Spinning method and device of single-component sheath-core fiber

A spinning device and sheath-core technology, which is applied in the field of fiber manufacturing, can solve the problems of reduced fiber elongation, spinning difficulties, and increased raw material costs, and achieve the effects of reduced usage, low cost, and reduced raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

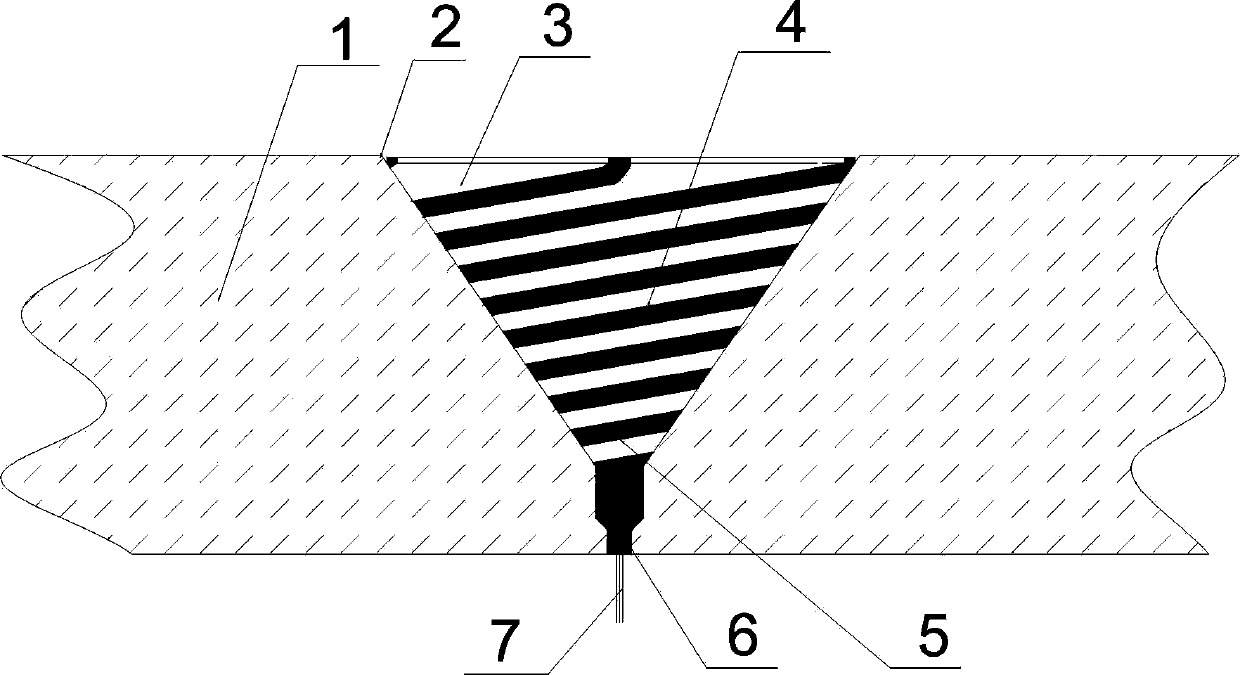

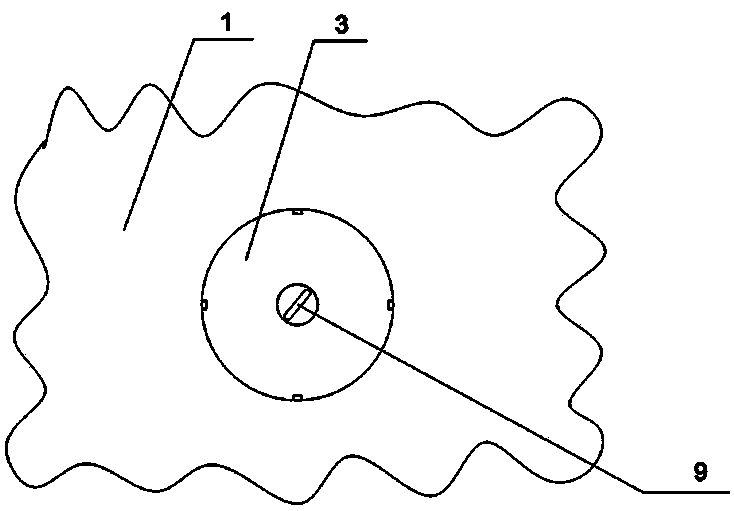

[0020] Reference figure 1 with figure 2 , Install a cone 3 with spiral melt channel in the spinneret guide hole 2 of the spinneret 1 of the spinning machine; the cone with spiral melt channel is a solid cone structure; the spiral melt channel 4 is a four-helix structure ; The hook 9 on the cone facilitates removal and installation.

[0021] Install the cone 3 with spiral melt channel in the spinneret guide hole 2 of the spinneret 1 of the spinning machine for spinning single-component sheath-core fiber; the spinning melt 5 containing functional particles can pass The spiral melt channel 4 on the surface of the cone installed in the spinneret guide hole of the spinneret rotates and flows into the spinneret micro-hole 6 at high speed, and is sprayed and solidified into a single-component sheath-core fiber 7; due to the high-speed rotation of the melt The huge centrifugal force urges the functional particles in the spinning melt to gather to the edge and eject them through the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com