Test device for accomplishing polymer melting plasticization using superaudio vibration

A test device and polymer technology, which is applied in the preparation of test samples, measurement of DC flow characteristics, material inspection products, etc., can solve the problems of thin-walled products that are prone to short shots and difficult filling of trace melts, and achieve reliability High, practical, fast melting rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

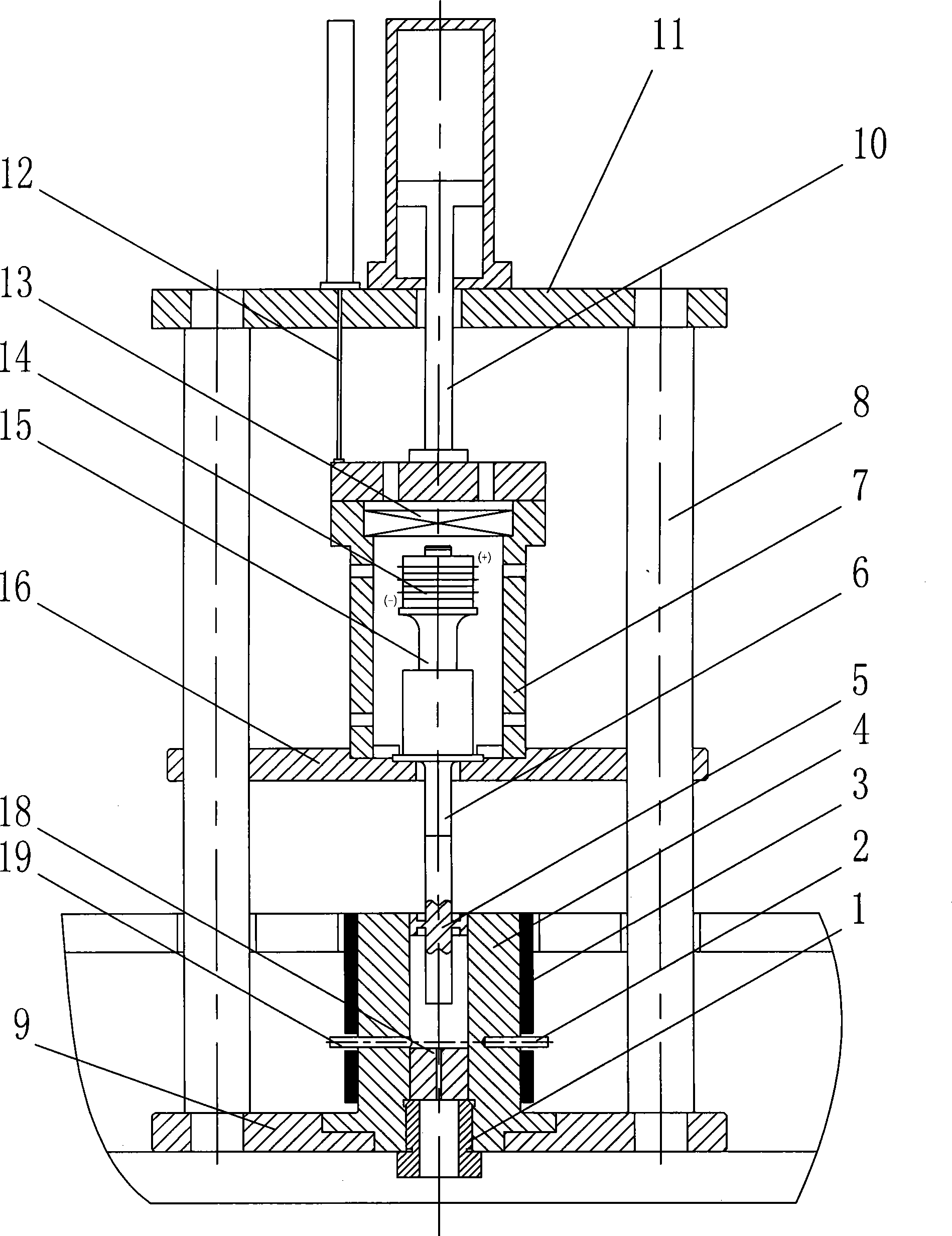

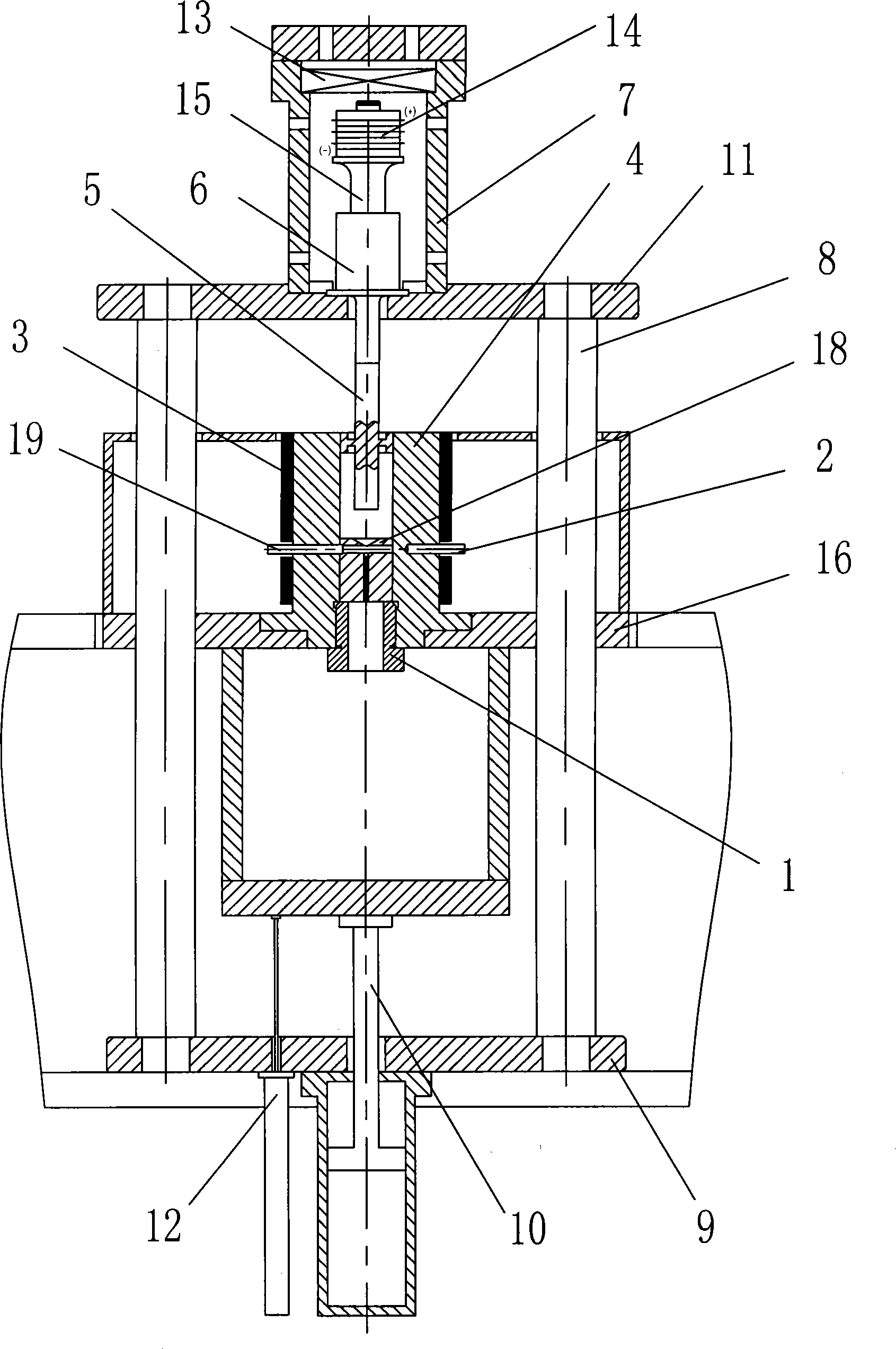

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

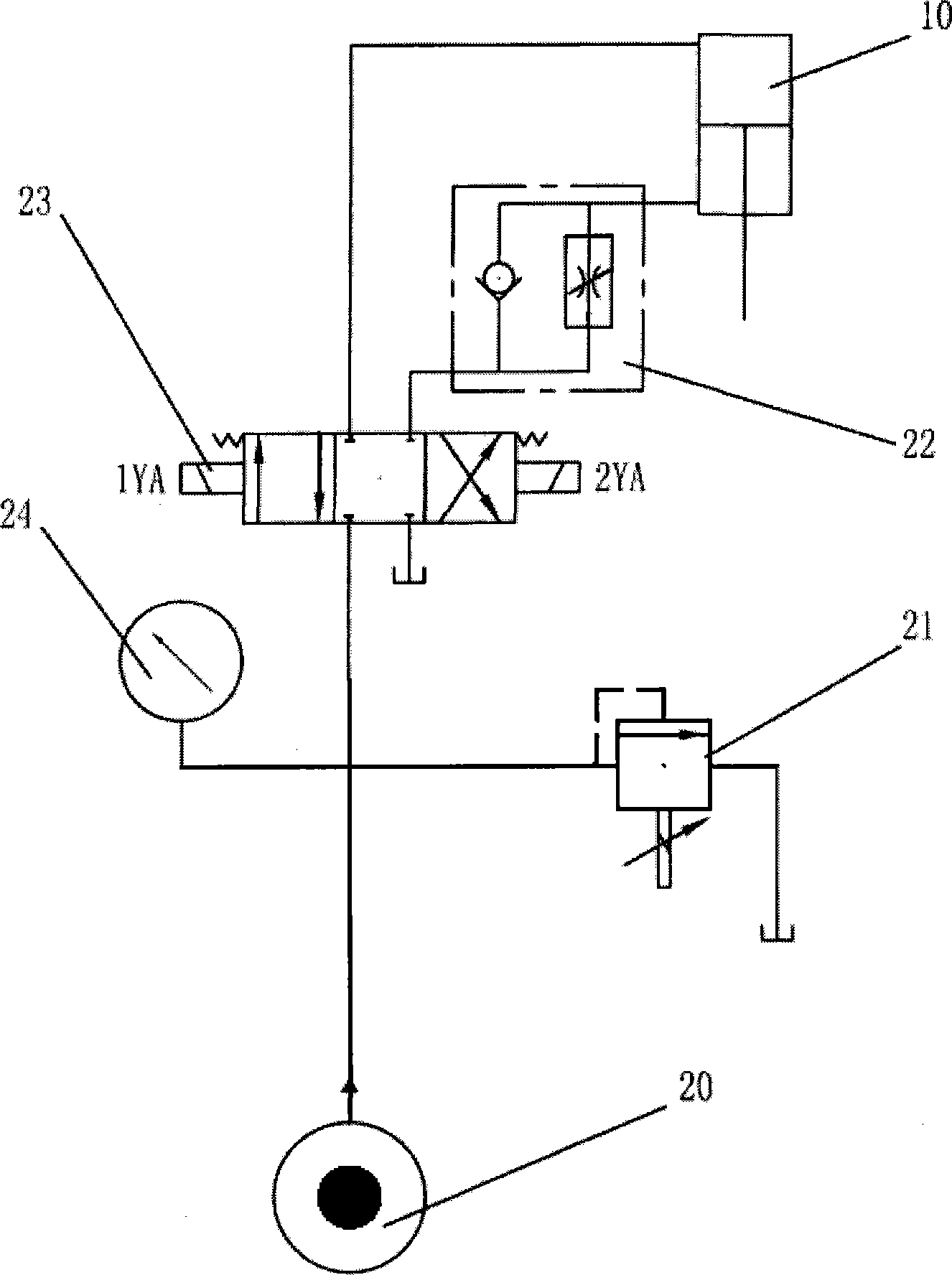

[0019] see figure 1 with image 3 , a barrel 4 is provided on the base 9, a capillary die 18, a threaded support block 1 and a tool head 5 are arranged in the barrel 4, a thermocouple 2, a heating ring 3 and a high-temperature melt temperature and pressure are provided on the barrel 4. The sensor 19, the lower end of the guide post 8 is arranged on the machine base 9, the upper end of the guide post 9 is provided with a frame 11, and an oil cylinder 10 is arranged on the frame 11, and the pumping station 20 is connected with one end of the oil cylinder 10 through an electromagnetic reversing valve 23, and the oil cylinder 10 The other end is connected to the electromagnetic reversing valve 23 through the one-way electro-hydraulic proportional speed regulating valve 22. The outlet of the pumping station 20 is provided with an electro-hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com