Plating solution for electroless Ni-Mo-B/GO multifunctional nano-composite deposition layer and preparation method and application of plating solution

A nano-composite and multi-functional technology, applied in the field of chemical plating, can solve the problems of not involving ultrasound and graphene oxide, no multi-functional nano-composite deposition layer preparation method, etc., to enhance wear resistance, increase coating brightness, The effect of good tissue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

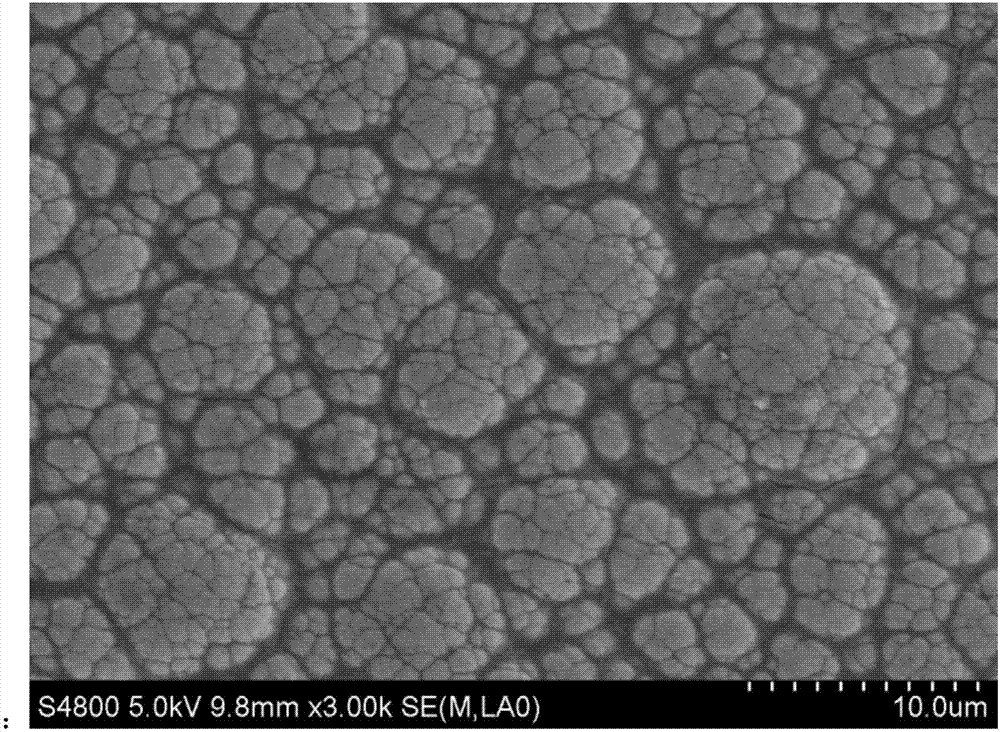

Image

Examples

Embodiment 1

[0024] A Ni-Mo-B / GO (graphene oxide) multifunctional nano-composite plating solution. Its characteristics are calculated per liter of plating solution. Its composition and content are as follows:

[0025]

[0026] Add nickel chloride hexahydrate, sodium borohydride, sodium molybdate, sodium hydroxide, ethylenediamine, sodium lauryl sulfate, graphene oxide, and lead acetate to distilled water in turn to dissolve, and then let it stand for 12 hours. The Ni-Mo-B / GO (graphene oxide) multifunctional nano composite plating solution was obtained.

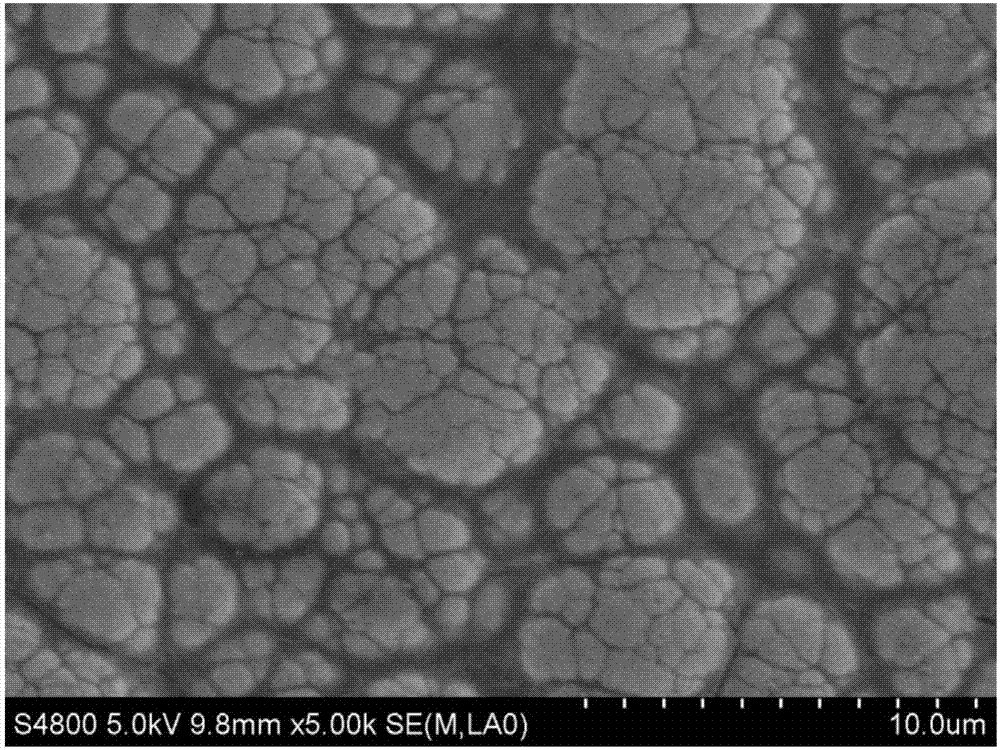

Embodiment 2

[0033] A Ni-Mo-B / GO (graphene oxide) multifunctional nano-composite plating solution. Its characteristics are calculated per liter of plating solution. Its composition and content are as follows:

[0034]

[0035] Add nickel chloride hexahydrate, sodium borohydride, sodium molybdate, sodium hydroxide, ethylenediamine, sodium lauryl sulfate, graphene oxide, and lead acetate to distilled water in turn to dissolve, and then let it stand for 12 hours. The Ni-Mo-B / GO (graphene oxide) multifunctional nano composite plating solution was obtained.

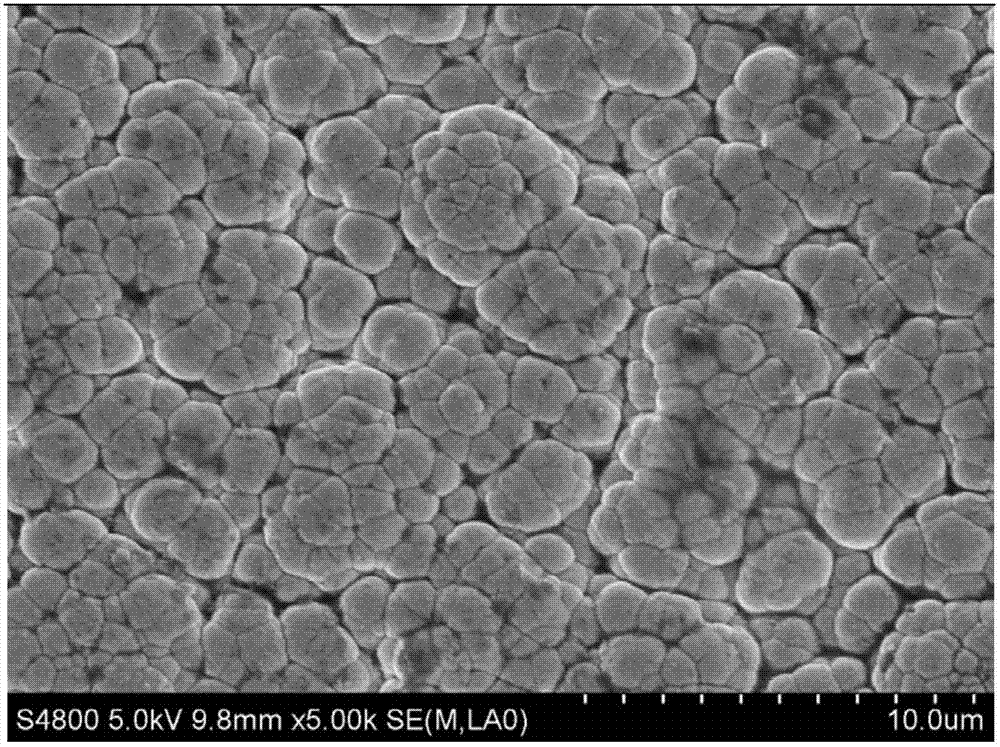

Embodiment 3

[0042] A Ni-Mo-B / GO (graphene oxide) multifunctional nano-composite plating solution. Its characteristics are calculated per liter of plating solution. Its composition and content are as follows:

[0043]

[0044] Add nickel chloride hexahydrate, sodium borohydride, sodium molybdate, sodium hydroxide, ethylenediamine, sodium lauryl sulfate, graphene oxide, and lead acetate to distilled water in turn to dissolve, and then let it stand for 12 hours. The Ni-Mo-B / GO (graphene oxide) multifunctional nano composite plating solution was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com