Auxiliary grid hot wire chemical vapor deposition process for preparing nano-diamond thin film

A nano-diamond and vapor deposition technology, which is applied in the field of preparing nano-diamond films, can solve problems such as affecting the smoothness of the film and destroying the smooth surface of the substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

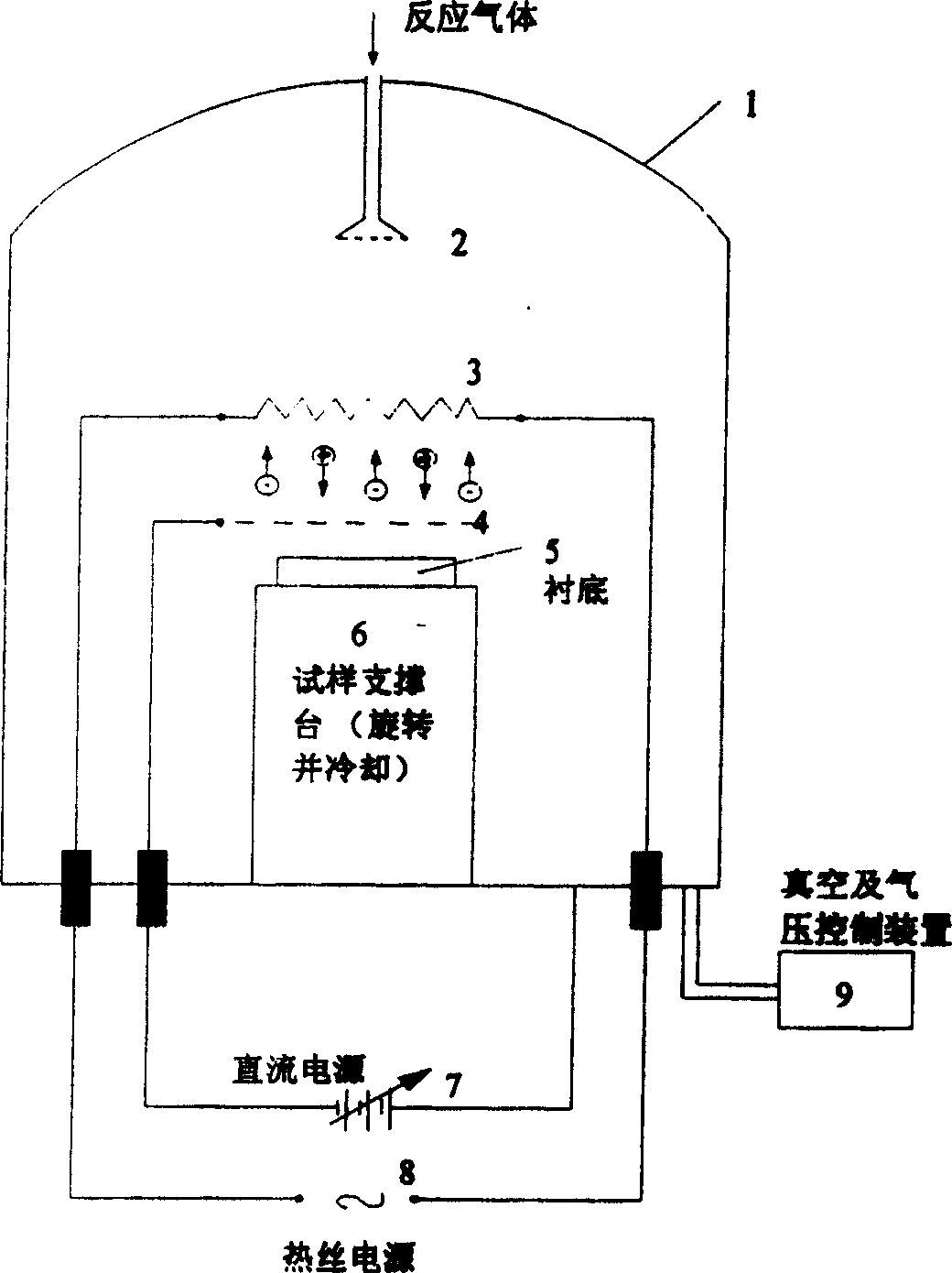

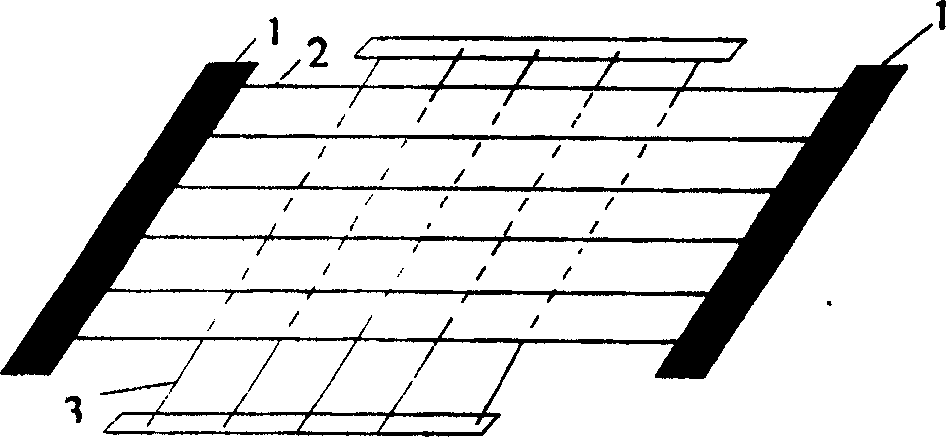

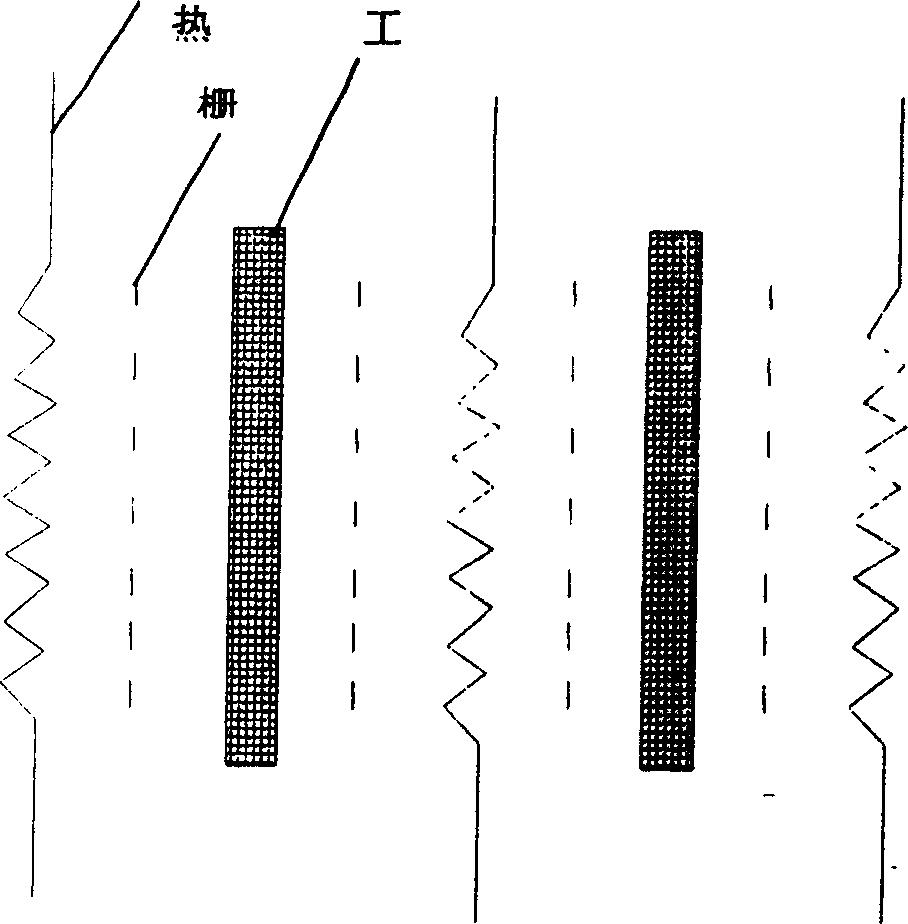

[0015] In order to better deal with the technical solution of the present invention, the planar substrate is taken as an example below, combined with the auxiliary hot-wire CVD device and coating detection results for further description. figure 1 is the schematic diagram of the auxiliary grid hot wire CVD device, in which 1 is the reaction chamber, 2 is the reaction gas inlet, 3 is the hot wire (a group of Czochralski parallel hot wires), 4 is the auxiliary grid (a group of parallel graphite strips), and the thermal The plane where the wire is located is parallel to the plane where the grid is located, but if figure 2 As shown, the direction of the hot wire 2 is perpendicular to the direction of the grid strip 3, 5 is the sample (planar substrate), 6 is the sample support platform, which can rotate and cool, and 7 is the DC adjustable power supply ( The hot wire is connected to the positive pole, the grid is connected to the negative pole), 8 is the hot wire power supply, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com