Method for digitally and quickly detecting and analyzing sand core

A sand core, fast technology, applied in the direction of measuring device, image data processing, design optimization/simulation, etc., can solve the problem of high assembly precision of crankshaft and thrust pad, achieve core assembly and scraping and modification of sand core, reduce cost, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in combination with specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

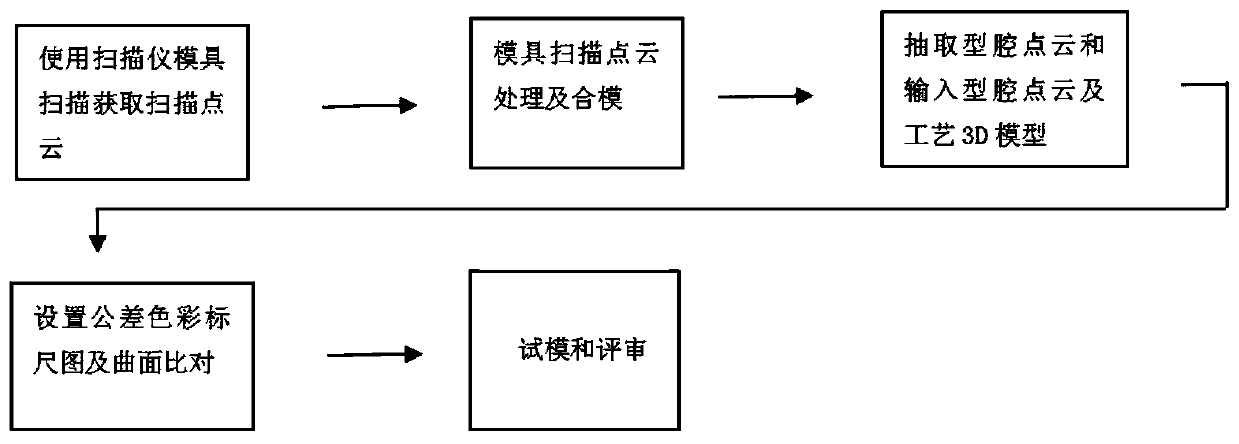

[0019] Such as figure 1 Shown, described a kind of method of digital rapid detection and analysis sand core, it is characterized in that:

[0020] Include the following steps:

[0021] S1: Use the scanner to scan the mold to obtain the scanning point cloud, and use the laser scanner to scan the mold. Before the mold is scanned, paste the photosensitive point on the surface. The photosensitive point is the main reference point for the laser scanner to automatically rotate back to the absolute coordinates. Then spray a thin layer of developer on the surface of the mold to allow the laser to better identify the surface of the casting contour; after scanning the mold, collect the point cloud obtained from the mold scan, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com