In-mold injection molding method of curved window

A technology of in-mold injection molding and windowing, applied in the direction of coating, etc., can solve problems such as poor mold design and unreasonable setting of injection molding process parameters, and achieve the effects of mold design optimization, high-speed precision positioning, and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

[0029] figure 1 It is a product technology roadmap of the present invention, and the specific steps are as follows:

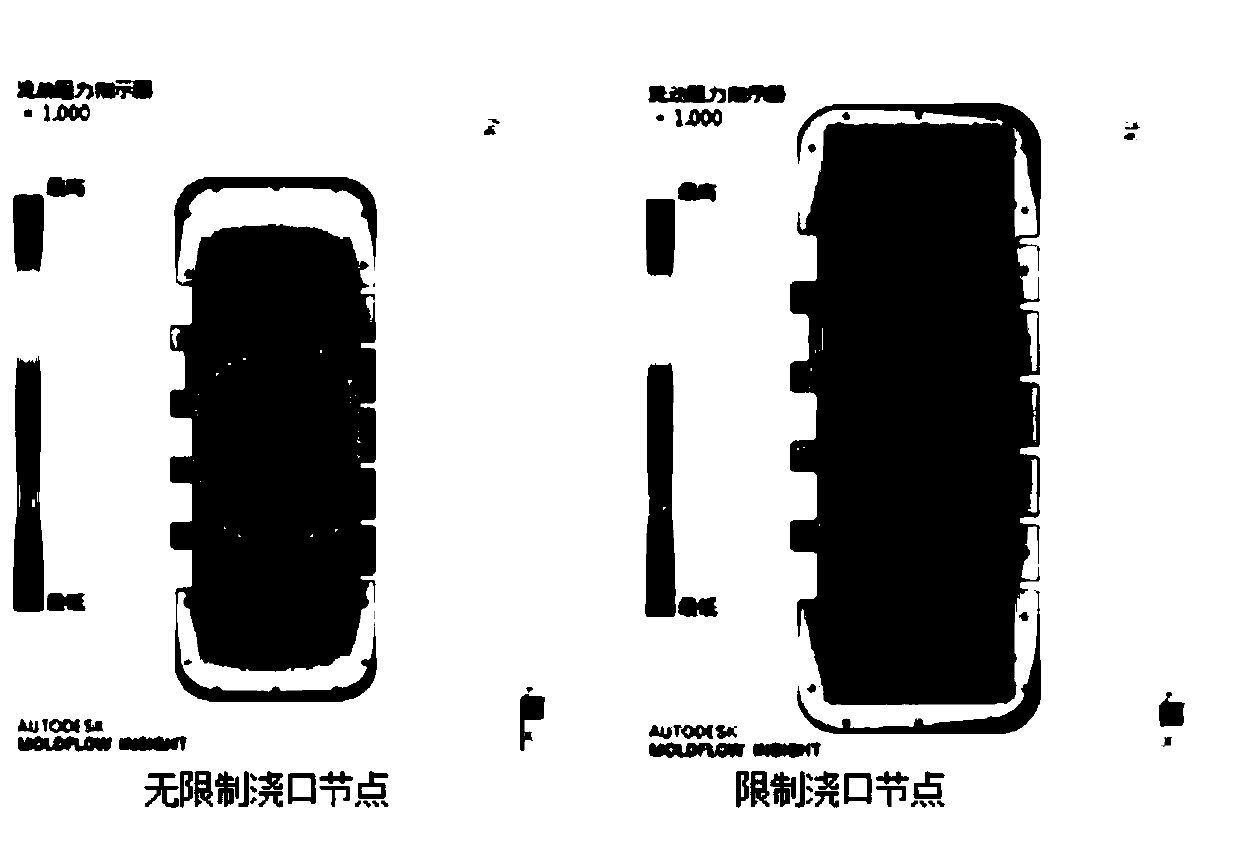

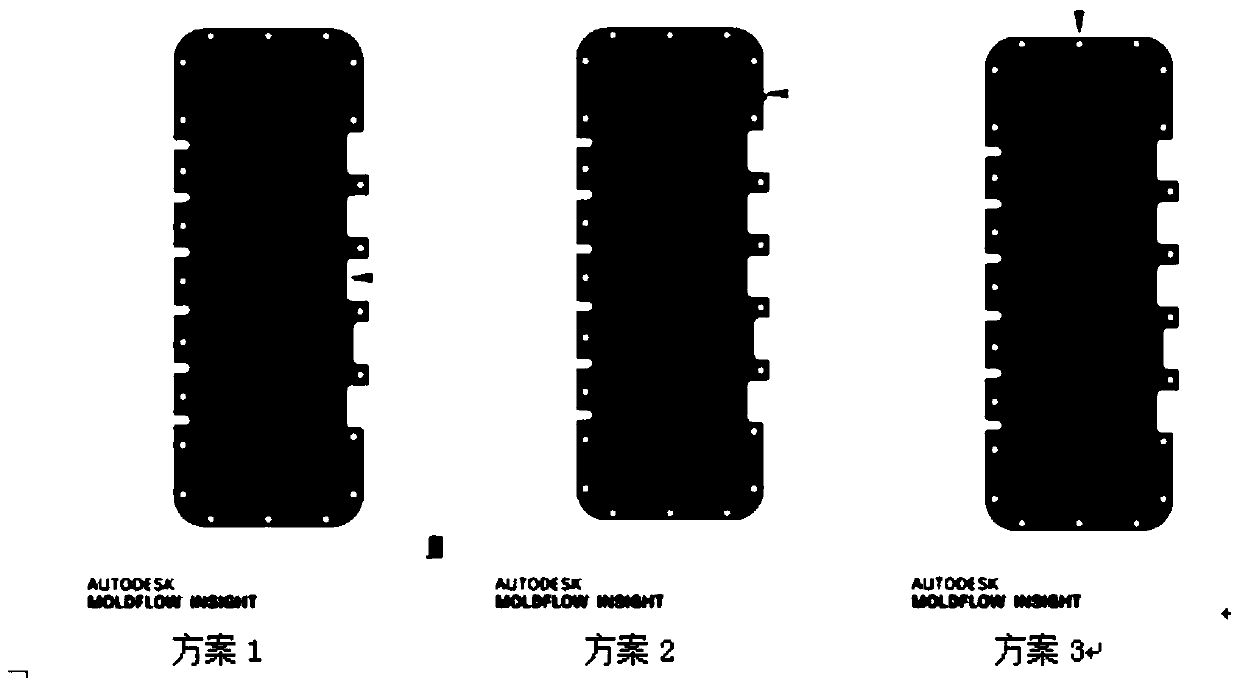

[0030] 1. Using Moldflow software for mold flow analysis research and structural optimization

[0031] 1 Mold flow analysis using Moldflow software

[0032] First, use UG software to build a 3D model of the curved window product, import the established 3D model of the curved window product into the Moldflow software, select the Fusion format for mesh division, and correct the defects of the mesh.

[0033] Table 1 Summary of product analysis data

[0034]

[0035] Second, the process parameter setting

[0036] ①Mould temperature—the default value of the software is 60°C. Now according to the molding material, three temperatures of 60°C, 70°C, and 80°C are selected respectively. Through the simulation of the software under the three mold temperature conditions, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com