Method for improving yield of PVB film extruder

An extruder and film technology, applied in the field of increasing the output of PVB film extruders, can solve the problems of increasing material movement resistance, increasing production costs, and consuming cooling water, so as to improve production efficiency, save costs, and improve plasticizing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

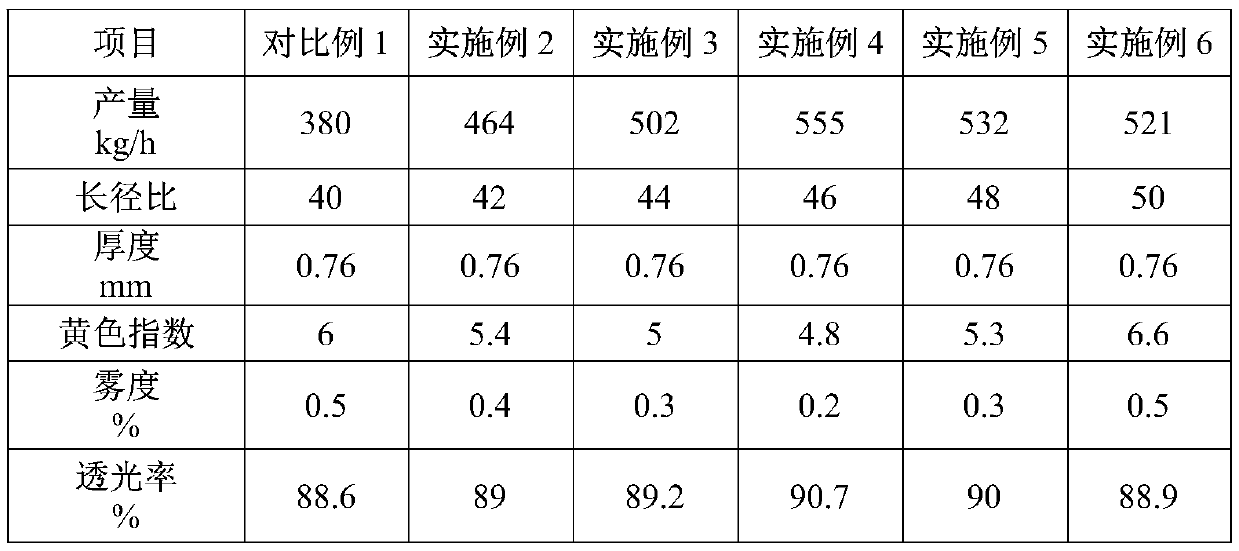

[0022] This embodiment produces PVB film specification 0.76mm, and the type of PVB film extruder used in production is the same as that of Comparative Example 1, the difference is that this embodiment is based on the PVB film extruder used in Comparative Example 1, and its conveying section is increased and the effective length of the screw in the melting section, so that the length-to-diameter ratio of the screw is increased to 42:1, and the ratio of the increased length of the screw in the conveying section to the melting section is 1:1. Add a new extruder barrel in the corresponding screw growth area, and control the temperature of the added conveying section barrel to 135°C and the added melting section barrel temperature to 150°C during production. Simultaneously, a conveying element 72 / 72 is added in the screw growth area of the conveying section, and a shear element 45° / 5 / 56 is added in the screw growth area of the melting section.

[0023] The output of the PVB fil...

Embodiment 3

[0025] The difference between this embodiment and Embodiment 2 is that the length-to-diameter ratio of the screw is set to 44.

[0026] The output of the PVB film of this embodiment is 502kg / h, and the output of the extruder has increased by 32% compared with Comparative Example 1. The performance indexes of the obtained PVB film are as shown in Table 1.

Embodiment 4

[0028] The difference between this embodiment and embodiment 2 is that the length-to-diameter ratio of the screw is set to 46.

[0029] The output of the PVB film of this embodiment is 555kg / h, and the output of the extruder has increased by 46% compared with Comparative Example 1. The performance indexes of the obtained PVB film are as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com