A composite dispersion method for polyimide chopped fibers

A technology of chopped fiber and polyimide, applied in the direction of fiber treatment, fiber type, fiber raw material treatment, etc., can solve the problems of unsuitable fiber dispersion for a long time, unable to effectively prevent fiber bending and flocculation into agglomerates, etc. Increase the roughness and hydrophilic ability, ensure the uniformity of fiber dispersion, and reduce the effect of aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

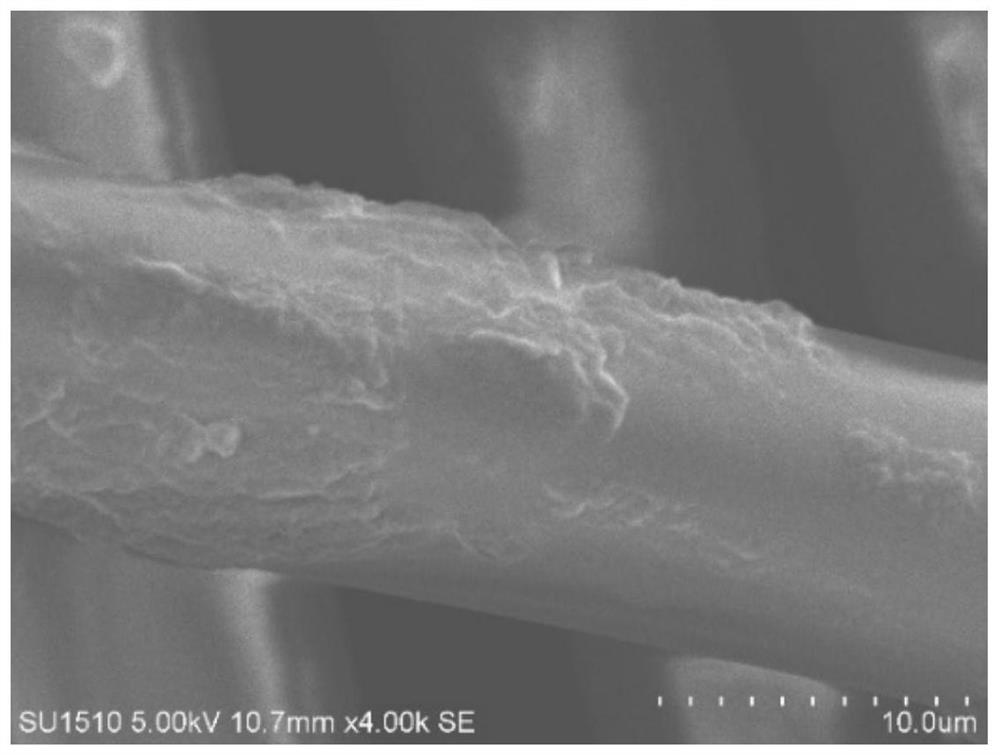

Image

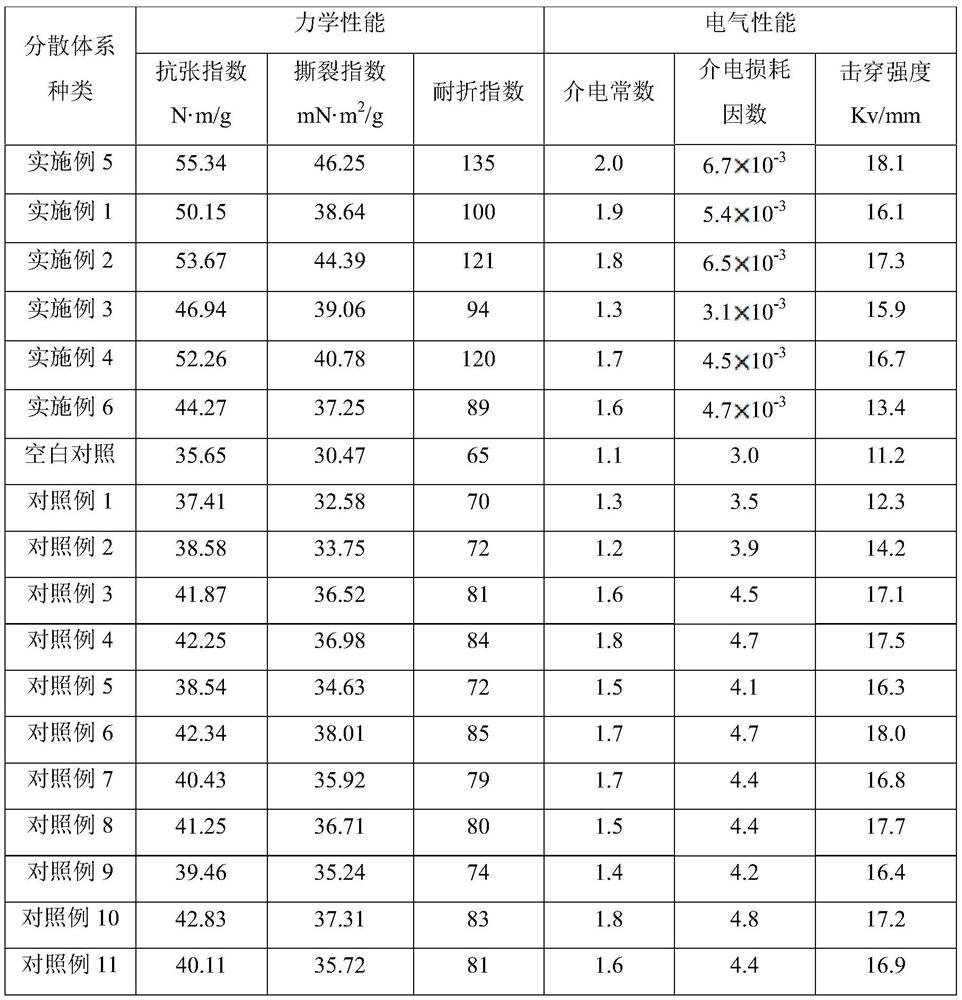

Examples

Embodiment 1

[0065] A method for preparing polyimide fiber base paper, comprising the steps of:

[0066] (1) Take 1000mL of water in a beaker, and add 6g of HCl into 1000mL of water at a ratio of 6.0:500 according to the mass-volume ratio g / mL to obtain an acid solution; according to the mass-volume (water) ratio g / mL is 1.0: 500 ratio, 2.0g of 3mm polyimide chopped fibers were added to the solution; the polyimide chopped fibers were filtered out through a filter screen after acid treatment at room temperature for 25min, washed with water and dried to obtain acid-treated polyimide fiber;

[0067] (2) According to the ratio of the mass volume ratio g / mL of hexamethylenediamine crystals and water to 0.9:500, and according to the ratio of 0.5:500 to the mass volume ratio g / mL of cationic surfactant CTMAB and water, weigh 1.8g Hexamethylenediamine crystals and 1.0g CTMAB were added to a beaker with 1000mL of water, and a mixed solution was obtained after the two were fully dissolved; then aci...

Embodiment 2

[0072] A method for preparing polyimide fiber base paper, comprising the steps of:

[0073] (1) Take 1000mL of water in a beaker, and mix 5.0g of H 2 SO 4 Add to 1000mL water, according to the ratio of mass volume (water) g / mL is 1.6:500, add 3.2g of 5mm polyimide chopped fibers into the solution; the polyimide chopped fibers are treated with acid at room temperature After 30 minutes, it is filtered through a filter screen, washed and dried to obtain acid-treated polyimide fibers;

[0074] (2) According to the ratio of the mass volume ratio g / mL of hexamethylenediamine crystals to water of 0.6:500, and according to the ratio of 0.4:500 of the mass volume ratio g / mL of the cationic surfactant CTMAB to water, weigh 1.2g Hexamethylenediamine crystals and 0.8g CTMAB were added to a beaker with 1000mL of water, and after the two were fully dissolved, a mixed solution was obtained; acid-treated polyimide chopped fibers were added to the mixed solution, and in a magnetic stirrer (...

Embodiment 3

[0079] A method for preparing polyimide fiber base paper, comprising the steps of:

[0080] (1) Take 1000mL of water in a beaker, and mix 10.4g of HNO 3 Add to 1000mL water, according to the ratio of mass volume (water) g / mL is 2.0:500, add 4.0g of 5mm polyimide chopped fibers into the solution; the polyimide chopped fibers are treated with acid at room temperature After 40min, it was filtered through a filter screen, washed with water and dried to obtain acid-treated polyimide fibers;

[0081] (2) According to the ratio of the mass volume ratio g / mL of hexamethylenediamine crystals and water to 0.8:500, and according to the ratio of 0.7:500 to the mass volume ratio g / mL of the cationic surfactant CTMAB and water, weigh 1.6g Hexamethylenediamine crystals and 1.4gCTMAB were added to a beaker with 1000mL of water, and a mixed solution was obtained after the two were fully dissolved; then the acid-treated polyimide chopped fibers were added to the mixed solution, and in a magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com