Preparation method for highly thermal stable CPVC blend composition

A technology of high thermal stability and blending materials, applied in the field of polymer materials, can solve the problems of difficult CPVC processing and high cost of thermal stabilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

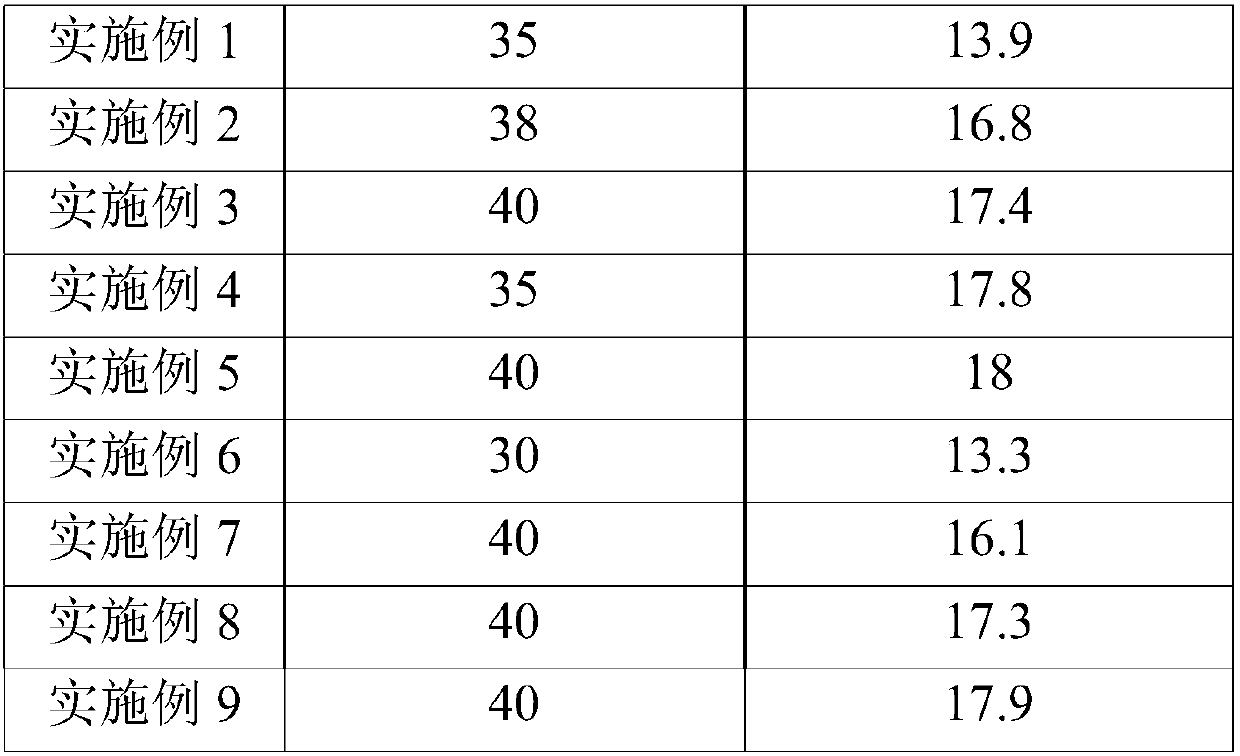

Examples

Embodiment 1

[0020] Add 100 parts of CPVC to the first mixer at a low speed of 200r / min, then adjust the speed of the first mixer to a high speed of 1000r / min; when the temperature rises to 60℃, add 0.4 parts of hydrotalcite and 1.5 Parts of ethyl tin heat stabilizer; when the temperature rises to 82°C, add 6.2 parts of impact modifier; when the temperature rises to 90°C, add 0.8 parts of paraffin wax, 1.4 parts of PE wax, 1.4 parts of fillers, 1.1 parts of processing Additives and 0.3 parts antioxidant; when the temperature rises to 115°C, the mixing is over. The mixture in the first mixer is transferred to the second mixer, and the mixture is cooled to 40° C. to finish discharging to obtain a CPVC blend.

Embodiment 2

[0022] Add 100 parts of CPVC in the first mixer at low speed of 300r / min, then adjust the speed of the first mixer to high speed of 1300r / min; when the temperature rises to 65℃, add 0.6 parts of hydrotalcite and 1.5 Parts of ethyl tin heat stabilizer; when the temperature rises to 88 ℃, add 6 parts of impact modifier; when the temperature rises to 95 ℃, add 1 part of paraffin wax, 1.6 parts of PE wax, 1.8 parts of filler, 1 part of processing Additives and 0.4 parts antioxidant; when the temperature rises to 120°C, the mixing is over. The mixture in the first mixer is transferred to the second mixer, and the mixture is cooled to 50° C. to finish discharging to obtain a CPVC blend.

Embodiment 3

[0024] Add 100 parts of CPVC at 210r / min in the first mixer at low speed, then adjust the speed of the first mixer to 1100r / min at high speed; when the temperature rises to 61℃, add 0.8 parts of hydrotalcite and 1.5 Parts of ethyl tin heat stabilizer; when the temperature rises to 83 ℃, add 6.4 parts of impact modifier; when the temperature rises to 91 ℃, add 0.9 parts of paraffin wax, 1.5 parts of PE wax, 1.5 parts of fillers, 1.5 parts of processing Additives and 0.35 parts of antioxidants; when the temperature rises to 116°C, the mixing is complete. The mixture in the first mixer is transferred to the second mixer, and the mixture is cooled to 42° C. to finish discharging to obtain a CPVC blend.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com