Heating device and plastifying device used for improving cable inner end plastifying quality

A heating device and equipment technology, applied in the field of cable processing, can solve the problems of uncontrollable temperature and low mold temperature, and achieve the effects of precise control of heating and cooling, quality assurance, and convenient loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

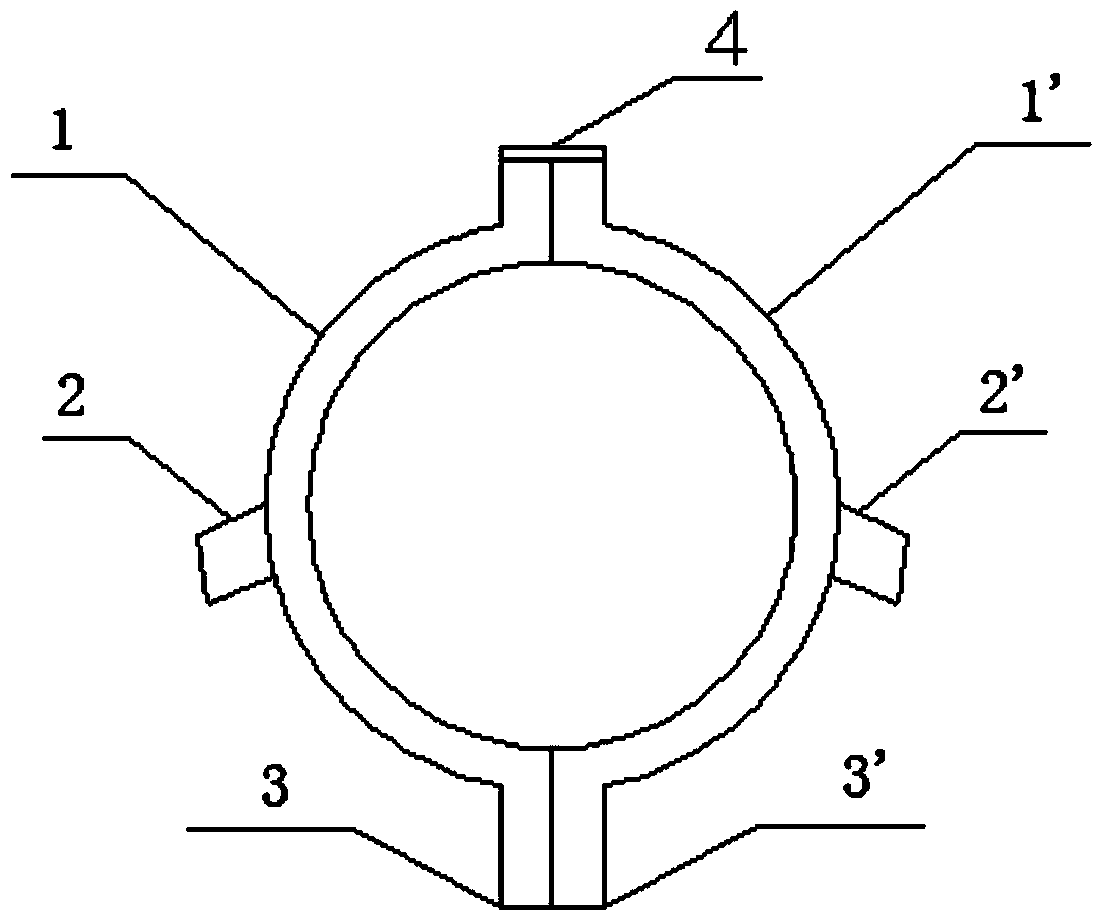

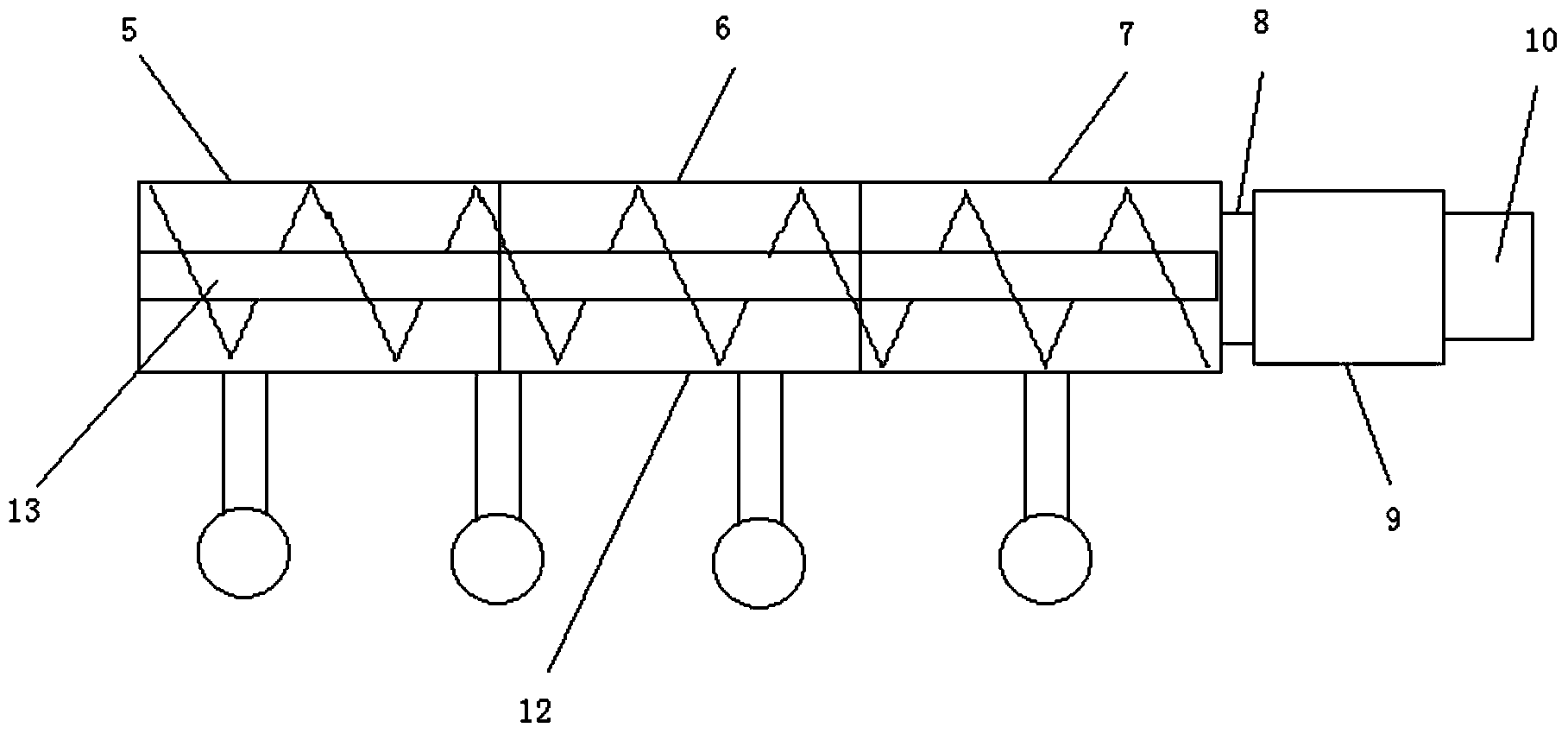

[0035] Such as figure 1 As shown, the present invention provides a heating device for improving the plasticization quality of the inner end of the cable, comprising:

[0036] The first arc-shaped heater 1 and the second arc-shaped heater 1' connected by a hinge 4 at one end form an annular structure;

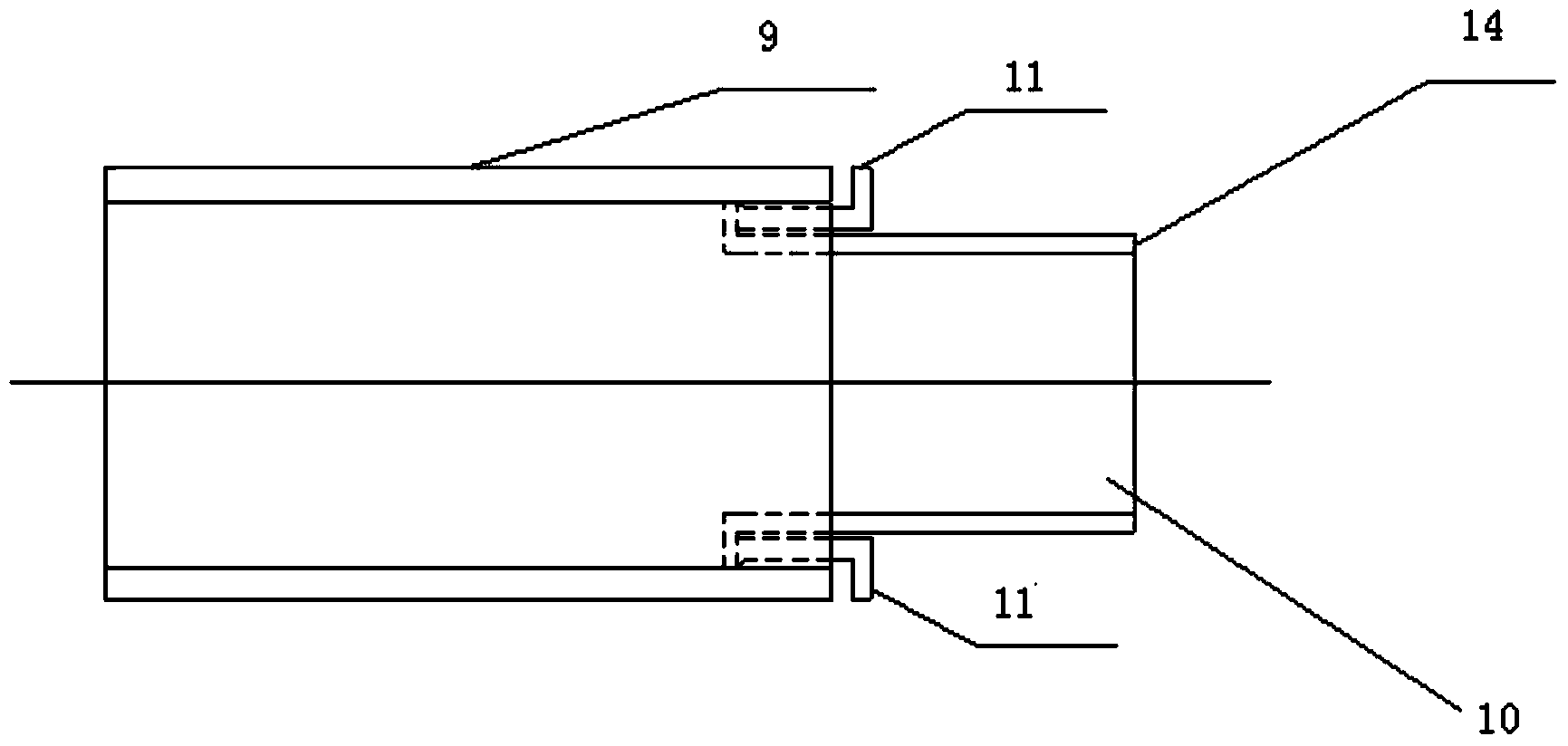

[0037] The other end of the first arc-shaped heater 1 and the second arc-shaped heater 1' is provided with snap-fit parts for connection to form an opening and closing structure for being sleeved on the mold 10 of the plasticizing equipment;

[0038] Further, the buckle parts include:

[0039] The magnets at the other ends of the first arc-shaped heater 1 and the second arc-shaped heater 1' are respectively arranged to form a snap-fit connection;

[0040] The first arc heater 1 and the second arc heater 1' are also respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com