Plastic section bar and technology for processing same

A technology for plastic profiles and processing technology, applied in the field of plastic profiles, can solve the problems of poor processing performance, poor impact resistance and aging resistance, high cost, polluted air, etc., to improve plasticizing quality, high welding strength, and small dust pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

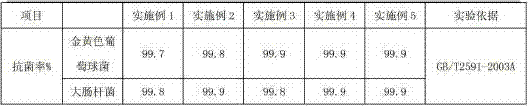

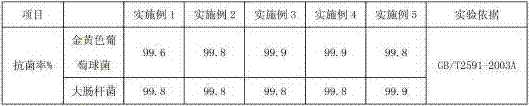

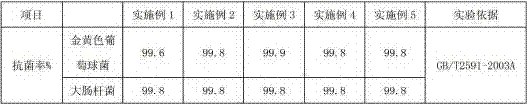

Examples

Embodiment 1

[0024] A plastic profile, comprising by weight components: 100 parts of polyvinyl chloride resin, 2 parts of organic tin carboxylate, 1 part of polyacrylate resin, 8 parts of chlorinated polyethylene, 5 parts of activated calcium carbonate, rutile type 4 parts of titanium dioxide, 0.5 parts of polyethylene wax, and 0.5 parts of antibacterial and antibacterial additives.

[0025] Specifically, the density of the polyvinyl chloride resin is 1.35~1.45g / cm 3 , the apparent density is 0.4~0.5 g / cm 3 .

[0026] Specifically, the polyvinyl chloride resin is a loose polyvinyl chloride resin with a particle size of 0.1-0.2 mm and is in the shape of cotton balls.

[0027] Specifically, the organotin carboxylate is di-n-octyltin dilaurate.

[0028] Specifically, the antibacterial and bacteriostatic additive is a mixture of nano zinc oxide powder and nano silver powder.

[0029] A processing technology for preparing the described plastic profiles, comprising the following steps:

[0...

Embodiment 2

[0036] A plastic profile, comprising by weight components: 105 parts of polyvinyl chloride resin, 2.25 parts of organotin carboxylate, 1.25 parts of polyacrylate resin, 8.5 parts of chlorinated polyethylene, 6 parts of activated calcium carbonate, rutile type 4.5 parts of titanium dioxide, 0.6 parts of polyethylene wax, and 0.6 parts of antibacterial and antibacterial additives.

[0037] Specifically, the density of the polyvinyl chloride resin is 1.35~1.45g / cm 3 , the apparent density is 0.4~0.5 g / cm 3 .

[0038] Specifically, the polyvinyl chloride resin is a loose polyvinyl chloride resin with a particle size of 0.1-0.2 mm and is in the shape of cotton balls.

[0039] Specifically, the organotin carboxylate is di-n-octyltin dilaurate.

[0040] Specifically, the antibacterial and bacteriostatic additive is a mixture of nano zinc oxide powder and nano silver powder.

[0041] A processing technology for preparing the described plastic profiles, comprising the following ste...

Embodiment 3

[0048] A plastic profile, comprising by weight components: 110 parts of polyvinyl chloride resin, 2.5 parts of organic tin carboxylate, 1.5 parts of polyacrylate resin, 9 parts of chlorinated polyethylene, 7 parts of activated calcium carbonate, rutile type 5 parts of titanium dioxide, 0.7 parts of polyethylene wax, and 0.7 parts of antibacterial and antibacterial additives.

[0049] Specifically, the density of the polyvinyl chloride resin is 1.35~1.45g / cm 3 , the apparent density is 0.4~0.5 g / cm 3 .

[0050] Specifically, the polyvinyl chloride resin is a loose polyvinyl chloride resin with a particle size of 0.1-0.2 mm and is in the shape of cotton balls.

[0051] Specifically, the organotin carboxylate is di-n-octyltin dilaurate.

[0052] Specifically, the antibacterial and bacteriostatic additive is a mixture of nano zinc oxide powder and nano silver powder.

[0053] A processing technology for preparing the described plastic profiles, comprising the following steps: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com