Patents

Literature

126 results about "Surgical Gloves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

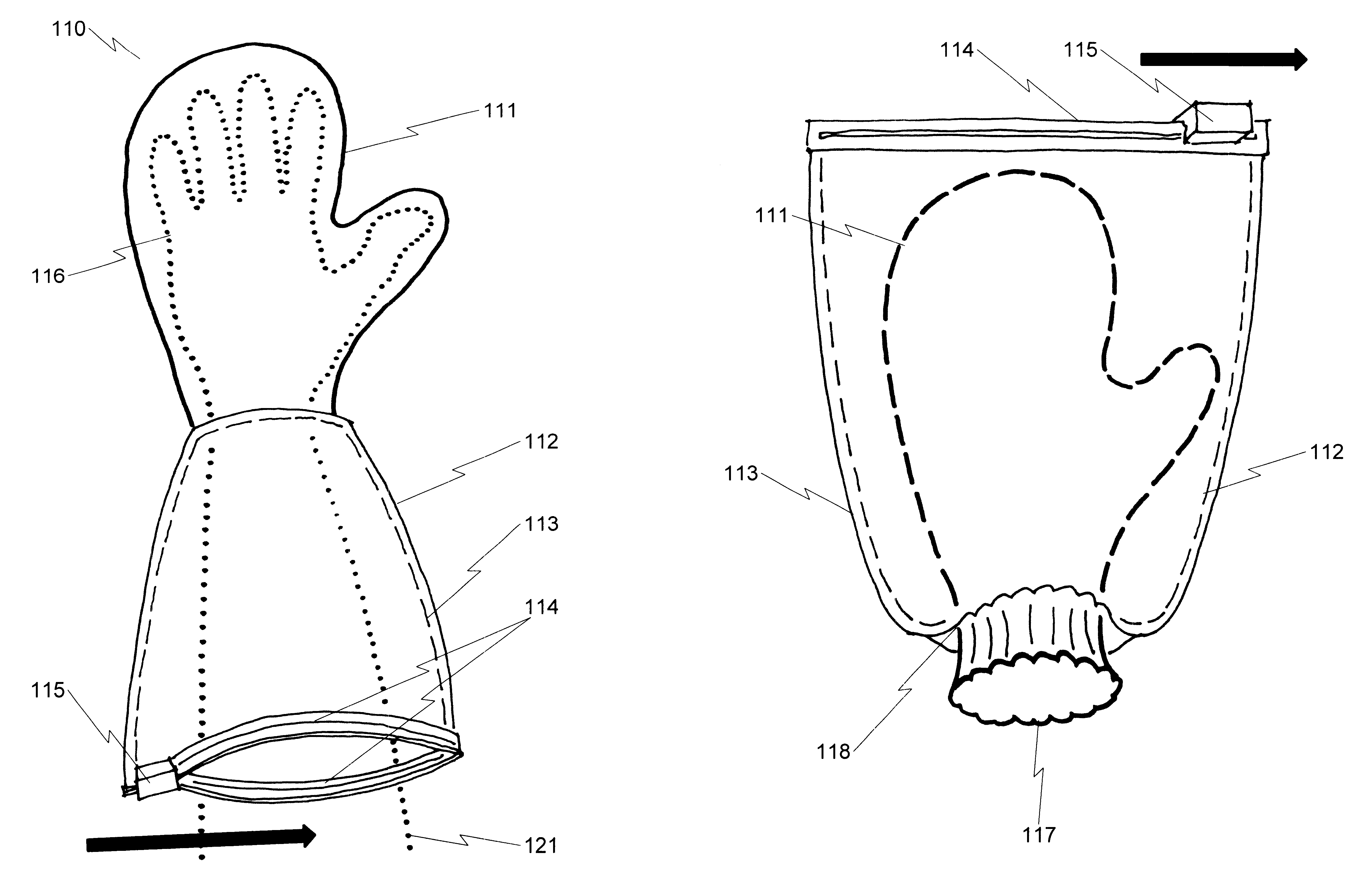

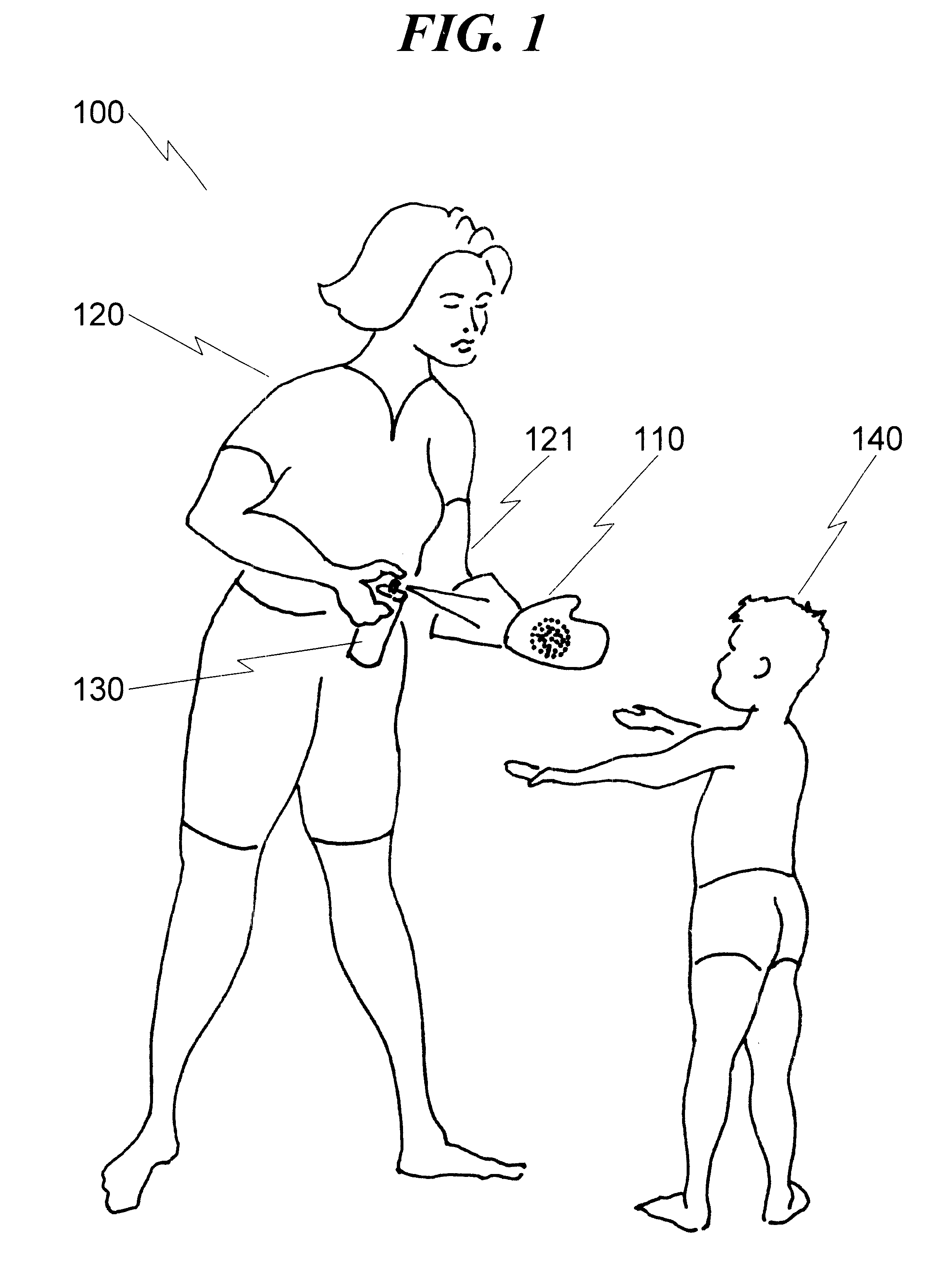

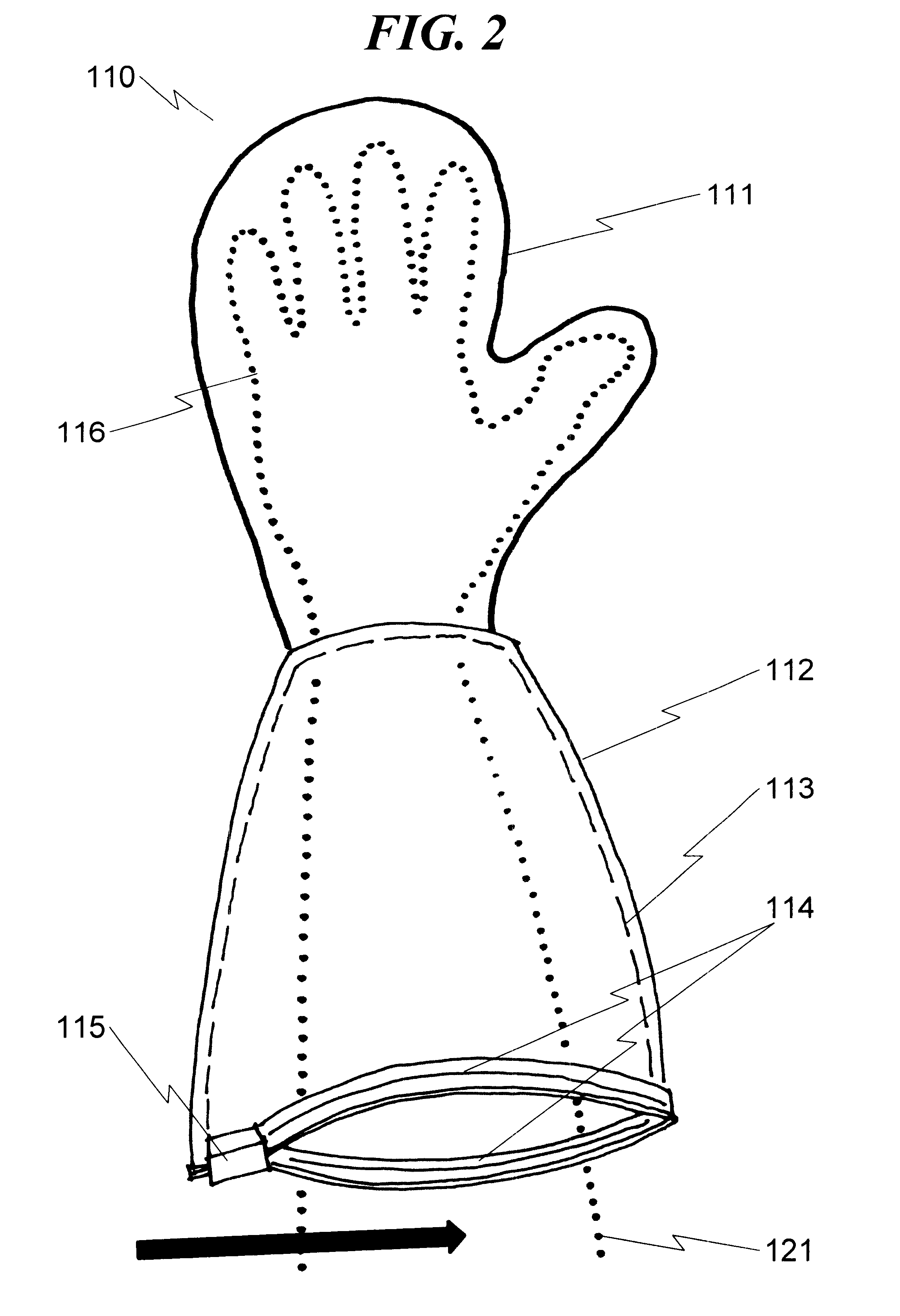

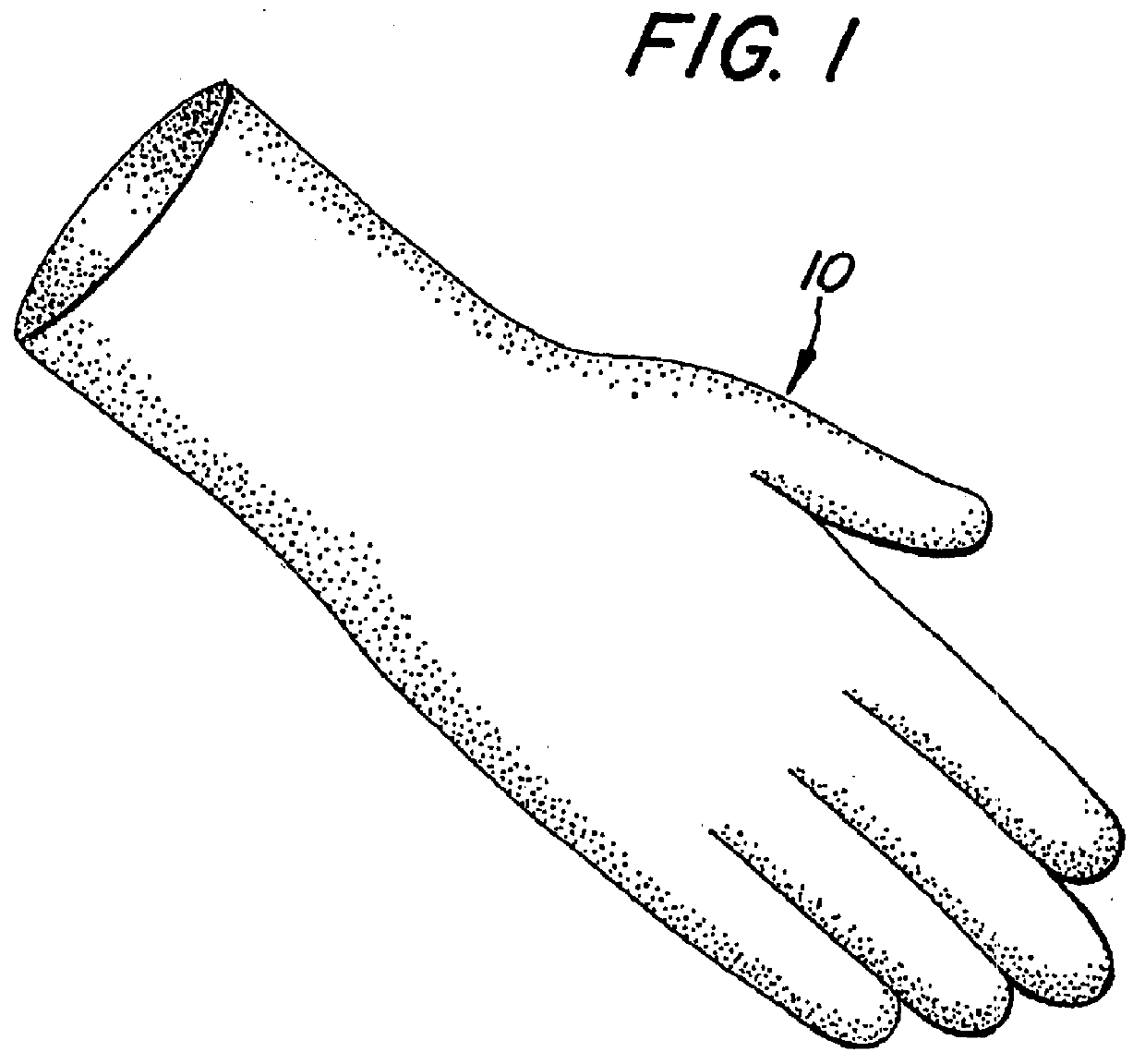

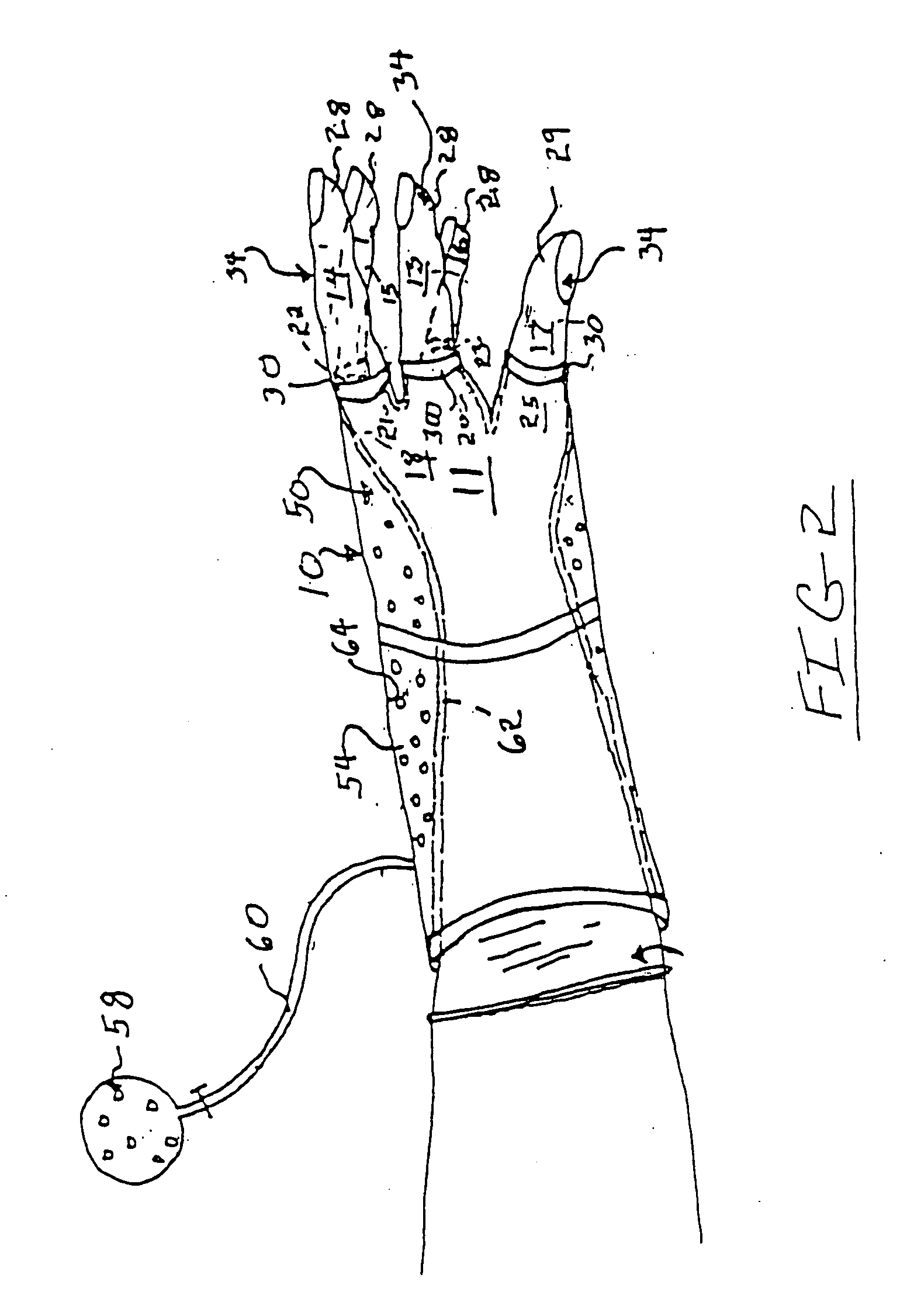

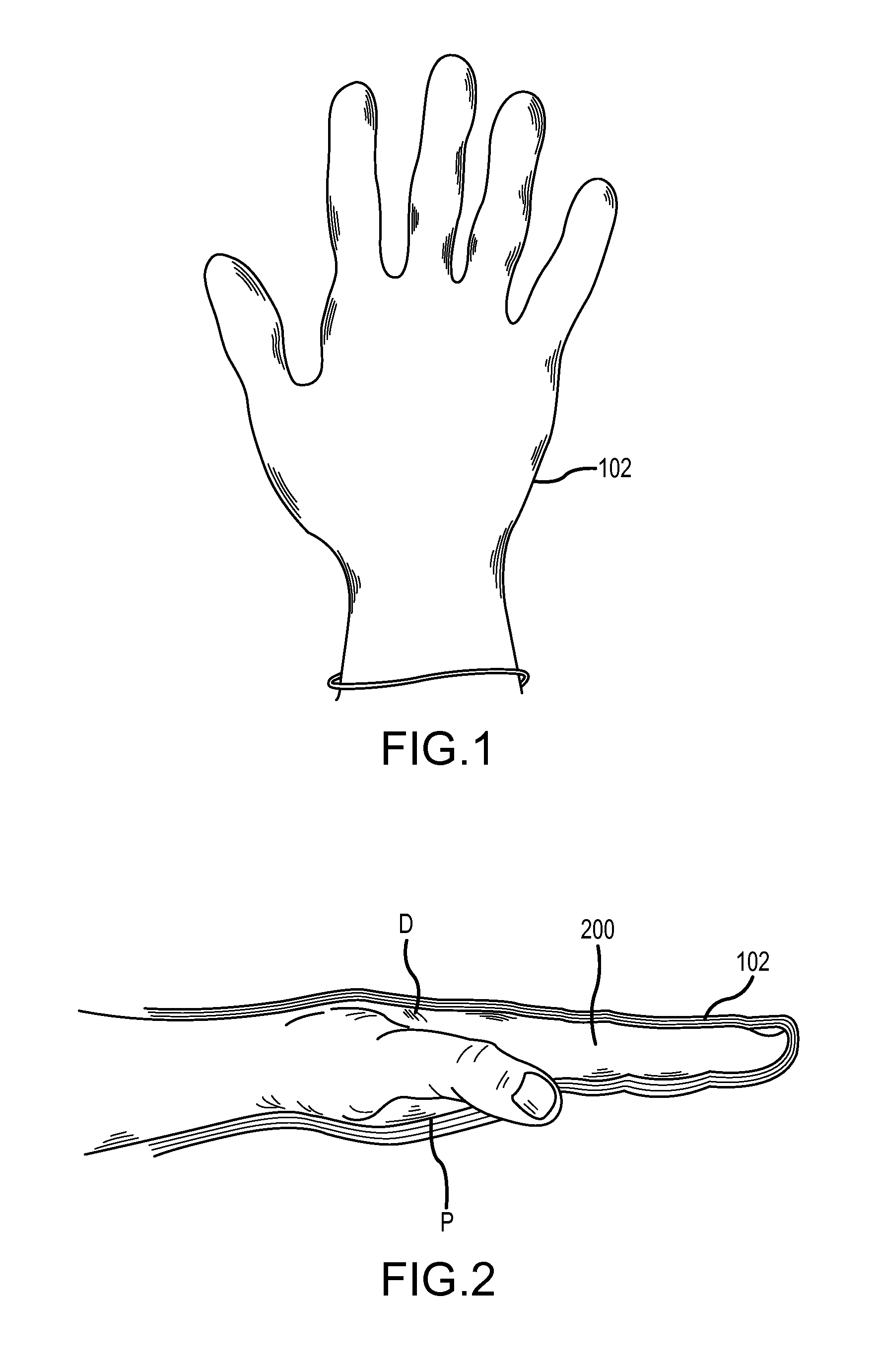

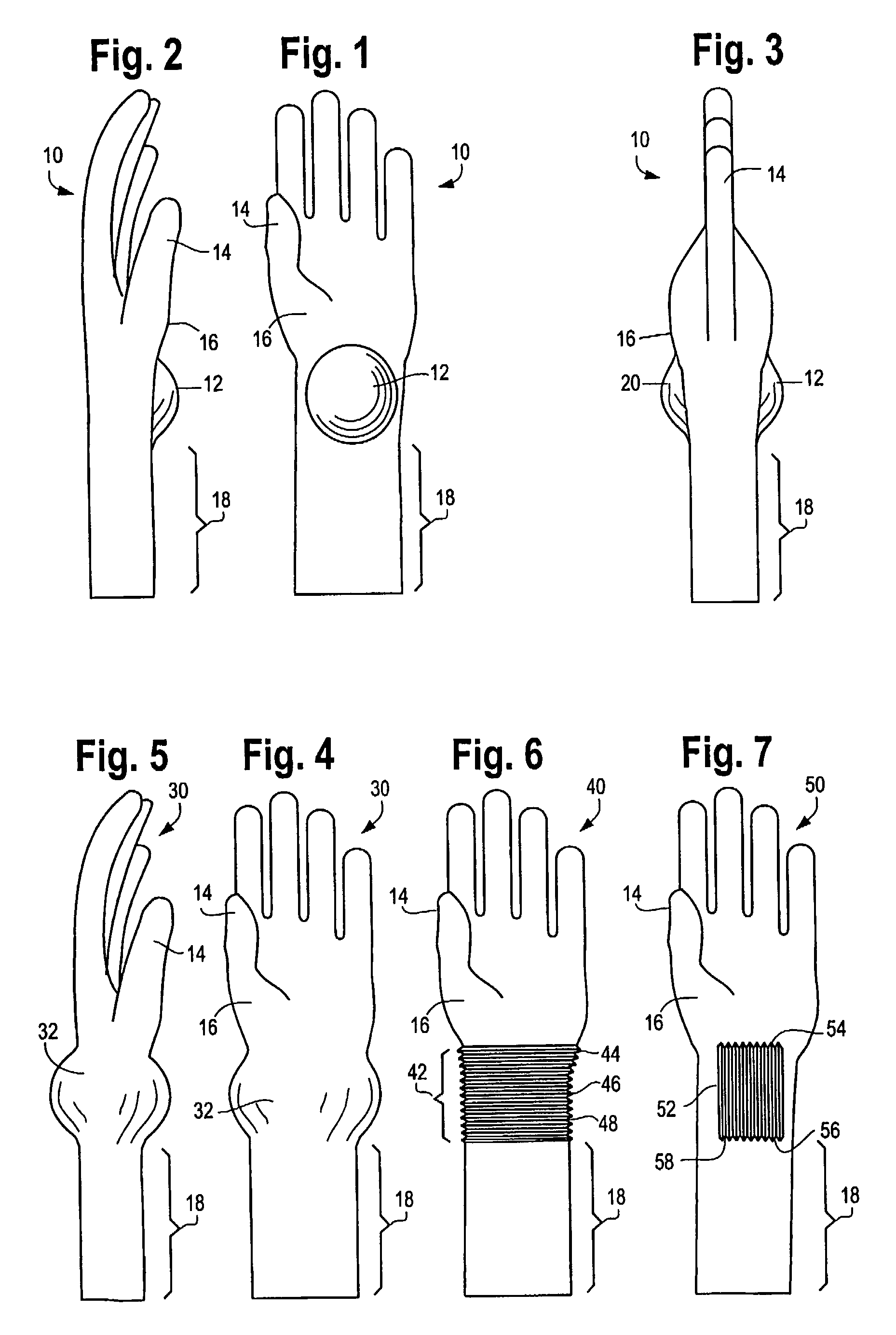

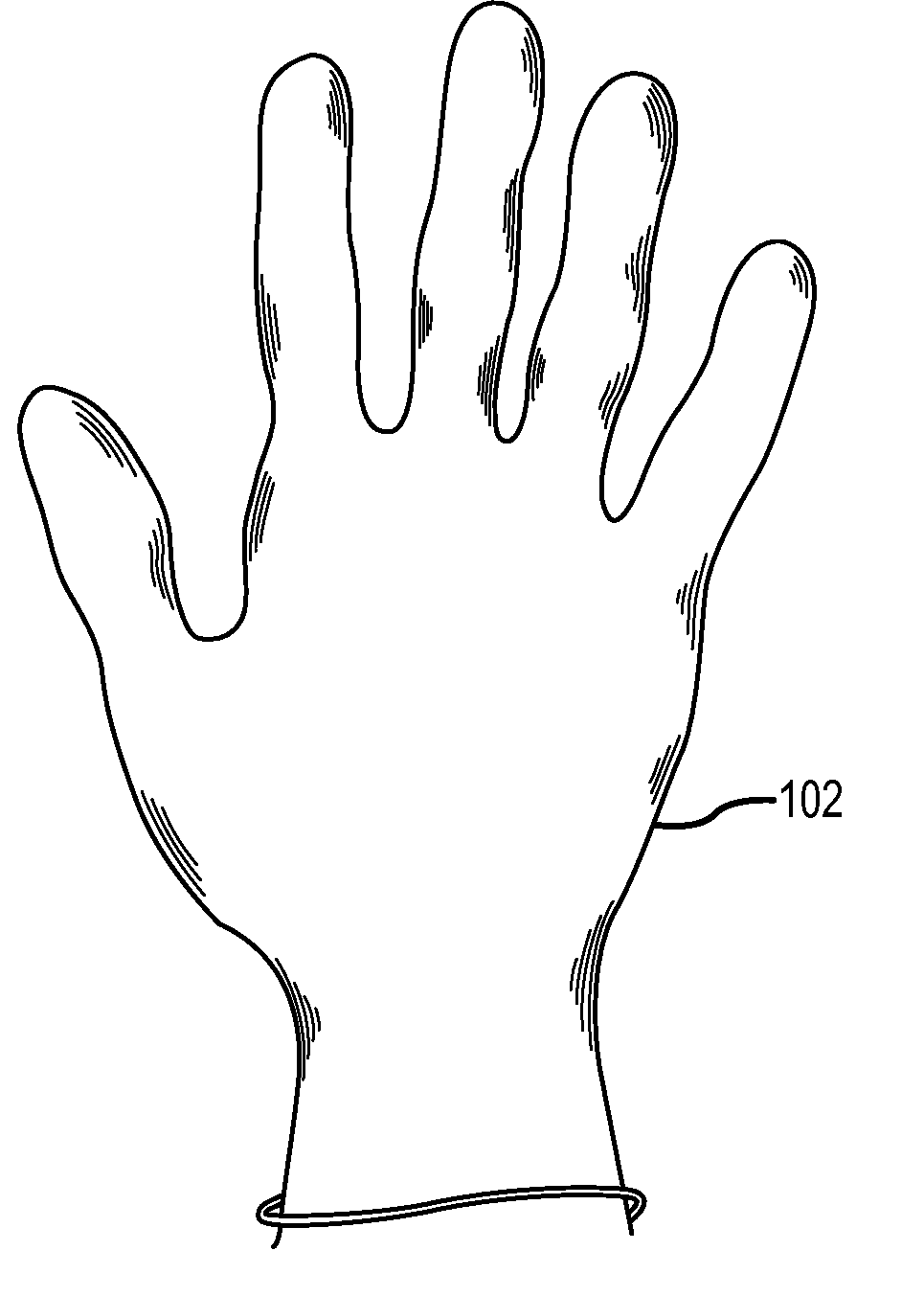

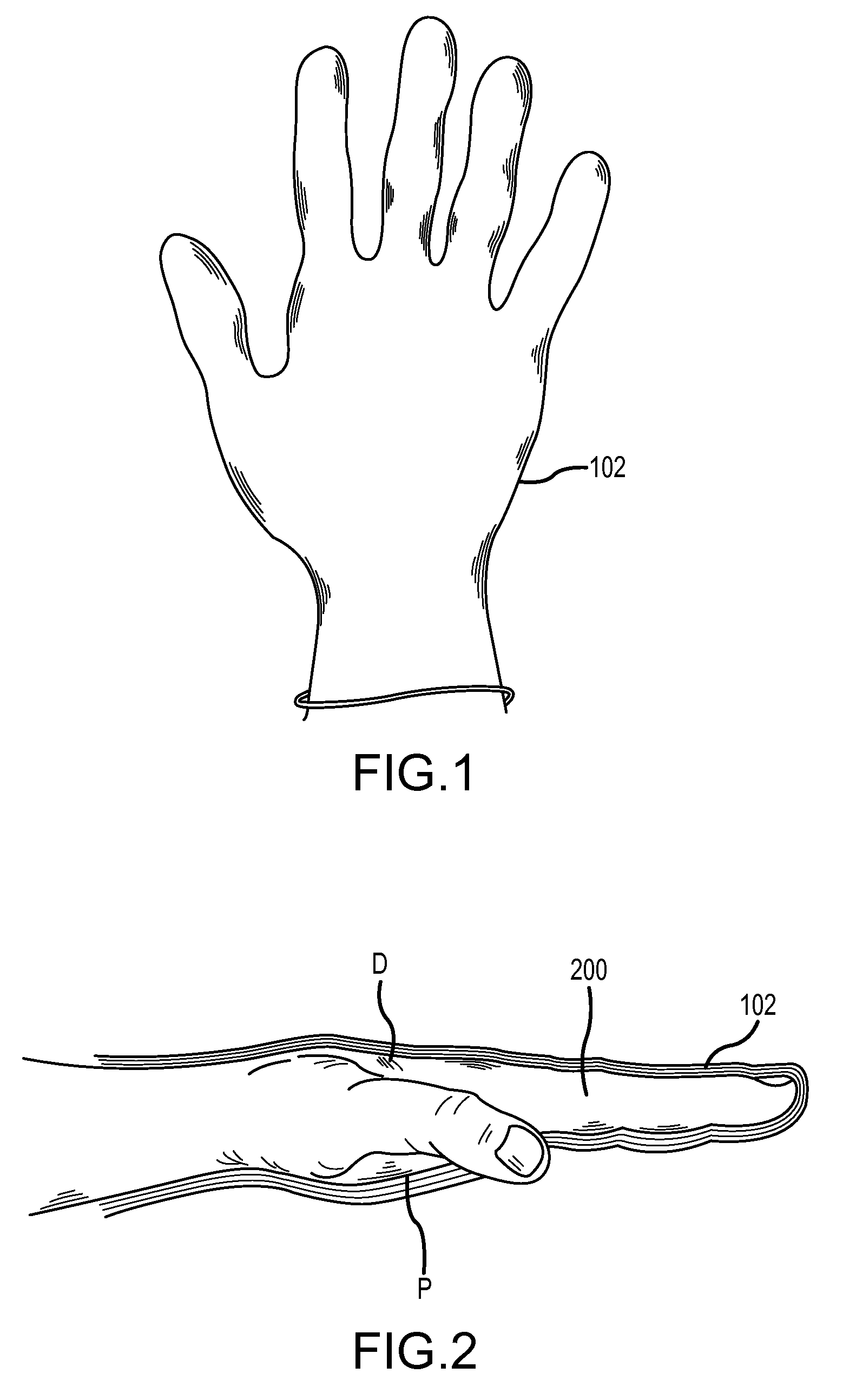

Safety applicator glove system and method

A safety applicator glove system and method is disclosed that is particularly suitable for use in situations where insect repellent and the like must be applied to human skin without contaminating the hands of the person applying the insect repellent. The basic system disclosed includes a glove or mitten with an absorbent outer surface and an internal barrier lining to prevent penetration of liquid on the outer surface of the glove with the person's hand that has been inserted into the glove / mitten. Attached to the glove / mitten proximally to the hand entry point is a protective sleeve / gauntlet that may be extended over the surface of the glove and sealed to act as a containment vessel for the liquid-soaked glove. When retracted, this protective sleeve / gauntlet serves to prevent contamination of the person making use of the glove / mitten system. Various embodiments of the present invention may also be applied with advantage to the control of contamination associated with biohazardous waste, including but not limited to use with surgical gloves and the like.

Owner:PETERS JR GEORGE A

Surgical and examination gloves

InactiveUS6684405B2Avoid stimulationEasy to donPeptide/protein ingredientsSynthetic resin layered productsHuman typeEnzyme inhibitor

An examination or surgical glove having an inner coating of a compound which prevents the degranulation of mast cells which releases medicators of inflammation. The coating includes anti-mast cell and anti-inflammatory agents such cromolyn compounds and human type protease inhibitors.

Owner:LEZDEY JOHN

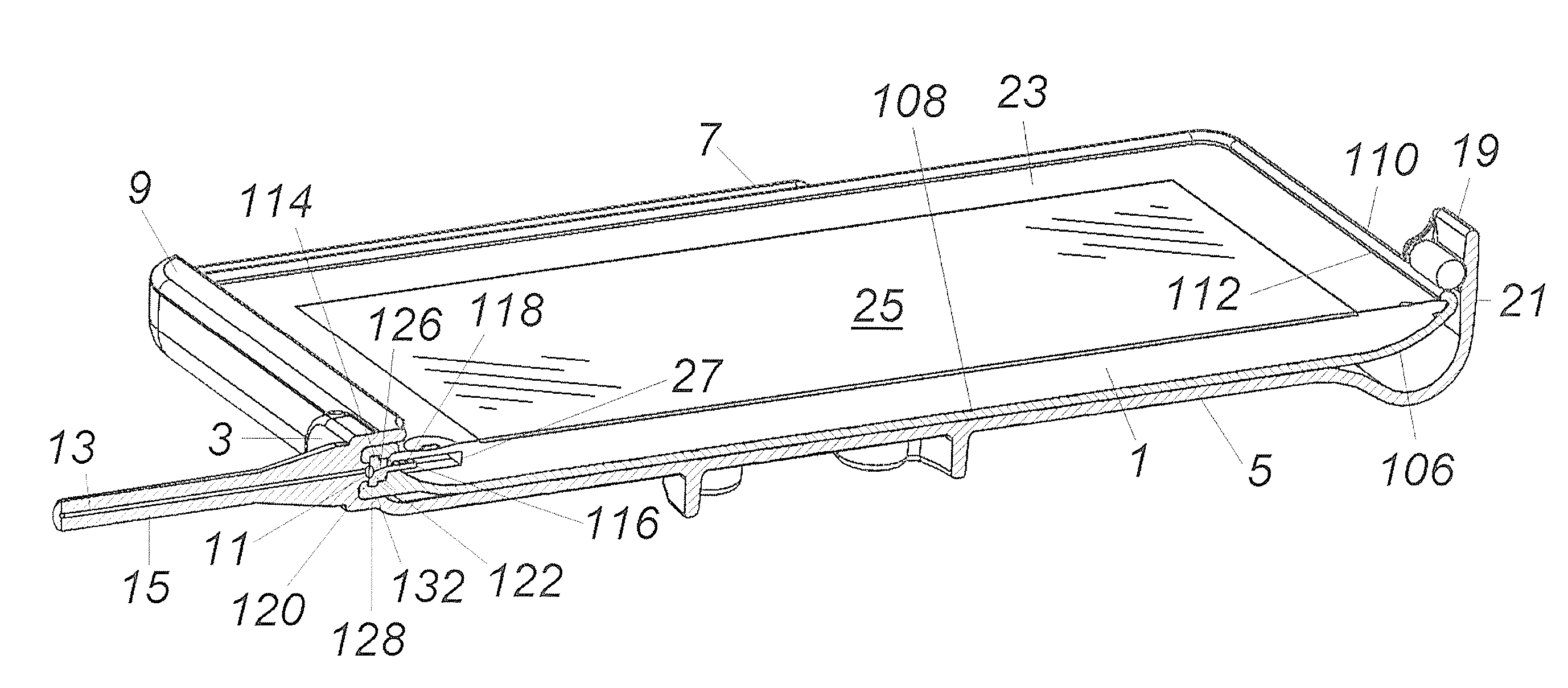

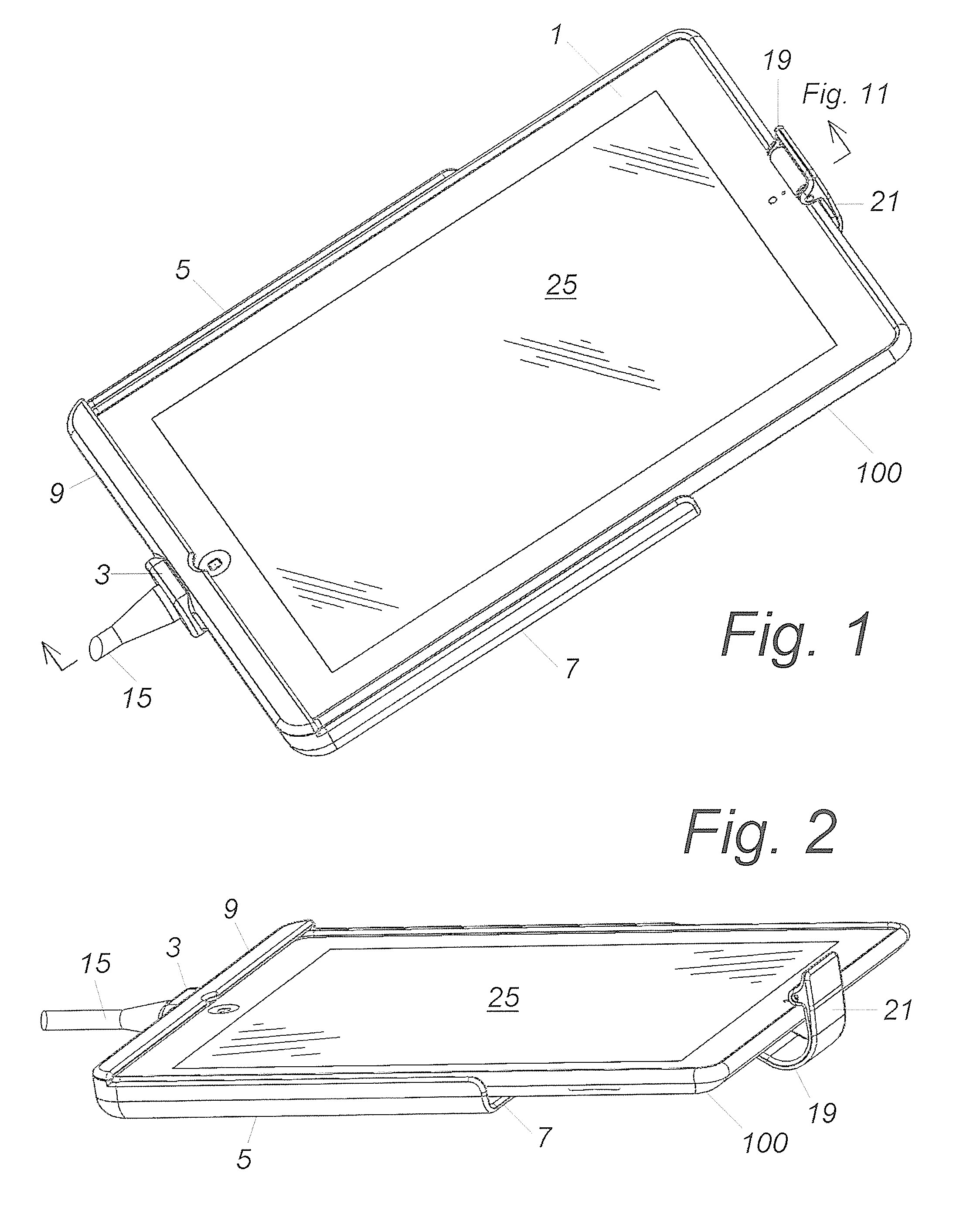

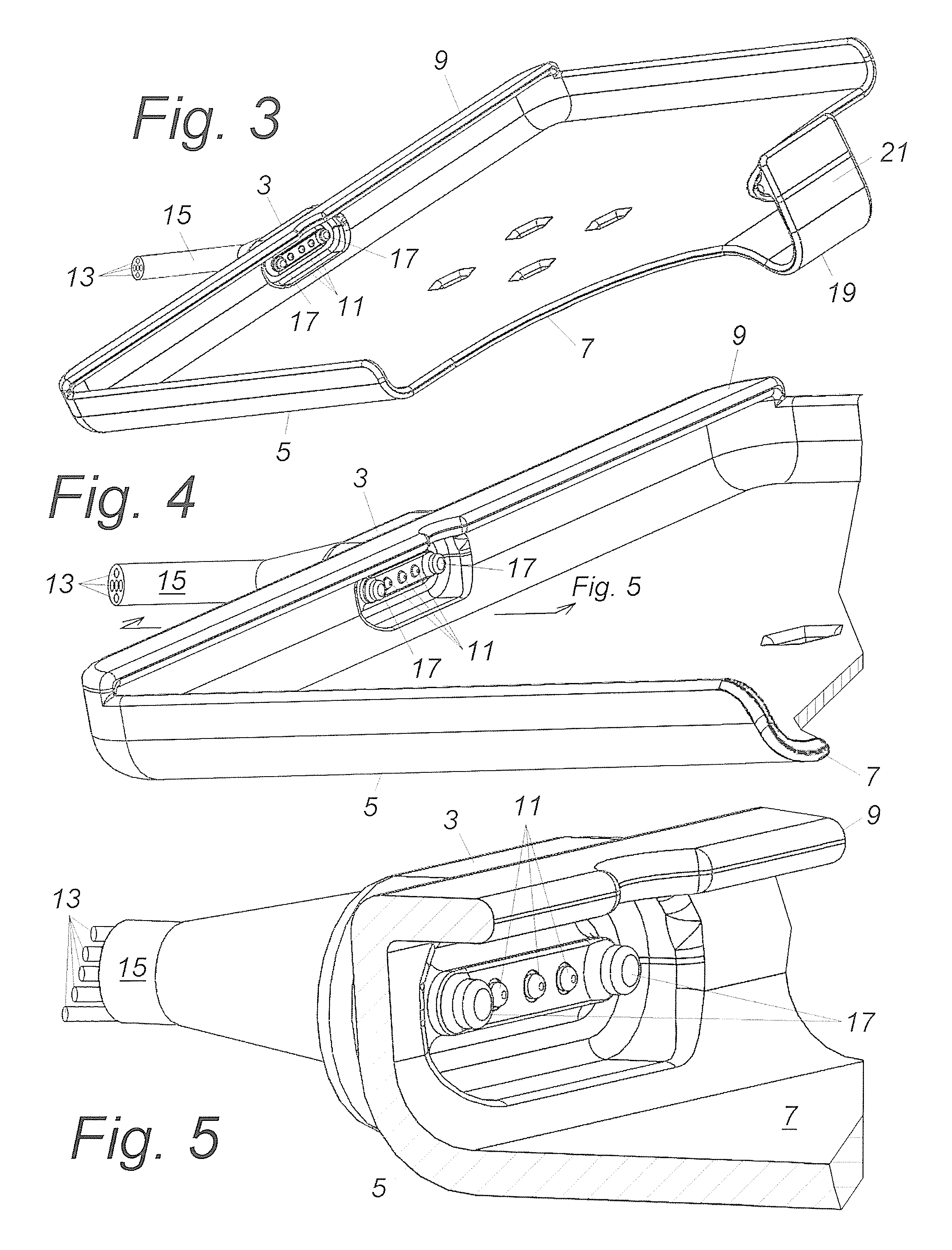

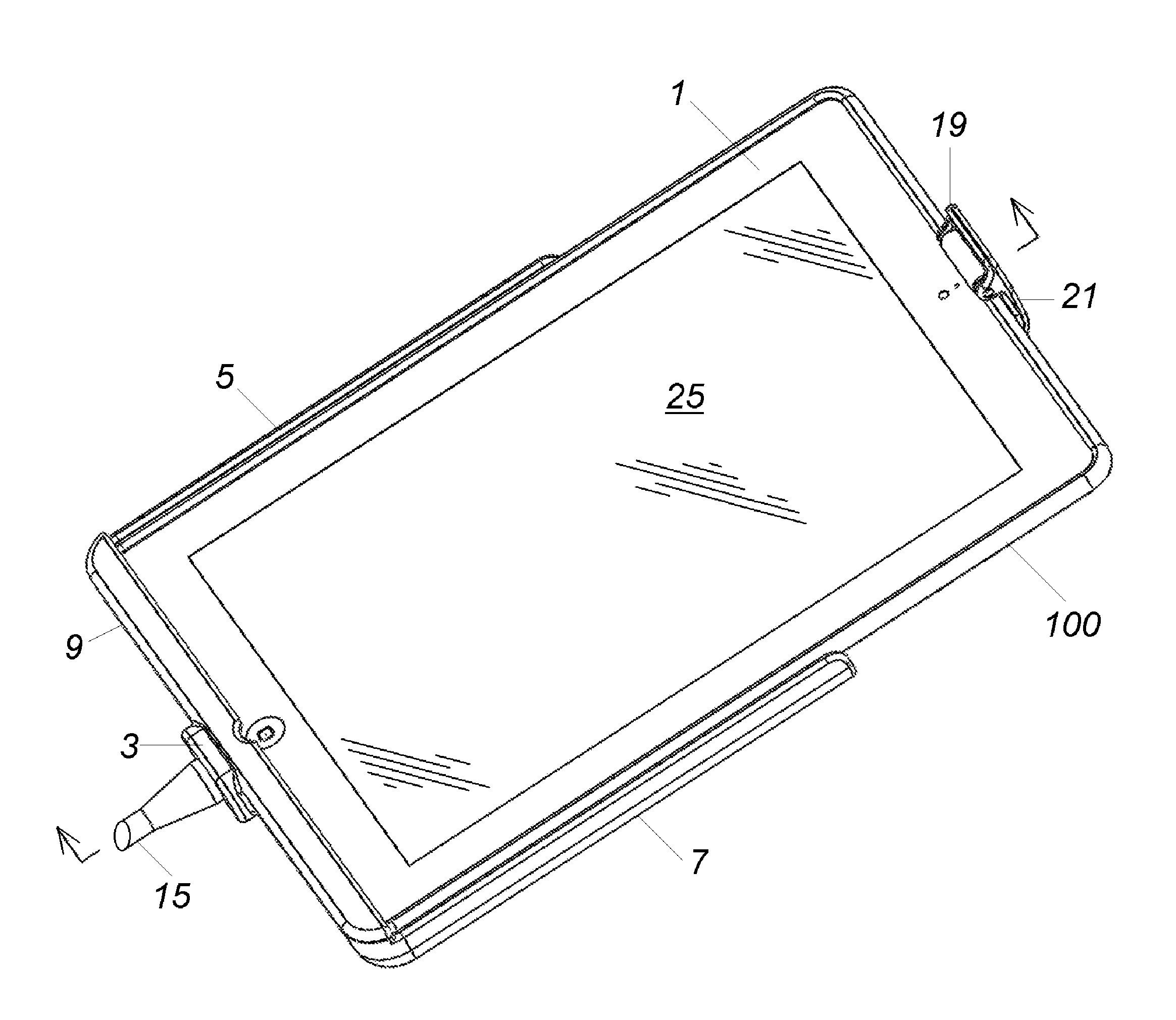

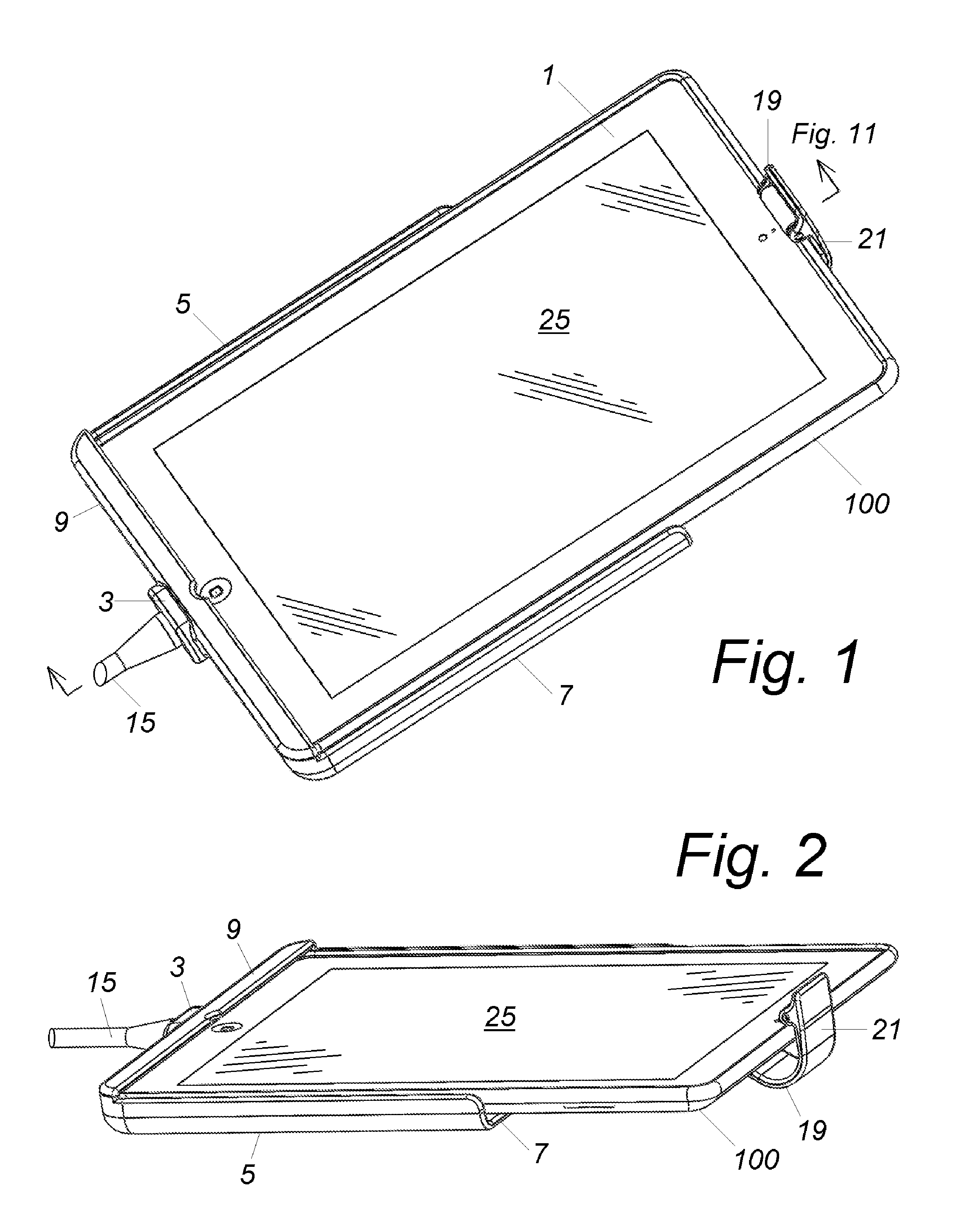

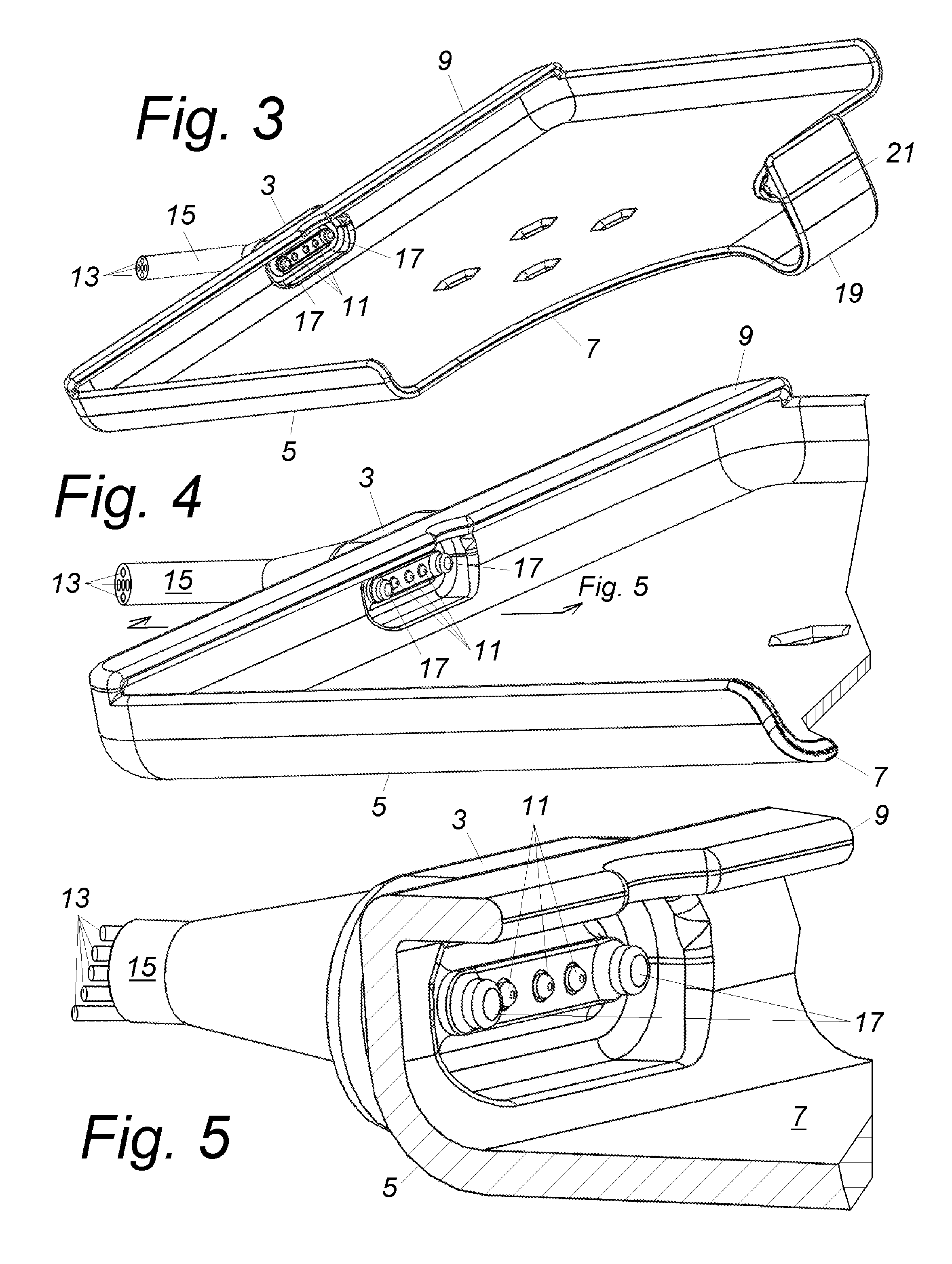

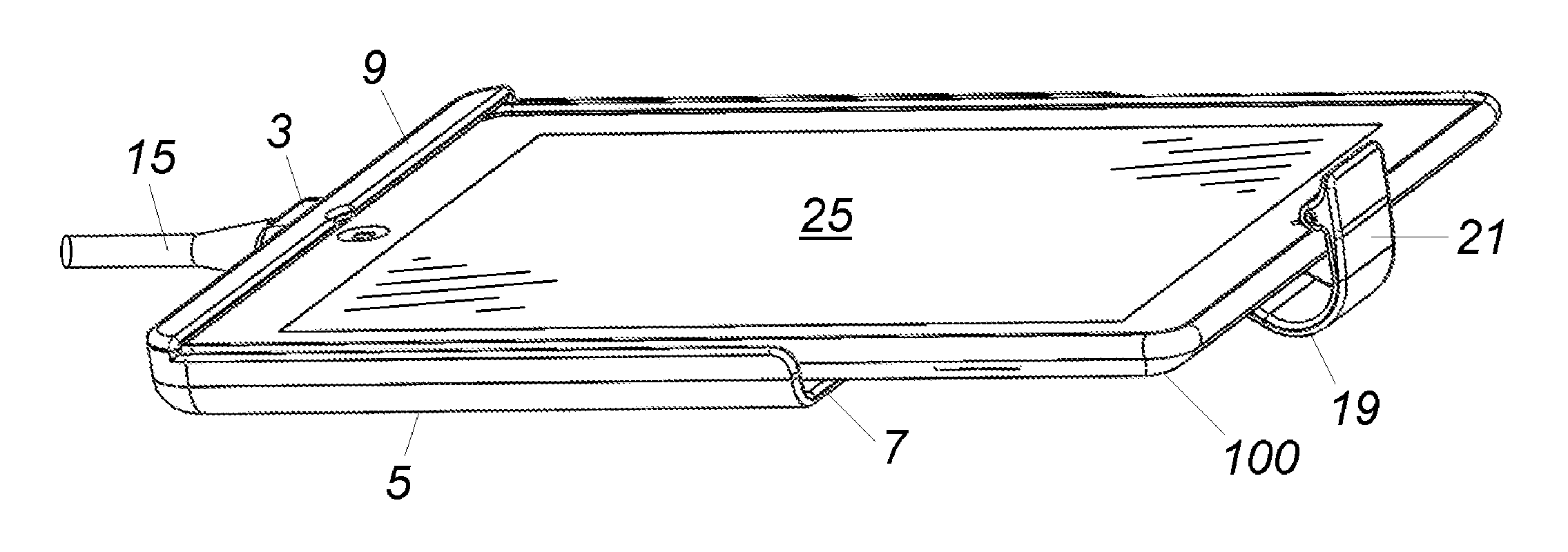

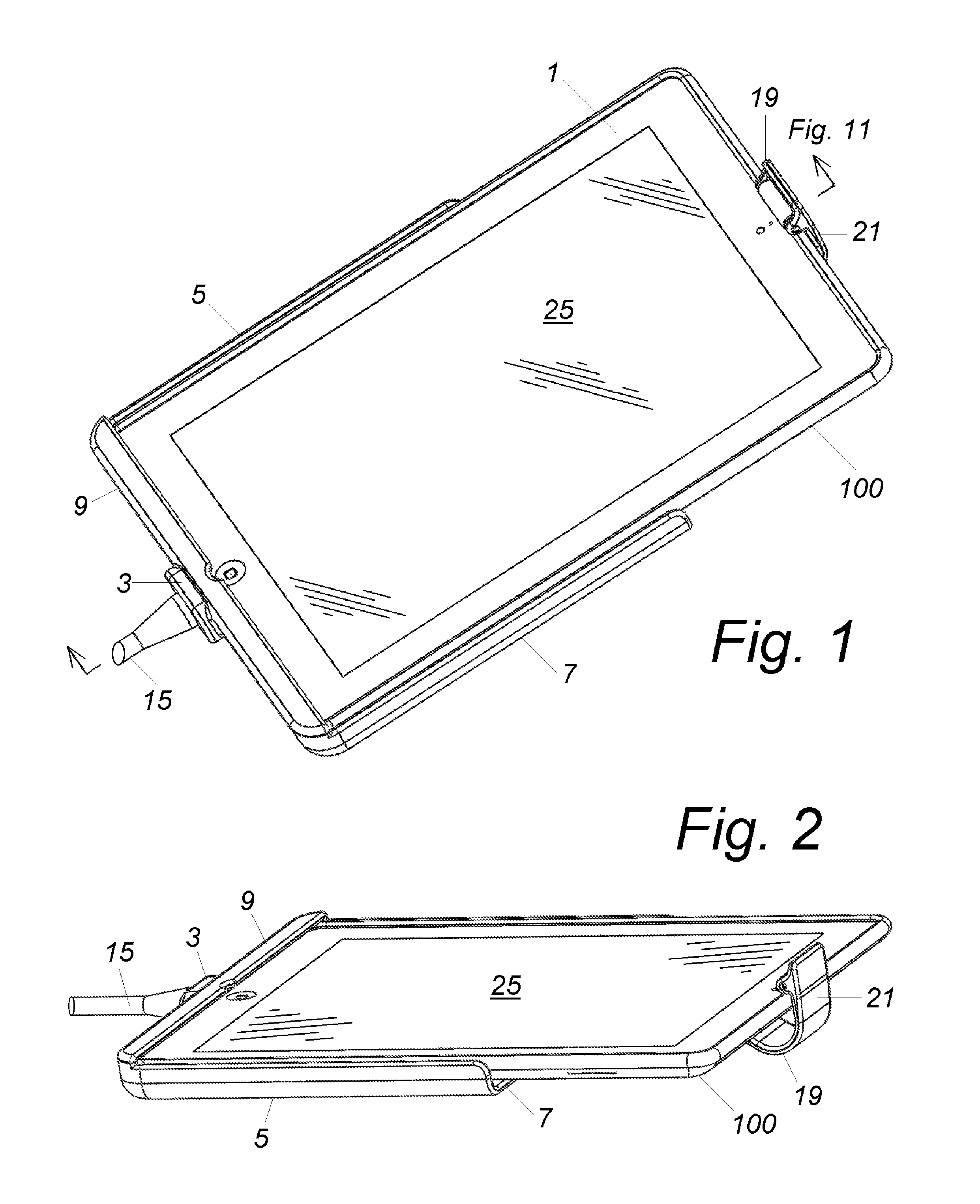

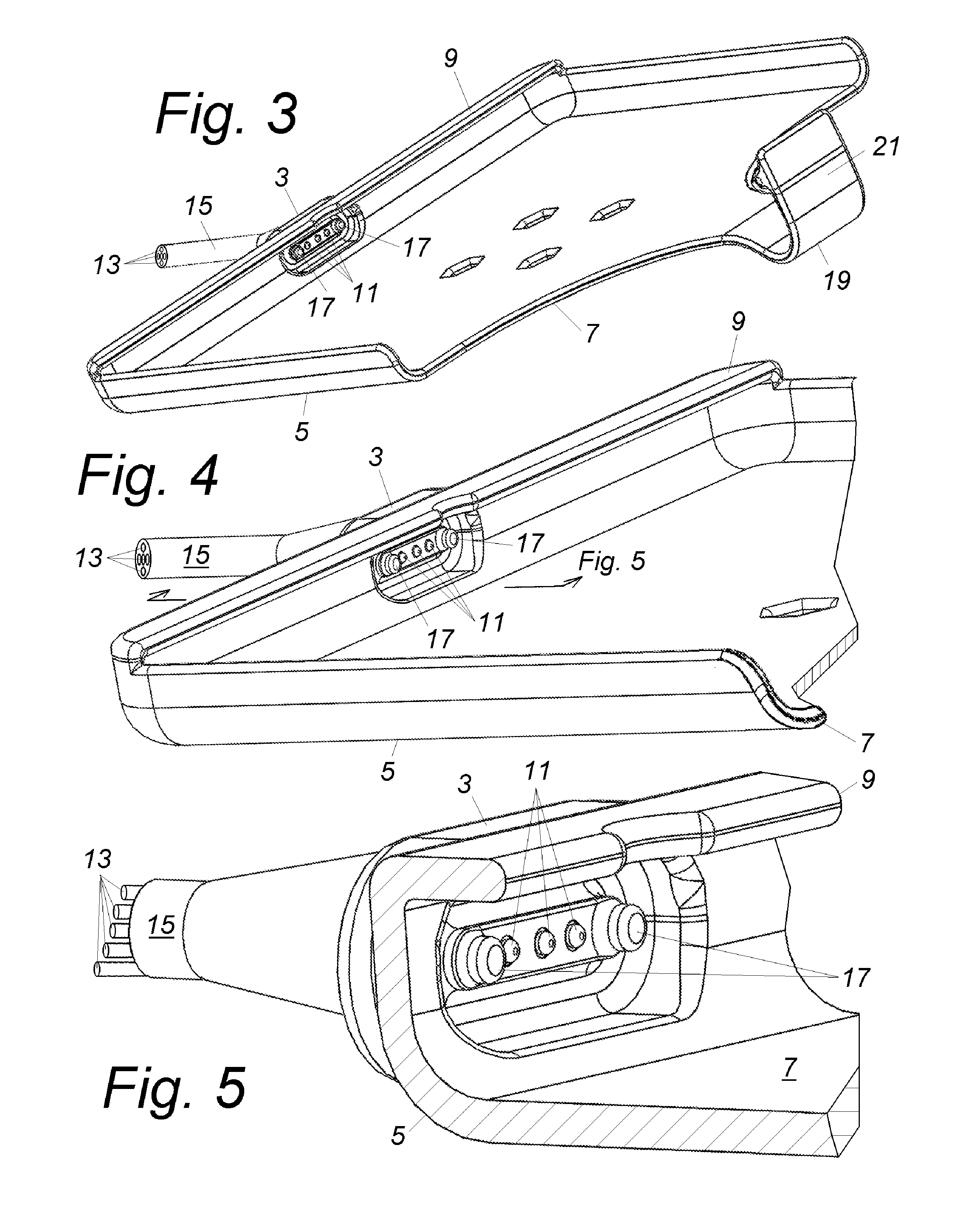

Docking sleeve with electrical adapter

ActiveUS20150241931A1Low costSmooth connectionCoupling device detailsTwo-part coupling devicesTablet computerElastomer

A docking sleeve having an elastomeric protective cover, or skin, adapted for partially enveloping a portable electronic device, such as a smartphone or tablet or another portable electronic device of the prior art having a port for a docking connector. The protective cover is a sheath molded of a suitable elastic or flexibly resilient elastomer in a size and shape to fit over and closely conform to the particular portable electronic device so that the cover fits the device like a surgical glove.An adapter is provided for electrically connecting to the female input / output socket of the particular electronic device, including a male plug having a plurality of electrical connectors extended internally of the sheath and arranged for mating with the female input / output socket of the device, and a plurality of contacts electrically coupled to different ones of the plurality of electrical connectors and exposed externally of the sheath.

Owner:NAT PRODS

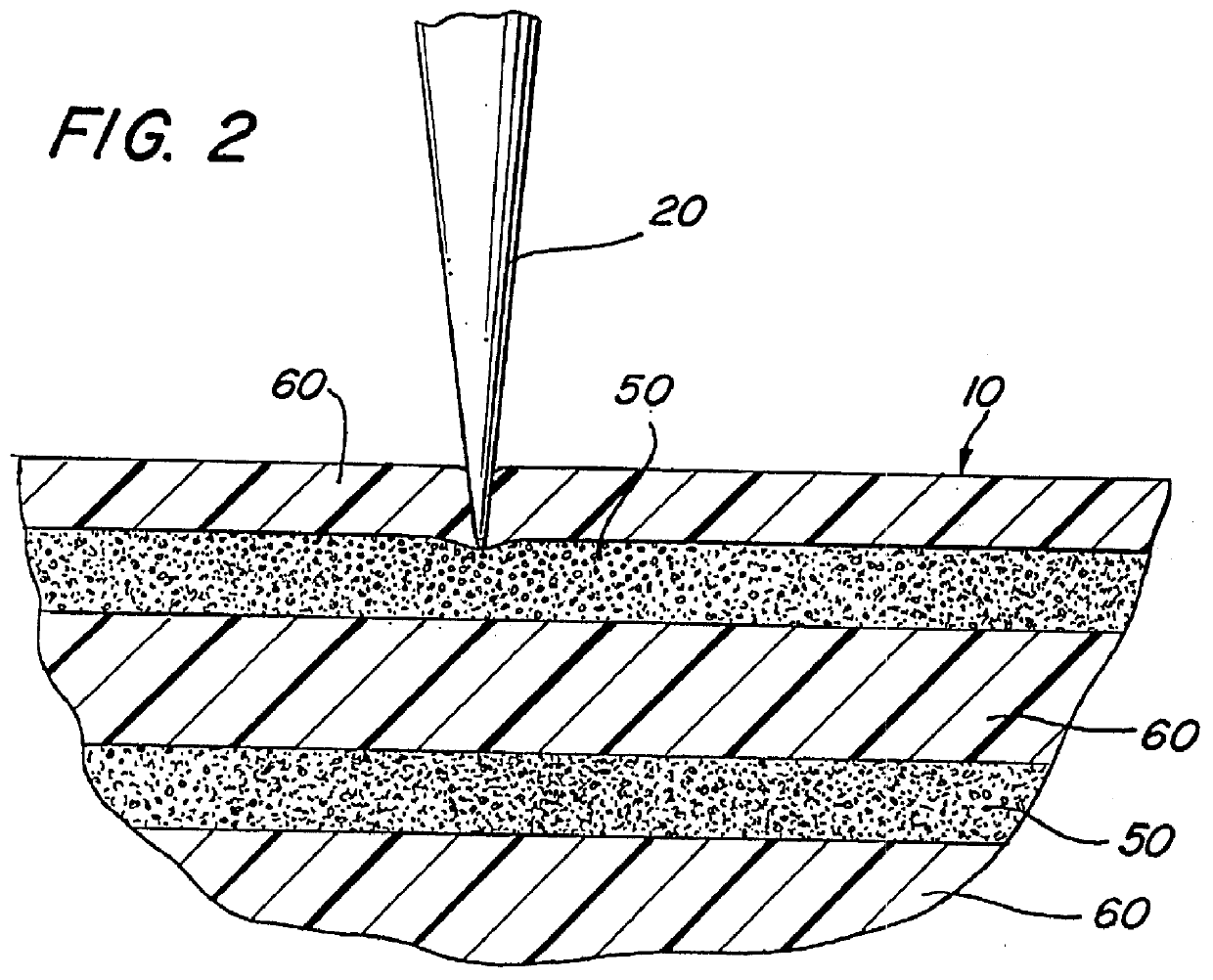

Cut and puncture resistant surgical glove

A surgical glove and method for making same is disclosed comprised of a polymeric matrix with at least one compact layer of very small particulate characterized by a very high hardness disposed therein. The disclosed glove and method is cost effective, easily adapted to present manufacturing methods, and provides a surgical glove which demonstrates a high resistance to cuts and punctures while maintaining a high level of elasticity and touch. The proposed particulate is one of a series of powders such as silicon carbide, carborundum, or diamond dust having a mean particle size of between 1-85 microns and a preferred particle size of between 5-8 microns, which can be applied to a curing elastic glove via spray or pre-mixing the particulate in the molten polymeric matrix prior to forming. The estimated thickness of the finished glove is approximately 2-7 millimeters, although greater thicknesses can be achieved by repeated processing at a cost of superior tactility but without loss of elasticity. More protection can be achieved by generating multiple layers of particulate sandwiched between layers of the polymer matrix.

Owner:DARRAS ROBERT

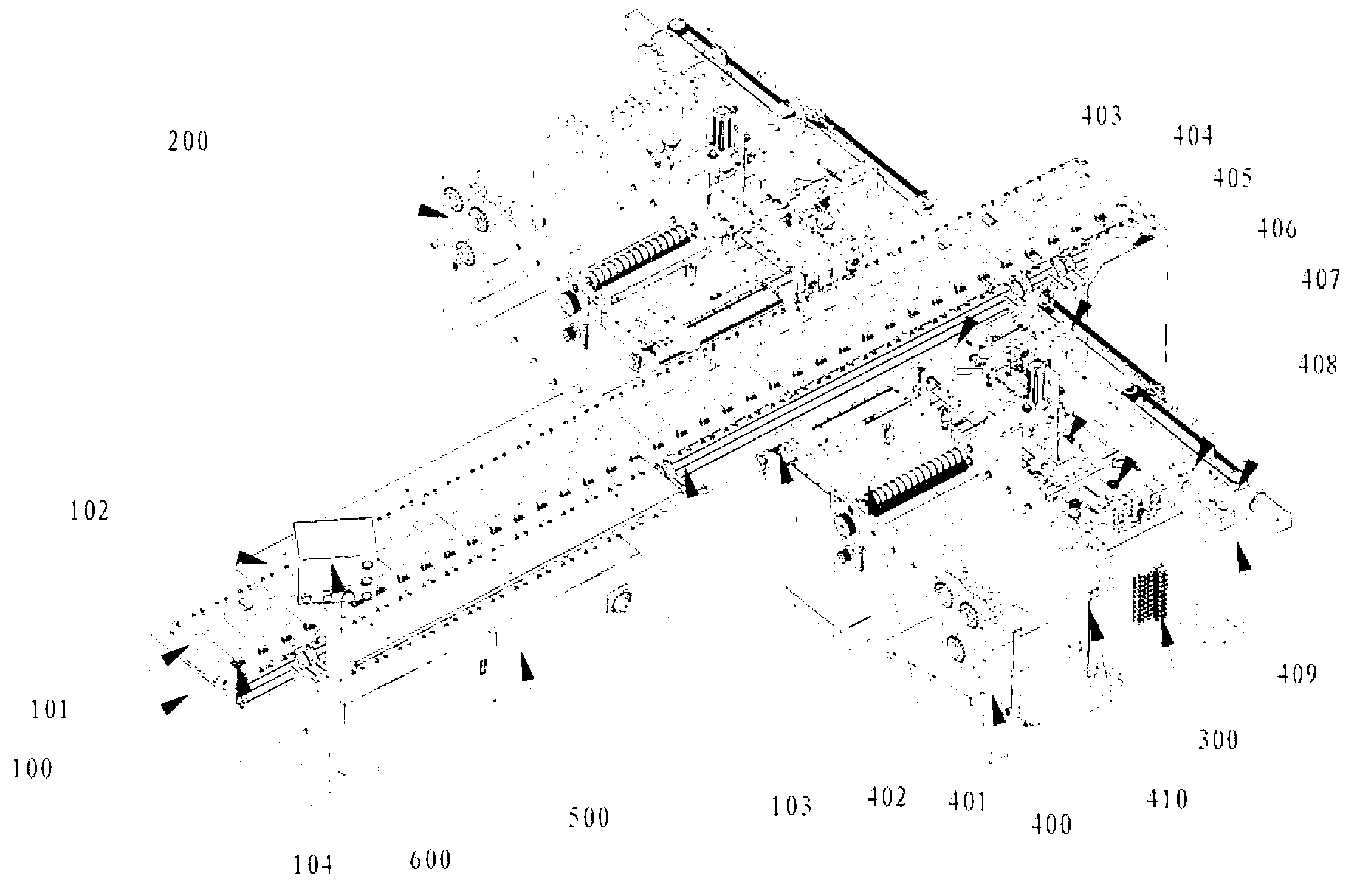

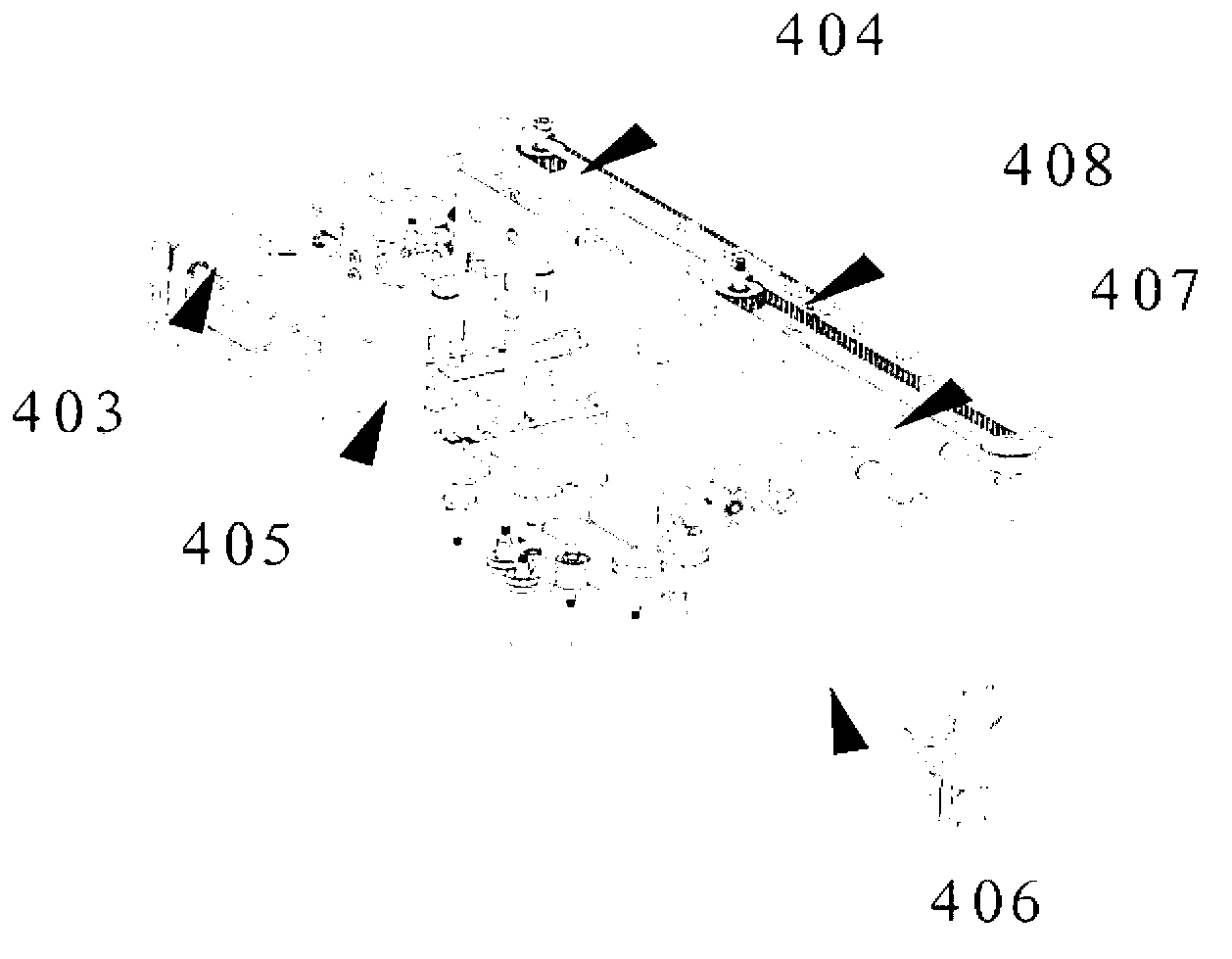

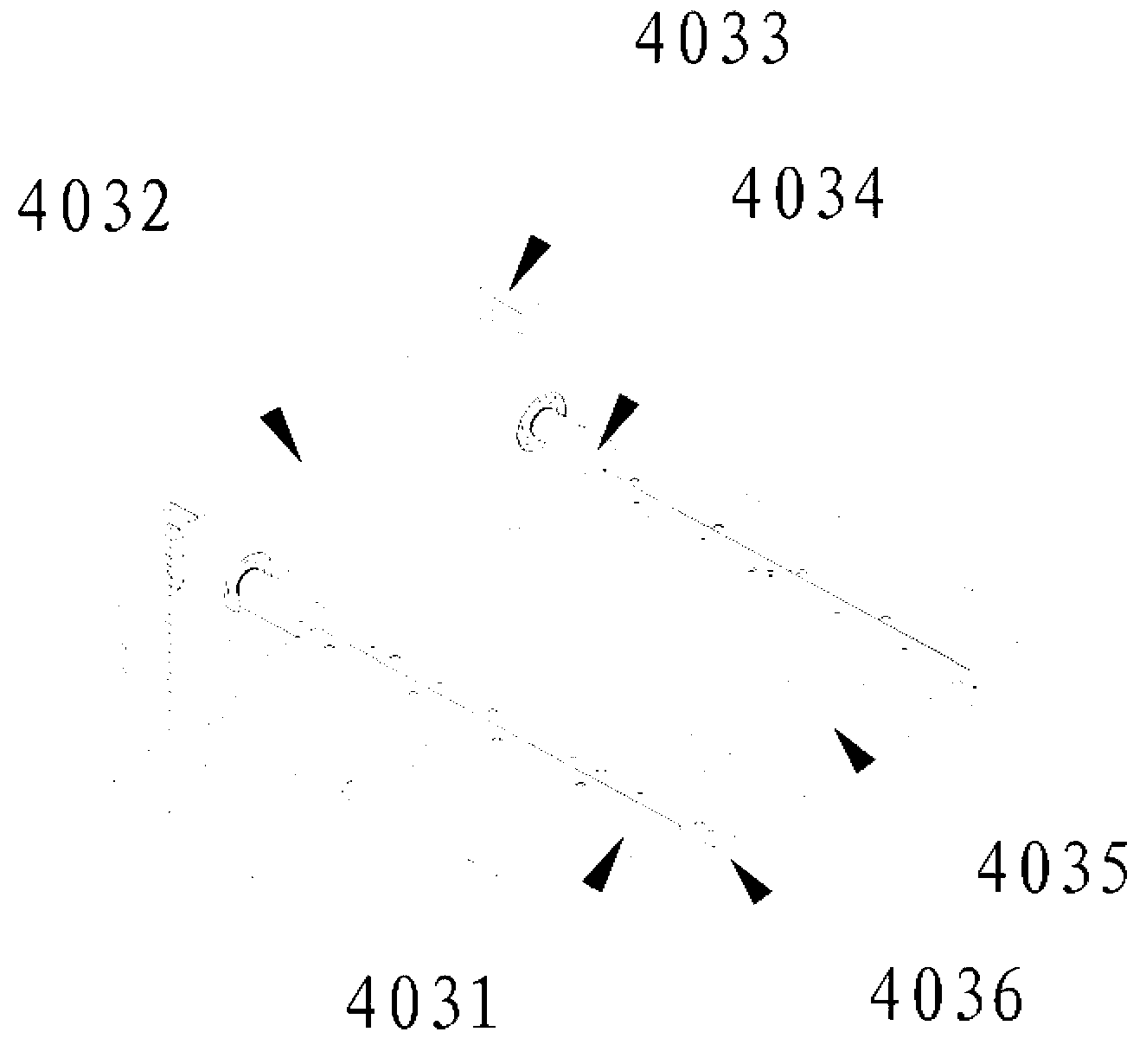

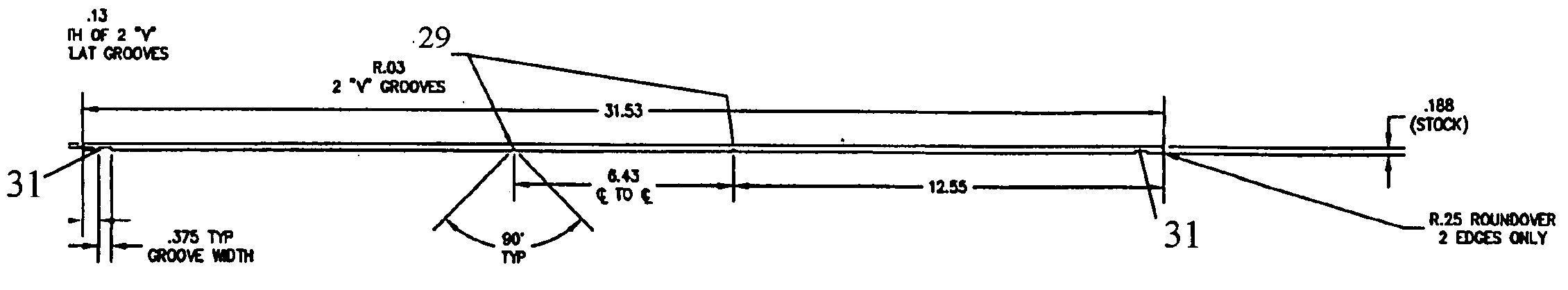

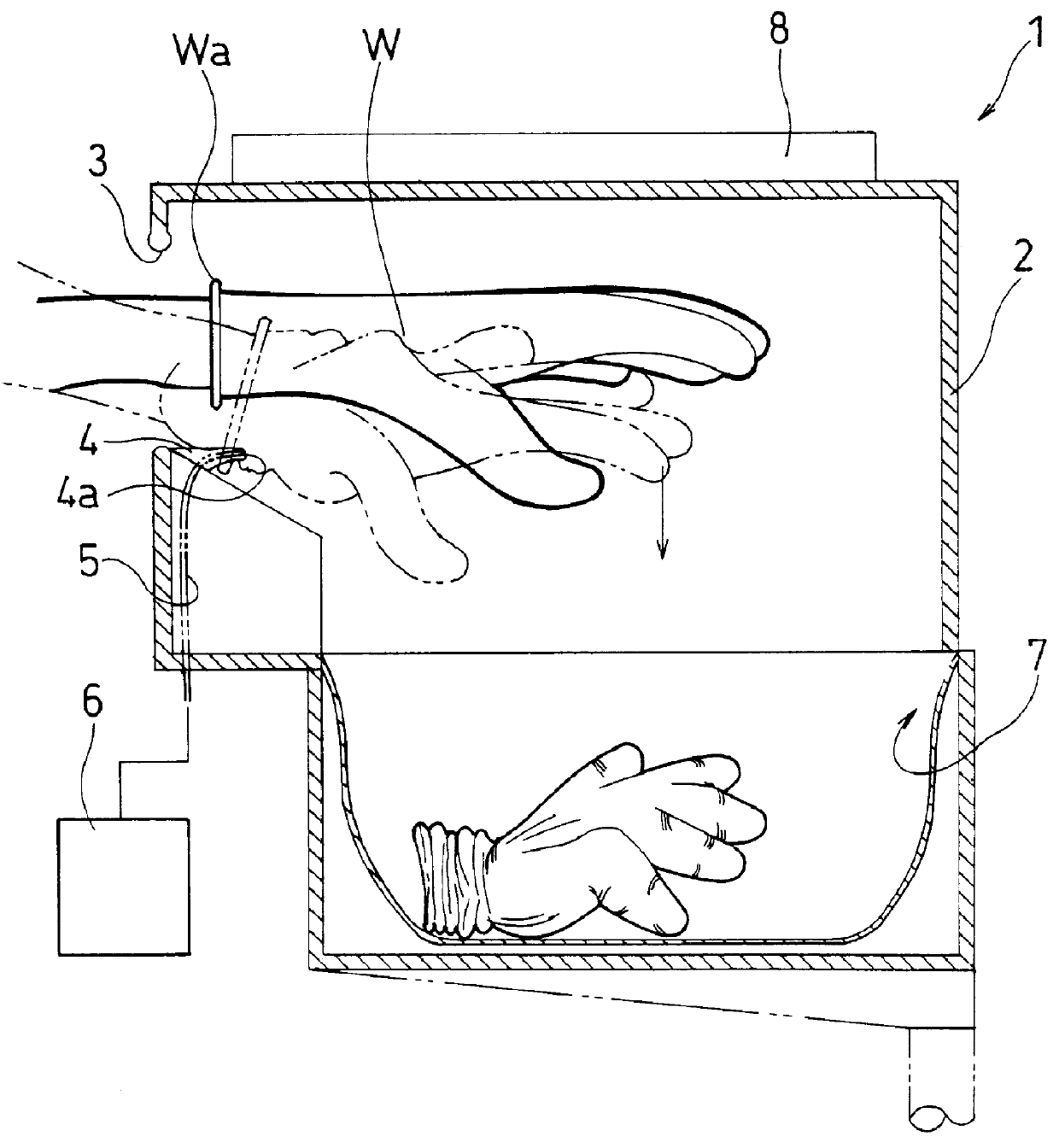

Lined paper packaging machine for surgical gloves

ActiveCN103010503AFast packHigh degree of automationWrapper folding/bending apparatusWrappingFolded formPulp and paper industry

The invention relates to a lined paper packaging machine for surgical gloves. The lined paper packaging machine for surgical gloves aims at the problems that in conventional surgical glove packaging process, the manual paper folding speed and packaging speed are low, the forming size is lack of standardization, the material loss is large, and the yield and the production efficiency of glove packages are directly affected and the like. The lined paper packaging machine for surgical gloves comprises a glove conveying system which conveys the gloves and one or more packaging systems arranged on one side or both sides of the glove conveying system to package the surgical gloves. The system can finish steps of paper cutting, paper folding and glove packaging and the like. Manual operation is replaced by an automatic robot, so that the packaging speed is improved, and the paper cutting size and the paper folding forming size are standardized, and the medical and sanitary requirements are ensured.

Owner:广州市山本机械有限公司

Radiation-proof rubber protective gloves

ActiveCN101894596AImprove the attenuation effectGood mechanical propertiesShieldingBeam energyAntioxidant

The invention discloses radiation-proof rubber protective gloves. The gloves comprise the following components in percentage by weight: 29 to 56 percent of rubber latex, 0.1 to 0.5 percent of sulfur, 0.1 to 2.5 percent of zinc oxide, 0.2 to 0.5 percent of rubber accelerator, 0.3 to 0.5 percent of rubber antioxidant and 40 to 70 percent of radiation-proof material. In the gloves, when the beam energy is 60KVp, the attenuation rate is over 45 percent; when the beam energy is 80KVp, the attenuation rate is over 35 percent; when the beam energy is 100KVp, the attenuation rate is over 26 percent; when the beam energy is 120KVp, the attenuation rate is over 22 percent; and the gloves have very good attenuation effect on X-rays and have good protection effect. The gloves have good mechanical property, the tension at break is more than 16N, the elongation at break is over 750 percent, and the gloves meet the requirement of Disposable Sterilized Rubber Surgical Gloves of GB7543-2006 and have high practical value.

Owner:ZHENJIANG SUHUI LATEX PROD

Nonaqueous coating composition for elastomeric articles and articles containing the same

InactiveUS20080020023A1Improved therapeutic propertyEasy transferCosmetic preparationsToilet preparationsSkin contactIrritation

The invention described herein relates to a therapeutic, moisturizing coating composition for elastomeric articles which is applied directly onto the skin-contacting surface of the article as part of the manufacturing process. The coating composition is thermally stable and subsequently transfers when in contact with a skin surface to convert into a liquid “lotion” form during wearing of the article. The coating composition provides therapeutic benefits to the wearer's skin as a result of wearing the article, such as improved skin moisturization, softness of feel, improved skin elasticity and firmness, and reduced redness and irritation. The invention is particularly useful in medical gloves, including examination and surgical gloves.

Owner:ALLEGIANCE CORP

Carboxylic acid-modified nitrile-based copolymer latex composition and dip molded article including the same

The present invention relates to a carboxylic acid-modified nitrile-based copolymer latex composition and a dip molded article including the same, the composition including: a carboxylic acid-modified nitrile-based copolymer latex having a glass transition temperature of −30 to −20° C.; and a bentonite dispersion solution. The dip molded article using the carboxylic acid-modified nitrile-based copolymer latex composition according to the present invention has high tensile strength and excellent wearable sensation, and thus the dip molded article may be usefully applied to dip molded latex articles such as surgical gloves, checkup gloves, a condom, a catheter, industrial gloves, household gloves, or health care articles.

Owner:LG CHEM LTD

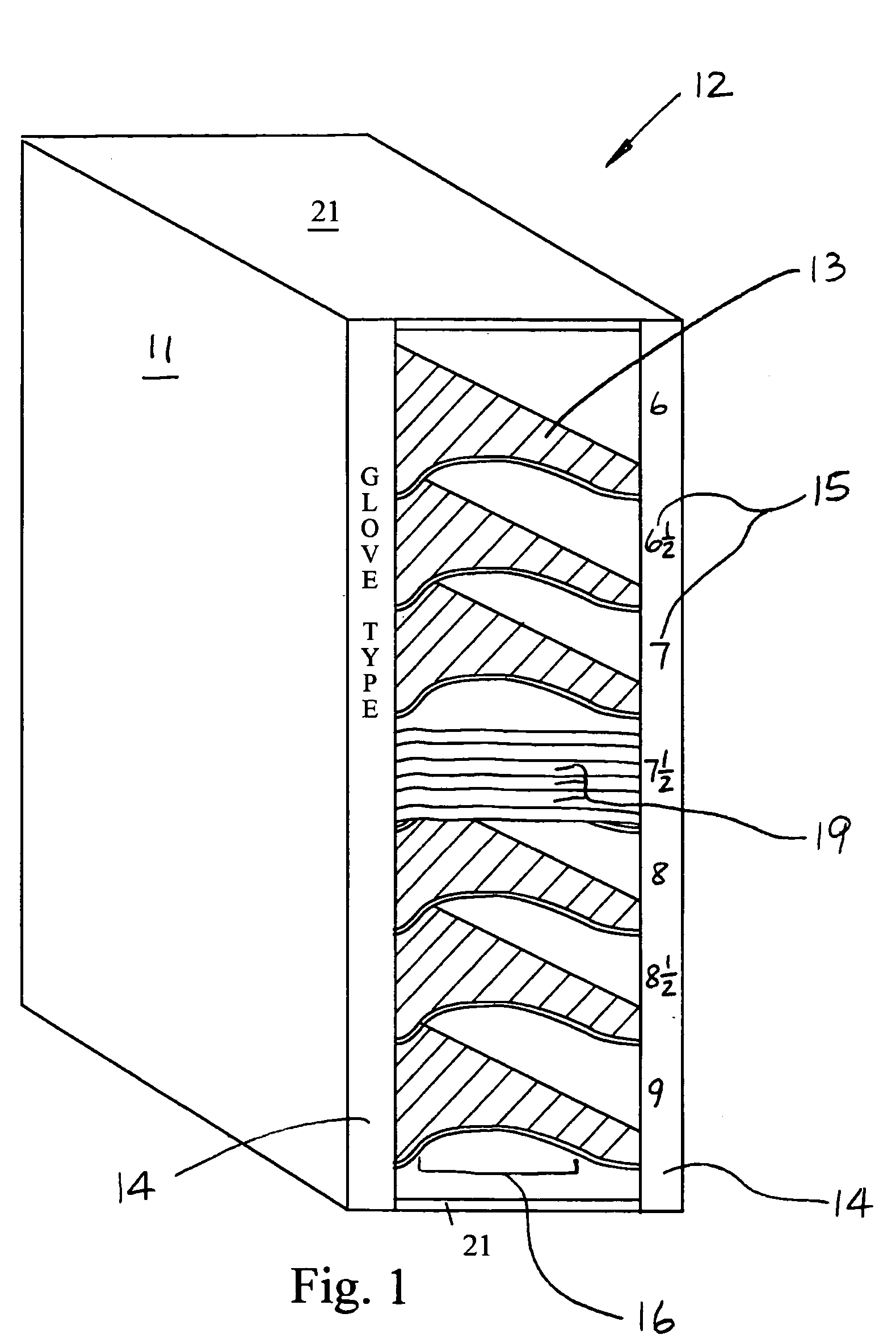

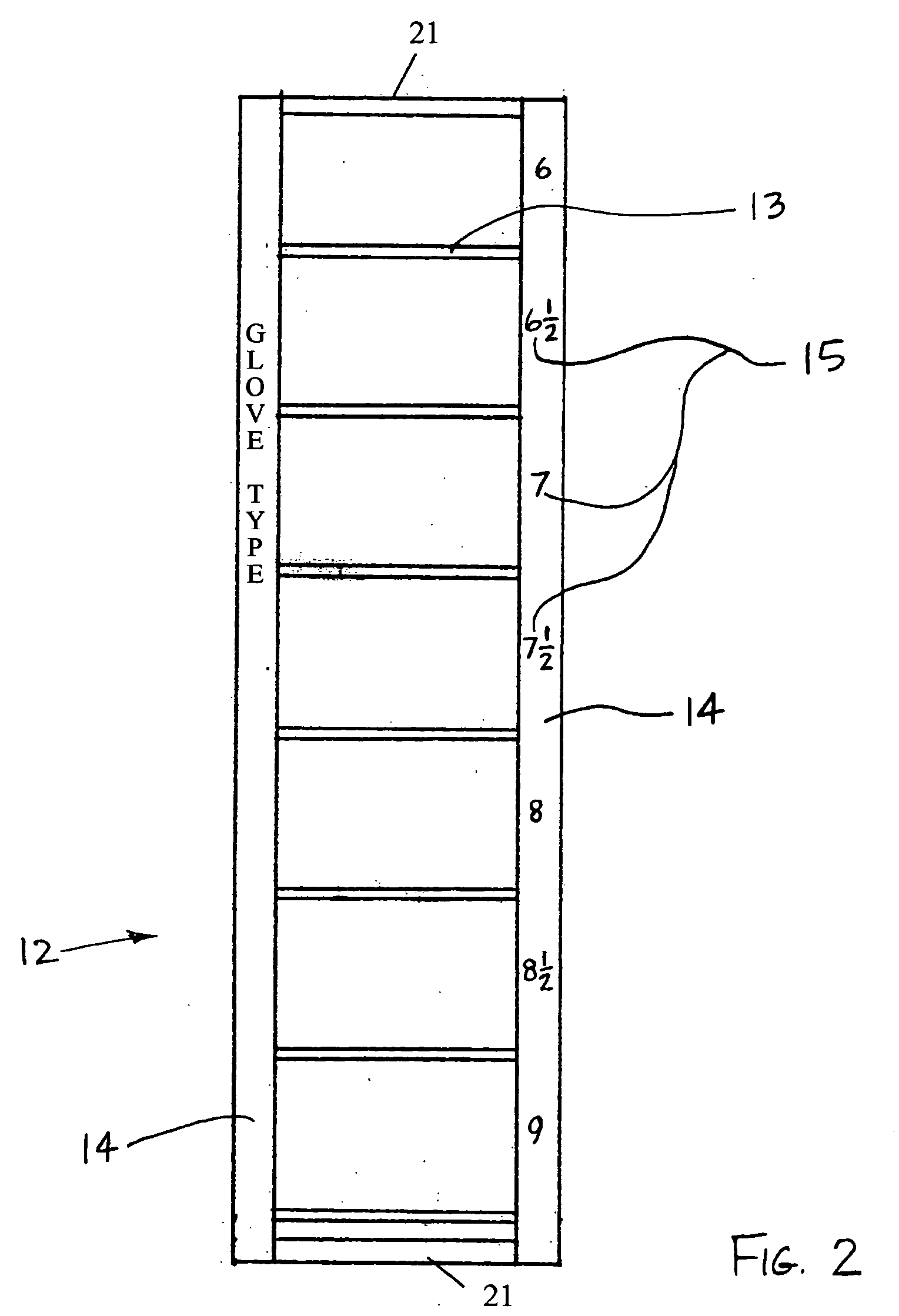

Sterile surgical glove dispenser

InactiveUS20050000975A1Easy to masterPrevent inadvertent removalSurgical furnitureDiagnosticsEngineeringSurgical Gloves

An organized dispenser for sterile surgical gloves comprising separate compartments within an enclosure for receiving a supply of like sized packages of sterile gloves. The compartments are separated by dividers having notches for facilitating the grasping of a single package of gloves and the enclosure is provided with flanges for allowing the single package of gloves to be pulled from the enclosure while retaining the remaining portion of the supply of gloves within the enclosure. The dispenser is provided with a selectable mounting arrangement, and with sets of labels for marking the compartments for easy identification of the size and type of gloves contained within each of the compartments.

Owner:CARCO DARLENE MARIE +1

Birthing gloove

A birthing glove exposes portions of the finger and thumb, which may be covered by a regular surgical glove. The birthing glove has a trank having an inner wall covering the palm and backhand of the birthing practitioner. Four finger sleeves and a thumb sleeve extend from the trank and terminate over the first phalanx of each finger. A cuff extends from the trank for covering at least a portion of the practitioner's forearm and an inflatable bladder is disposed over the inner wall of the trank adjacent to the back of the hand for inflation in order to expand behind the exposed fingers and thumb of the practitioner in order to dilate the birth canal and provide access to the head of the infant.

Owner:NGUYEN BICH VAN

Docking sleeve with electrical adapter

ActiveUS9331444B2Low costSmooth connectionCoupling device connectionsDigital data processing detailsElectricityElastomer

A docking sleeve having an elastomeric protective cover, or skin, adapted for partially enveloping a portable electronic device, such as a smartphone or tablet or another portable electronic device of the prior art having a port for a docking connector. The protective cover is a sheath molded of a suitable elastic or flexibly resilient elastomer in a size and shape to fit over and closely conform to the particular portable electronic device so that the cover fits the device like a surgical glove. An adapter is provided for electrically connecting to the female input / output socket of the particular electronic device, including a male plug having a plurality of electrical connectors extended internally of the sheath and arranged for mating with the female input / output socket of the device, and a plurality of contacts electrically coupled to different ones of the plurality of electrical connectors and exposed externally of the sheath.

Owner:NAT PRODS

Automated surgical illumination system

The present invention provides illumination for a surgical procedure. Using an optical tracking system, the illumination is made to automatically track an optical marker on a surgical glove worn by a clinician to provide more consistent illumination for a surgical procedure.

Owner:KIM GABRIEL MIN +1

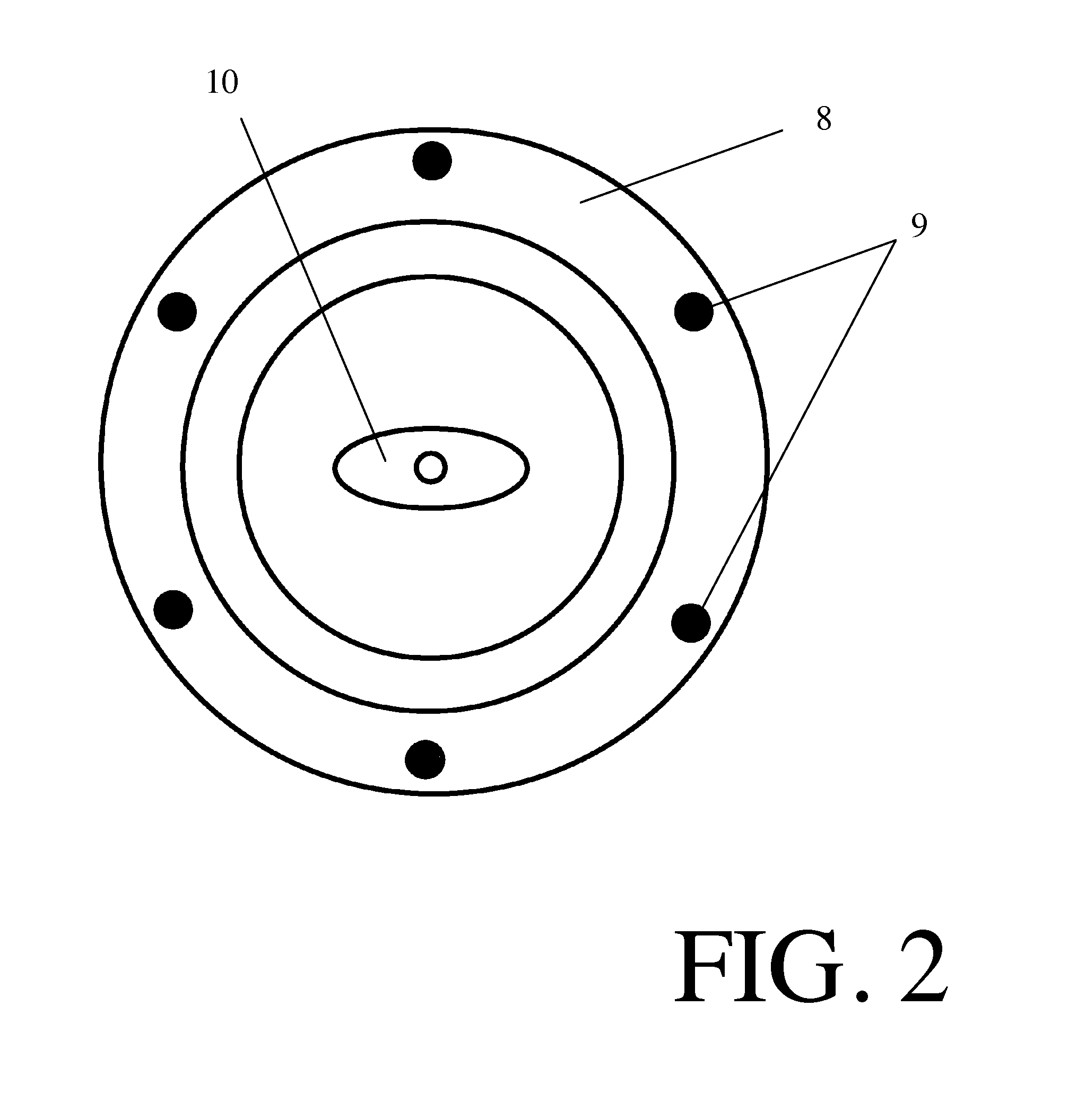

Glove release apparatus and method for the same

InactiveUS6021935AEasily be pulled off from the handFraction between the hand and glove is decreasedApparel holdersDiagnosticsEngineeringHepatitis B virus

Since surgical gloves contact patients' blood and focuses, there is a possibility of infection, especially the case of Hepatitis B virus and AIDS if hands contact blood on the gloves. Therefore, a glove release apparatus of the present invention is for safely and sanitarily pulling off a glove made of a stretchable material from a hand and comprises a housing having an opening to which the hand wearing the glove is inserted, and an engagement unit for hooking an insertion opening of the glove, please near the opening of the housing. In order to pull off the glove, the hand wearing the glove is inserted into the opening of the housing and the insertion opening of the glove is hooked to the engagement unit. Then, as the hand is moved towards the opening of the housing, the glove is gradually pulled off from the hand.

Owner:YONEZAWA NARIMITSU

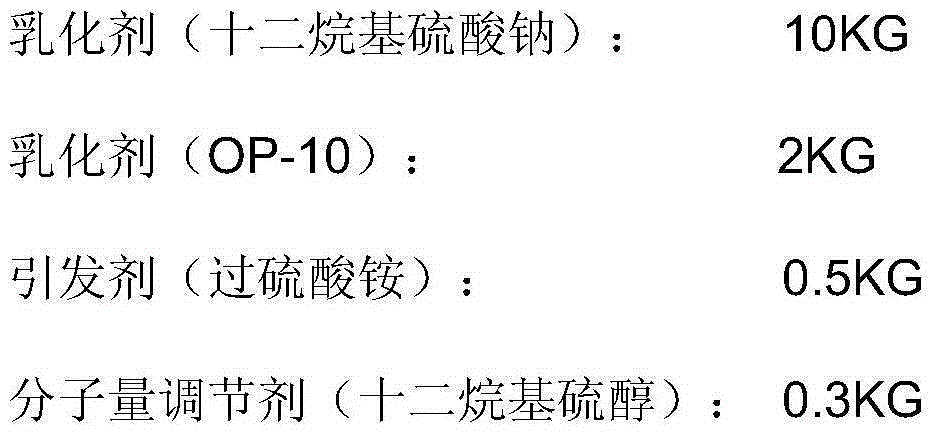

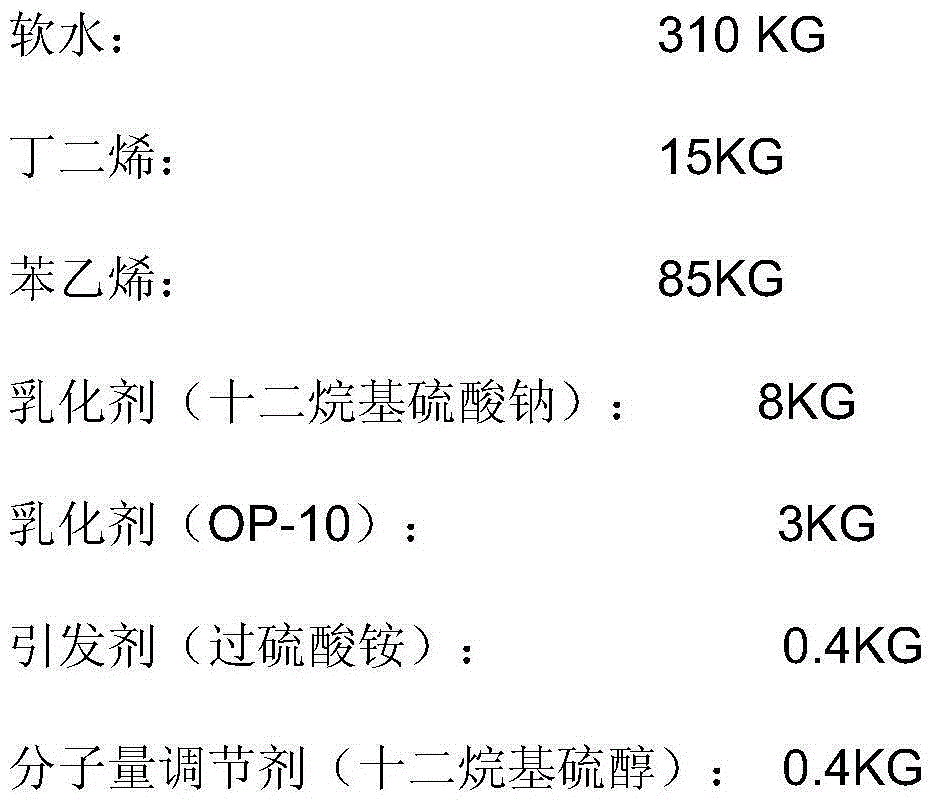

Method for preparing high performance carboxylic acrylonitrile butadiene rubber latexes

The invnetino discloses a method for preparing high performance carboxylic acrylonitrile butadiene rubber latexes. The carboxylic acrylonitrile butadiene rubber latexes use an emulsion polymerization process which uses styrene-butadiene latexes as seeds, are dropped with a part of monomers, use butadiene and acrylonitrile as main monomers, use unsaturated carboxylate and are assisted by multi-functional monomers such as multiple double bond crosslinking monomers, and use a complex emulsifier system which is reactive emulsifiers and less anionic emulsifiers when polymerizing, wherein persulfate is an initiator, alkyl sulfhydryl is a molecular weight regulator and other assistants, the reaction temperature is 40-60 DEG C, and the conversion rate is above 98%. Raw materials which are dropped during the production process of the high performance carboxylic acrylonitrile butadiene rubber latexes are dispersed by adopting an ultrasonic homogenizer or a high pressure homogenizer, thereby forming 50-500nm steady miniemulsion, and then being dropped into a reaction kettle. The carboxylic acrylonitrile butadiene rubber latexes which is prepared through the method for preparing the high performance carboxylic acrylonitrile butadiene rubber latexes is 100-120nm in particle size, is excellent in mobility, moderate in viscosity, excellent in mechanical stability and chemical stability, greatly improves toughness and bonding strength, and is particularly suitable to soak gloves, surgical gloves and wear-resistant materials and the like.

Owner:杭州蓝励新材料有限公司

Coating composition for skin-contacting surface of elastomeric articles and articles containing the same

The invention described herein relates to a therapeutic, moisturizing coating composition for elastomeric articles which is applied directly onto the skin-contacting surface of the article as part of the manufacturing process. The coating composition is thermally stable and subsequently hydrates when contacted with a moisturized skin surface to convert into a liquid “lotion” form during wearing of the article. The coating composition provides therapeutic benefits to the wearer's skin as a result of wearing the article, such as improved skin moisturization, softness of feel, improved skin elasticity and firmness, and reduced redness and irritation. The invention is particularly useful in medical gloves, including examination and surgical gloves.

Owner:ALLEGIANCE CORP

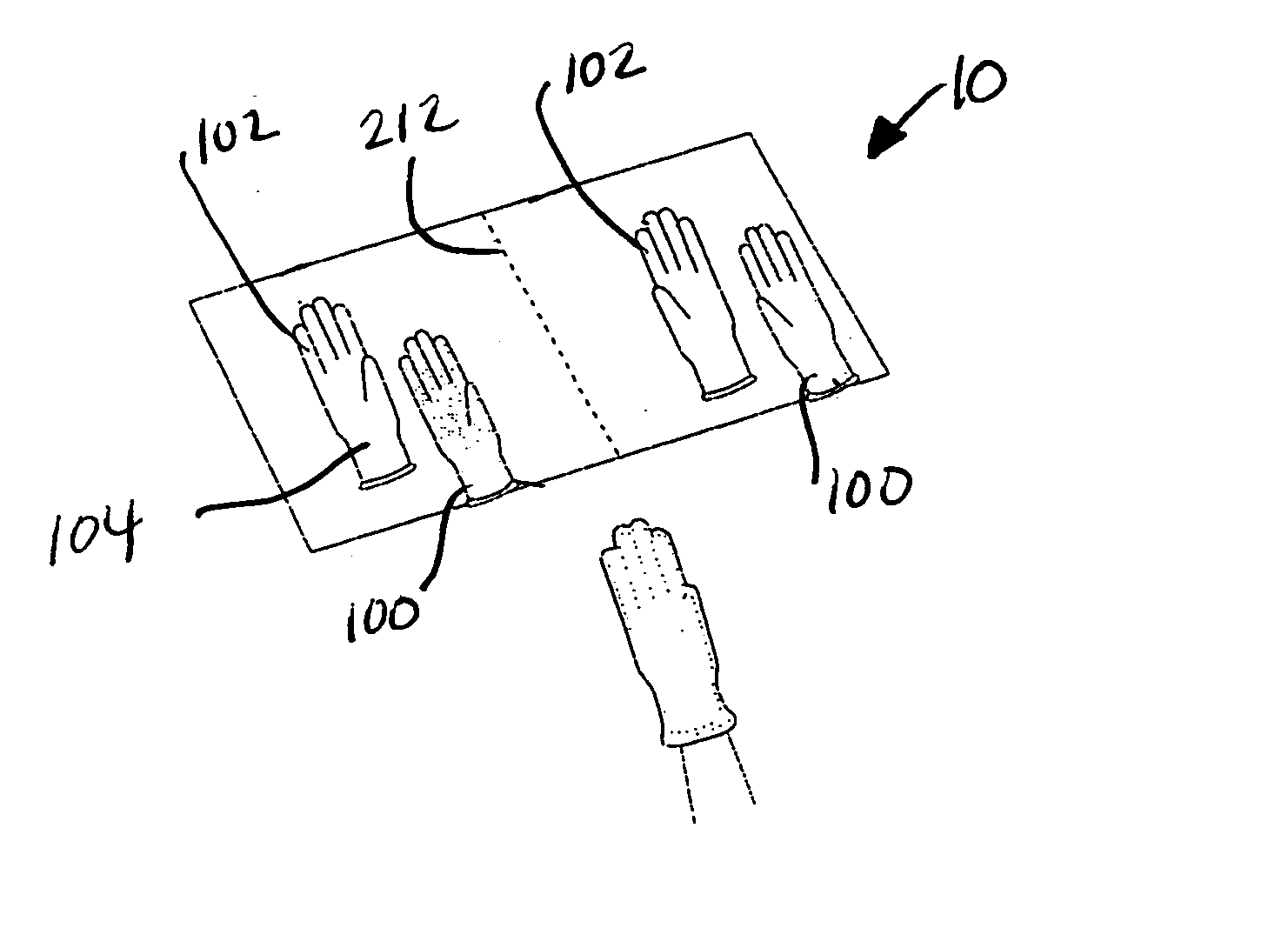

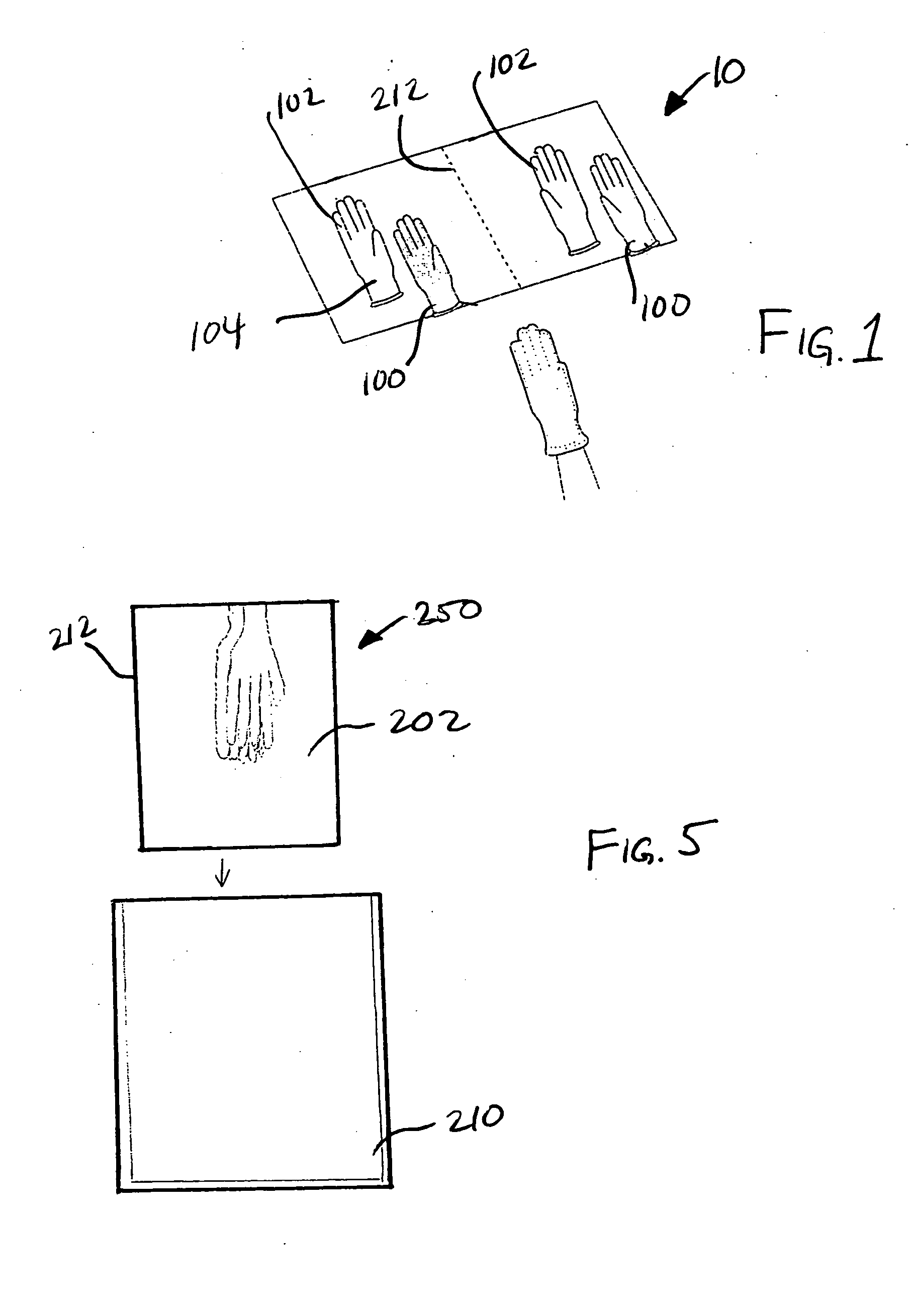

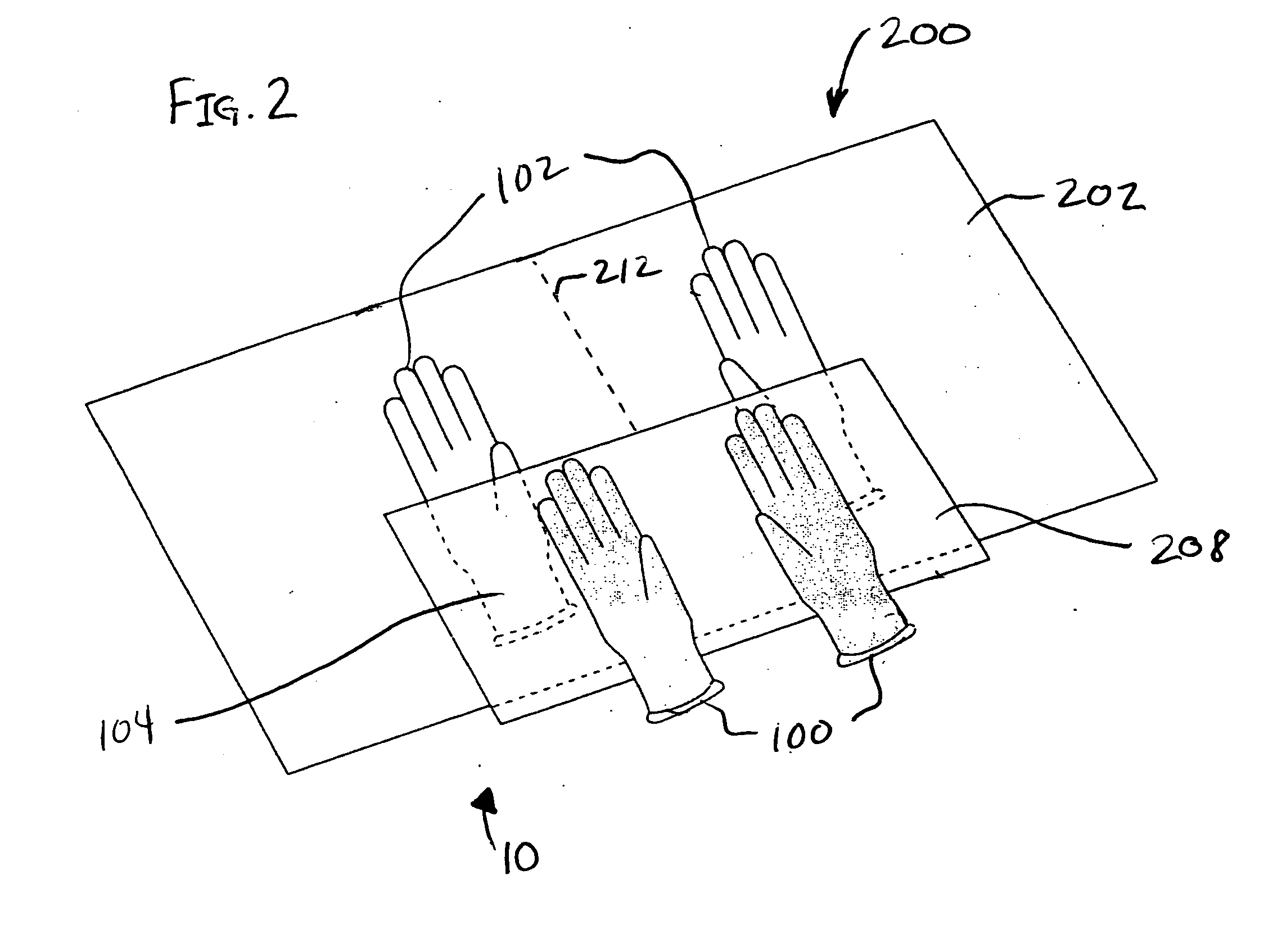

Surgical double glove set and packaging therefor

InactiveUS20050006264A1Improve logisticsImprove supply issueDiagnosticsSurgical needlesSTERILE FIELDSurgical Gloves

A surgical double glove set is provided which has a first pair of inner gloves and a second pair of outer gloves, the outer gloves being slightly larger than and longer than the inner gloves, and both pairs of gloves being of reduced thickness, lower in modulus and having a higher elongation at break, in comparison to standard orthopedic surgical gloves. The double glove set is packaged in a single sterile pack in which an outer sterile field sheet has the outer hand-specific gloves place side-by-side thereon, a separator sheet is placed over the pair of outer gloves, and the pair of inner gloves is placed a top the separator sheet The outer sterile field sheet is folded over to sandwich the gloves and separator sheet between the folded portions, and the folded outer sterile field sheet is sealed inside of a sterile pack.

Owner:LOW CHIN G

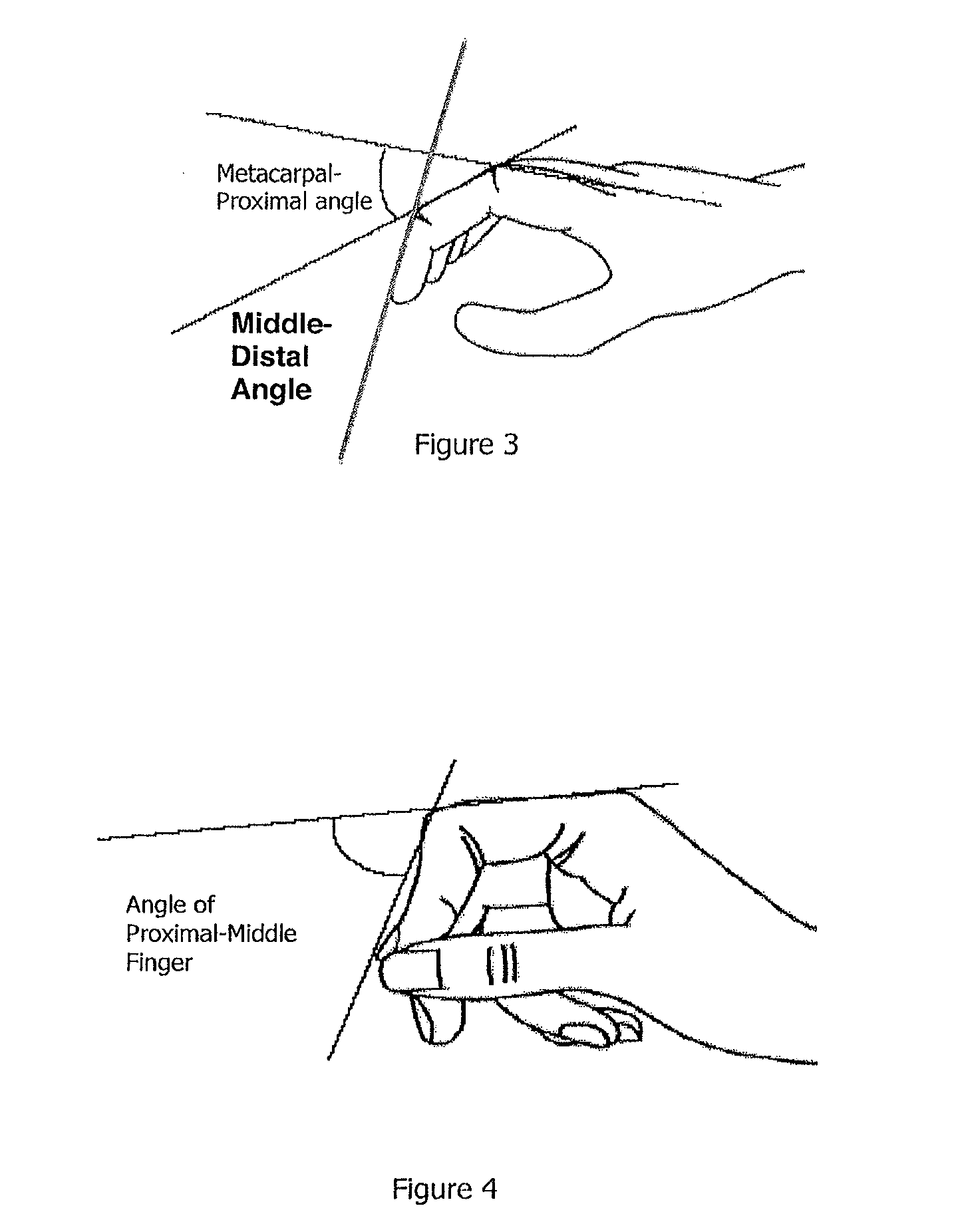

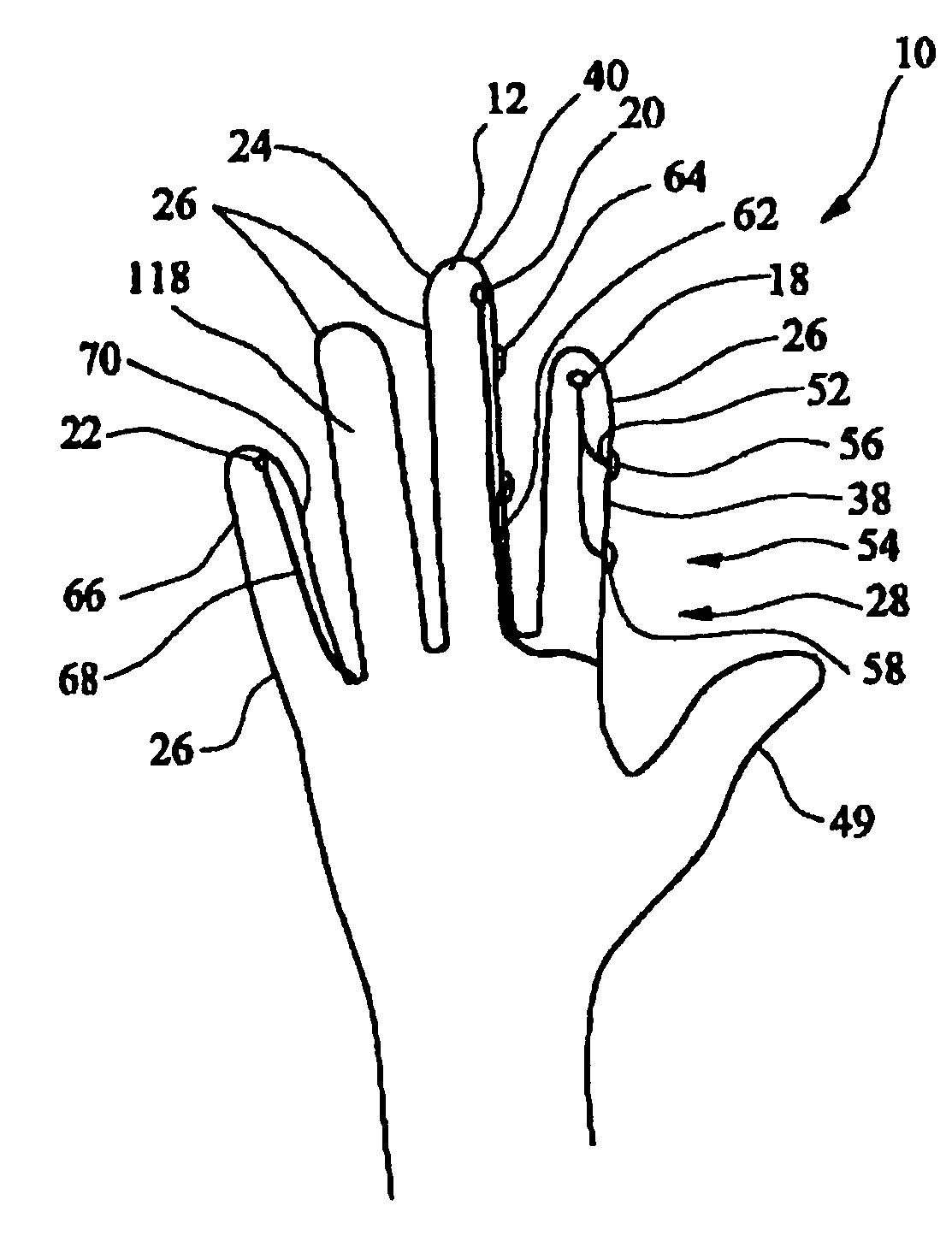

Ergonomic glove for medical procedures

InactiveUS20140208481A1Reduce bias forceAmount of biasing force that must be overcomeDiagnosticsGlovesEngineeringSurgical department

Owner:EXSOMED CORP

Surgical glove with modified frictional interface and method for producing same

InactiveUS20070000020A1Increase coefficient of frictionNatural movement is restrictedGarment special featuresGlovesElastomerMicron scale

An elastomeric article having a mechanically or chemo-mechanically modified surface for improved anti-slip-down protection, and certain methods for producing the article are disclosed. The methods involve applying a colloidal particle-containing slurry or an abrasive-impregnated substrate to the an exposed elastomeric matrix surface to create a rough, textured or scabrous surface with a topography of micron-scale ridges and dimples.

Owner:KIMBERLY-CLARK WORLDWIDE INC

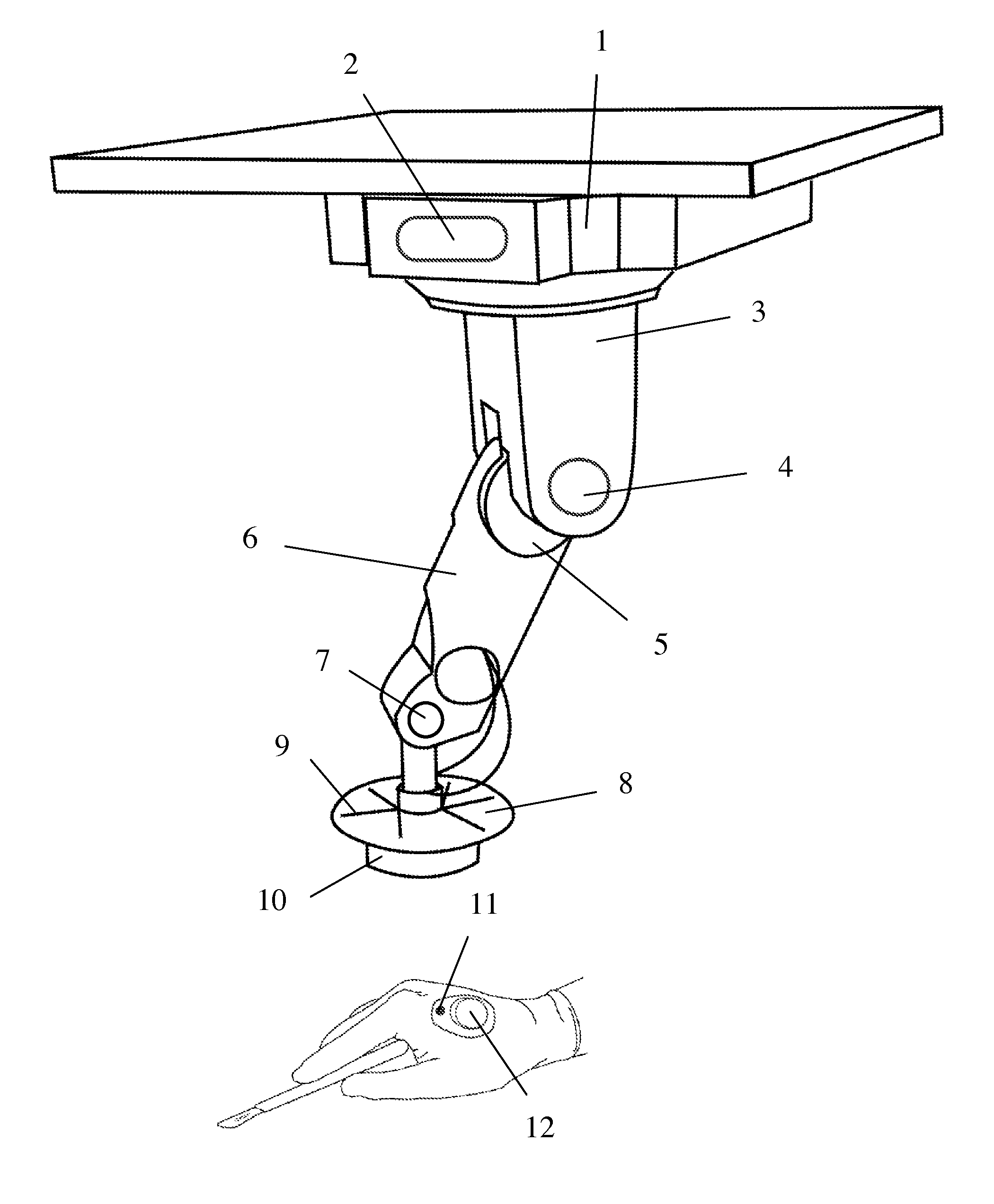

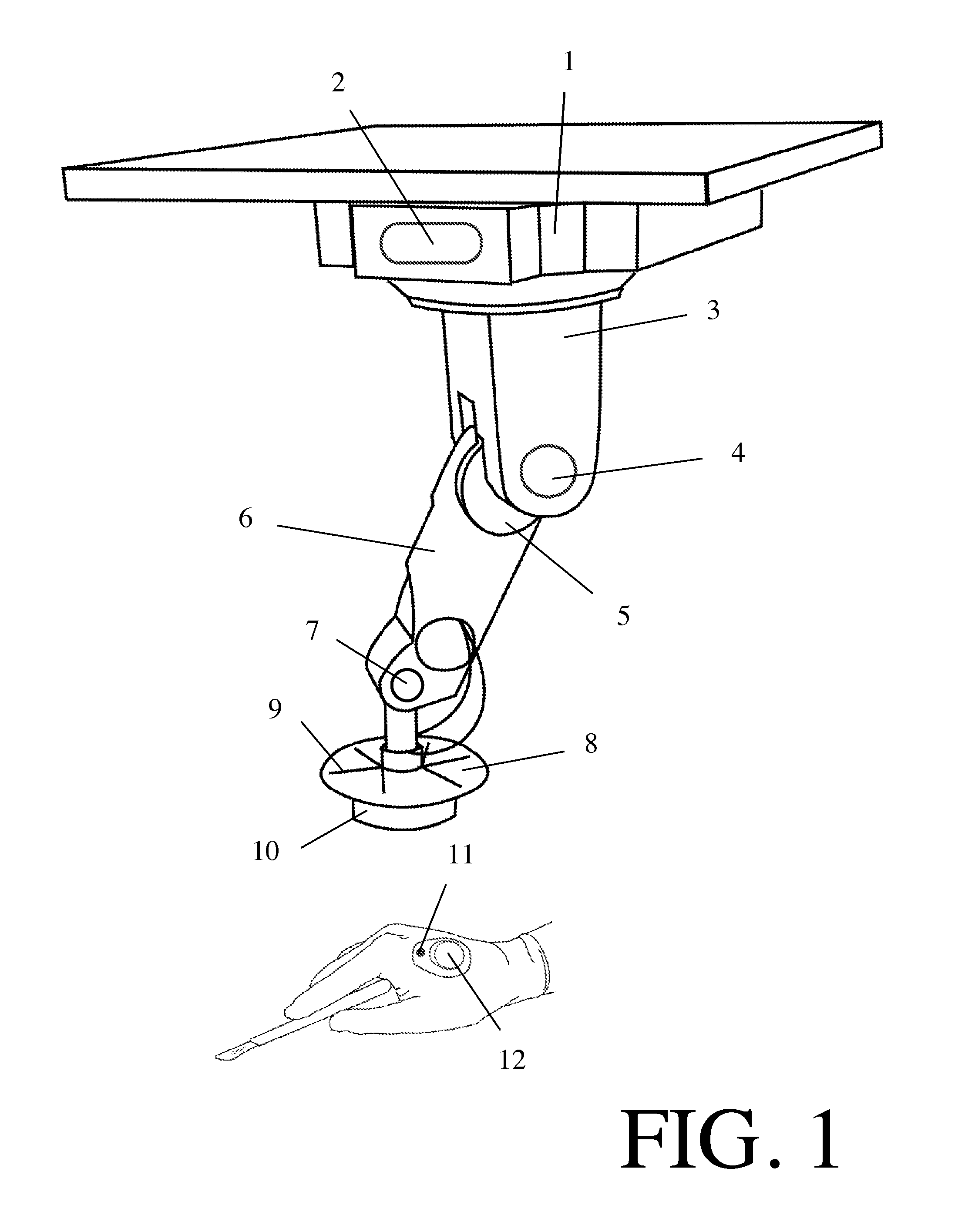

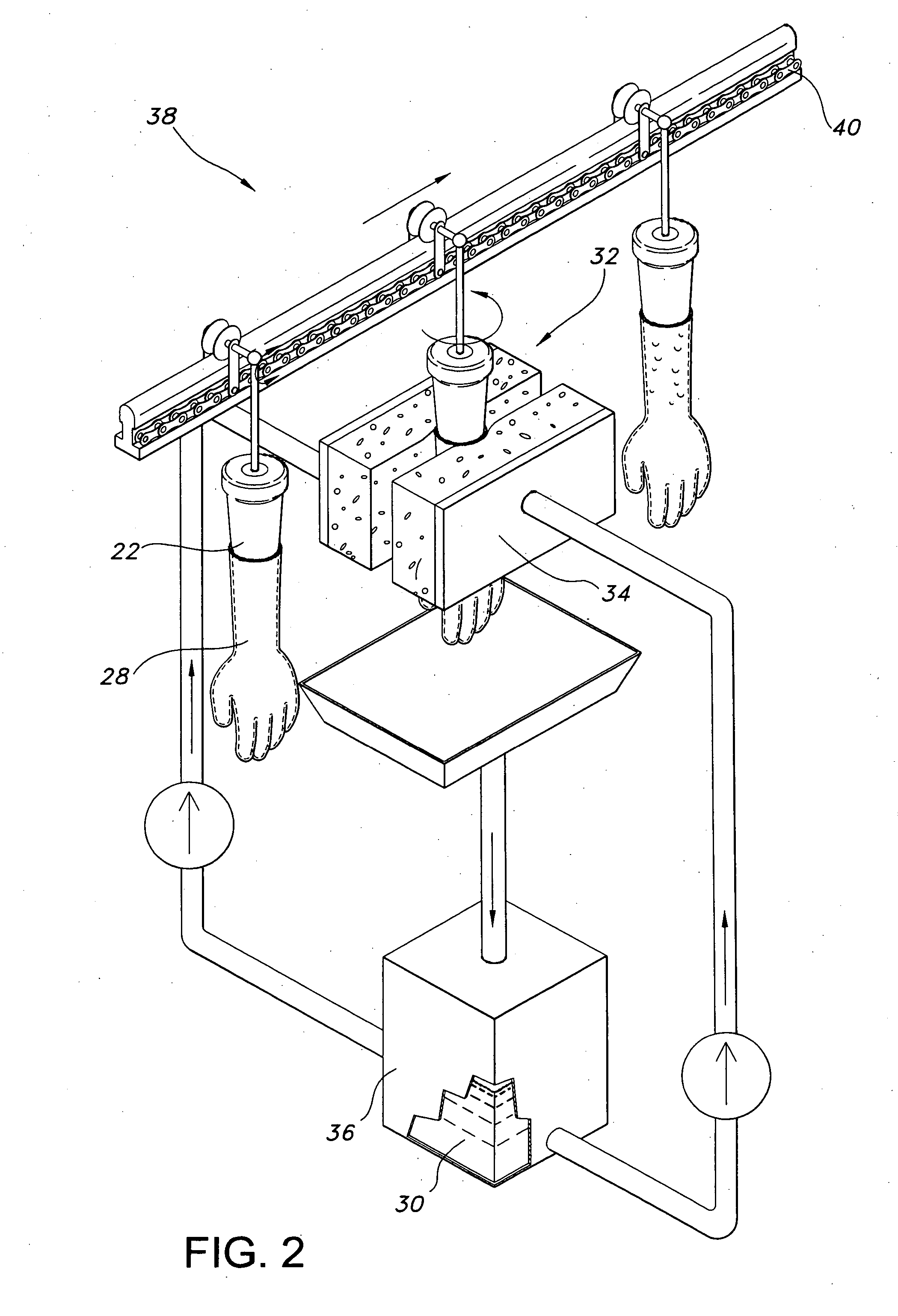

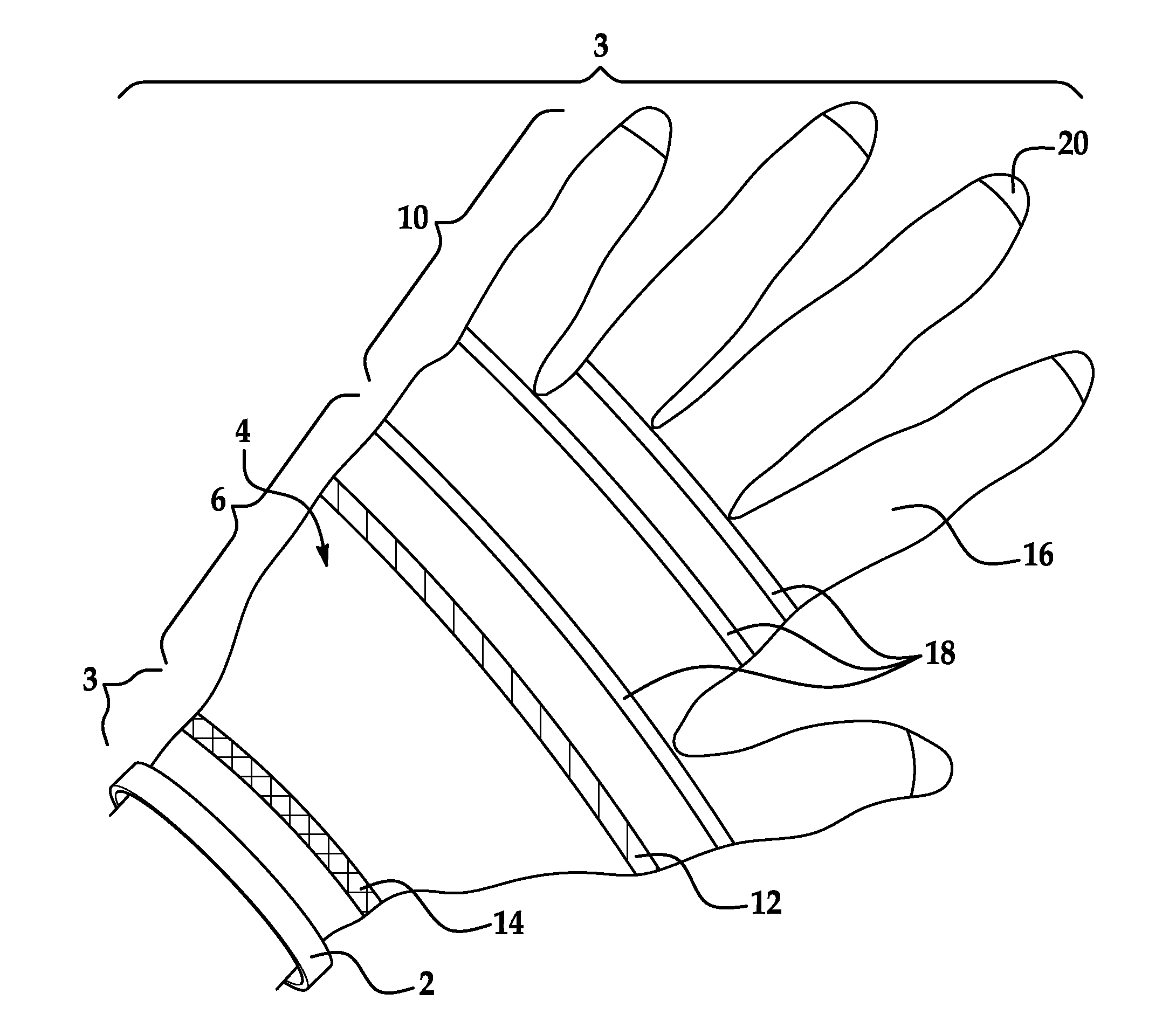

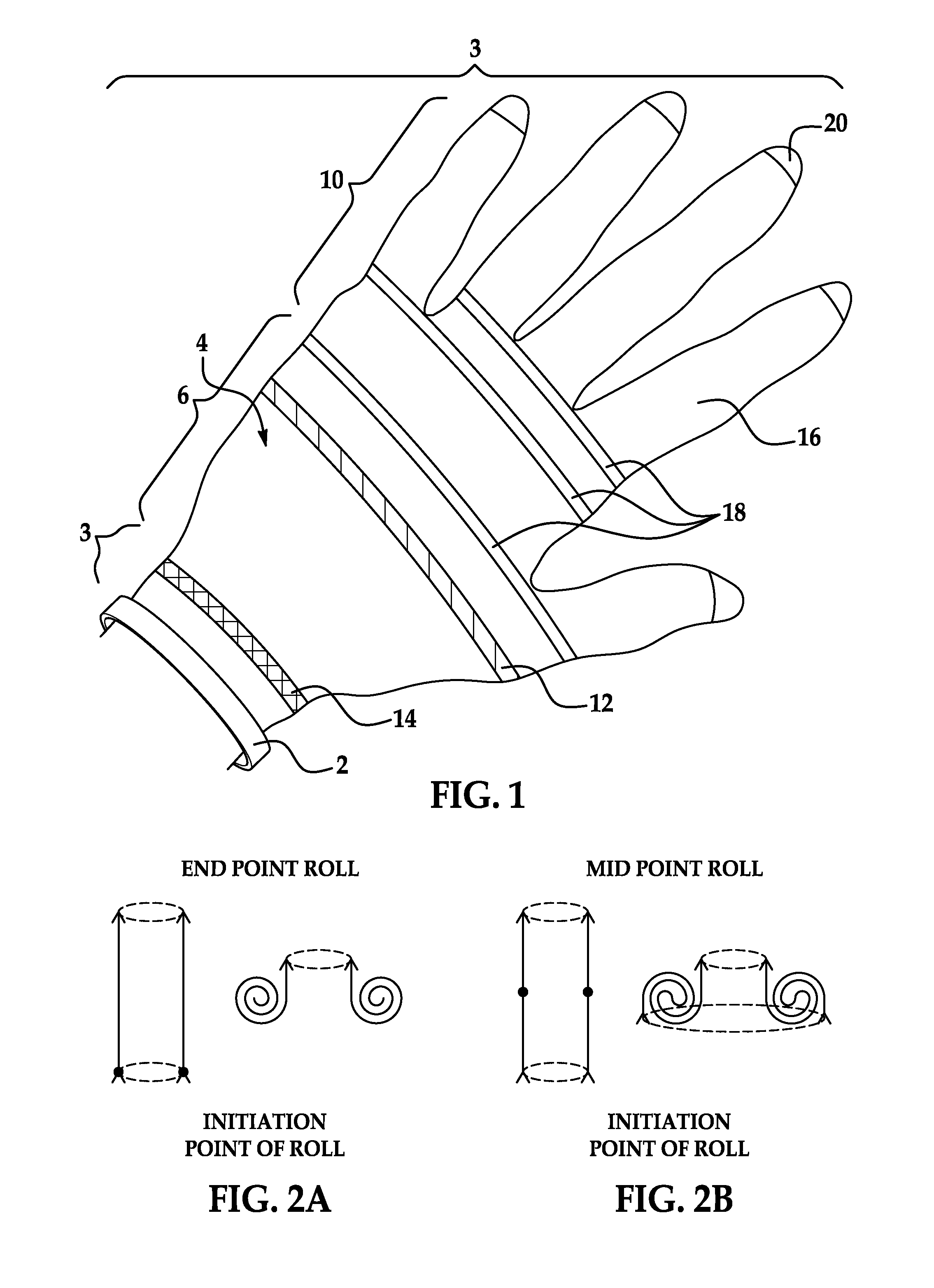

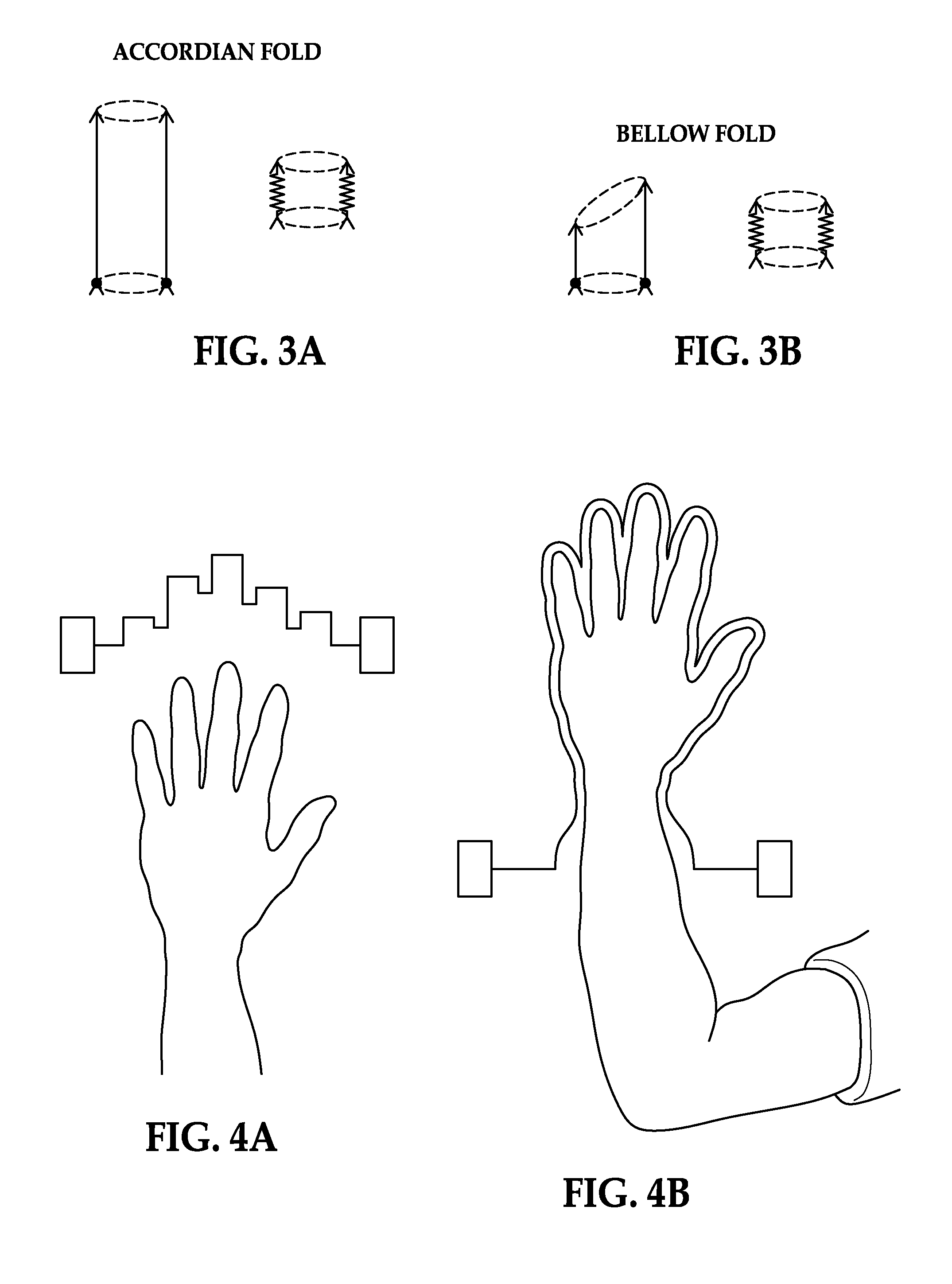

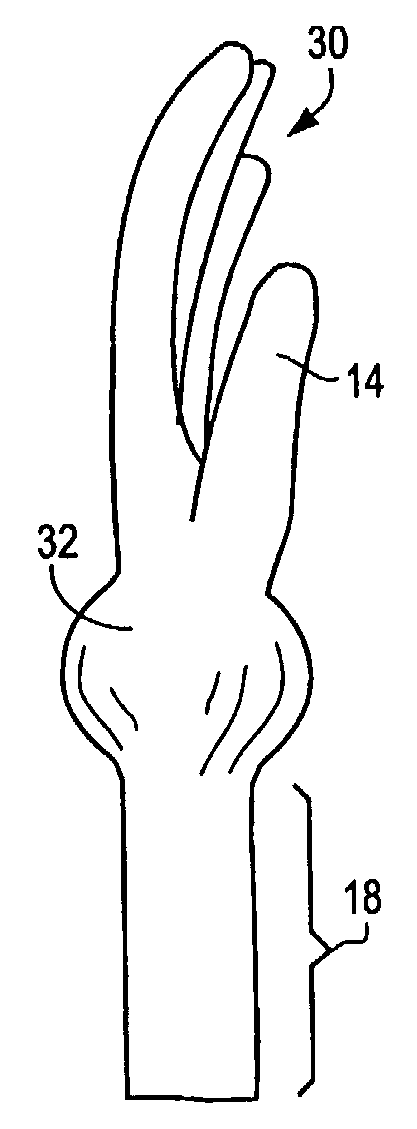

Surgical glove appliance device

ActiveUS20120137402A1Easy to deployGood flexibilityApparel holdersDiagnosticsSurgical GlovesMechanical engineering

A protective barrier, such as a medical examination glove is provided that includes a bracelet defining a plane with a cylinder attached to the bracelet at a first end. The cylinder is compressed into a compressed conformation in the plane without rolling about the bracelet. When the barrier is a glove, three fenestrated caps are provided, each such cap attached to the cylinder at different locations along the length of the cylinder when said first cylinder is in an extended conformation. Multiple finger cylinders are each attached to the cylinder at a location of a fenestrated cap, the finger cylinders each having an end cap. The first cylinder and the finger cylinders each compressed into a compressed conformation in the plane such that each of the caps forms a portion of the surface of the plane.

Owner:KANTROWITZ ALLEN B +1

Presulfurized natural latex/chitosan/polyhydroxybutyrate blend material and preparation method thereof

ActiveCN104788753AImprove mechanical propertiesGood biocompatibilityBiocompatibility TestingDrainage tubes

The invention provides a presulfurized natural latex / chitosan / polyhydroxybutyrate blend material and a preparation method thereof. The presulfurized natural latex / chitosan / polyhydroxybutyrate blend material comprises the following components in parts by weight on dry basis: 100 parts of presulfurized natural latex, 0.5-5.0 parts of chitosan and 0.5-5.0 parts of polyhydroxybutyrate. The preparation method comprises the following steps: presulfurizing a concentrated natural latex; preparing chitosan and polyhydroxybutyrate into a 5-10% chitosan / polyhydroxybutyrate water dispersion, adding into the presulfurized natural latex, stirring, filtering, and standing for defoaming to obtain an emulsion presulfurized natural latex / chitosan / polyhydroxybutyrate blend material; and carrying out solidifying, leaching, drying and other conventional techniques for latex product production to obtain the blend rubber film. The method fully utilizes the respective excellent characteristics of the natural latex, chitosan and polyhydroxybutyrate, so that the prepared natural-latex-base medical material maintains excellent elasticity of the natural rubber, has favorable biocompatibility, and can be used for producing surgical gloves, medical examination gloves, catheters, condoms, drainage tubes and other medical latex products.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Viscosity enhanced natural rubber latex dipping media and dipped articles of greater thickness prepared therefrom

Increasing the viscosity of latex dipping media is achieved by adding a minor amount of a viscosity-increasing fumed silica. The more viscous latex dispersions allow preparation of dipped articles of increased thickness at the same latex solids concentration. The dipped articles, for example surgical gloves, contain low levels of extractable proteins.

Owner:AMDUR SHIMON

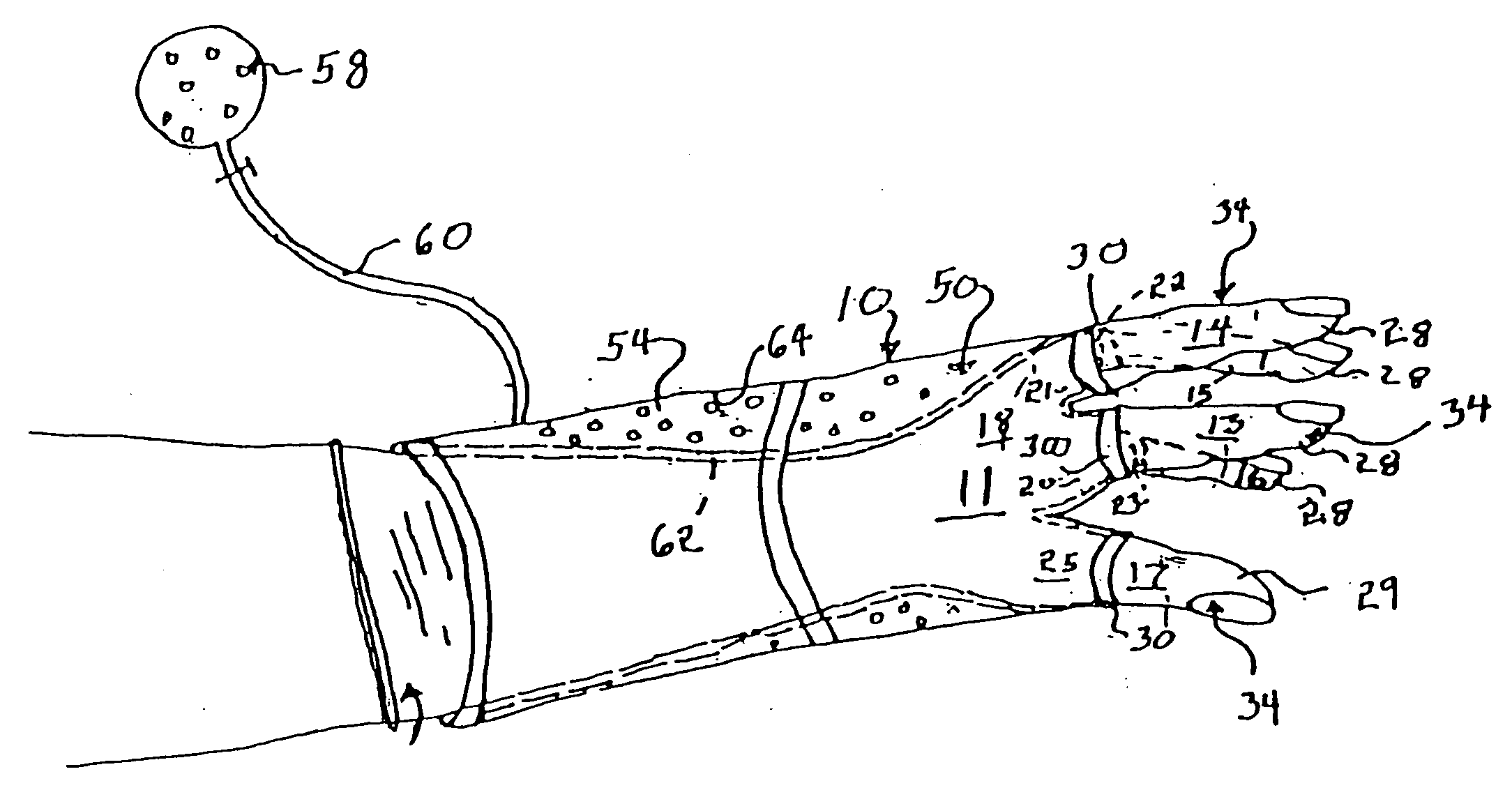

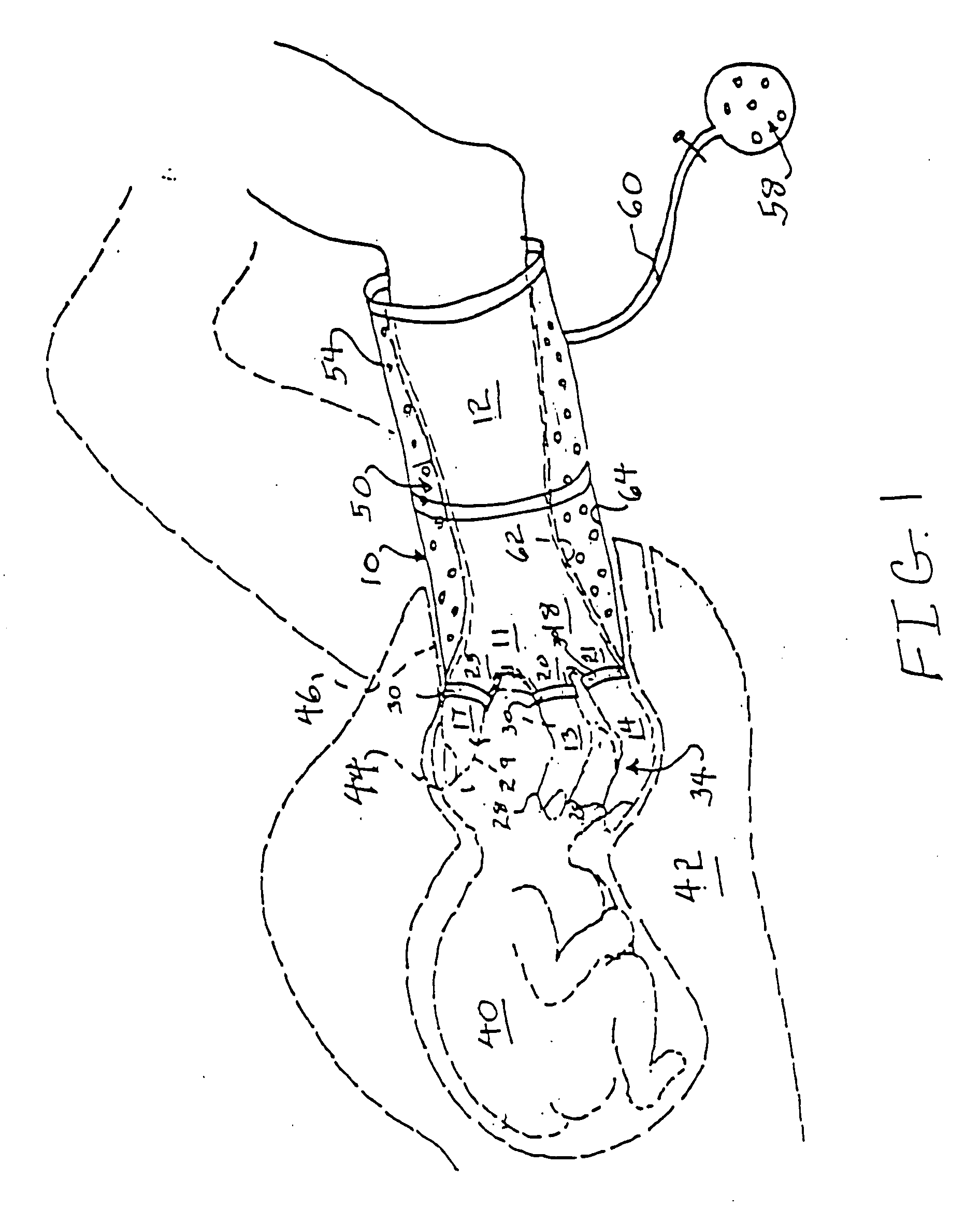

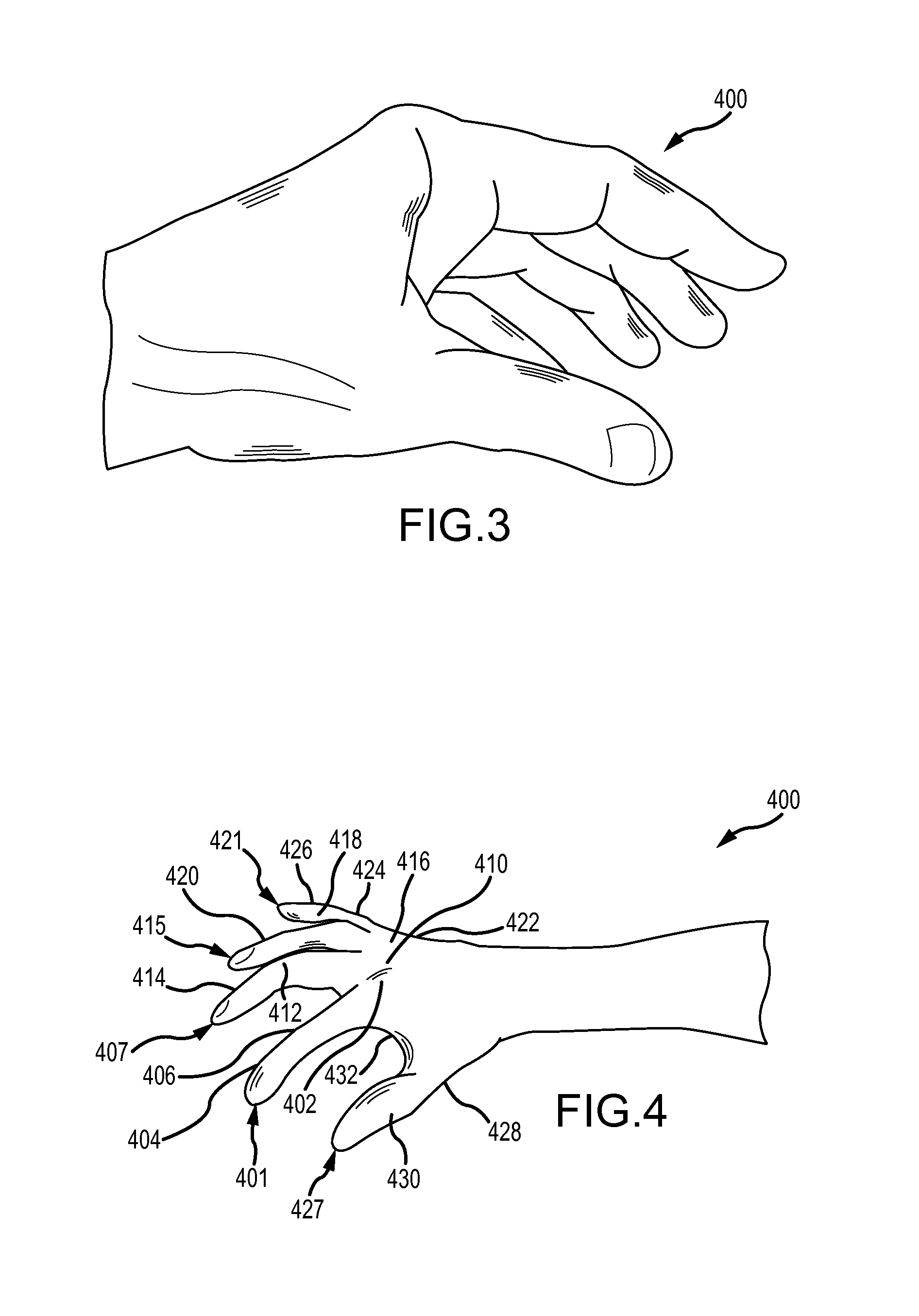

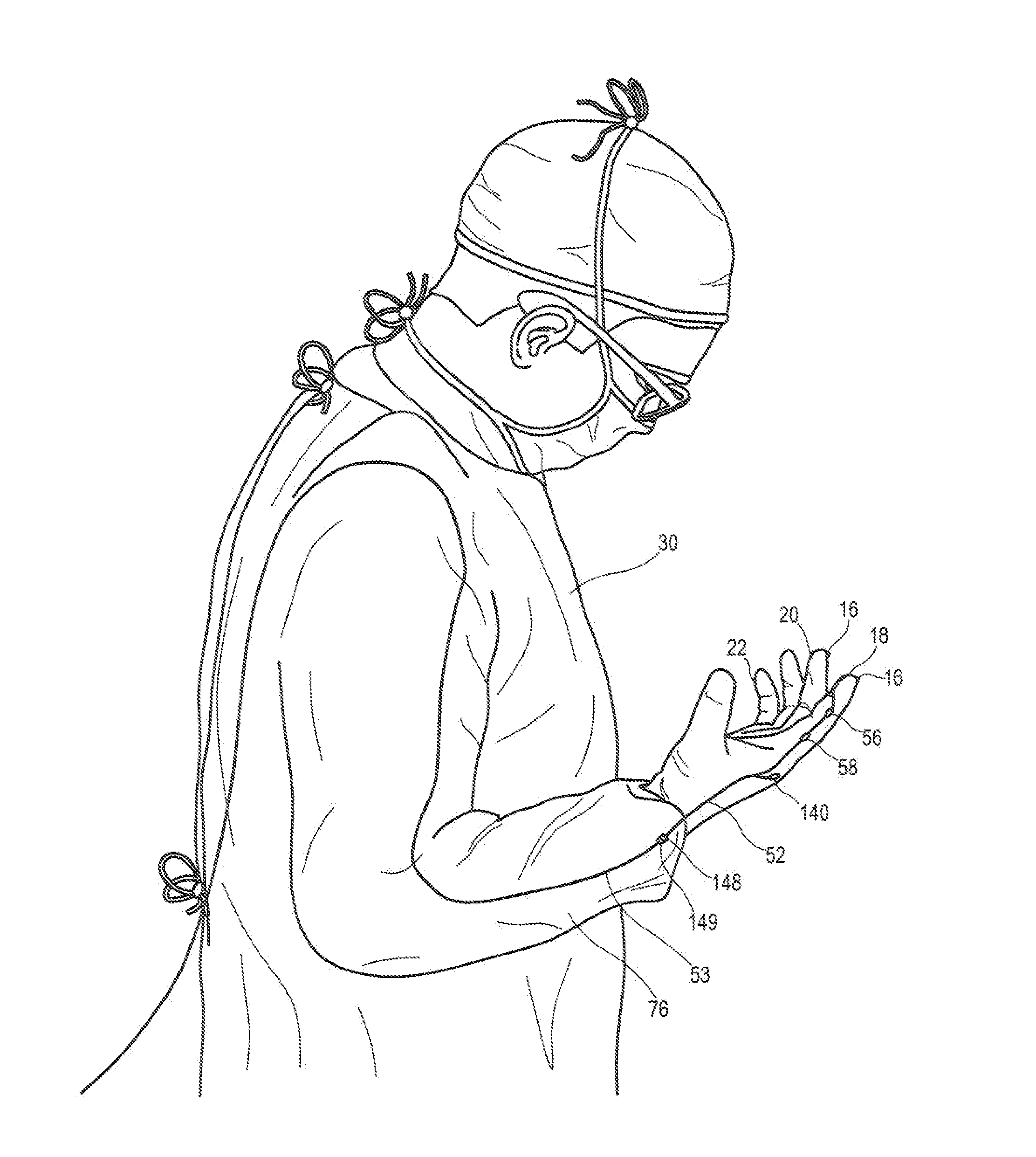

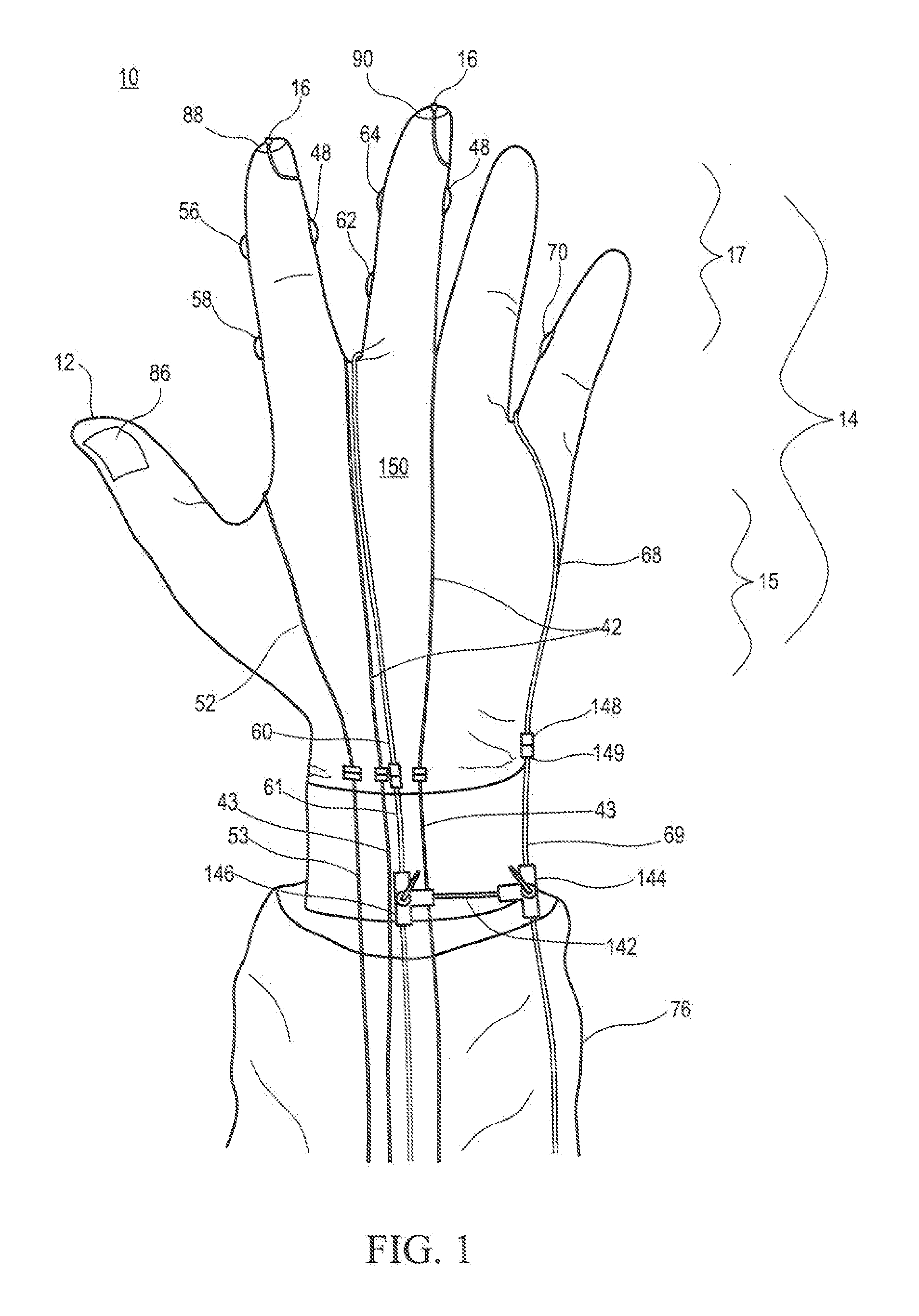

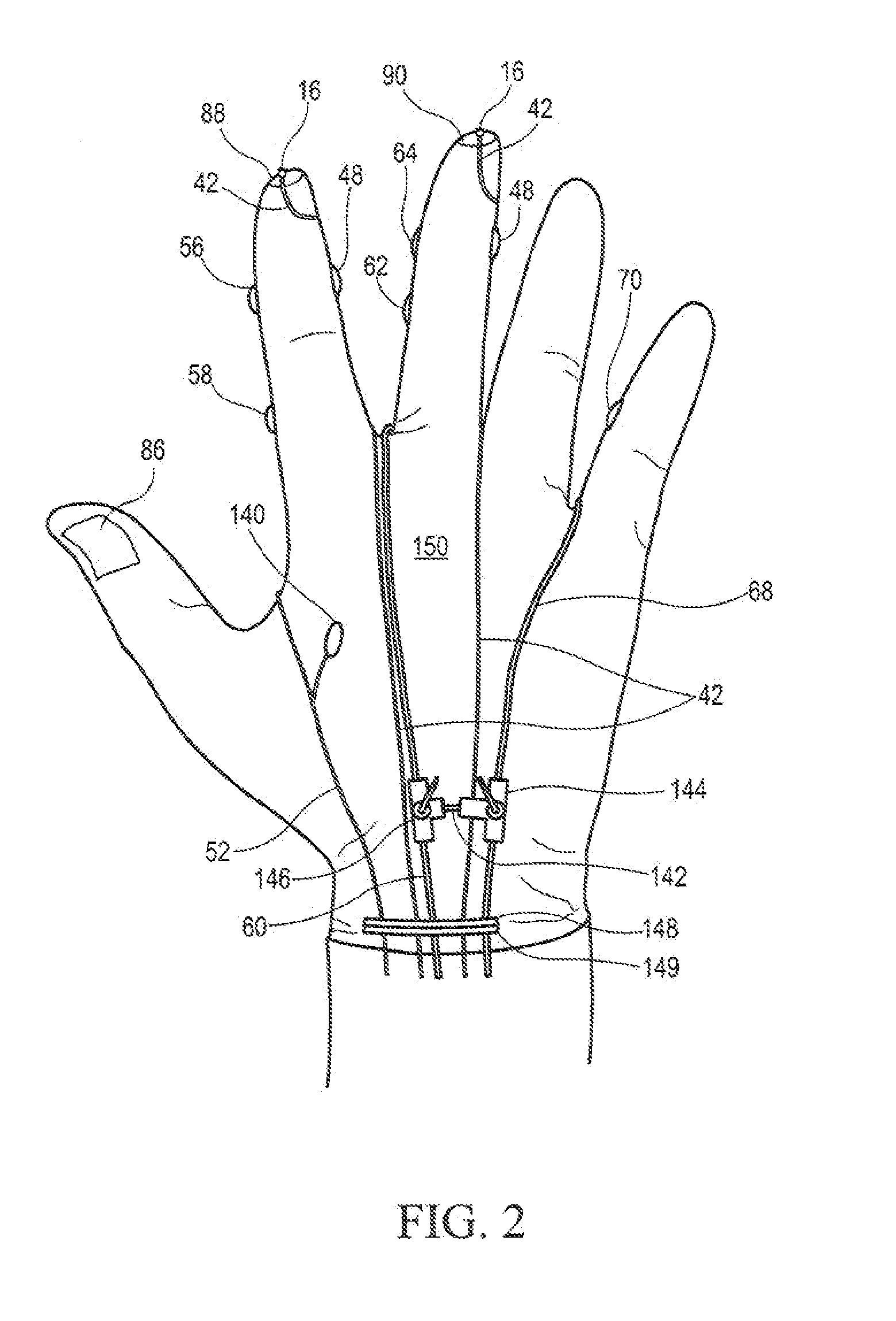

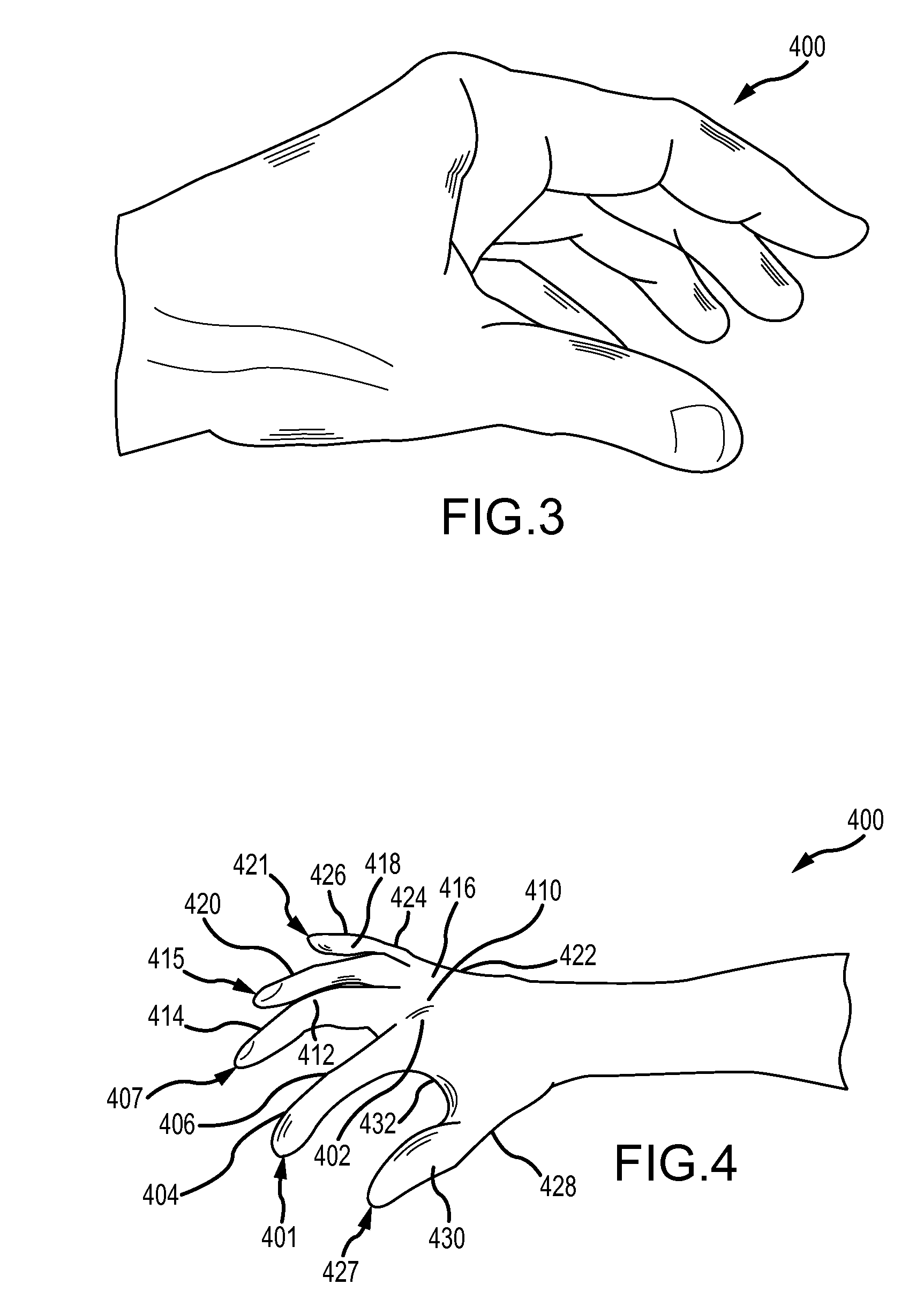

Surgical glove systems and method of using the same

ActiveUS20130046302A1Eliminates entanglement problemEasy to useDiagnosticsSurgical drapesSupporting systemCatheter

A surgical system including one or two surgical gloves having support systems such as, but not limited to, lights, electrical cautery, suction, and irrigation, attached to fingers of the surgical glove. The support systems may be controlled with switches positioned on the fingers upon which each support system is positioned. The switches may be operable with the thumb on the human hand upon which the surgical glove is attached. The system may also include (i) a safety switch coupled to the glove for controlling the first surgical system so that the first surgical system will not operate unless both the first switch and the safety switch are actuated, or (ii) a shunt for controlling fluid flow between the first and second conduits. Different support systems may be included in each glove for a bilateral system or may be combined into a single glove system.

Owner:SCHNEIDER ANDREW I

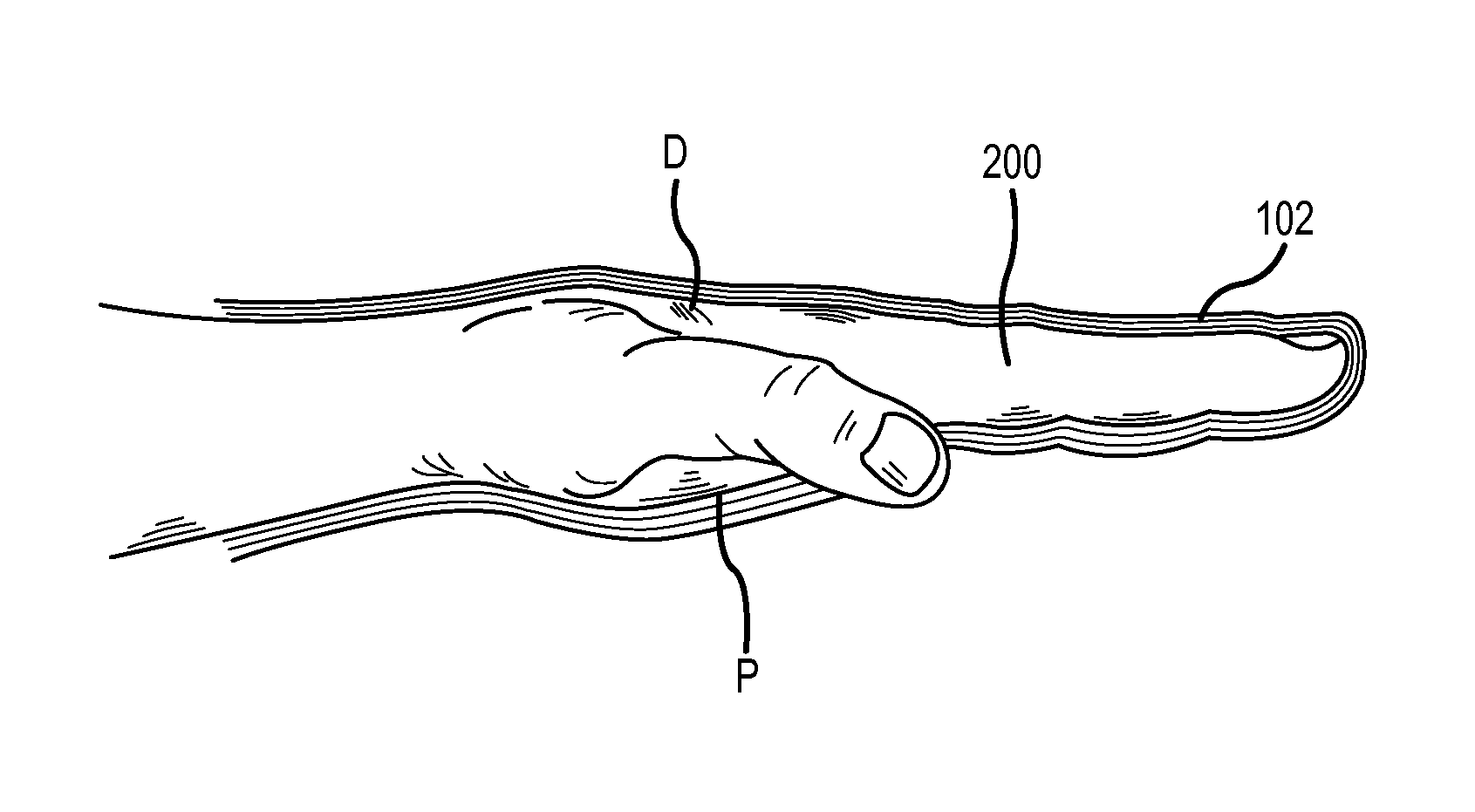

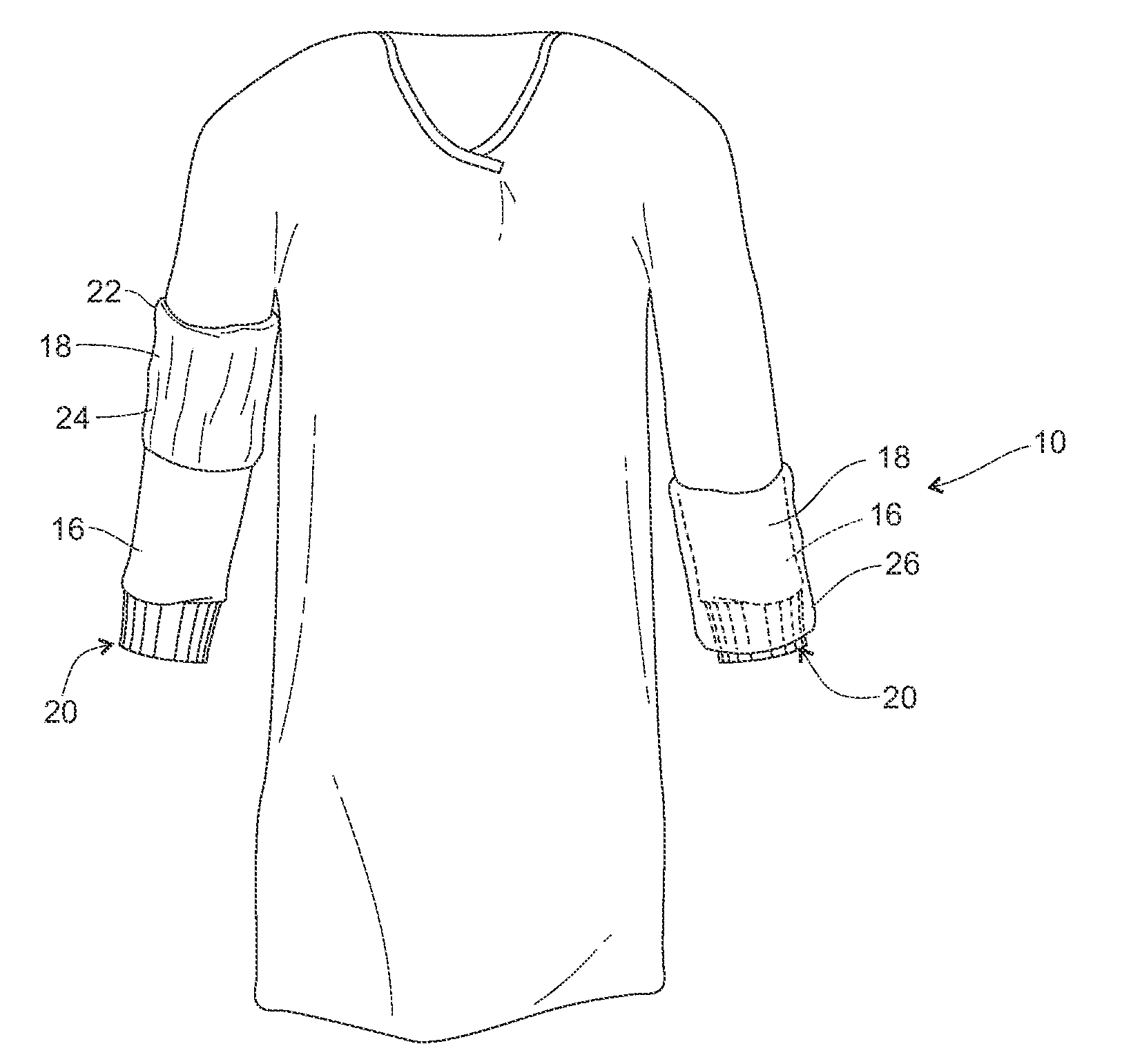

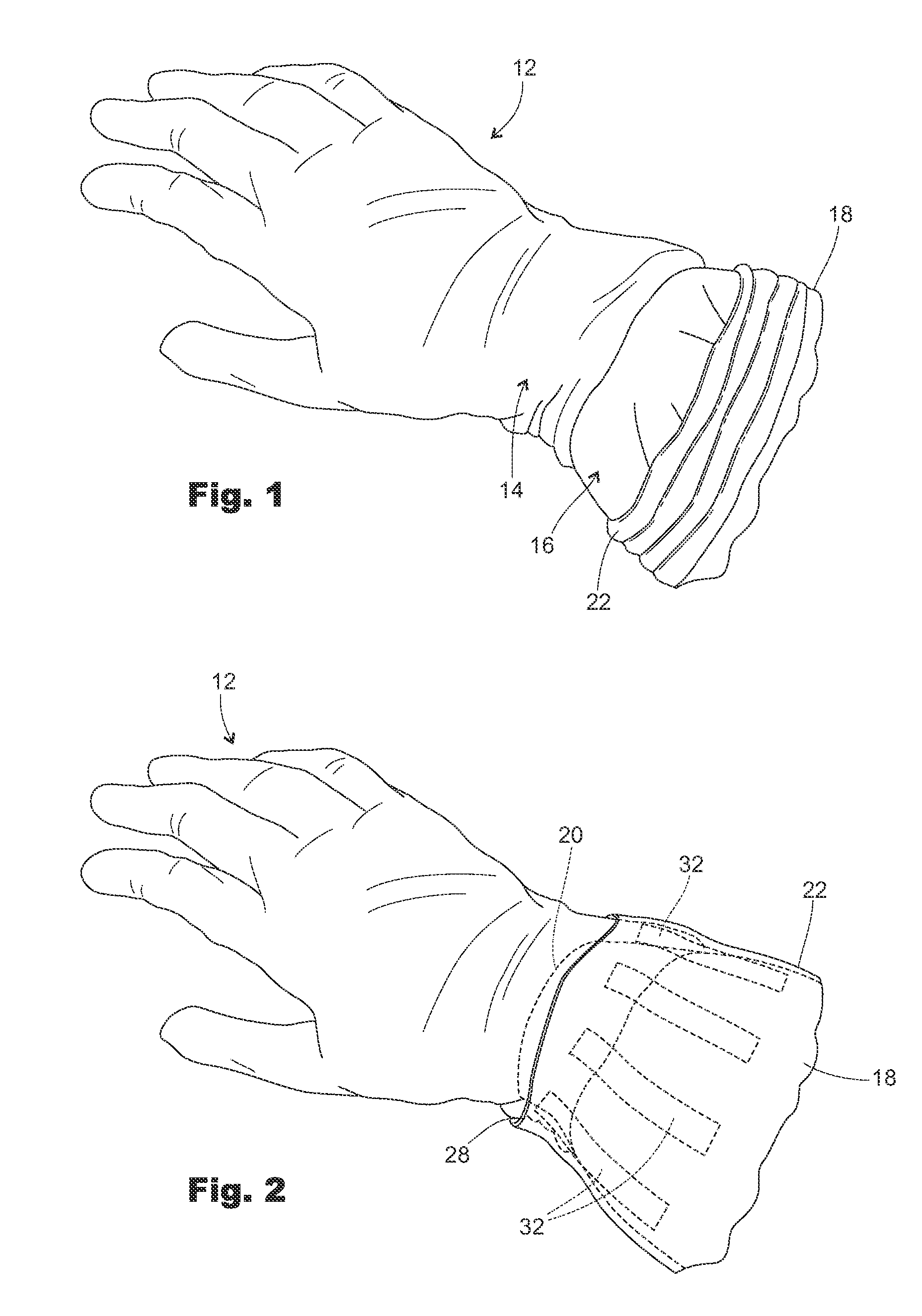

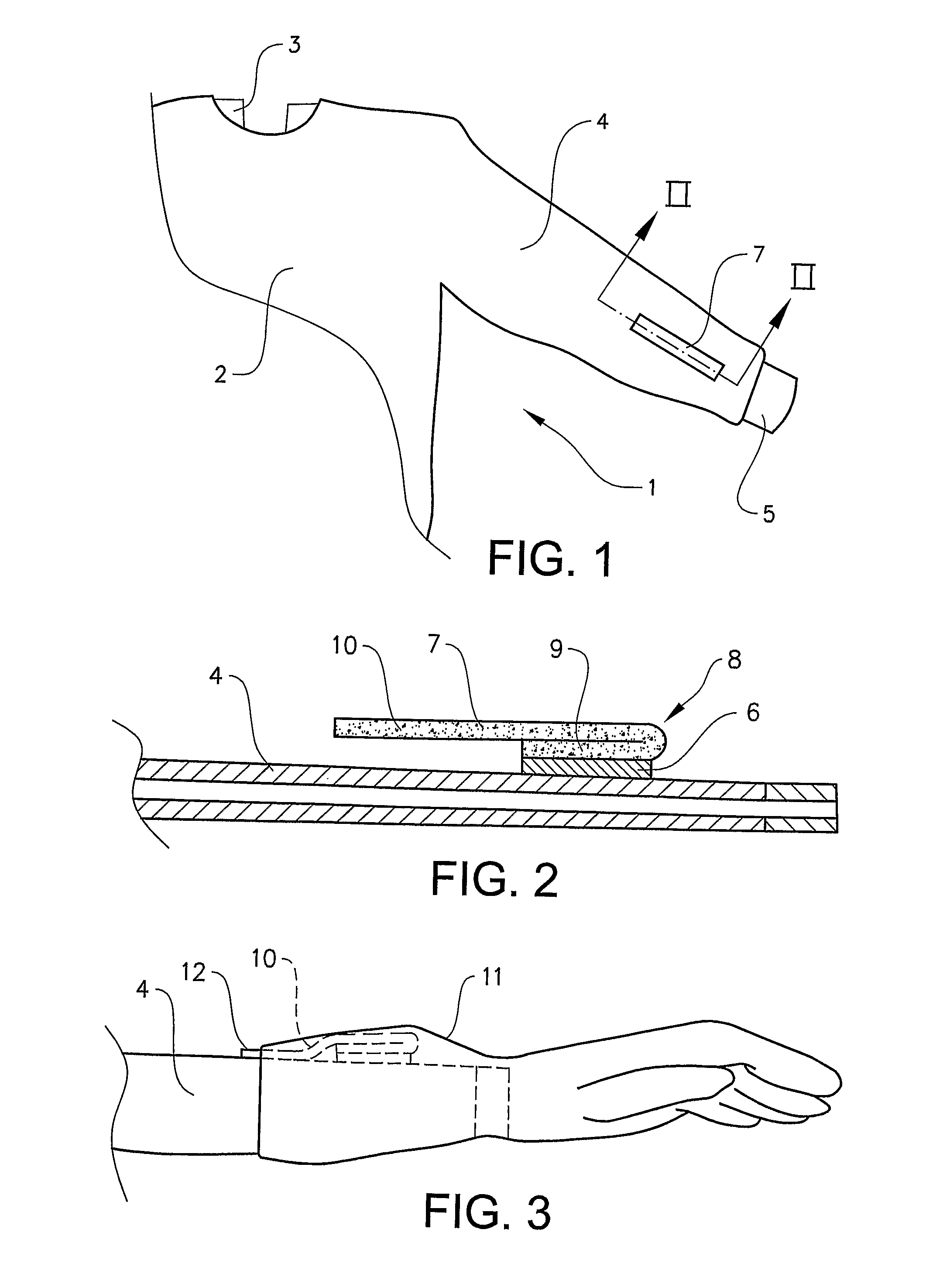

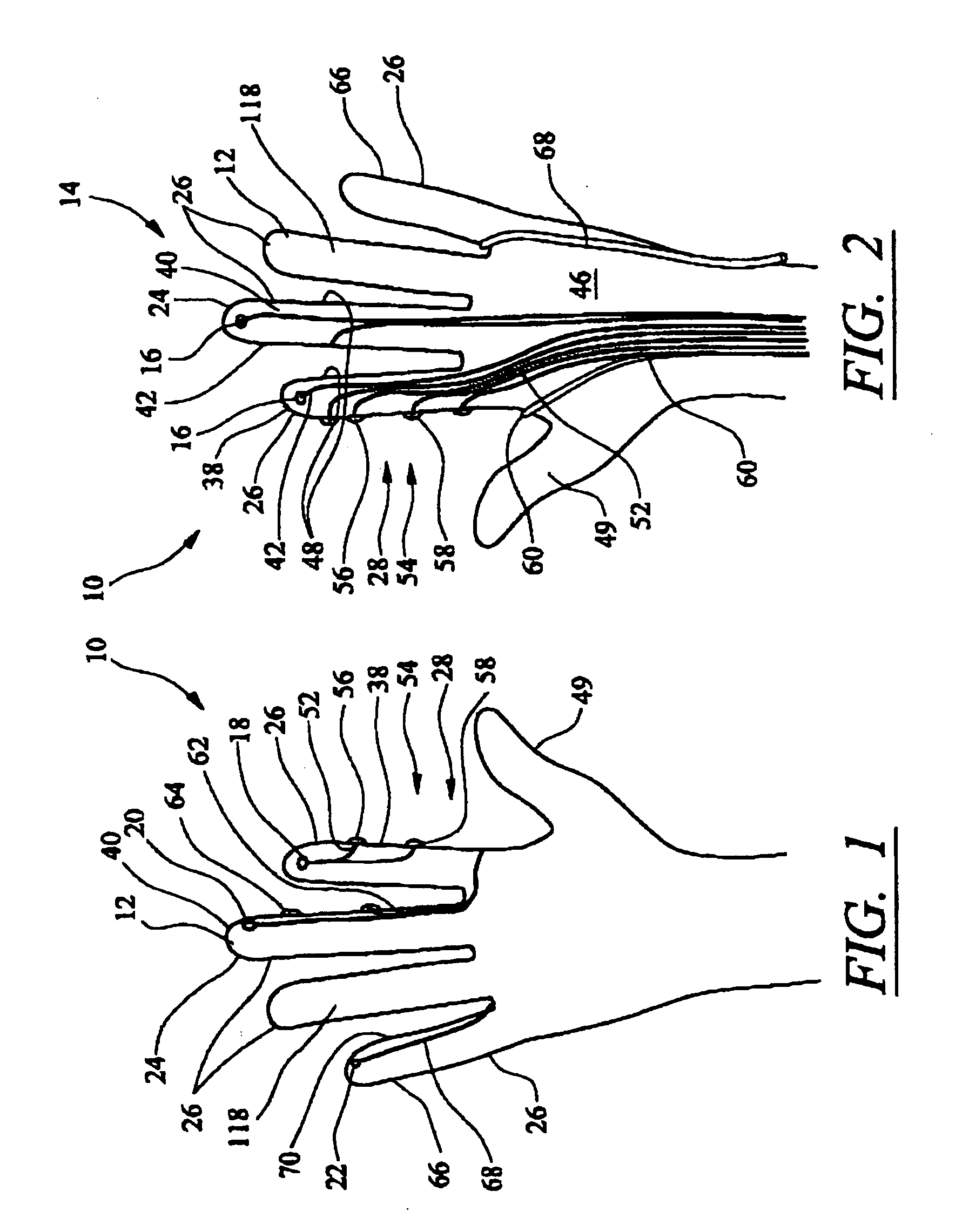

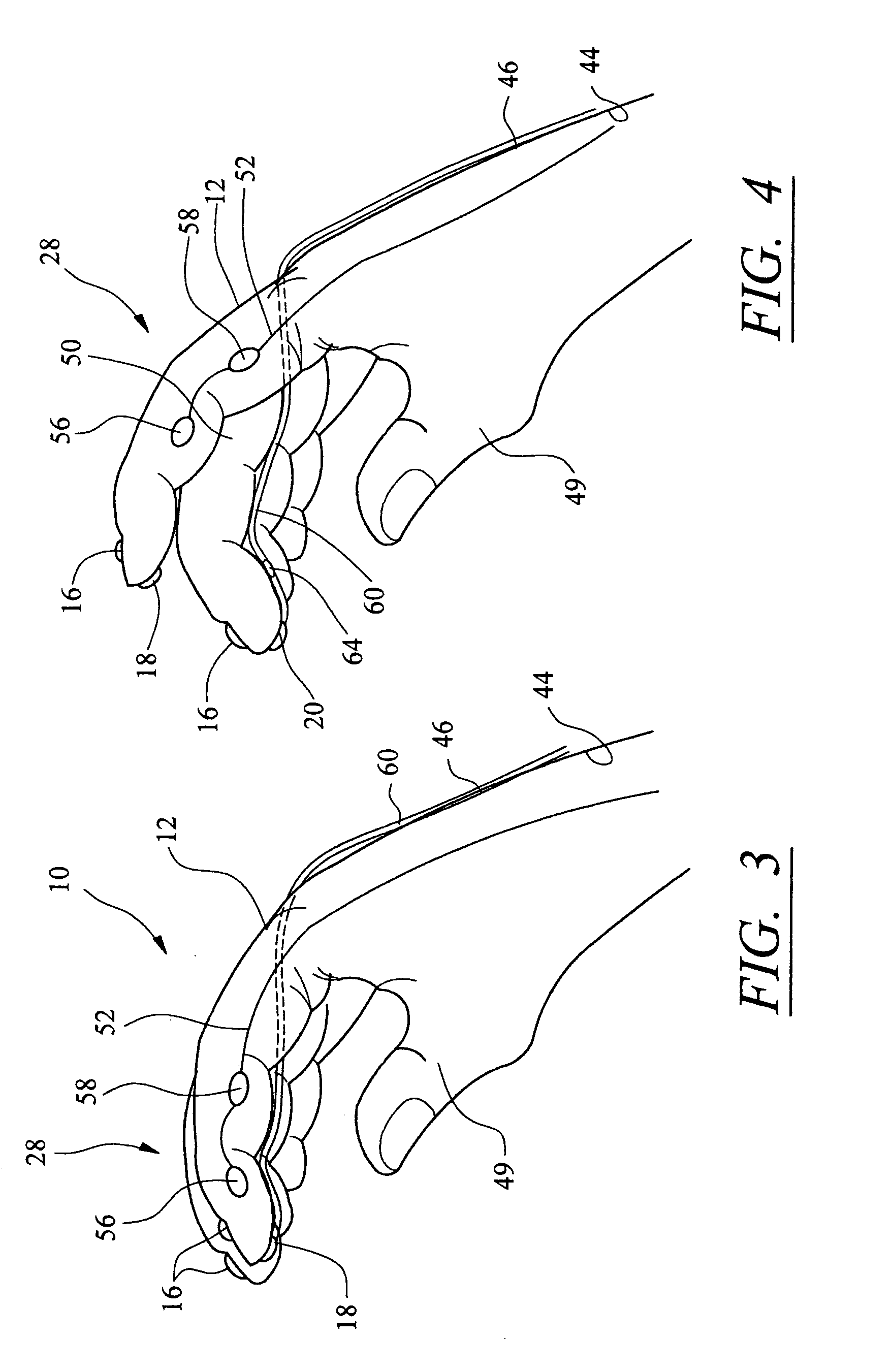

Medical gown with a secondary sleeve for extending over a surgical glove

A protective gown with a tubular overlay, or tube, on each gown sleeve attached on one end at the user's forearm as the tube extends toward the upper arm as a surgical glove is donned and the gown sleeve is tucked within the glove cuff. The tube then extends downward toward the sleeve end and over the glove cuff forming a channel in which the glove cuff is positioned and retained. The tube is secured to the glove from within the tube as it engages the glove cuff. Areas of increased frictional resistance may be added to the tube underside to engage the glove cuff secondary surface as the sleeve is tucked within the glove cuff. Increased frictional resistance may be obtained by employing strips or a coating with a low tack surface.

Owner:THOMPSON W FREDERICK

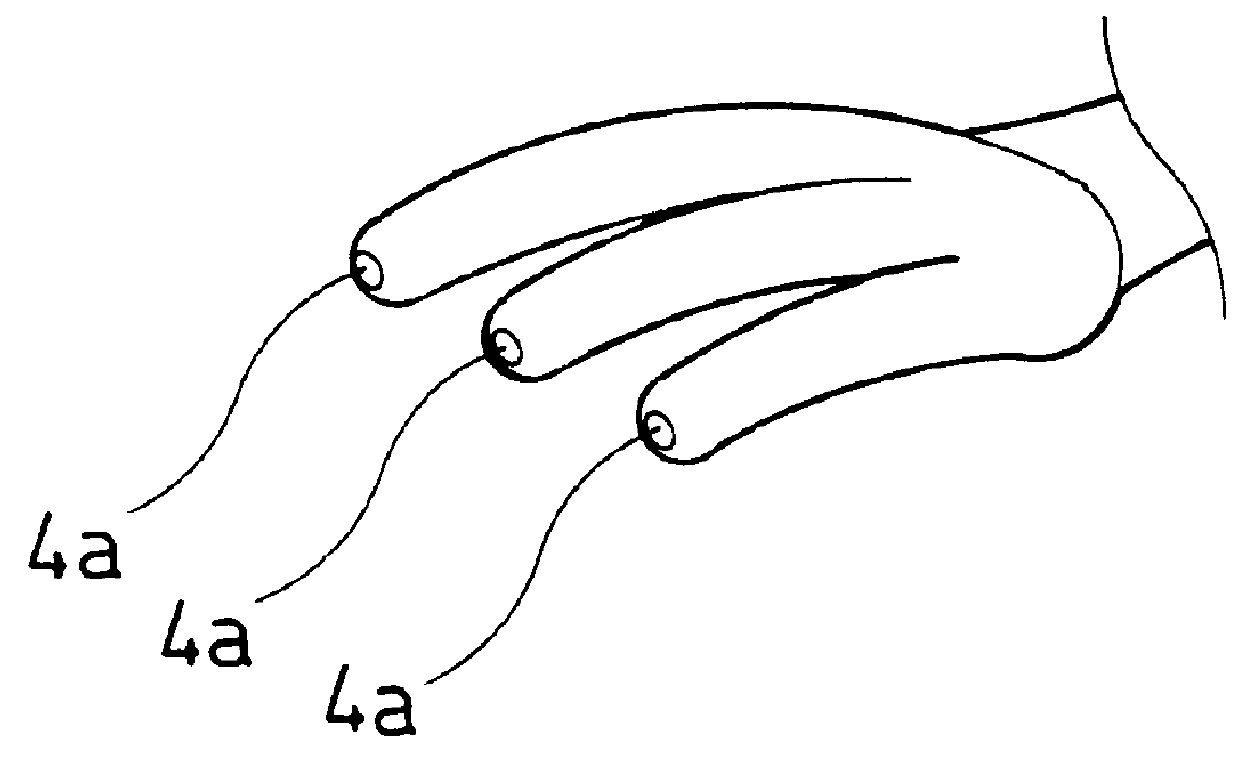

Surgical glove

A surgical glove is made using a mould having a set of digits, consisting of thumb and index, middle, ring and little fingers that are disposed in positions consistent with that of a human hand when holding a surgical implement. In one embodiment, the digits include at least one major bend. In another embodiment, each of the digits includes two bends. By adopting a shape for the surgical glove that mimics the position of the surgeon's hand while holding a surgical implement, finger stress and hand fatigue during a prolonged surgical procedure can be significantly reduced.

Owner:GUAN LOW CHIN

Surgicl Glove

A surgical glove adapted to be worn by a user has a portion at the underside of the wrist area of the glove which is enlarged or expandable provides relief from pressure to the wrist of a user wearing the glove during use of the glove. A second enlarged or expandable portion positioned at the dorsal side of the wrist area of the glove further provides relief from pressure to the wrist of the wearer of the glove.

Owner:SHAPIRO DAVID D

Docking sleeve with electrical adapter

ActiveUS20150244126A1Low costSmooth connectionElectric discharge tubesDigital data processing detailsTablet computerElastomer

A docking sleeve having an elastomeric protective cover, or skin, adapted for partially enveloping a portable electronic device, such as a smartphone or tablet or another portable electronic device of the prior art having a port for a docking connector. The protective cover is a sheath molded of a suitable elastic or flexibly resilient elastomer in a size and shape to fit over and closely conform to the particular portable electronic device so that the cover fits the device like a surgical glove.An adapter is provided for electrically connecting to the female input / output socket of the particular electronic device, including a male plug having a plurality of electrical connectors extended internally of the sheath and arranged for mating with the female input / output socket of the device, and a plurality of contacts electrically coupled to different ones of the plurality of electrical connectors and exposed externally of the sheath.

Owner:NAT PRODS

Surgical glove with ergonomic features

ActiveUS20140208480A1Reduce bias forceAccurate fitDiagnosticsGlovesSurgical GlovesMechanical engineering

Owner:EXSOMED CORP

Presulfurized natural latex/polyhydroxybutyrate blend material and preparation method thereof

ActiveCN104788754ASolve Blending ProblemsColloid performance is stableEmulsionBiocompatibility Testing

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

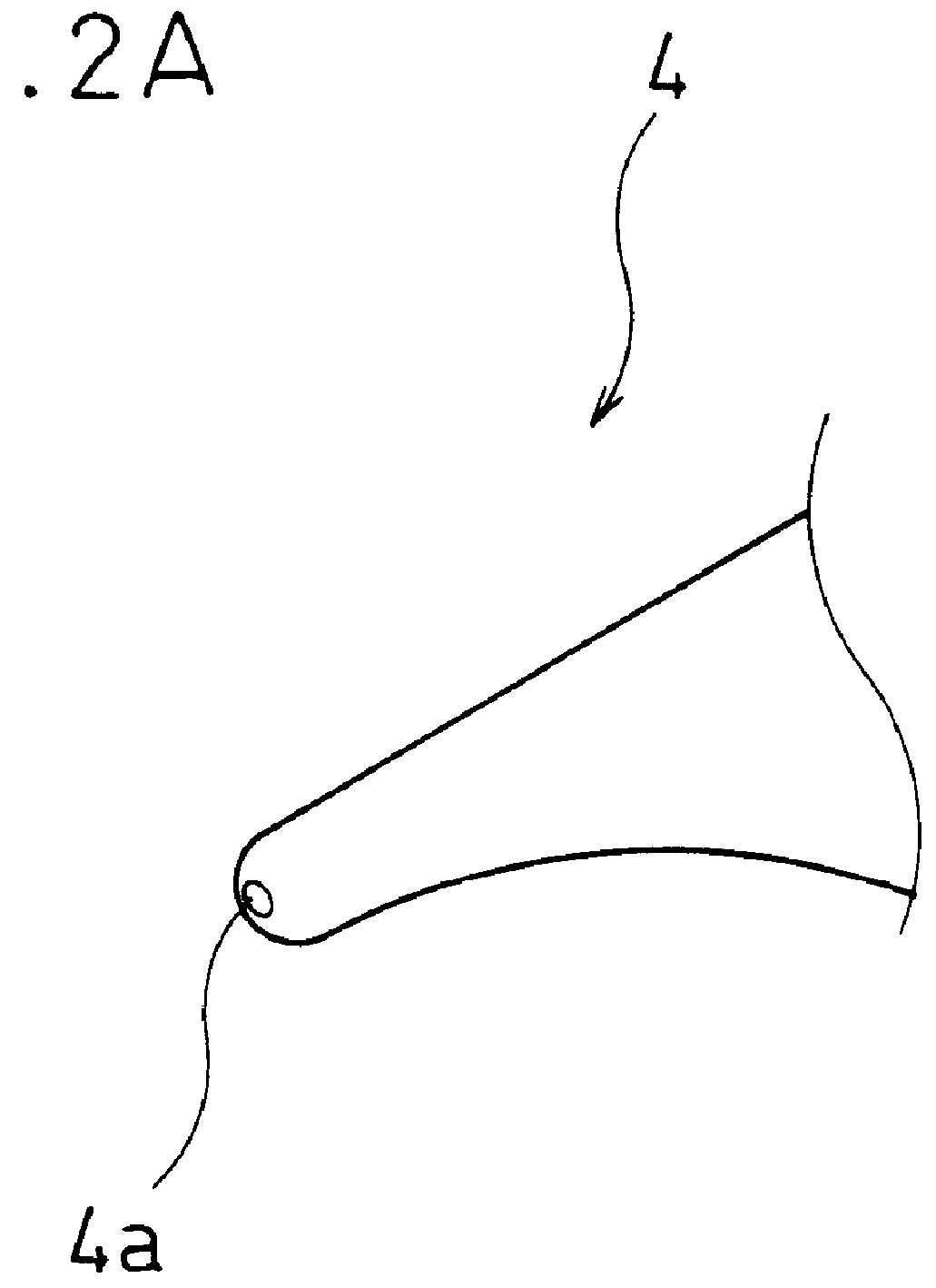

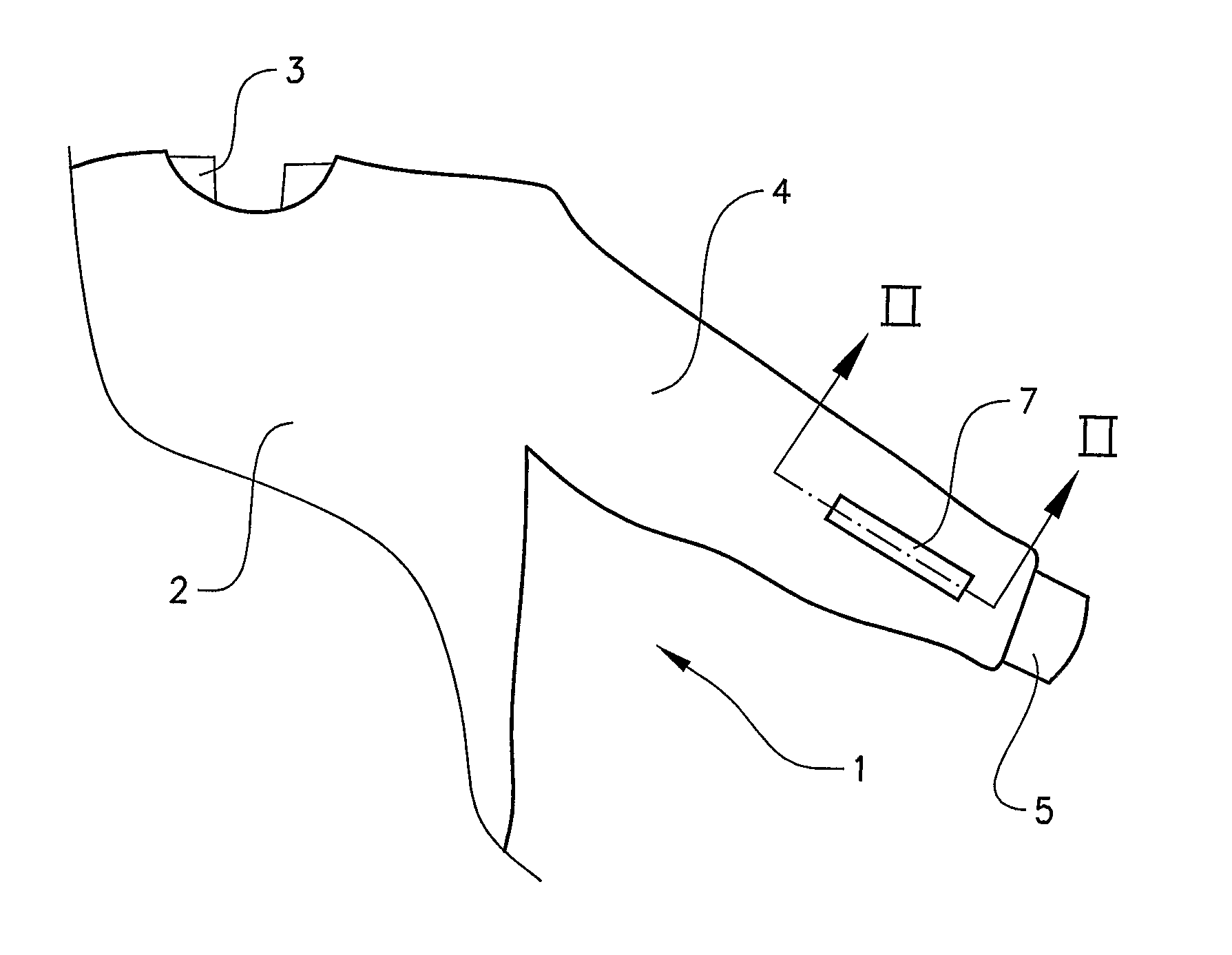

Surgical garment with means for affixing a glove thereto

A surgical garment (1) has a front portion (2) and a back portion (3) and two sleeves (4). Each sleeve (4) has at least one adhesive region (6) for affixing a donned surgical glove (11) thereto, each such region (6) being covered by a strip (7) of release material being removable from the associated adhesive region (6) in a sterile manner after donning of the surgical glove (11).

Owner:MOLNLYCKE HEALTH CARE AB

Surgical glove system

ActiveUS20070174947A1Delays operative procedureRule out the possibilityLighting support devicesDiagnosticsSupporting systemSurgical Gowns

A surgical system including a surgical glove having support systems such as, but not limited to, lights, electrical cautery, suction, and irrigation. The surgical glove may include one or more lights, electrical cautery, suction, and irrigation positioned on distal ends of fingers of the surgical glove. The support systems may be controlled with switches positioned on the fingers upon which each support system is positioned. The switches may be operable with the thumb on the human hand upon which the surgical glove is attached. The surgical system may also include a surgical gown having a connection system for attaching support conduit to the surgical gown. The surgical system enables a surgeon to have a plurality of support systems immediately available and reduces entanglement problems endemic with conventional systems.

Owner:SCHNEIDER ANDREW I

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com