A kind of screw speed control method for improving plasticizing quality of injection molding machine

A technology of screw speed and injection molding machine, which is applied in the field of setting the screw speed value in the plasticizing process of the injection molding machine, can solve the problems of many times of mold trial and long time for determining process parameters, so as to improve the plasticization quality and improve the melt plasticity. The effect of improving uniformity and reducing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described below through specific embodiments. The following description is only a part of the embodiments, and any non-creative replacement or modification based on the embodiments of the present invention, other obtained embodiments fall within the protection scope of the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

[0021] The invention is a screw speed control method for improving the plasticizing quality of an injection molding machine. Wait.

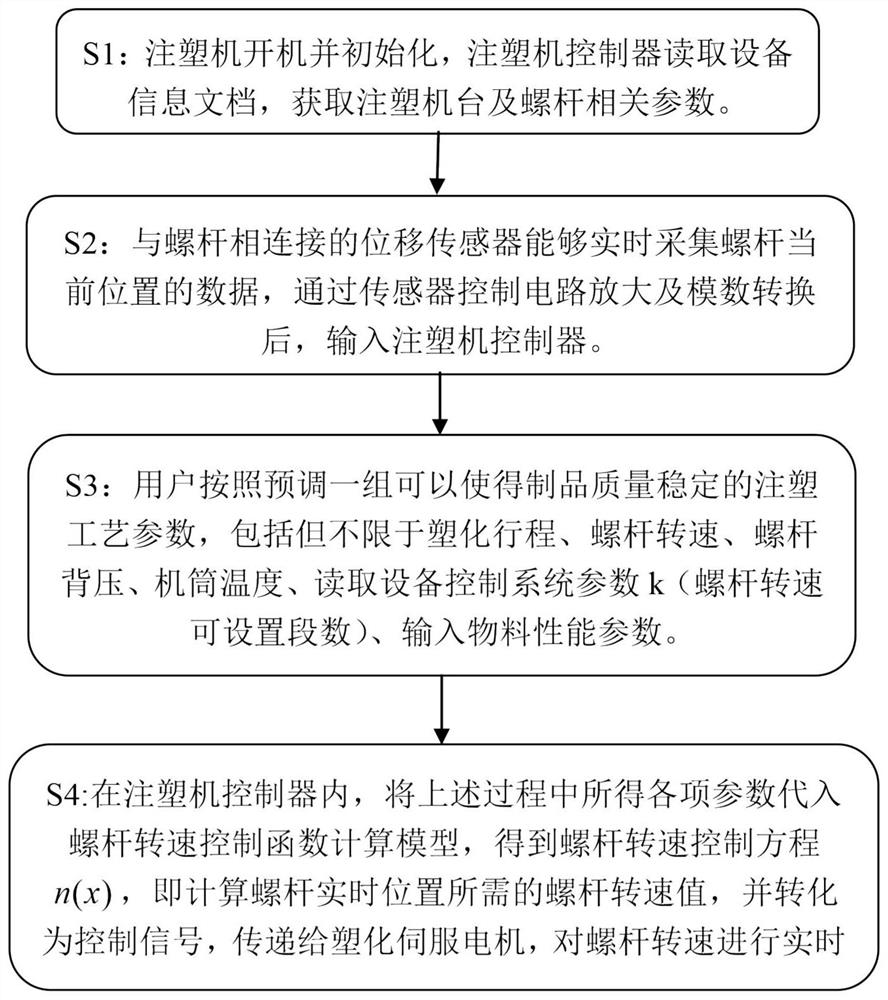

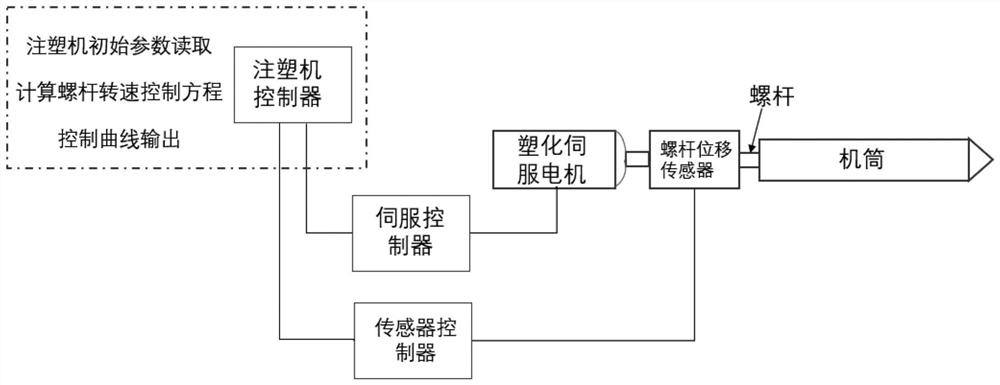

[0022] A screw speed control method for improving the plasticizing quality of an injection molding machine, the implementation process mainly includes the following four steps S1-S4:

[0023] S1: The injection molding machine is powered on and initialized, the injection molding machine controller reads the equipment informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com