Extrusion screw

A technology for extruding screw and extruding section, applied in the field of injection molding machine, can solve the problems of insufficient transparency, easy occurrence of blockage and coke, and low plasticization quality of plastic products, so as to improve plasticization quality and reduce melting point. Bulk crystal point, the effect of solving the reduction of transport efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

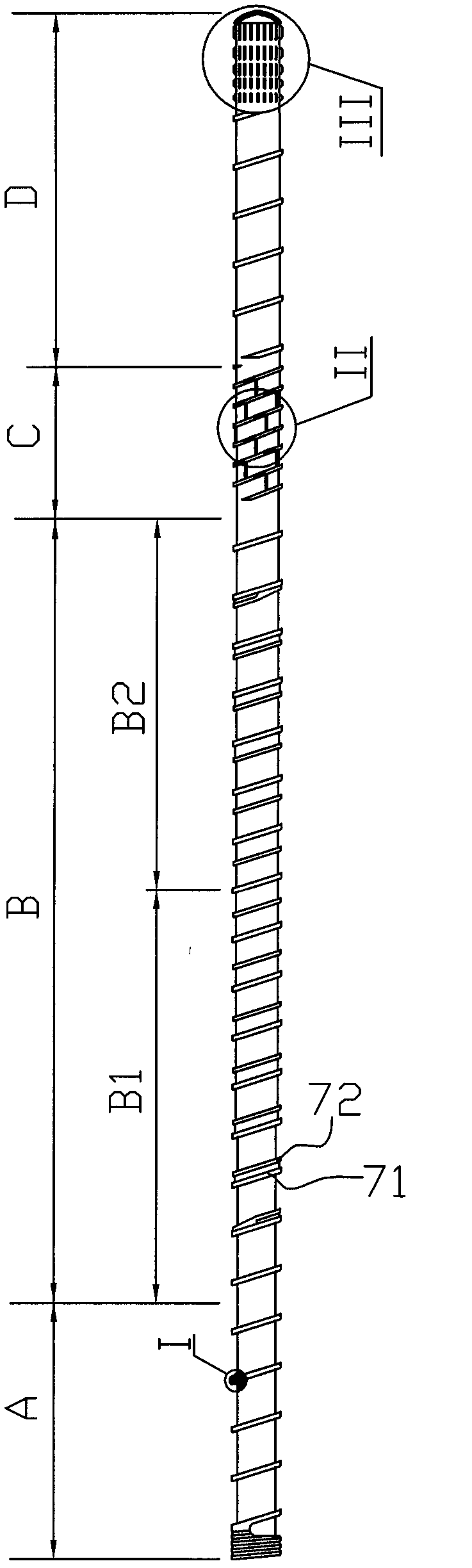

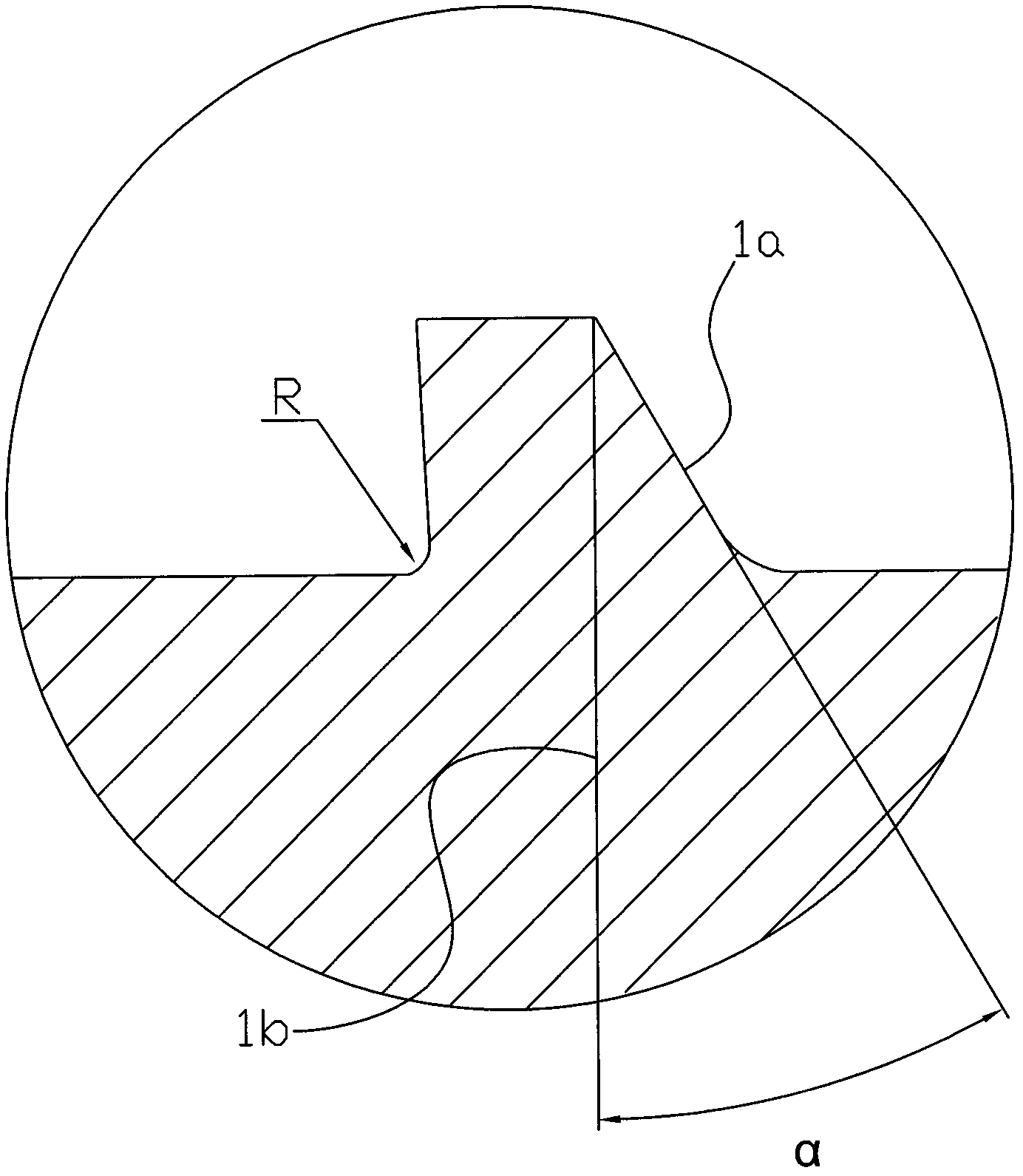

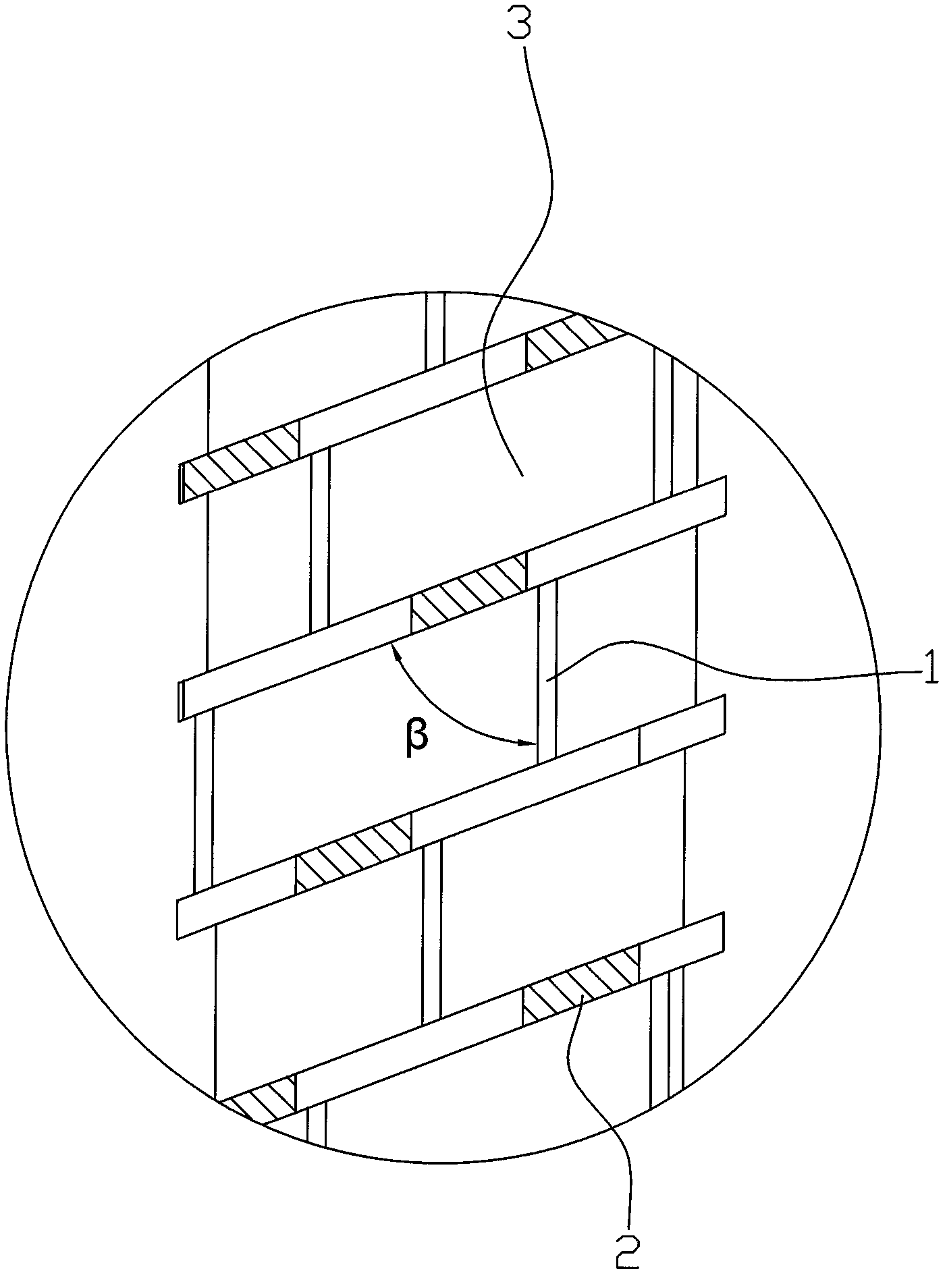

[0021] Such as Figures 1 to 5 As shown, the extrusion screw has a length-to-diameter ratio of 31:1, including a feed section A, a melting section B, a plasticizing section C, and an extrusion section E. In the feeding section A, the melting section B, and the plasticizing section C. The extrusion section E is provided with screw flights, the screw flights of the plasticizing section C are provided with auxiliary screw flight grooves 2 at intervals, and the screw flights of the plasticizing section C are axially provided with transverse ribs 1, and the transverse ribs 1 and The flight of the plasticizing section C forms several main flight grooves 3 . The thickness of the rib 1 is smaller than the thickness of the screw rib of the plasticizing section C. The angle β formed by the rib 1 and the screw rib of the plasticizing section C is 69°. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com