Shell of electronic device and manufacturing method of shell

A technology of electronic devices and manufacturing methods, applied in the direction of electrical equipment casings/cabinets/drawers, electrical components, and other household appliances, which can solve the problems of increased printing and drying time and labor costs, affecting product competitiveness, shadow traces, etc. problems, to save time and labor costs, improve the overall aesthetics, and avoid the effect of ink flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

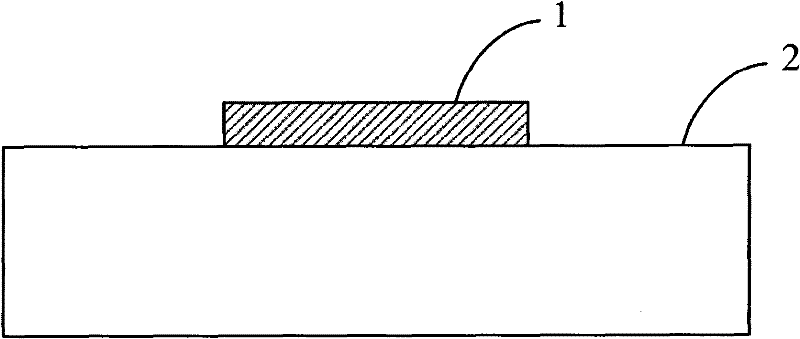

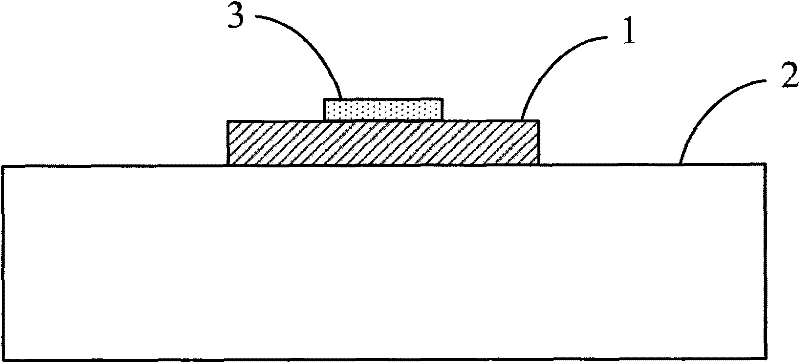

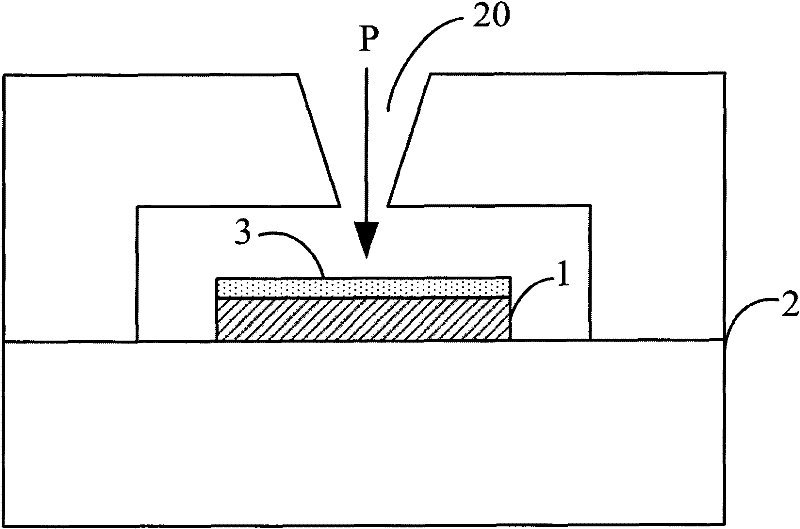

[0019] A first embodiment of the present invention is a method for manufacturing an electronic device casing. In one embodiment of the present invention, the manufacturing method of the casing of the electronic device is an in-mold film (IMF) injection molding method, but not limited thereto.

[0020] Please refer to figure 2 , figure 2 Shown is a flow chart of an embodiment of the manufacturing method of the electronic device casing of the present invention. Such as figure 2 As shown, the manufacturing method of the electronic device casing in this embodiment includes the following steps: First, the method executes step S10, providing a film with an anti-wash sheet in a mold. In practical applications, the film with the anti-flushing ink sheet can be obtained by pasting the anti-flushing ink sheet on the film. As for the scope and size of the area where the anti-wash ink sheet is pasted on the film, there is no certain limit, depending on actual needs.

[0021] Genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com