Composite wood-plastic material blow molding machine

A wood-plastic composite material and molding machine technology, which is applied in the field of processing and molding equipment for wood-plastic composite materials, can solve the problems that the initial performance of the material cannot be well maintained in the final product, it is difficult to maintain the final product, and the melt flow performance is poor. , to avoid deformation, reduce processing costs, and improve the quality of plasticization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

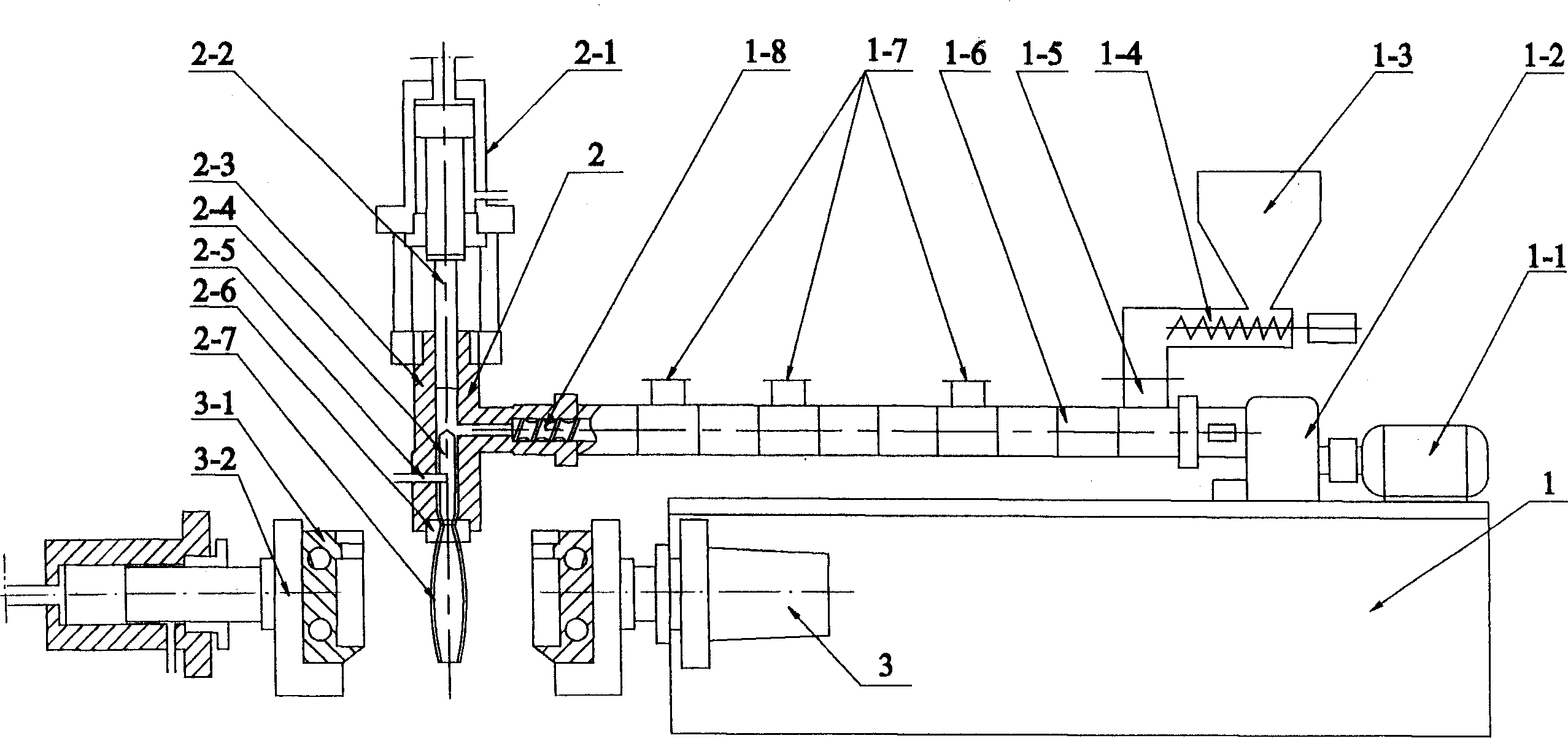

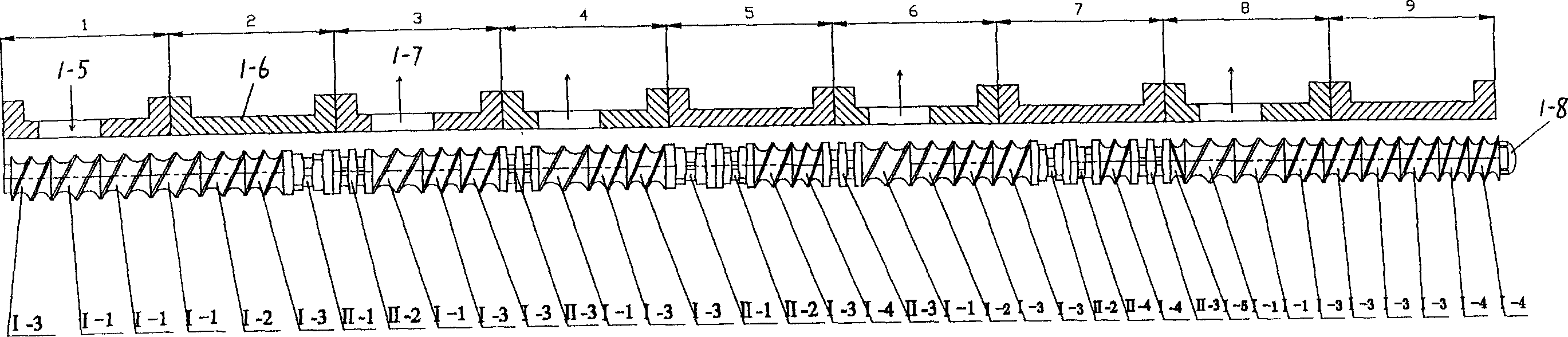

[0047] figure 1 It is a schematic diagram of a wood-plastic composite material blow molding machine, including an extrusion device, that is, a parallel co-rotating twin-screw extruder 1, and is equipped with a storage cylinder device 2 and a mold clamping device 3; the parallel co-rotating twin-screw extruder The outlet of the discharge machine 1 communicates with the storage cylinder device 2; the outlet of the storage cylinder device 2 is located above the clamping device 3.

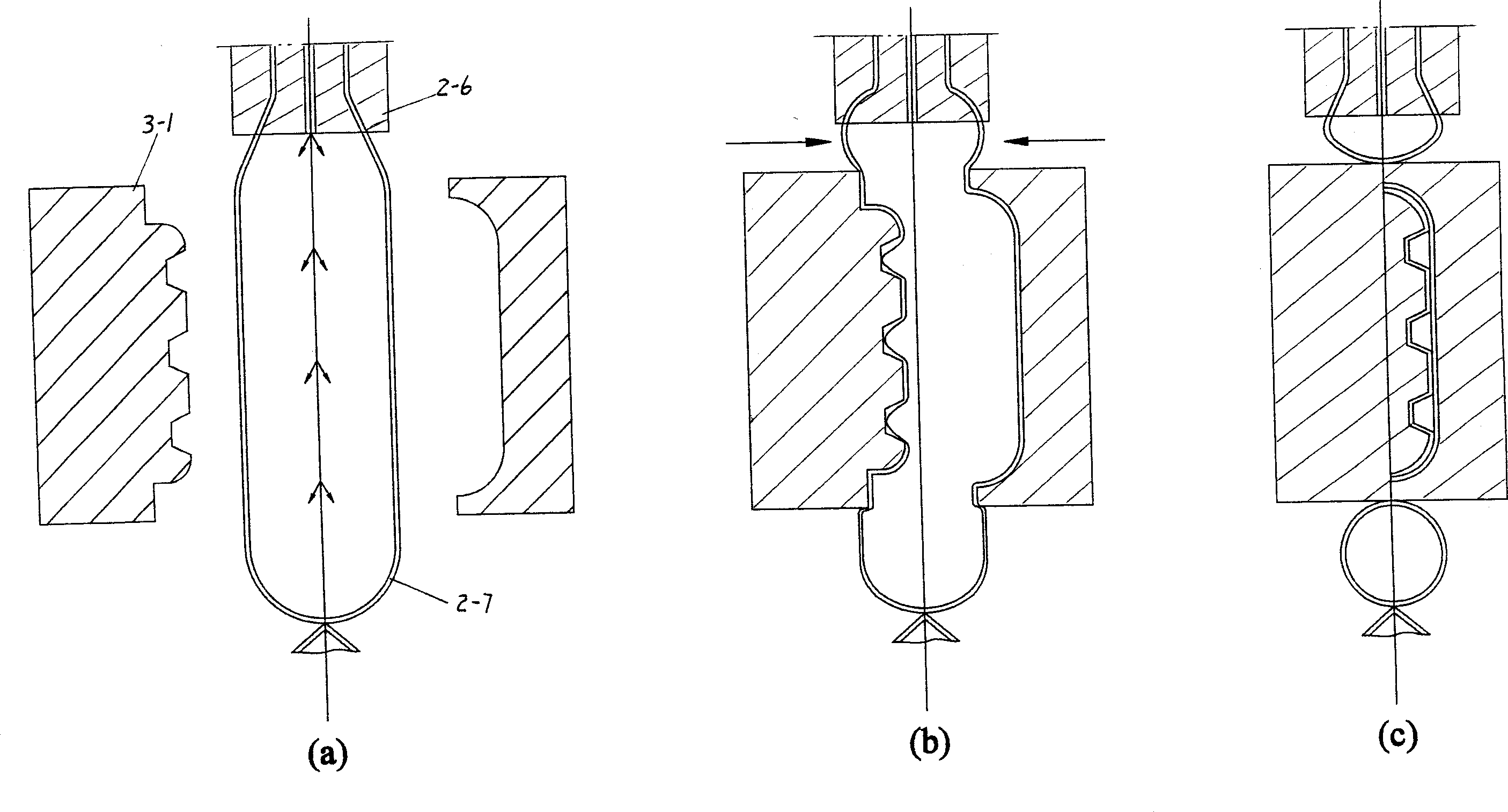

[0048] The storage cylinder device 2 is a plunger type cylinder storage device, wherein the storage cylinder 2-3 is equipped with a plunger 2-2, and the plunger 2-2 is reciprocally pushed by the air cylinder or oil cylinder 2-1, and the storage cylinder 2-3 A shunting mandrel 2-4 with an air blowing assembly 2-5 is arranged inside, and a parison die 2-6 is installed at the outlet of the storage cylinder 2-3.

[0049] Be equipped with the mold clamping assembly 3-2 in the mold clamping device 3 below p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com