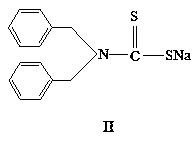

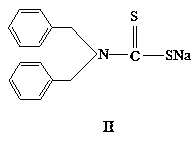

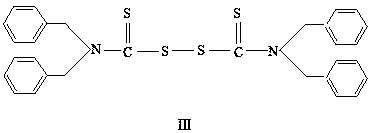

A kind of tetrabenzylthiuram monosulfide and its preparation method and application

A technology of tetrabenzylthiuram and carbon disulfide, which is applied in the direction of organic chemistry, can solve the problems of internal quality and "green" environmental protection technology gap, etc., and achieve the effects of good scorch safety, high melting point, and good rapid vulcanization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of tetrabenzylthiuram monosulfide, the steps are as follows:

[0041] 1. Weigh each raw material: 100g of dibenzylamine, 21g of solid sodium hydroxide, 40g of carbon disulfide, 31g of 30wt% hydrogen peroxide solution, and 300g of water.

[0042] 2. Add dibenzylamine and solid sodium hydroxide into water according to the proportion, add carbon disulfide dropwise at room temperature, and react for 0.5-1 hour after the drop to obtain a reaction solution.

[0043] 3. Add 25wt% sulfuric acid dropwise to the reaction solution in step 2, adjust the pH to 5-6, add aqueous hydrogen peroxide solution dropwise, and react for 2.5-3 hours after dropping to obtain a reaction solution.

[0044] 4. Add 10wt% sodium hydroxide to the reaction liquid in step 3, adjust the pH to 7-8, feed hydrogen with a hydrogen bottle, control the pressure at 0.8MPa, control the reaction temperature at 145°C, and react for 2 hours. Filter, wash, and dry under vacuum to obtain 124.49...

Embodiment 2

[0046] Prepare tetrabenzylthiuram monosulfide according to the method of Example 1, the difference is: the amount of each raw material is: dibenzylamine 100g, solid sodium hydroxide 21g, carbon disulfide 43g, 30wt% hydrogen peroxide solution 34g, water 300g, The hydrogen reaction pressure is 0.8MPa, and the reaction temperature is 140°C. The obtained product was 123.71g, the appearance was white, the melting point measured by the automatic capillary melting point apparatus was 94.3°C, the purity measured by the high performance liquid chromatography analyzer was 98.2%, and the yield was 95.2%.

Embodiment 3

[0048] Prepare tetrabenzylthiuram monosulfide according to the method of Example 1, the difference is: the amount of each raw material is: dibenzylamine 100g, solid sodium hydroxide 21g, carbon disulfide 43g, 30wt% hydrogen peroxide solution 34g, volume fraction 10 % ethanol aqueous solution 300g, hydrogen reaction pressure 0.8MPa, reaction temperature 150°C to obtain 124.10g of the product, the appearance is white, the melting point measured by the automatic capillary melting point instrument is 93.5°C, and the purity measured by the high performance liquid chromatography analyzer is 98.4%. The yield was 95.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com