HDPE modified material for improving pearly luster color masterbatch forming line and application of material

A technology of pearlescent color masterbatch and modified material, applied in the field of material application, can solve problems such as increasing production cost, and achieve the effect of improving production efficiency, good effect and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Outer layer: Weigh 90 parts of HDPE5502, 10 parts of LDPE951000, and 4 parts of pearlescent masterbatch, then put them into a mixer and stir for 5 minutes;

[0057] Inner layer: Weigh 100 parts of HDPE5502 and 4 parts of common color masterbatch respectively, then put them into the mixer and stir for 5 minutes.

[0058] (2) Add the mixed inner layer and outer layer materials into the corresponding hopper of the blow molding machine.

[0059] (3) Process parameter setting:

[0060] Outer layer screw temperature: 170~175℃;

[0061] Inner layer screw temperature: 165~170℃;

[0062] Die head temperature: 170~180℃;

[0063] Inner layer screw speed: 22%

[0064] Outer screw speed: 12%

[0065] Finally, a product with a qualified appearance is formed.

Embodiment 2

[0067] (1) Outer layer: Weigh 75 parts of HDPE5502, 25 parts of LDPE951000, and 4 parts of pearlescent masterbatch, then put them into a mixer and stir for 5 minutes;

[0068]Inner layer: Weigh 100 parts of HDPE5502 and 4 parts of common color masterbatch respectively, then put them into the mixer and stir for 5 minutes.

[0069] (2) Add the mixed inner layer and outer layer materials into the corresponding hopper of the blow molding machine.

[0070] (3) Process parameter setting:

[0071] Outer layer screw temperature: 170~175℃;

[0072] Inner layer screw temperature: 165~170℃;

[0073] Die head temperature: 170~175℃;

[0074] Inner layer screw speed: 20%

[0075] Outer screw speed: 10%

[0076] Finally, a product with a qualified appearance is formed.

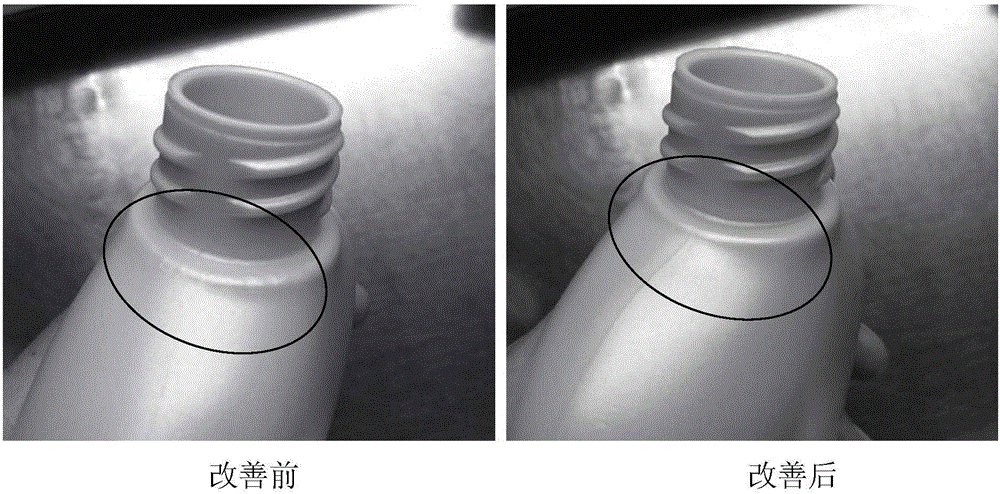

[0077] figure 1 It is the improvement of flow marks by the HDPE modified material of this example. See the circled part. Before improvement, there are flow marks on the shoulder of the product, resulting in uneven sur...

Embodiment 3

[0079] (1) Outer layer: Weigh 50 parts of HDPE5502, 50 parts of LLDPE7042, and 4 parts of pearlescent masterbatch, then put them into a mixer and stir for 5 minutes;

[0080] Inner layer: Weigh 100 parts of HDPE5502 and 4 parts of common color masterbatch respectively, then put them into the mixer and stir for 5 minutes.

[0081] (2) Add the mixed inner layer and outer layer materials into the corresponding hopper of the blow molding machine.

[0082] (3) Process parameter setting:

[0083] Outer layer screw temperature: 165~170℃;

[0084] Inner layer screw temperature: 165~170℃;

[0085] Die head temperature: 170~175℃;

[0086] Inner layer screw speed: 23%

[0087] Outer screw speed: 8%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com