Shielding shaft vertical jacking mold testing device and method

A model test device and jacking technology, applied in teaching models, educational tools, instruments, etc., can solve problems affecting the safety and durability of tunnel structures, complex engineering conditions, and low numerical accuracy, and achieve simple structure and low cost. Inexpensive, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

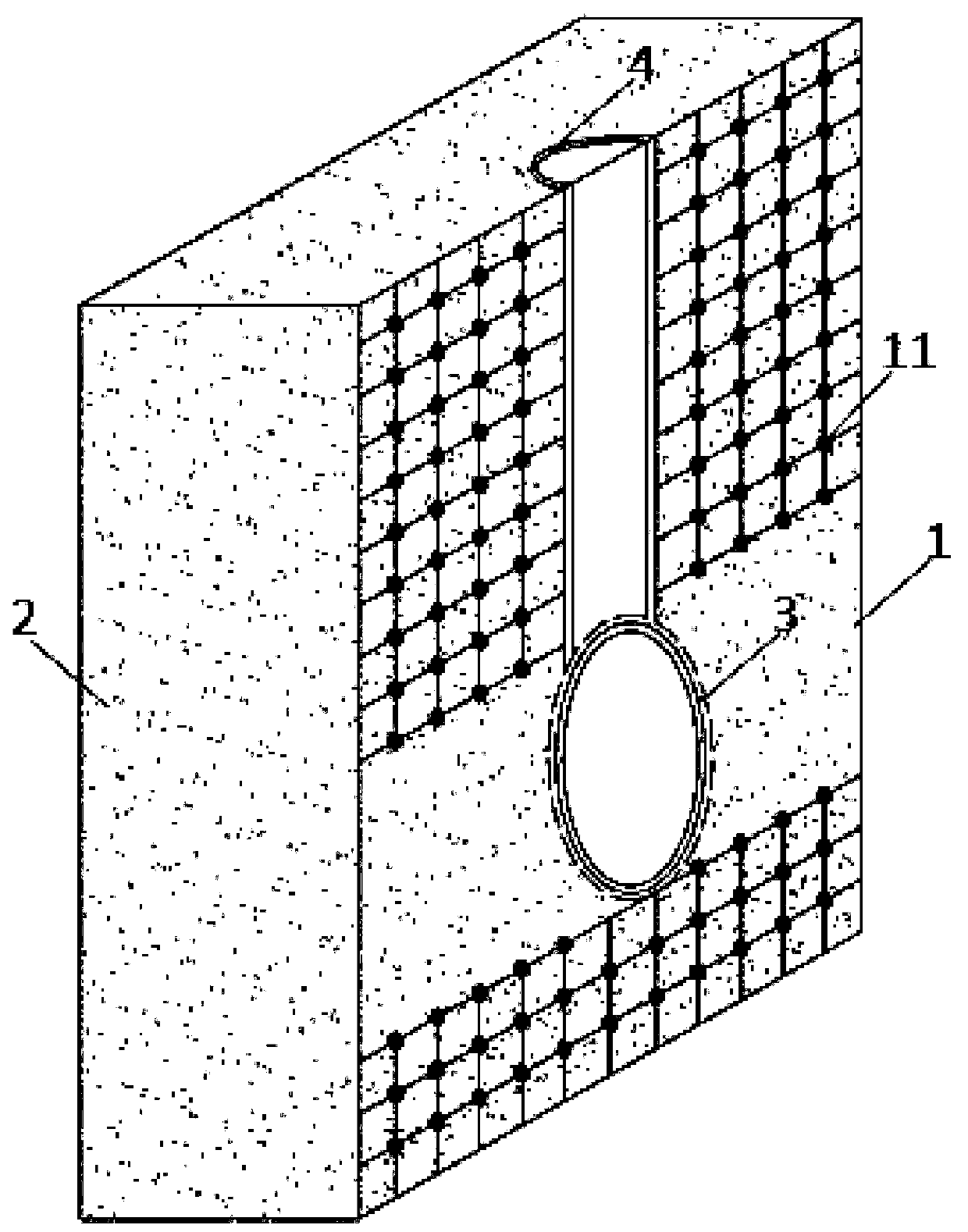

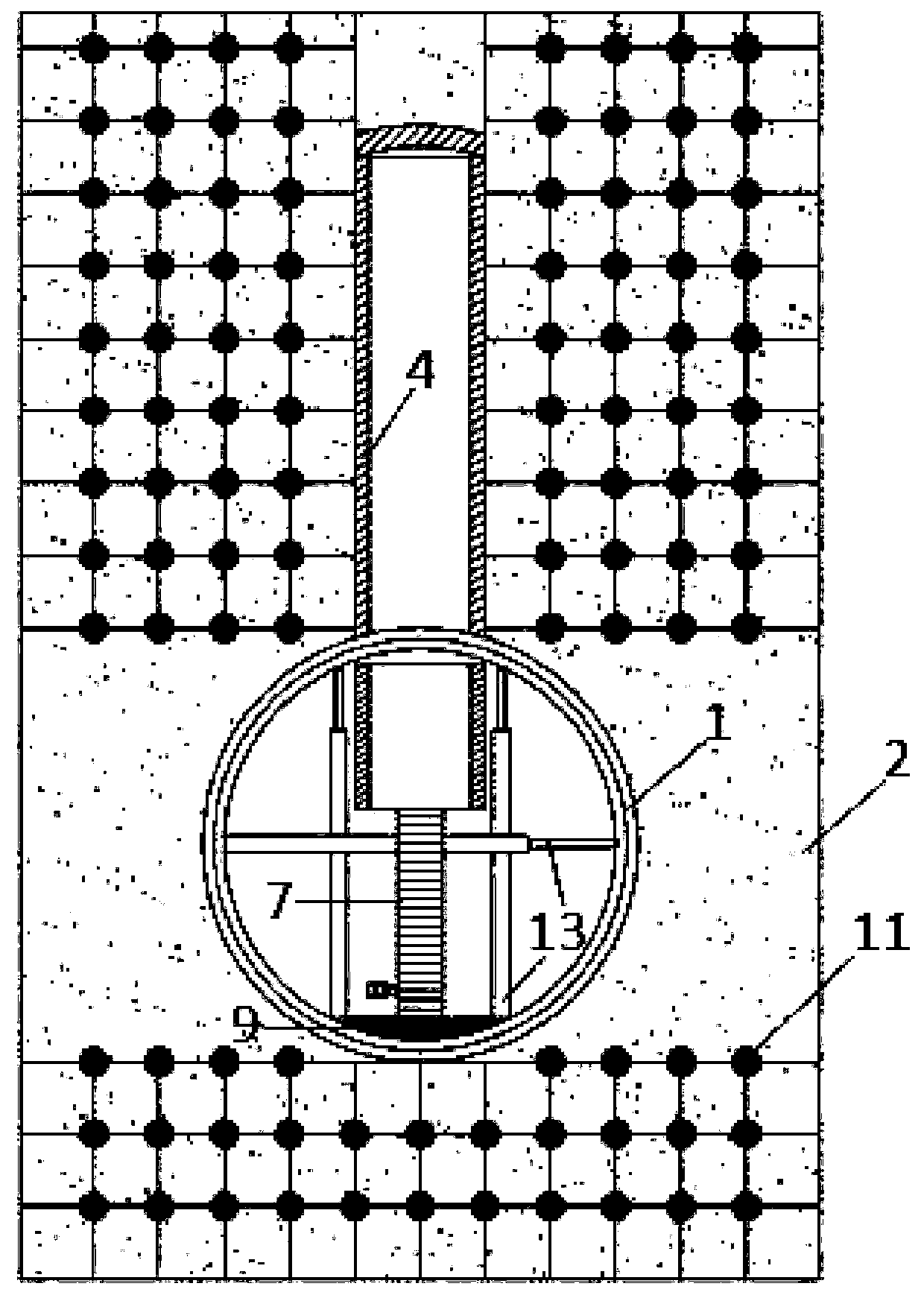

Embodiment 1

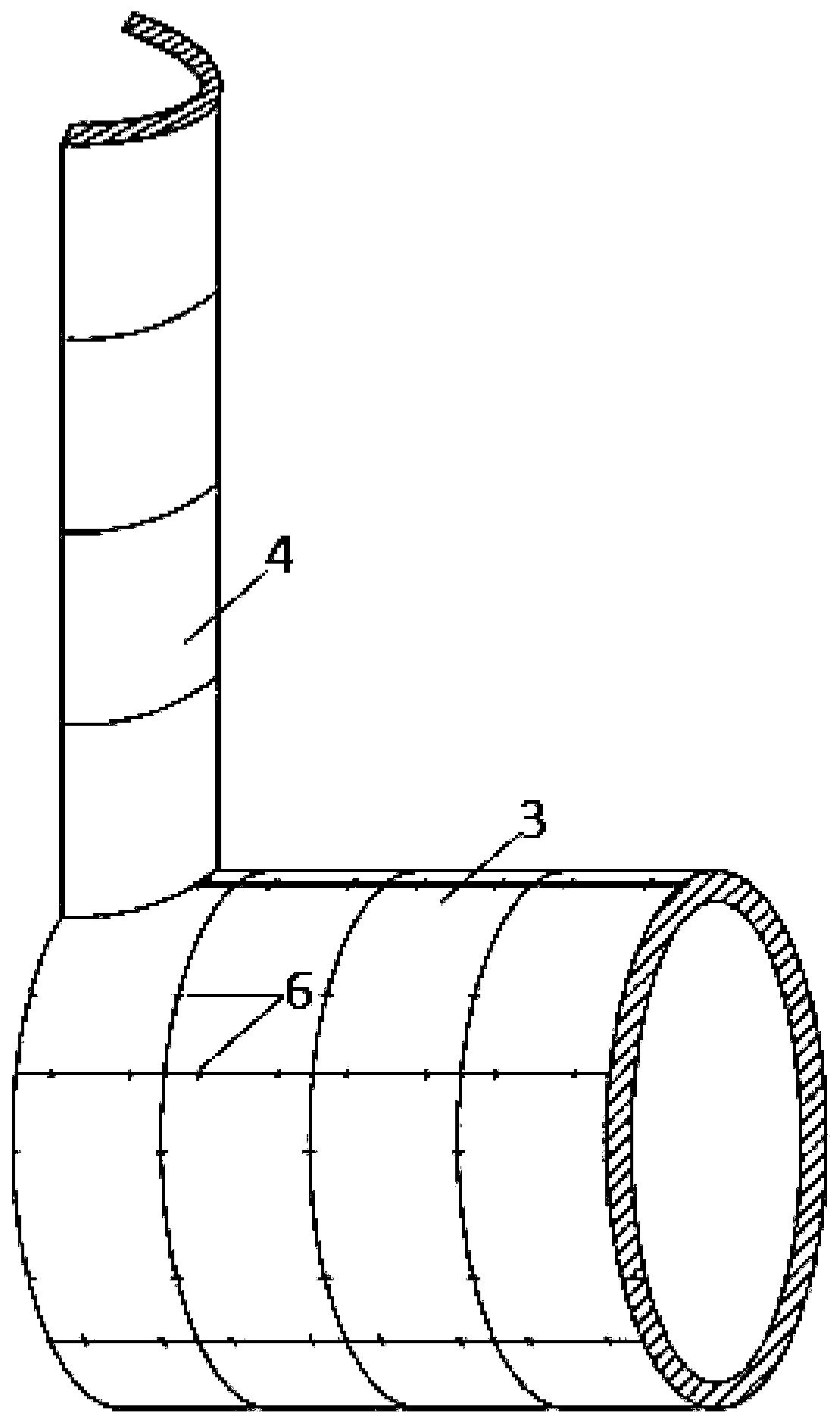

[0055] Embodiment 1, using a PE pipe with a diameter of 600mm, a thickness of 30mm, and a ring width of 150mm to simulate a shield tunnel 3, including a 20° capping block, two 62° adjacent blocks and three 72° standard blocks , to meet the similarity ratio of 1:10. The shield tunnel 3 includes four pipe rings with a total length of 600 mm. There are 12 and 11 longitudinal ring joints 6 of the shield tunnel 3 respectively. According to the similarity theory and the principle of equivalent stiffness, a 10 mm wide plastic sheet and bolts 5 constitutes the longitudinal circular seam joint 6. The pipe jacking tunnel 4 is simulated with a PE pipe with a diameter of 180 mm, a thickness of 20 mm, and a ring width of 200 mm. The opening of the shield tunnel 3 with the pipe jacking is a semicircular ring with a diameter of 95 mm. The counter force diffusion block 9 has a width of 200mm, the bottom is attached to the shield tunnel 3, and the height of the midpoint is 30mm.

[0056] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com