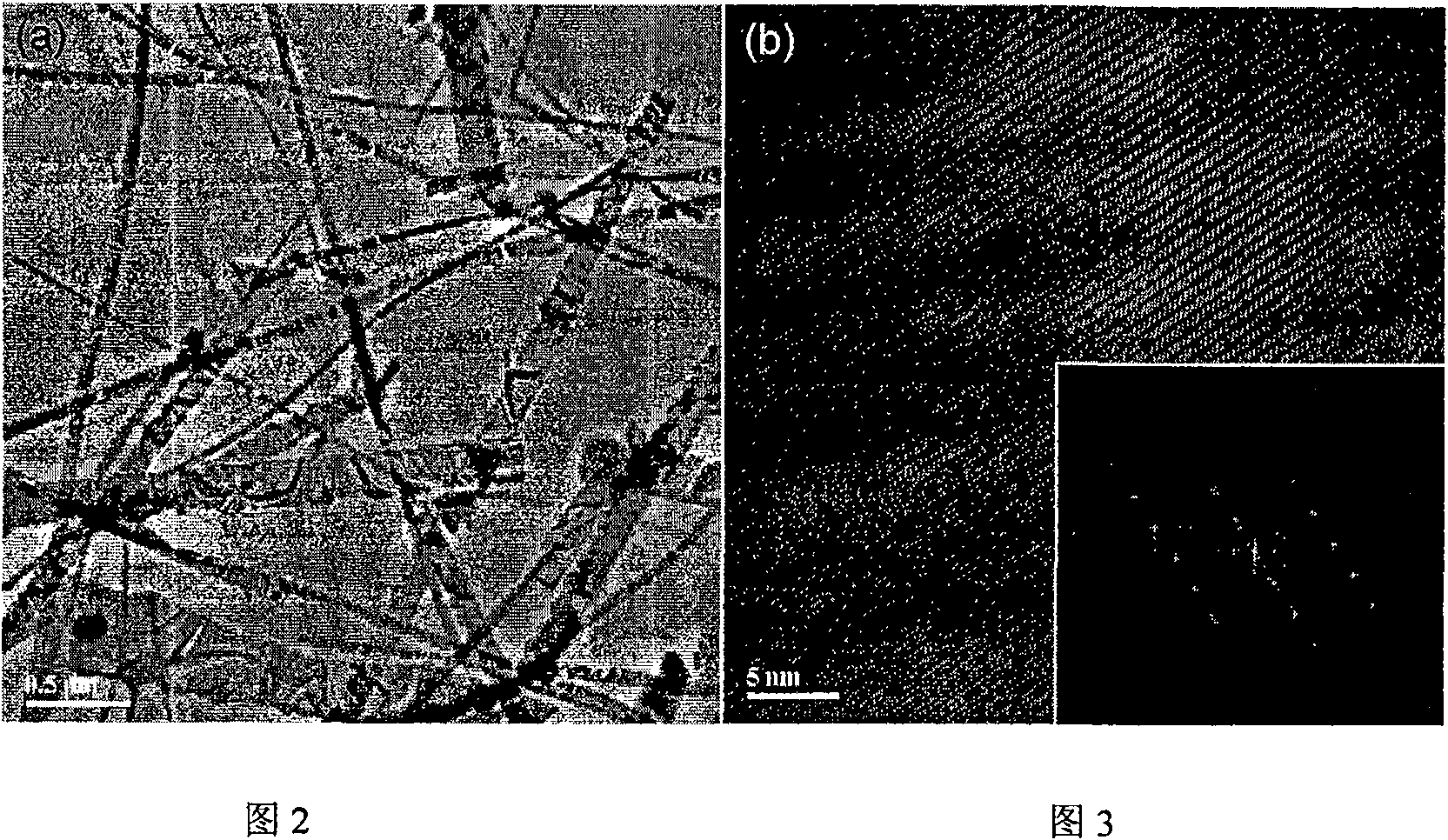

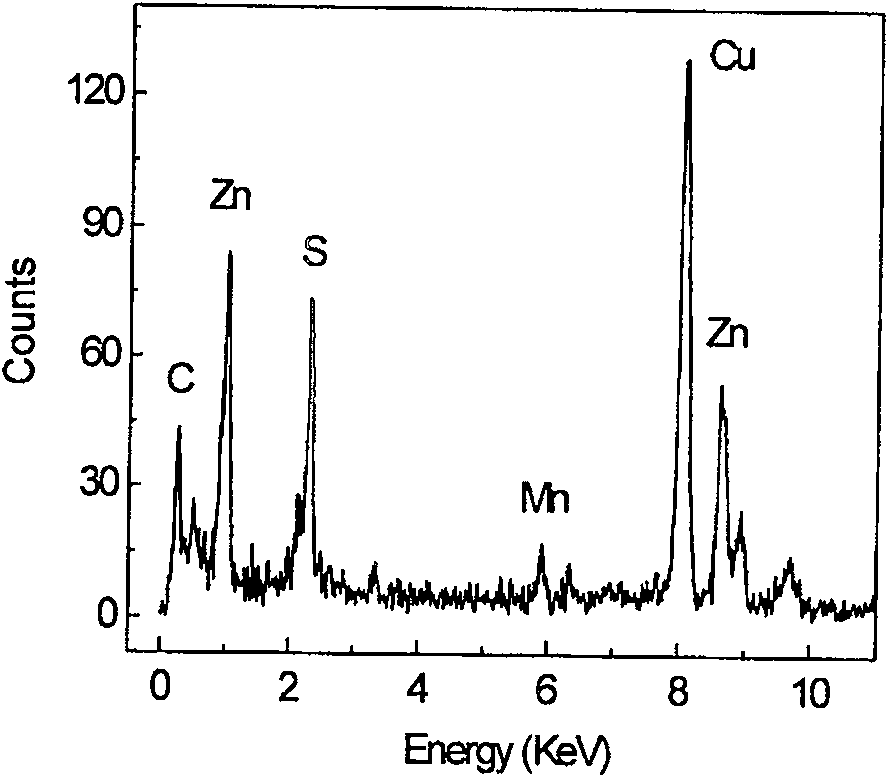

Method for preparing Mn-doped ZnS nanostructure

A nanostructure and evaporation source technology, applied in the direction of zinc sulfide, can solve the problems affecting the performance of Mn-doped ZnS nanomaterials, and achieve the effects of easy industrial production, low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Use a blank (no metallized film) silicon wafer as the receiving substrate. Silicon substrates were ultrasonically cleaned in alcohol and acetone, respectively.

[0020] 2. A mixed gas of argon and hydrogen with a flow rate of 110 ml / min (the volume ratio of hydrogen and argon is 10:100) is introduced into the tube furnace.

[0021] 3. ZnS powder and MnCl 2 The powder is placed in a quartz boat as an evaporation source, and the boat with the evaporation source and the cleaned silicon wafer are placed in a tube furnace. Wherein, the evaporation source is placed in the inlet direction of the argon-hydrogen mixed gas flow, the silicon chip is placed in the outlet direction of the argon-hydrogen mixed gas flow, and the horizontal distance between the silicon chip and the evaporation source is 4 mm.

[0022] 4. Raise the temperature of the tube furnace to 900°C, the holding time is 100min, and the pressure in the furnace is 0.015MPa. Cool down with the furnace after the...

Embodiment 2

[0025] 1. Use a blank (no metallized film) silicon wafer as the receiving substrate. Silicon substrates were ultrasonically cleaned in alcohol and acetone, respectively.

[0026] 2. A mixed gas of argon and hydrogen with a flow rate of 113 ml / min (the volume ratio of hydrogen and argon is 13:100) is fed into the tube furnace.

[0027] 3. ZnS powder and MnCl 2 The powder is placed in a quartz boat as an evaporation source, and the boat with the evaporation source and the cleaned silicon wafer are placed in a tube furnace. Wherein, the evaporation source is placed in the inlet direction of the argon-hydrogen mixed gas flow, the silicon chip is placed in the outlet direction of the argon-hydrogen mixed gas flow, and the horizontal distance between the silicon chip and the evaporation source is 3mm.

[0028] 4. Raise the temperature of the tube furnace to 910°C, the holding time is 200min, and the pressure in the furnace is 0.015MPa. Cool down with the furnace after the growth ...

Embodiment 3

[0030] 1. Use a blank (no metallized film) silicon wafer as the receiving substrate. Silicon substrates were ultrasonically cleaned in alcohol and acetone, respectively.

[0031] 2. A mixed gas of argon and hydrogen with a flow rate of 108 ml / min (the volume ratio of hydrogen and argon is 8:100) is introduced into the tube furnace.

[0032] 3. ZnS powder and MnCl 2 The powder is placed in a quartz boat as an evaporation source, and the boat with the evaporation source and the cleaned silicon wafer are placed in a tube furnace. Among them, the evaporation source is placed in the direction of the inlet of the argon-hydrogen mixed gas flow, the silicon chip is placed in the direction of the outlet of the argon-hydrogen mixed gas flow, and the horizontal distance between the silicon chip and the evaporation source is 6mm.

[0033] 4. Raise the temperature of the tube furnace to 920°C, the holding time is 60min, and the pressure in the furnace is 0.03MPa. Cool down with the furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com