High-flame-retardant PVC product containing hyperbranched polymer

A hyperbranched polymer, high flame-retardant technology, applied in the field of PVC products, can solve the problems of affecting the stability of PVC, not obvious effect, and reducing the fluidity of PVC.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

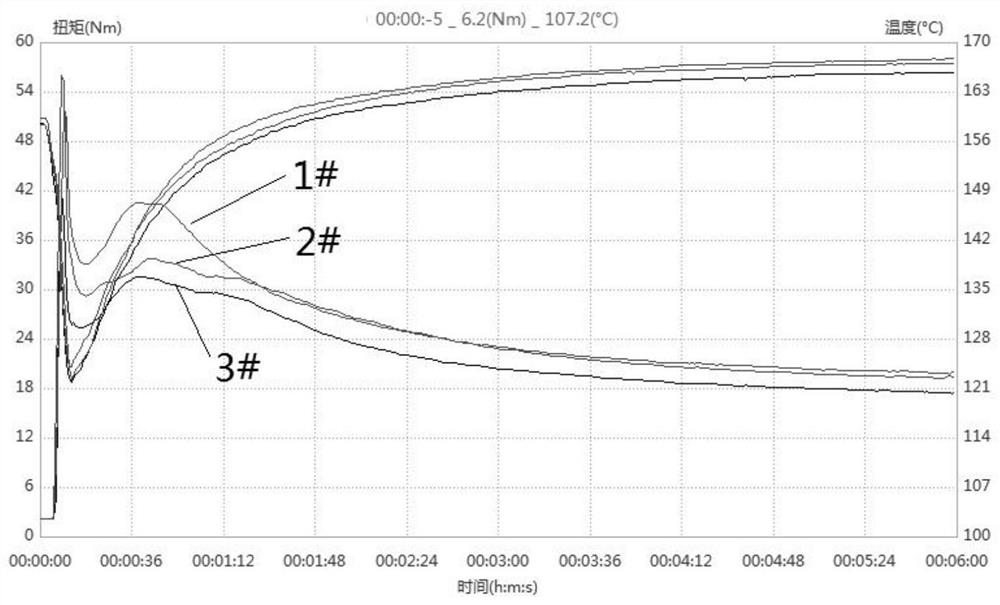

Image

Examples

Embodiment 1

[0023] The purpose of the present invention is to provide a high flame-retardant PVC product containing a hyperbranched polymer. Vinyl resin, the dioctyl terephthalate of 30 parts by weight, the light calcium carbonate of 40 parts by weight, the hydroxide of 25 parts by weight, the calcium zinc stabilizer of 4 parts by weight, the polyethylene wax of 0.5 parts by weight and 2 The hyperbranched polymer composition of weight part.

[0024] Among them, the density of hyperbranched polymer is 1.3g / cm 2 , the melting range is 140-160°C.

[0025] Among them, the median diameter of the polyvinyl chloride resin is 250 μm.

[0026] Among them, the molecular weight of dioctyl terephthalate is 375, and the viscosity at 25°C is 55×10 -3 Pa·s.

[0027] Wherein, the moisture content of the light calcium carbonate is 0.5wt%, and the median particle size is 5 μm.

[0028] Wherein, the hydroxide is aluminum hydroxide.

[0029] Among them, the median particle size of aluminum hydroxide is...

Embodiment 2

[0037] The purpose of the present invention is to provide a high flame-retardant PVC product containing a hyperbranched polymer. Vinyl resin, the dioctyl terephthalate of 20 parts by weight, the light calcium carbonate of 30 parts by weight, the hydroxide of 20 parts by weight, the calcium zinc stabilizer of 3 parts by weight, the polyethylene wax of 0.3 parts by weight and 1 The hyperbranched polymer composition of weight part.

[0038] Among them, the density of hyperbranched polymer is 1g / cm 2 , the melting range is 160-180°C.

[0039] Among them, the median diameter of the polyvinyl chloride resin is 30 μm.

[0040] Among them, the molecular weight of dioctyl terephthalate is 350, and the viscosity at 25°C is 50×10 -3 Pa·s.

[0041] Wherein, the moisture content of the light calcium carbonate is 0.1wt%, and the median particle size is 0.5μm.

[0042] Wherein, the hydroxide is aluminum hydroxide.

[0043] Wherein, the chlorine impurity content of magnesium hydroxide i...

Embodiment 3

[0051] The object of the present invention is to provide a high flame-retardant PVC product containing a hyperbranched polymer. Vinyl resin, the dioctyl terephthalate of 40 parts by weight, the light calcium carbonate of 50 parts by weight, the hydroxide of 30 parts by weight, the calcium zinc stabilizer of 5 parts by weight, the polyethylene wax of 0.7 parts by weight and 3 The hyperbranched polymer composition of weight part.

[0052] Among them, the density of hyperbranched polymer is 1.6g / cm 2 , the melting range is 140-160°C.

[0053] Among them, the median diameter of the polyvinyl chloride resin is 500 μm.

[0054] Among them, the molecular weight of dioctyl terephthalate is 400, and the viscosity at 25°C is 60×10 -3 Pa·s.

[0055] Among them, the moisture content of the light calcium carbonate is 1.0wt%, and the median particle size is 10 μm.

[0056] Wherein, the hydroxide is aluminum hydroxide.

[0057] Among them, the median particle size of aluminum hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com