Injection molding mechanism capable of evenly heating and efficiently plastifying

A high-efficiency and uniform technology, applied in the field of uniform heating and high-efficiency plasticization injection molding mechanism, can solve the problems of low rotation speed of heating screw, unobvious design effect, poor plasticization uniformity, etc., to improve water flow and collision speed, and improve crushing and melting efficiency , Improve the effect of plasticizing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

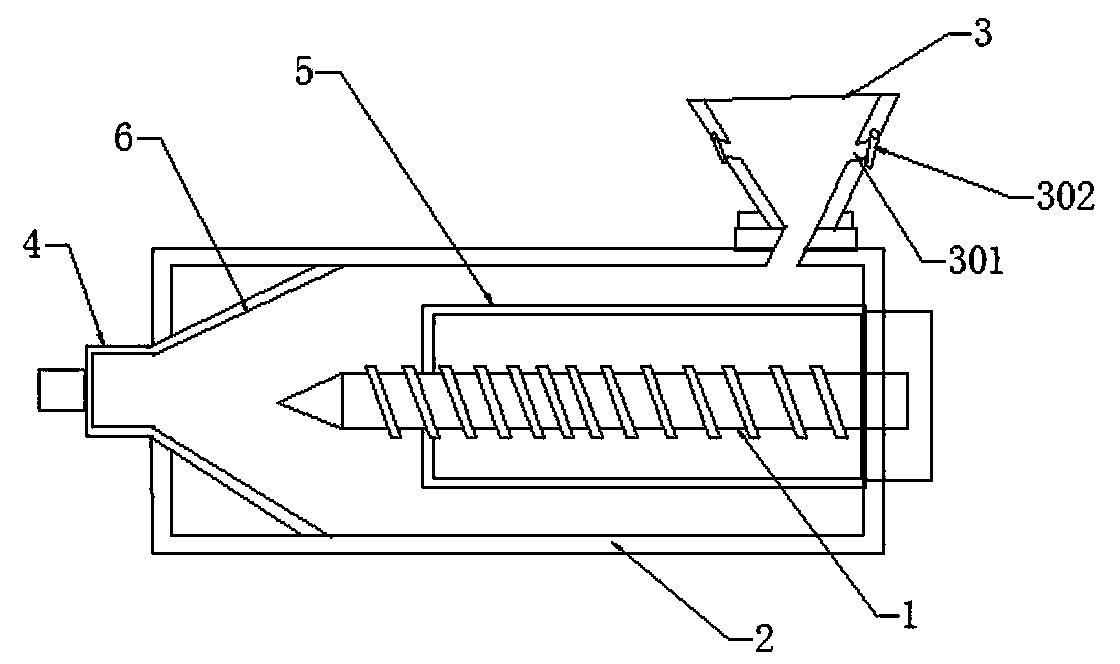

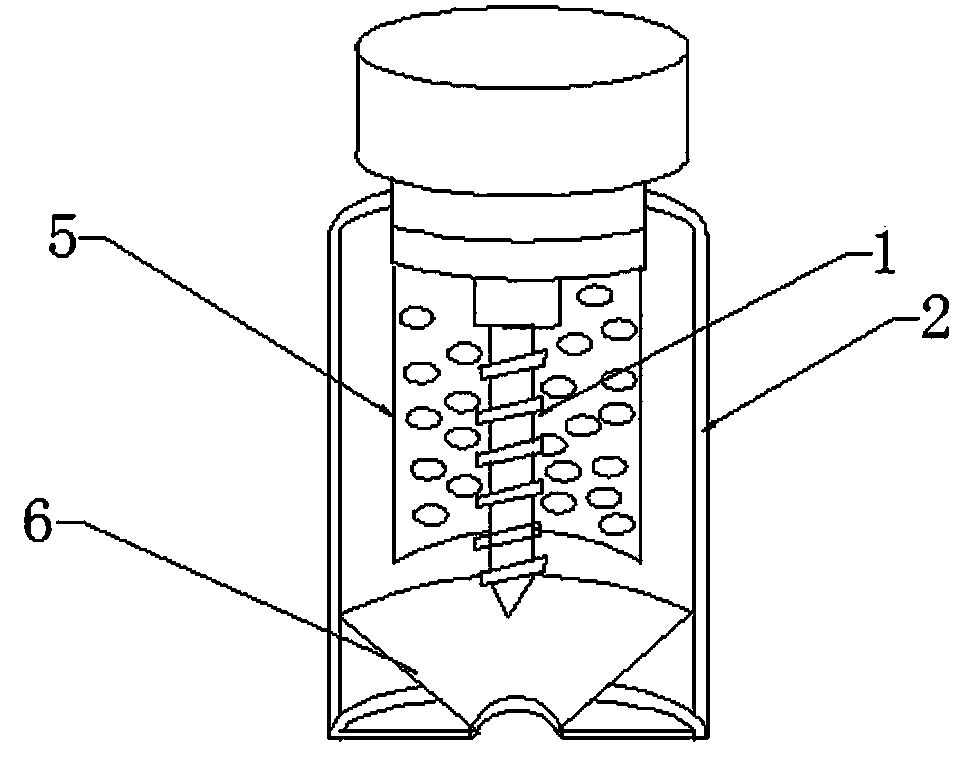

[0020] Such as figure 1 and figure 2 As shown, a uniform heating and high-efficiency plasticizing injection molding mechanism includes a heating screw 1, a heating chamber 2, a barrel 3 and a sprue sleeve connection end 4, the heating screw 1 is arranged in the heating chamber 2, and the barrel 3 is arranged in the heating chamber 2 and connected with the heating chamber 2, the sprue sleeve connecting end (4) is set at one end of the heating chamber (2) and communicated with the heating chamber (2). This patent also includes a Rafal net 5, a Rafal The net 5 is annular with the top and the bottom connected. The heating screw 1 is horizontally arranged in the Lafar net 5. One end of the Lafar net is connected with the motor, and the motor drives the La Far net to rotate. The heating screw 1 is connected to the screw transmission device. Connection; the direction of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com